PE water supply pipe and preparation method thereof

A water supply pipe and nylon technology, which is applied in the field of PE water supply pipe and its preparation, can solve the problems of complicated pipe preparation process, and achieve the effects of expanding the scope of application, improving the reduction of mechanical properties, and enhancing the bearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

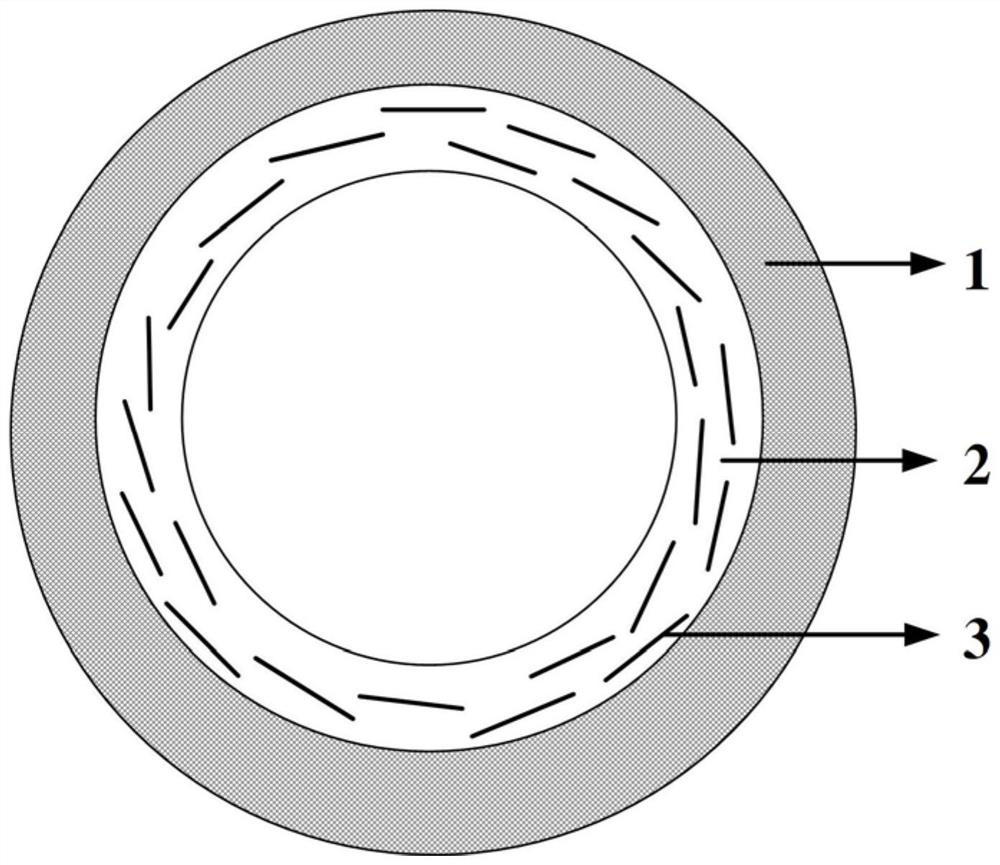

[0030] This embodiment provides a PE water supply pipe, its structure is as follows figure 1 As shown, from the outside to the inside, it includes the outer reinforcement layer 1 and the inner barrier layer 2 in sequence. The material of the inner barrier layer 2 is nylon-modified high-density polyethylene, wherein nylon 3 is dispersed in the high-density polyethylene in a layered form ; The material of the outer reinforcing layer 1 is fiber-reinforced modified polyethylene.

[0031] In parts by weight, the raw materials for preparing the nylon-modified high-density polyethylene include 85 parts of high-density polyethylene, 15 parts of nylon, 5 parts of compatibilizer, 0.5 part of plasticizer and 0.1 part of antioxidant.

[0032] Among them, the crystallinity of high-density polyethylene is 80% to 90%, the softening point is 125°C to 135°C, and the service temperature can reach 100°C. In this embodiment, the preferred high-density polyethylene is PetroChina Daqing Petrochemical

Embodiment 2

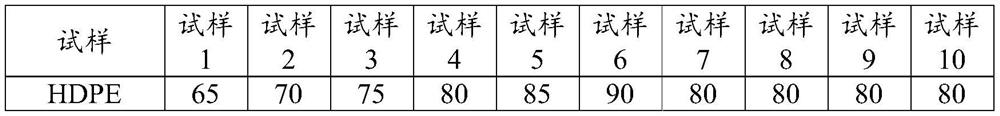

[0051] This example intends to analyze the effect of the proportion of high-density polyethylene, nylon, and compatibilizer on the mechanical properties and barrier properties of PE water supply pipes in nylon-modified high-density polyethylene. The specific test method is as follows.

[0052] With reference to the preparation raw material and preparation method of PE water supply pipe in embodiment 1, adjust the component distribution ratio of high density polyethylene, nylon, compatibilizer three in the inner barrier material nylon modified high density polyethylene of PE water supply pipe, the rest The preparation method is the same as in Example 1, and PE water supply pipes are obtained. The composition ratios of high-density polyethylene, nylon, and compatibilizer in each pipe sample are shown in Table 2.

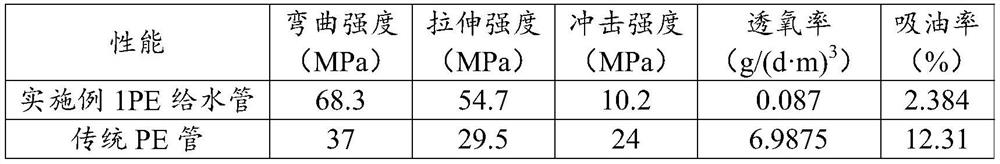

[0053] Referring to the method described in Example 1, the bending strength, tensile strength, impact strength, and barrier properties (oxygen permeability and oil absorp

Embodiment 3

[0064] This embodiment intends to analyze the influence of the viscosity of nylon and high-density polyethylene on the performance of PE water supply pipes, and the specific test method is as follows.

[0065] The raw materials and preparation method of the PE water supply pipe sample used in the test refer to Example 1, wherein the parts by weight of high-density polyethylene, nylon, and compatibilizer in the high-density polyethylene are 80 parts, 15 parts, and 5 parts respectively.

[0066] Sample 1: In this sample, when the screw shear rate is 1028s -1 At this time, the viscosity of high-density polyethylene is 115Pa·s, the viscosity of nylon is 212Pa·s, and the viscosity ratio of high-density polyethylene and nylon is 0.54.

[0067] Sample 2: In this sample, when the screw shear rate is 528s -1 At this time, the viscosity of high-density polyethylene is 235Pa·s, the viscosity of nylon is 316Pa·s, and the viscosity ratio of high-density polyethylene to nylon is 0.74.

[006

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap