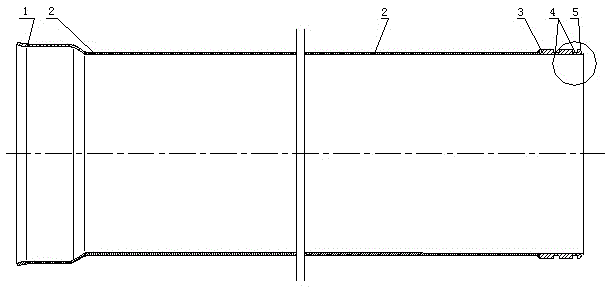

Steel pipe with bell and spigot joints

A socket and steel pipe technology, applied in the field of pipelines, can solve the problems of unreliable sealing, inconvenient maintenance, and low service life, and achieve the effects of high sealing reliability, convenient maintenance and disassembly, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

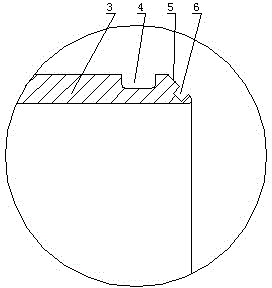

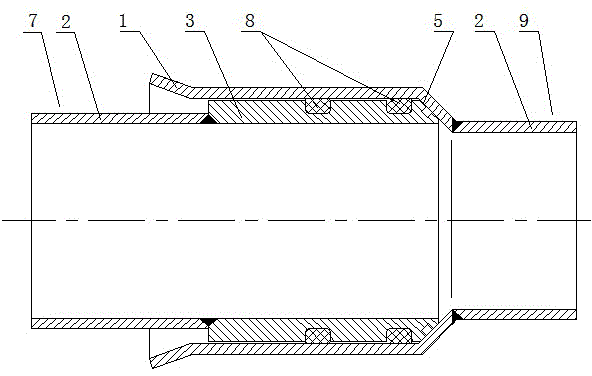

Embodiment 2

[0016] Example 2, manufacture a steel-plastic composite pipe with a diameter of φ500×9000, and the lining pipe is made of polyethylene. This embodiment is basically the same as Embodiment 1, the difference is that: the conical surface of the steel pipe socket steel pipe with the socket prepared in Embodiment 1 is provided with a turning groove 6, and using it as the base steel pipe, the steel pipe is manufactured. Plastic composite pipe. The polyethylene lining pipe is compounded and fixed in the base steel pipe 2 with the socket steel pipe 3 and the horn-shaped socket 1 fixedly connected, and a tapered flange is formed on the mouth edge of the socket steel pipe 3 . When connecting, the socket steel pipe 3 of the front steel-plastic composite pipe is in sealing contact with the tapered portion of the polyethylene liner pipe that is compounded with the trumpet-shaped socket 1 of the rear steel-plastic composite pipe through the tapered flange formed on the polyethylene liner pipe

Embodiment 3

[0017] Example 3, manufacturing a steel-plastic composite insulation pipe with a diameter of φ500×9000, the inner lining pipe is made of polyethylene, and the outer protective pipe is made of PE. This embodiment is basically the same as Embodiment 1, the difference is that the conical surface of the steel pipe socket steel pipe with the socket prepared in Embodiment 1 is provided with a turning groove 6, and using it as the base steel pipe 2, the steel pipe 2 is manufactured. Plastic composite insulation pipe. In the matrix steel pipe 2 that is fixedly connected with the socket steel pipe 3 and the trumpet-shaped socket 1, the polyethylene lining pipe is compounded and fixed, and a tapered flange is formed on the edge of the socket steel pipe 3, and the socket steel pipe 3 and the horn are fixedly connected. The base steel pipe 2 of the shaped socket 1 is covered with a PE outer protection pipe, and a foam insulation layer is arranged between them. When connecting, the socket st

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap