Laminated heat-preserving plastic composite pipe

A technology of composite pipes and interlayers, which is applied in the direction of heat preservation and protection of pipes and pipes through heat insulation, which can solve the problems of poor heat preservation performance, high construction difficulty, low construction efficiency, etc., and achieve broad application fields, good heat preservation effect, and not easy to deform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

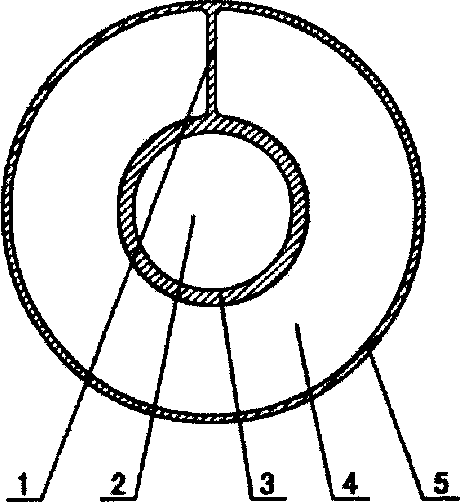

[0092] figure 1 , figure 2 In the first embodiment of the composition: the interlayer thermal insulation plastic composite pipe is set together by two pipes, the flow pipe 3 and the outer casing 5, and a connecting support rib 1 is positioned and supported to form the flow lumen 2 and the hollow interlayer 4.

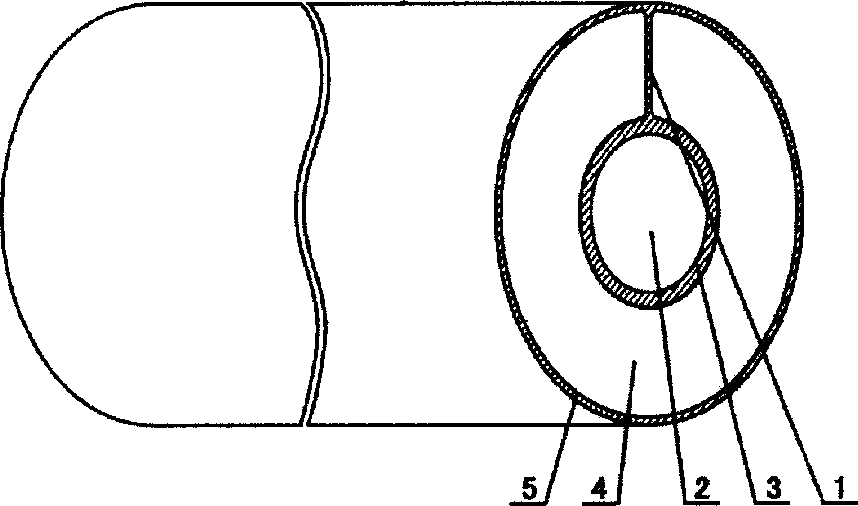

[0093] In the second embodiment composed of Fig. 3 and Fig. 4: the interlayer thermal insulation plastic composite pipe is set together by the flow pipe 3 and the outer pipe 5, and the outer surface of the outer pipe 5 is covered with an outer pipe reflective film 6, and there are two connecting supports The ribs 1 are positioned and supported to form a circulation lumen 2 and a hollow interlayer 4 .

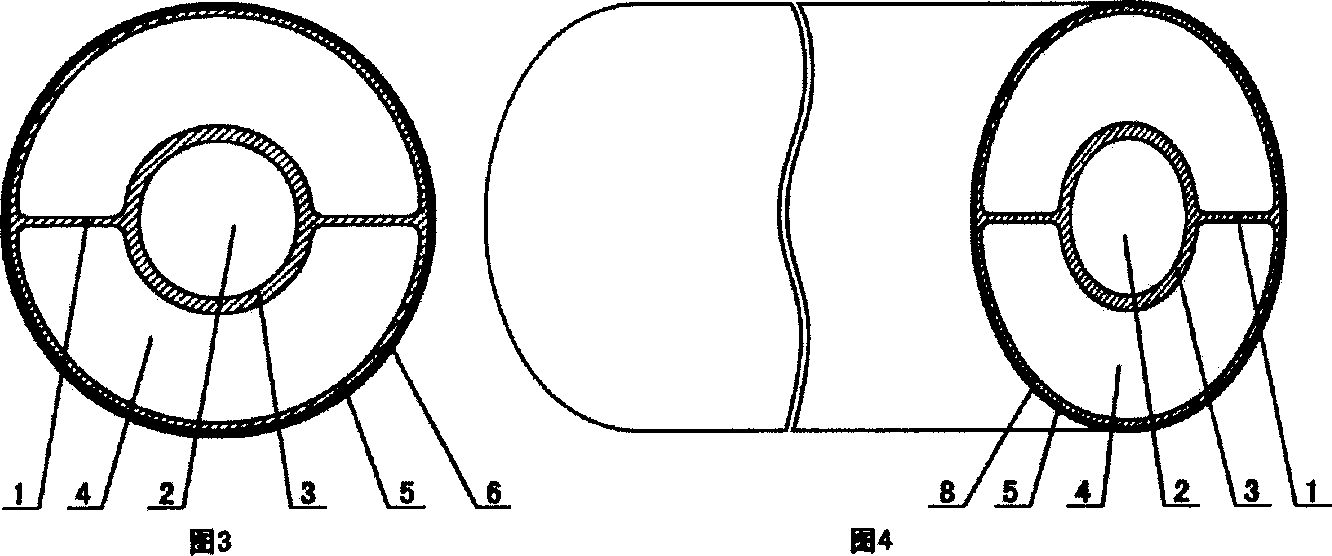

[0094] In the third embodiment composed of Fig. 5 and Fig. 6: the interlayer thermal insulation plastic composite pipe is set together by the flow pipe 3 and the outer pipe 5, the flow pipe 3 is sleeved with the inner pipe composite pipe 7, and the inner pipe composite pip

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap