Online series type drilling system for photovoltaic module backboard glass

A technology of back glass and photovoltaic modules, which is applied in the direction of work accessories, stone processing tools, manufacturing tools, etc., can solve the problems of high rate of defective products, inability to economically meet production capacity needs, and fast pace of production line processing. To achieve the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

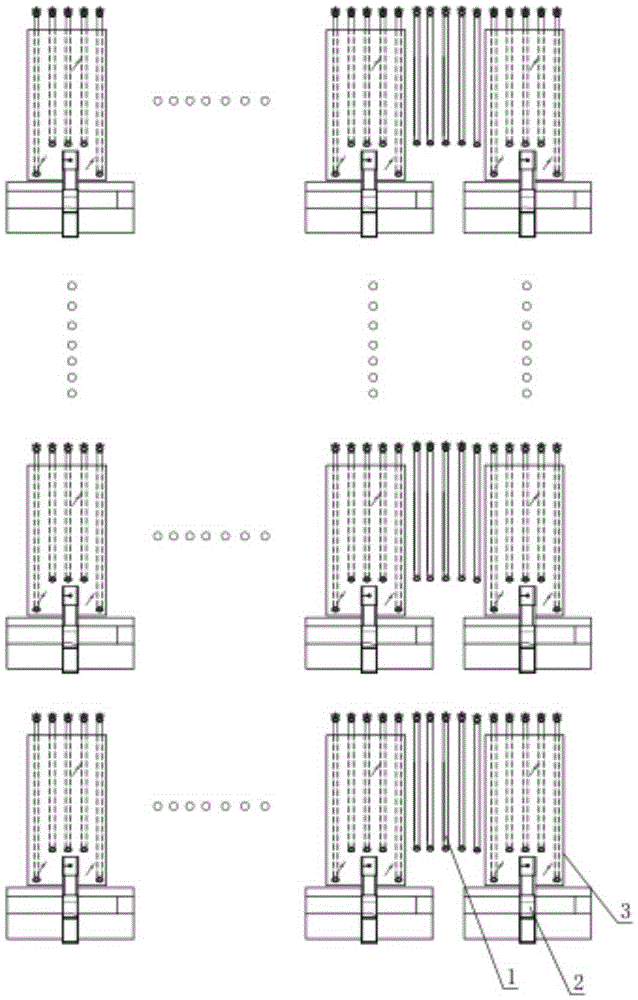

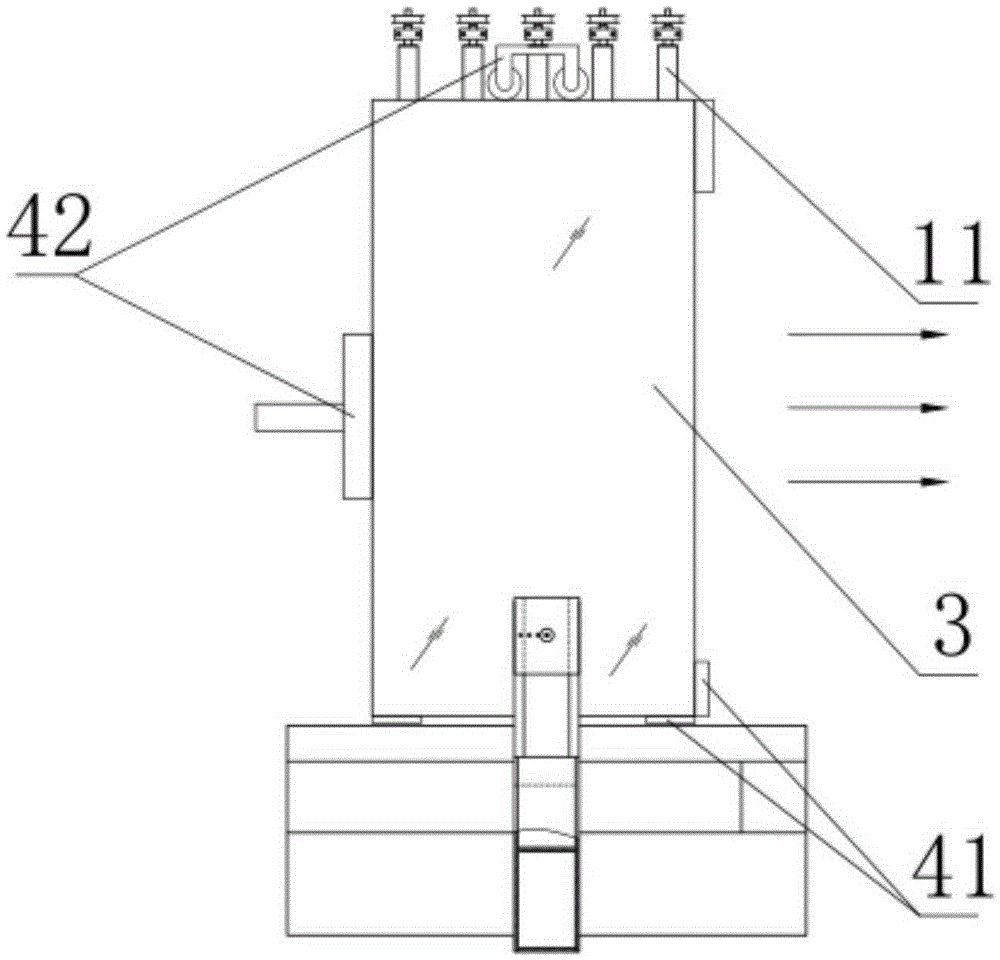

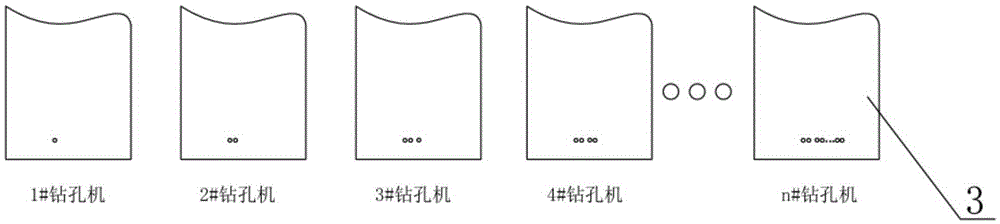

[0021] Such as Figure 1-3 As shown, the photovoltaic module backplane glass online series drilling system in this embodiment includes a transmission line 1 for conveying the backplane glass 3, an automatic positioning device located above the transmission line 1, and a drilling machine 2 located on the side of the transmission line 1 , the transmission line 1 parks the back glass 3 on one side of the drilling machine 2 according to the control signal, the automatic positioning device goes down and fastens the back glass 3, the back glass 3 is drilled by the corresponding drilling machine 2, and the transmission The assembly line 1, the automatic positioning device and the drilling machine 2 are controlled by a PLC control system. In this way, each device on the transmission line 1 is working at the same time, and the entire transmission line 1 has a back glass 3 being transported, as long as the position of the automatic positioning device corresponding to the 2 stations of each

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap