High-sensitivity pressure-limiting air valve of truck air pump

A high-sensitivity, air-pump technology, applied in safety valves, balance valves, valve devices, etc., can solve problems such as high pressure, corrosion, and accidents in gas storage tanks, and achieve the effect of compact internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

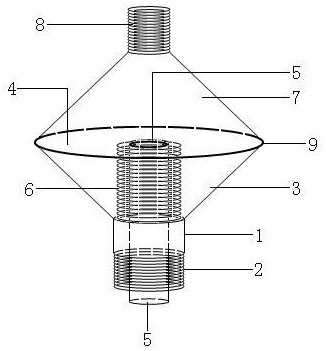

[0014] Now in conjunction with accompanying drawing and reference numeral, shape, structure of the present invention are described in detail:

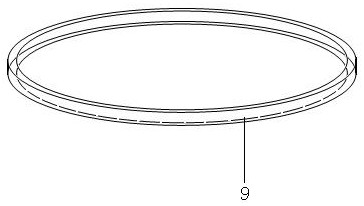

[0015] A high-sensitivity pressure-limiting air valve for a truck air pump, characterized by comprising: a pipe joint (8kpa) 1, a pipe joint outer wire 2, a lower cover (8kpa) 3, a rubber pad (8kpa) 4, a plastic push rod 5, and a pressure spring 6 , Upper cover (8kpa) 7, upper cover outer wire 8, buckle 9;

[0016] The pipe joint 1 is cylindrical, and the outer edge below the pipe joint 1 is provided with a spiral pipe joint outer wire 2, and the pipe joint outer wire 2 is connected with the circular opening above the air inlet valve plate on the top of the truck air pump;

[0017] The lower cover 3 is conical with a large mouth facing upwards, and an annular pressure ring with a width of 3-5mm is horizontally arranged on the outer edge of the upper opening of the lower cover 3, and the circular opening at the bottom of the lower cover 3

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap