Flexible ultrasonic suspension device

A levitation device and flexible technology, applied in electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve the problems of loss of piezoelectric material sound energy, increase in probe size, etc. , to achieve the effect of improving the sound field intensity, improving the effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

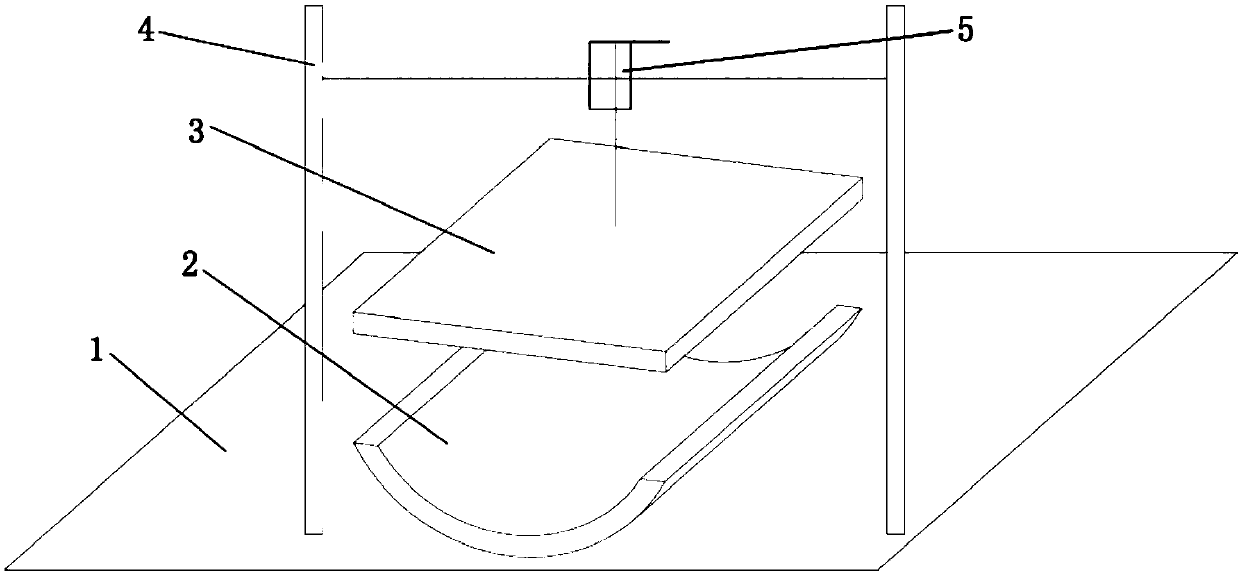

[0026] A flexible ultrasonic levitation device such as figure 1 As shown, it includes a base plate 1, an ultrasonic generator, an ultrasonic transducer, an electromechanical transducing material 2, a reflector 3 and a distance adjustment mechanism; the electromechanical transducing material 2 is placed on the base plate 1, and the ultrasonic generator, the ultrasonic transducer and the The electromechanical transducing materials 2 are connected sequentially; the electromechanical transducing materials 2 are flexible electromechanical transducing materials. Among them, the flexible electromechanical transducing material is a flexible piezoelectric electret film; the material of the flexible piezoelectric electret film is selected from polypropylene (PP), and the thickness of the flexible piezoelectric electret film is 180 μm; The polar film is a flexible piezoelectric electret film that has undergone electric polarization treatment; during the electric polarization treatment, a...

Embodiment 2

[0029] A flexible ultrasonic levitation device such as figure 1 As shown, it includes a base plate 1, an ultrasonic generator, an ultrasonic transducer, an electromechanical transducing material 2, a reflector 3 and a distance adjustment mechanism; the electromechanical transducing material 2 is placed on the base plate 1, and the ultrasonic generator, the ultrasonic transducer and the The electromechanical transducing materials 2 are connected sequentially; the electromechanical transducing materials 2 are flexible electromechanical transducing materials. Wherein, the flexible electromechanical transducing material is a flexible piezoelectric electret film; the material of the flexible piezoelectric electret film is selected from polytetrafluoroethylene (PTFE), and the thickness of the flexible piezoelectric electret film is 20 μm; The electroelectret film is a flexible piezoelectric electret film that has undergone electric polarization treatment; during the electric polariz...

Embodiment 3

[0031] A flexible ultrasonic levitation device such as figure 1 As shown, it includes a base plate 1, an ultrasonic generator, an ultrasonic transducer, an electromechanical transducing material 2, a reflector 3 and a distance adjustment mechanism; the electromechanical transducing material 2 is placed on the base plate 1, and the ultrasonic generator, the ultrasonic transducer and the The electromechanical transducing materials 2 are connected sequentially; the electromechanical transducing materials 2 are flexible electromechanical transducing materials. Among them, the flexible electromechanical transducing material is a flexible piezoelectric electret film; the material of the flexible piezoelectric electret film is selected from cycloolefin polymers, and the thickness of the flexible piezoelectric electret film is 100 μm; the flexible piezoelectric electret film The bulk film is a flexible piezoelectric electret film that has undergone electric polarization treatment; dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap