Preparation method of compound aluminum paper and aluminum plastic compound film packaging material with hydrophobic surface

A technology of aluminum-plastic composite film and packaging materials, which is applied in the field of preparation of composite aluminum paper and aluminum-plastic composite film packaging materials, which can solve the problem of high equipment and process requirements, limitations on the industrial application of hydrophobic and super-hydrophobic surfaces, and unsuitability for large-scale hydrophobicity surface preparation etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

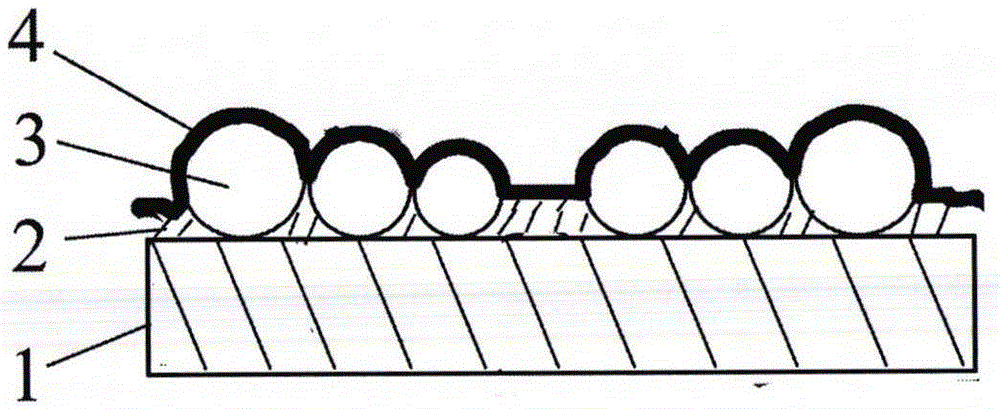

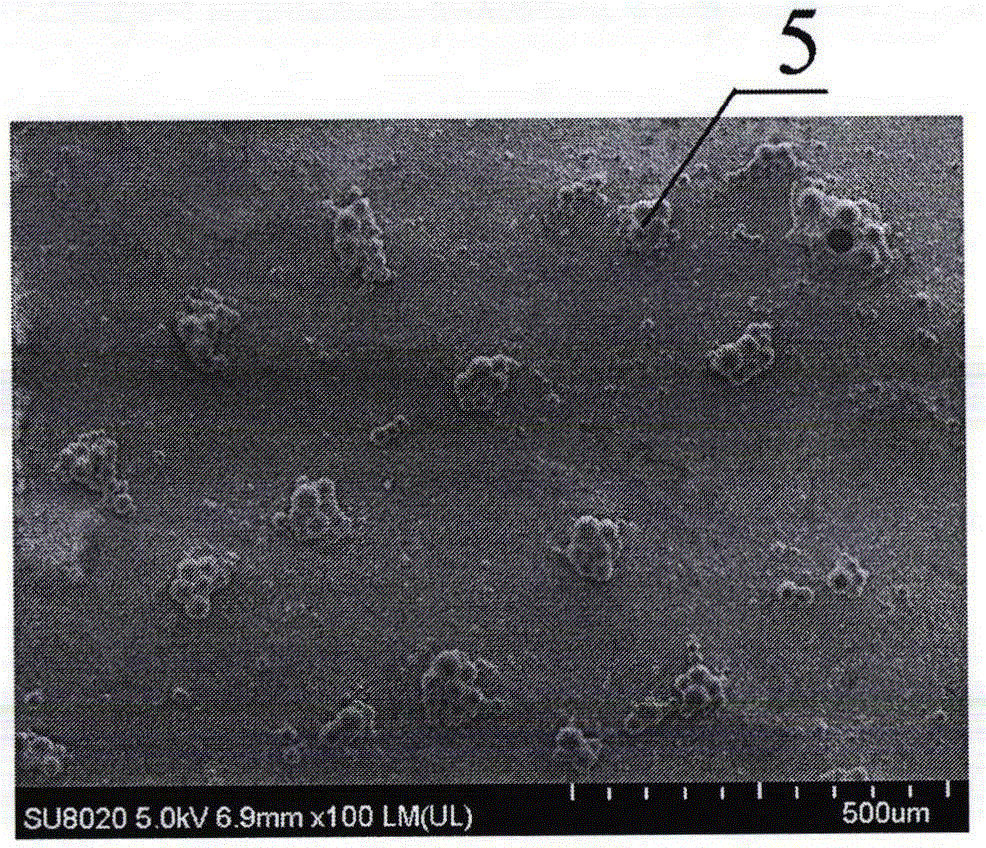

[0027] A layer of polymethyl methacrylate microspheres with a diameter of 10-30 microns is coated on the surface of kraft paper in a roll-to-roll manner. The distribution of the microspheres on the surface of the paper is the same as figure 2 Similarly, after curing, a layer of aluminum with a thickness of about 100nm was deposited on the surface of the microspheres by vacuum evaporation. After being placed at room temperature under oxygen-enriched conditions for 7 days, the water contact angle of the aluminum layer of the composite aluminum paper was tested to be 147°. The water rolling angle is 5°. Print graphics on the paper surface of the composite aluminum paper, then cut it into bags, and use it as a packaging bag for sticky traditional Chinese medicine ointment. The aluminum layer of the composite aluminum paper contacts the traditional Chinese medicine ointment. After taking out the ointment, the aluminum layer in the packaging bag hardly adheres to the Packed sticky her

Embodiment 2

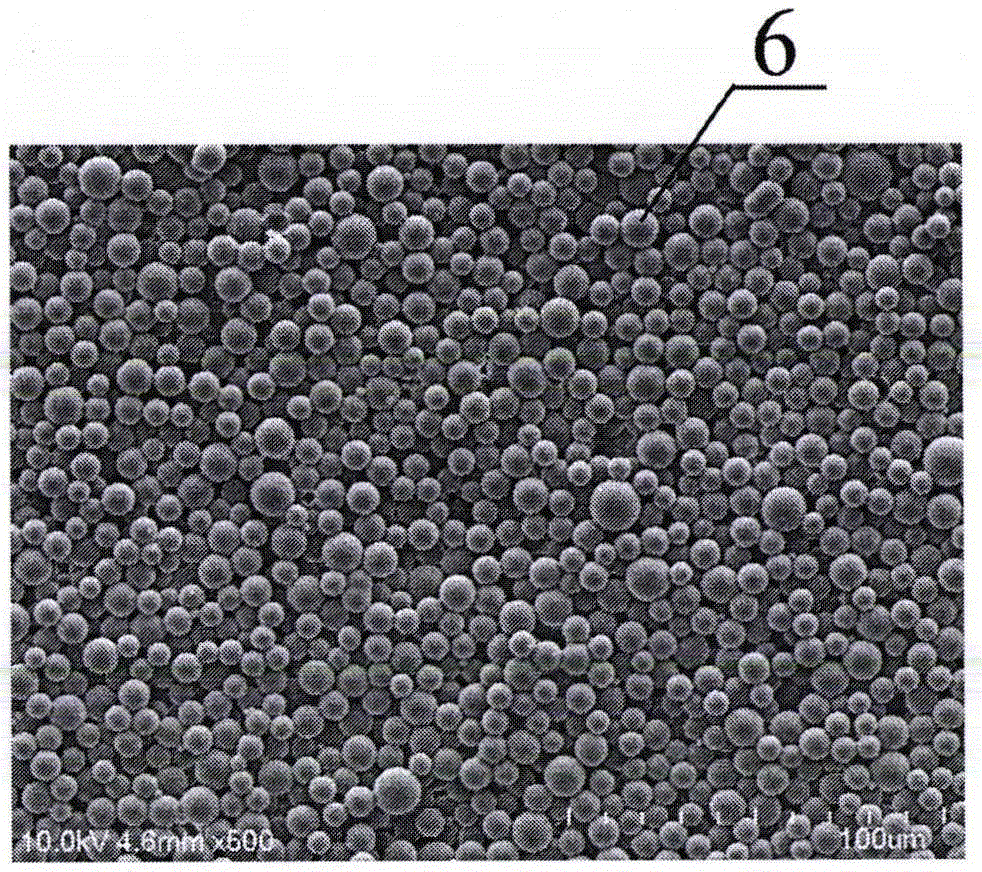

[0029] A layer of glass microspheres with a diameter of 10-30 microns is coated on the surface of a polyethylene film with a thickness of 18 microns in a roll-to-roll manner, and the distribution of the microspheres on the surface of the polyethylene film is the same as image 3 Similarly, after curing, a layer of aluminum with a thickness of about 200nm was deposited on the surface of the microspheres by vacuum evaporation, and after 7 days at room temperature under oxygen-enriched conditions, the water contact angle of the aluminum layer of the aluminum-plastic composite film was tested to be 153° , the water rolling angle is 4°. Print graphics on the plastic side of the aluminum-plastic composite film, then cut it into bags, and use it as a packaging bag for milk. The aluminum layer of the aluminum-plastic composite film contacts the milk. After drinking the milk, the aluminum layer in the packaging bag hardly adheres to the Packaged milk.

Embodiment 3

[0031] Coating a layer of polymethyl methacrylate microspheres with a diameter of 10-30 microns on the surface of a 12-micron thick polypropylene film in a roll-to-roll manner, the distribution of the microspheres on the surface of the polypropylene film and the Figure 4 Similarly, after curing, a layer of aluminum with a thickness of about 150nm is deposited on the surface of the microspheres by magnetron sputtering. After 10 days at room temperature under oxygen-enriched conditions, the water contact angle of the aluminum layer of the aluminum-plastic composite film is tested. 156°, the water roll angle is 3°. Print graphics on the plastic surface of the aluminum-plastic composite film, then cut it into bags, and use it as a packaging cover film for yogurt. The aluminum layer of the aluminum-plastic composite film contacts the yogurt, and the cover film of the yogurt cup is torn off. The layer hardly adheres to the packaged yoghurt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap