Nodular cast iron composite tube lined with epoxy ceramic and manufacturing method thereof

A technology of epoxy ceramics and ductile iron, which is applied in the field of composite pipes, can solve the problems of destroying the internal structure of ductile iron pipes, the trouble of replacing sewage pipes, and the imbalance of acid and alkali in sewage, so as to improve the anti-corrosion ability, save transportation costs, and improve the structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

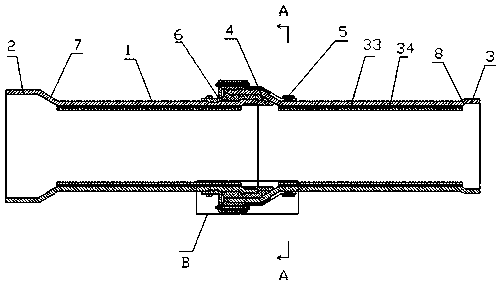

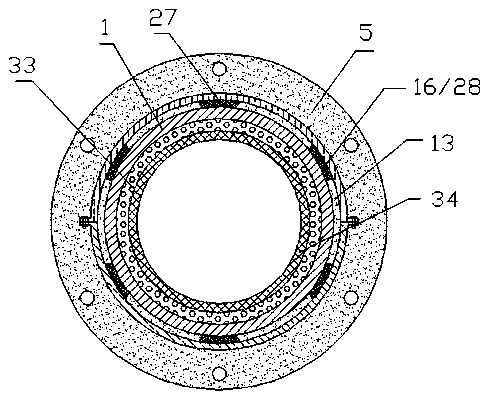

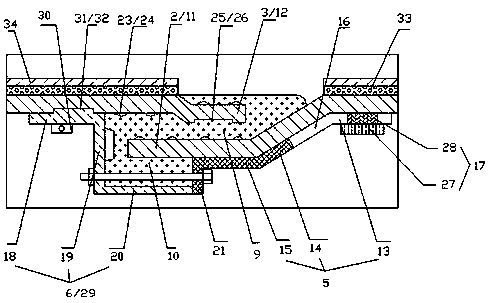

[0051] As shown in the figure, an epoxy ceramic-lined nodular cast iron composite pipe includes at least two cast pipe single pipes 1, and a socket 2 is fixed on the socket end of the cast pipe single pipe through a first transfer pipe 7 arranged obliquely. A socket 3 is fixed on the spigot end of the cast pipe single pipe through a second adapter pipe 8 arranged obliquely, the inner diameter of the socket is greater than the inner diameter of the socket, and the inner diameter of the socket is greater than the inner diameter of the cast pipe single pipe;

[0052] The socket of one of the cast tube single tubes is inserted into the socket of the other adjacent cast tube single tube, and fixedly connected through the interface structure;

[0053] A layer of adhesion layer 33 is arranged on the inner wall of the cast pipe single pipe, and a layer of epoxy ceramic layer 34 is arranged on the adhesion layer;

[0054] The composition of the adhesion layer is as follows in parts by wei

Embodiment 2

[0086] A kind of lining epoxy ceramic nodular cast iron composite pipe described in Embodiment 1, the difference is that,

[0087] The composition of the adhesion layer is as follows in parts by weight:

[0088] 35 parts of Portland cement, 2 parts of silicon dioxide, 1 part of ferric oxide, 5 parts of bentonite, 3 parts of nanofiber, 3 parts of polyurethane acrylate, 30 parts of water;

[0089] The composition of the epoxy ceramic layer is as follows in parts by weight:

[0090] 40 parts of water-based epoxy resin, 20 parts of water-based polyurethane resin, 15 parts of quartz powder, 3 parts of isopropanol, 8 parts of silicon dioxide, 5 parts of aluminum oxide, and 3 parts of hollow glass microspheres.

Embodiment 3

[0092] A kind of lining epoxy ceramic nodular cast iron composite pipe described in Embodiment 1, the difference is that,

[0093] The composition of the adhesion layer is as follows in parts by weight:

[0094] 55 parts of Portland cement, 8 parts of silicon dioxide, 4 parts of ferric oxide, 10 parts of bentonite, 6 parts of nanofiber, 10 parts of polyurethane acrylate, 45 parts of water;

[0095] The composition of the epoxy ceramic layer is as follows in parts by weight:

[0096] 50 parts of water-based epoxy resin, 25 parts of water-based polyurethane resin, 28 parts of quartz powder, 10 parts of isopropanol, 13 parts of silicon dioxide, 9 parts of alumina, and 15 parts of hollow glass microspheres.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap