Medical packaging film

A packaging film and pharmaceutical technology, applied in the field of environmentally friendly pharmaceutical packaging film, can solve problems such as light reaction, drug quality impact, and drug failure, and achieve the effects of reducing costs, reducing the use of white plates, and reducing solvent emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

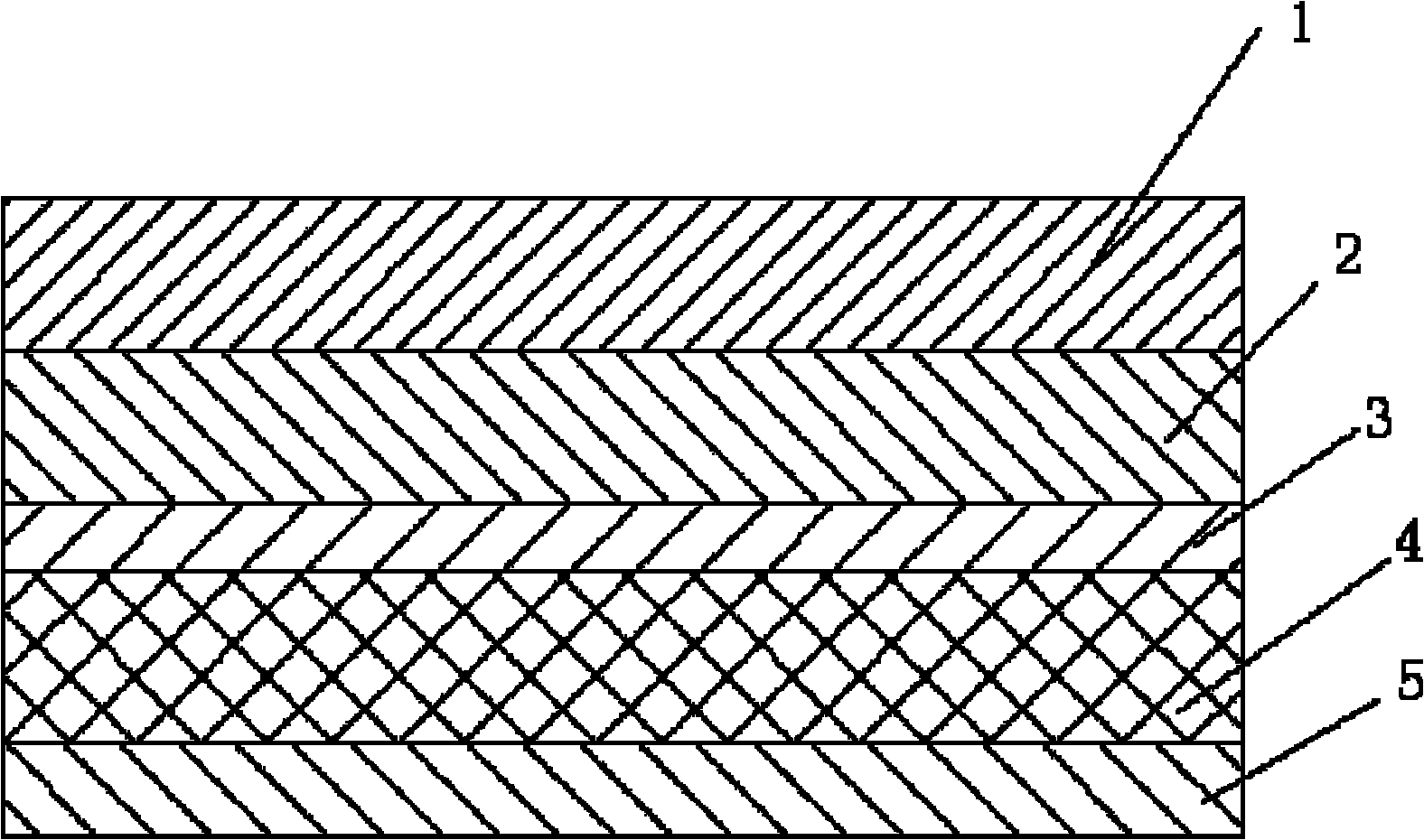

[0026] The medical packaging film consists of printing layer 1, mixed polyethylene layer 2, aluminum layer 3, and heat sealing layer from the outside to the inside. The heat sealing layer is a mixed layer of metallocene polyethylene layer 4 and sarin layer 5. The metallocene polyethylene layer 4 is located between the aluminum layer 3 and the sarin layer 5.

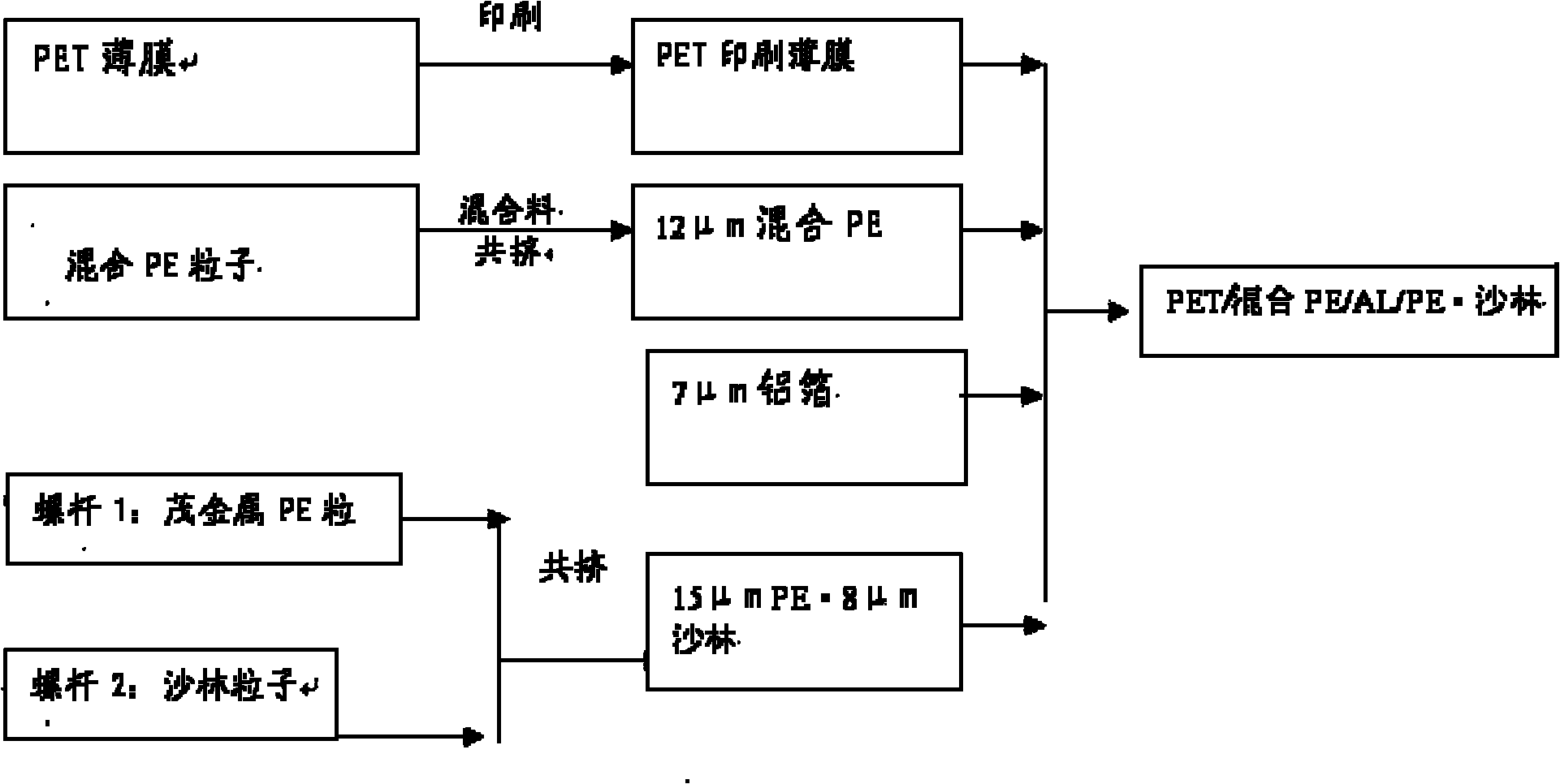

[0027] The preparation method of the present invention is:

[0028] (1) Printing: In the printing workshop, the temperature of the environment is controlled between 20-30℃, and the PET printing film is printed by a gravure printing machine;

[0029] (2) Double die head extrusion compounding: Put PET in the first position, AL (aluminum foil) in the second position, put the low density polyethylene 1C7A, ethylene-acrylic acid copolymer material EAA5050, white masterbatch UF880, the weight ratio 75:25:10 is added to the screw, fully mixed and extruded in the form of a mixture between PET and AL. In the other two screws, one screw is

Embodiment 2

[0031] Except for low density polyethylene 1C7A, ethylene-acrylic acid copolymer material EAA5050, and white masterbatch UF880, the weight ratio of which is 100:20:12, the rest is the same as in Example 1.

Embodiment 3

[0033] Except for low density polyethylene 1C7A, ethylene-acrylic acid copolymer material EAA5050, and white masterbatch UF880, the weight ratio of which is 90:30:8, and the rest is the same as in Example 1.

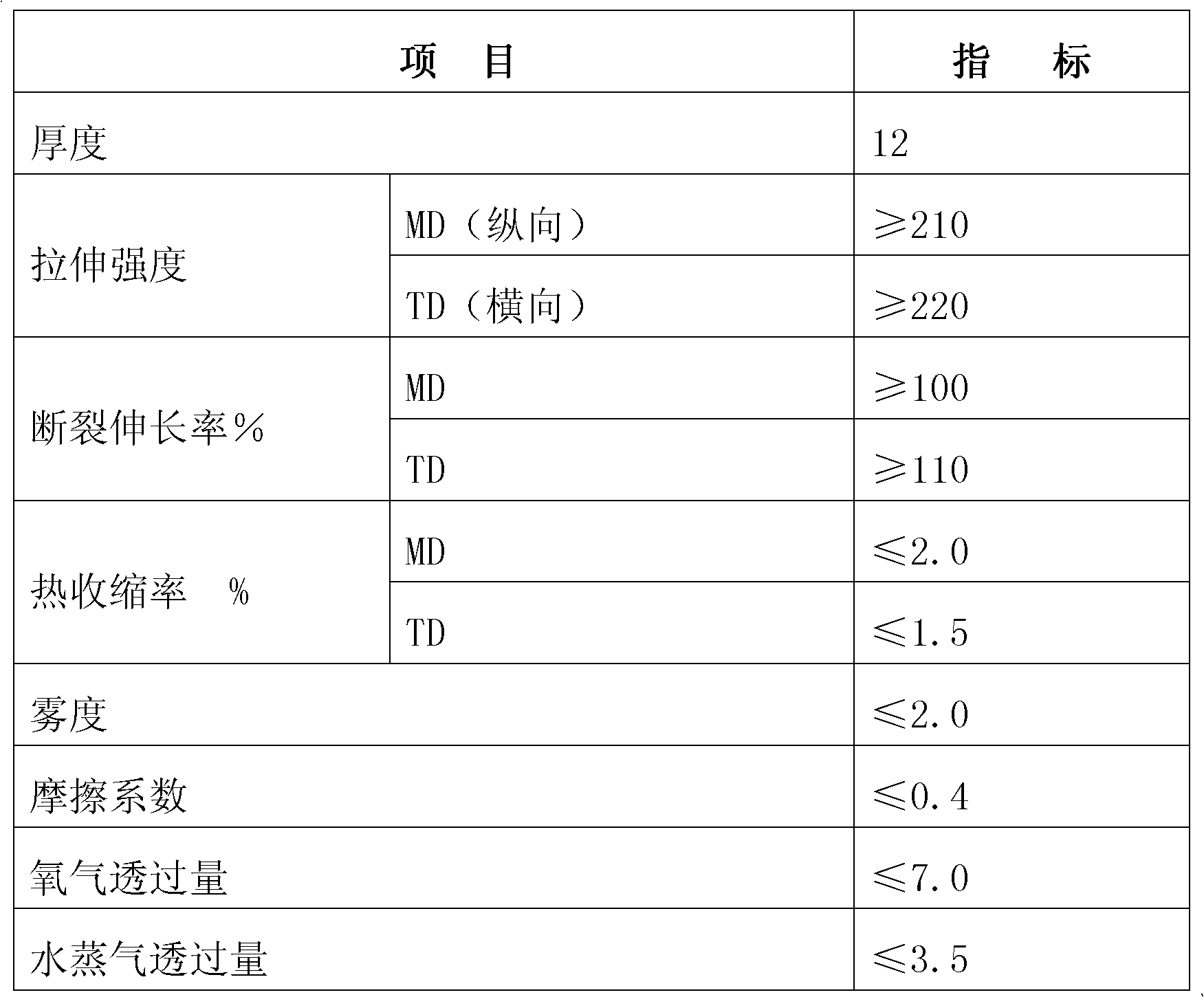

[0034] The technical indicators of Embodiment 1 of the present invention are as follows:

[0035]

[0036]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap