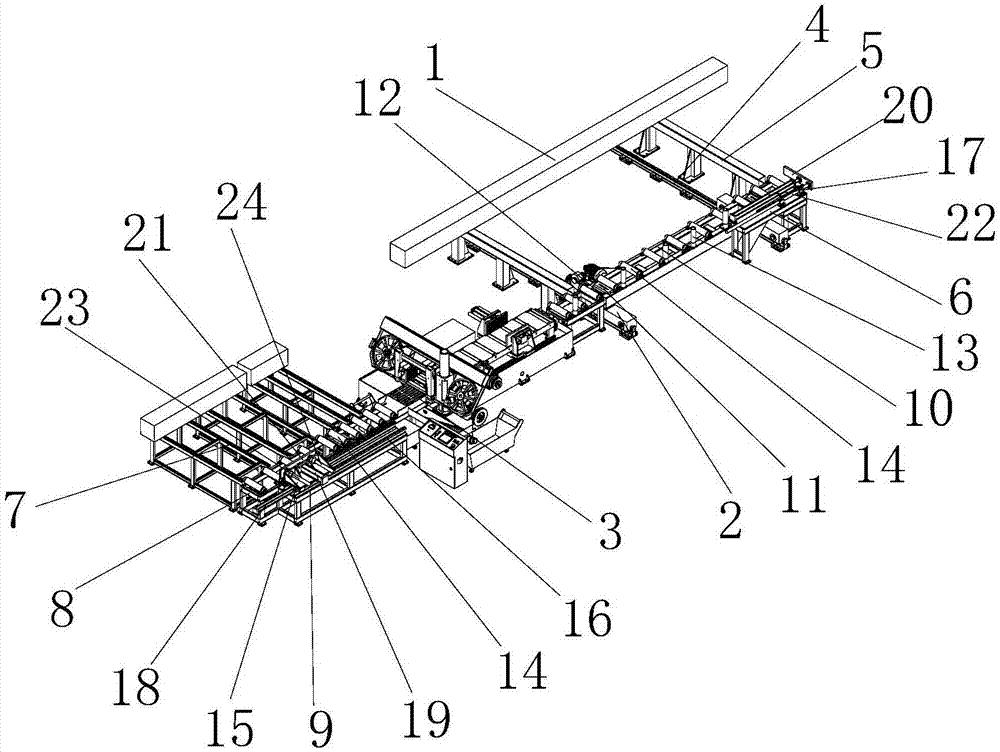

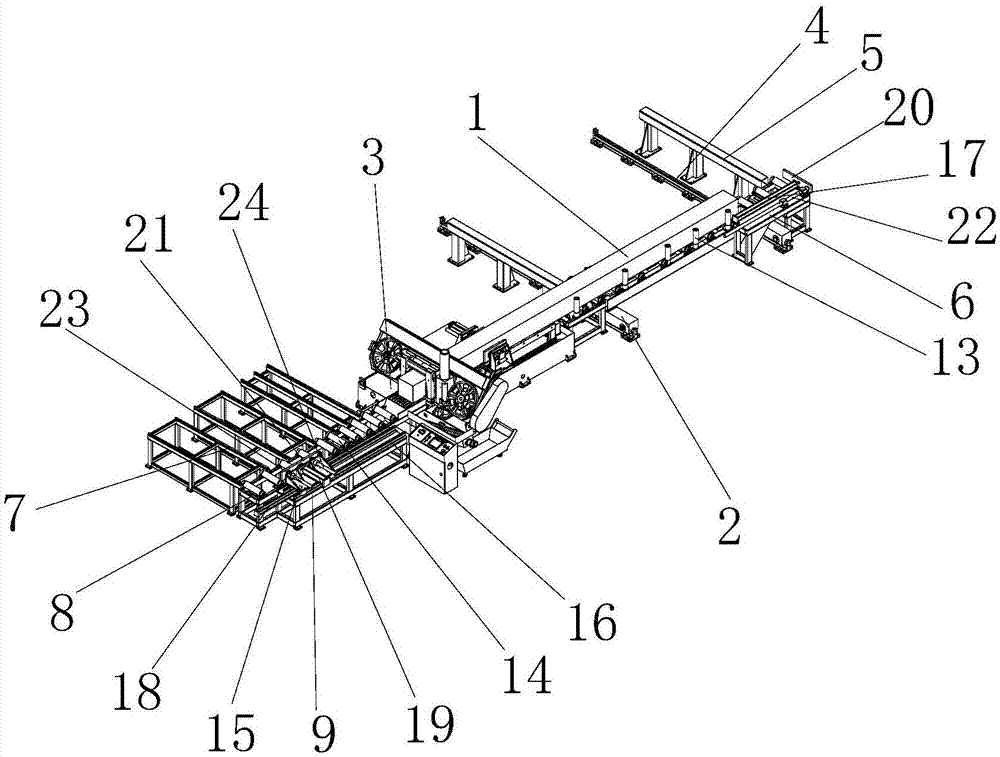

Full-automatic end face cutting assembly line of high-speed rail axle

A fully automatic, assembly line technology, applied in metal sawing equipment, sawing machine equipment, metal processing equipment, etc., can solve the problem that the feeding and feeding of large square materials are not suitable, the feeding mechanism is large, and the use is inconvenient, etc. problems, to achieve the effect of easy popularization and use, diversified functions and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0018] Such as Figure 1-2 As shown, a fully automatic end face cutting assembly line for high-speed railway axles is divided into a feeding mechanism, a feeding mechanism, a machine tool 3 and a discharging mechanism in sequence. The feeding mechanism includes a moving mechanism, a guide rail 4, a material rack 5, and a material rack 5 There are two and are arranged at intervals on one side of the feeding direction of the material 1. The guide rail 4 is arranged between the two racks 5 and is perpendicular to the feeding direction of the material 1. The moving mechanism moves back and forth along the guide rail 4 and can carry the material 1. Move to the docking position of the feeding port of the machine tool 3, the feeding

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap