Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Cooling temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cooling Food. Cooling time starts at 135°F. Food may be left at room temperature until it drops to 135°F. Cool from 135°F to 70°F in 2 hours, then from 70°F to 41°F in 4 hours. If the temperature is more than 70°F in 2 hours, reheat to 165°F and start over. . Reheating can only be done.

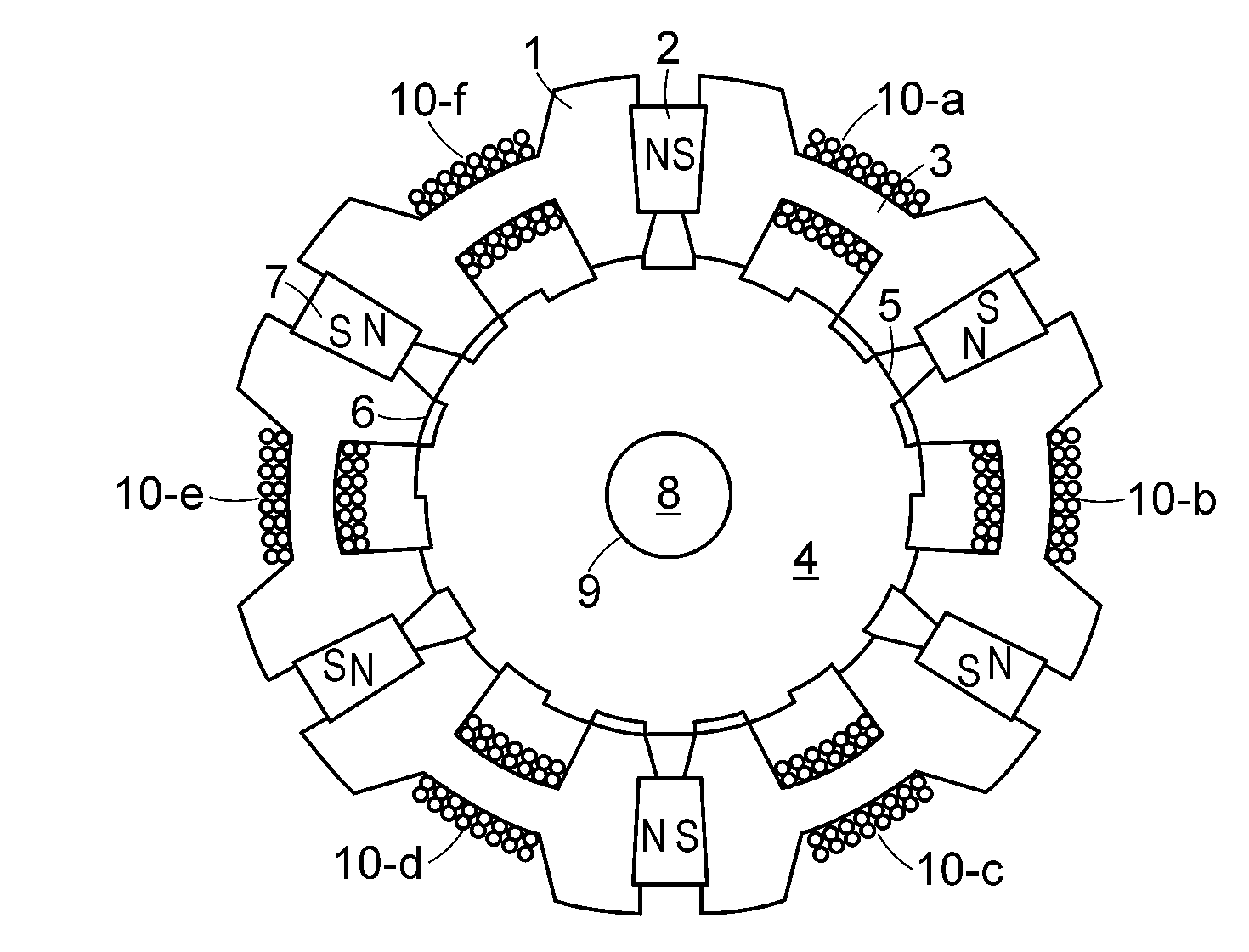

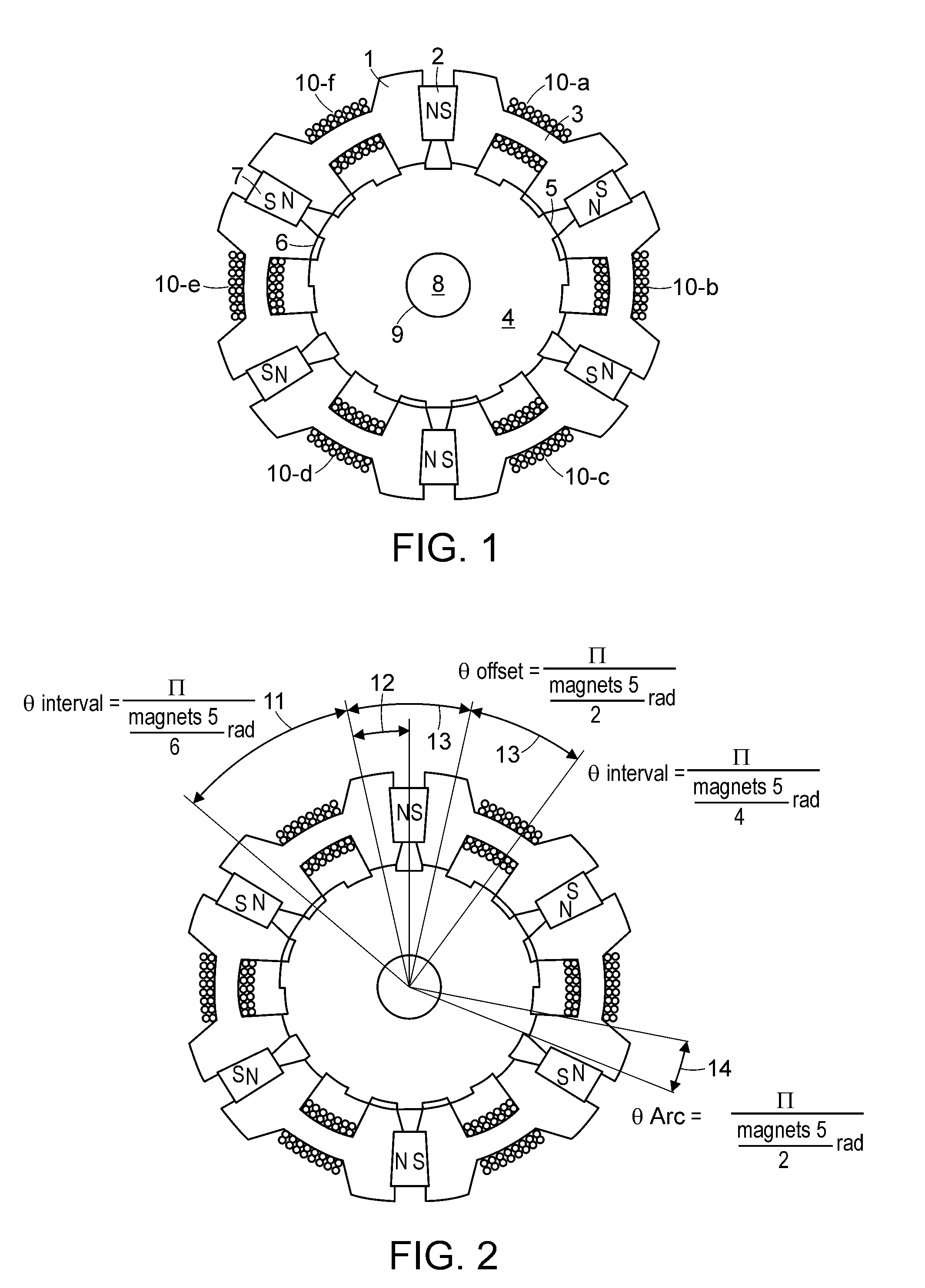

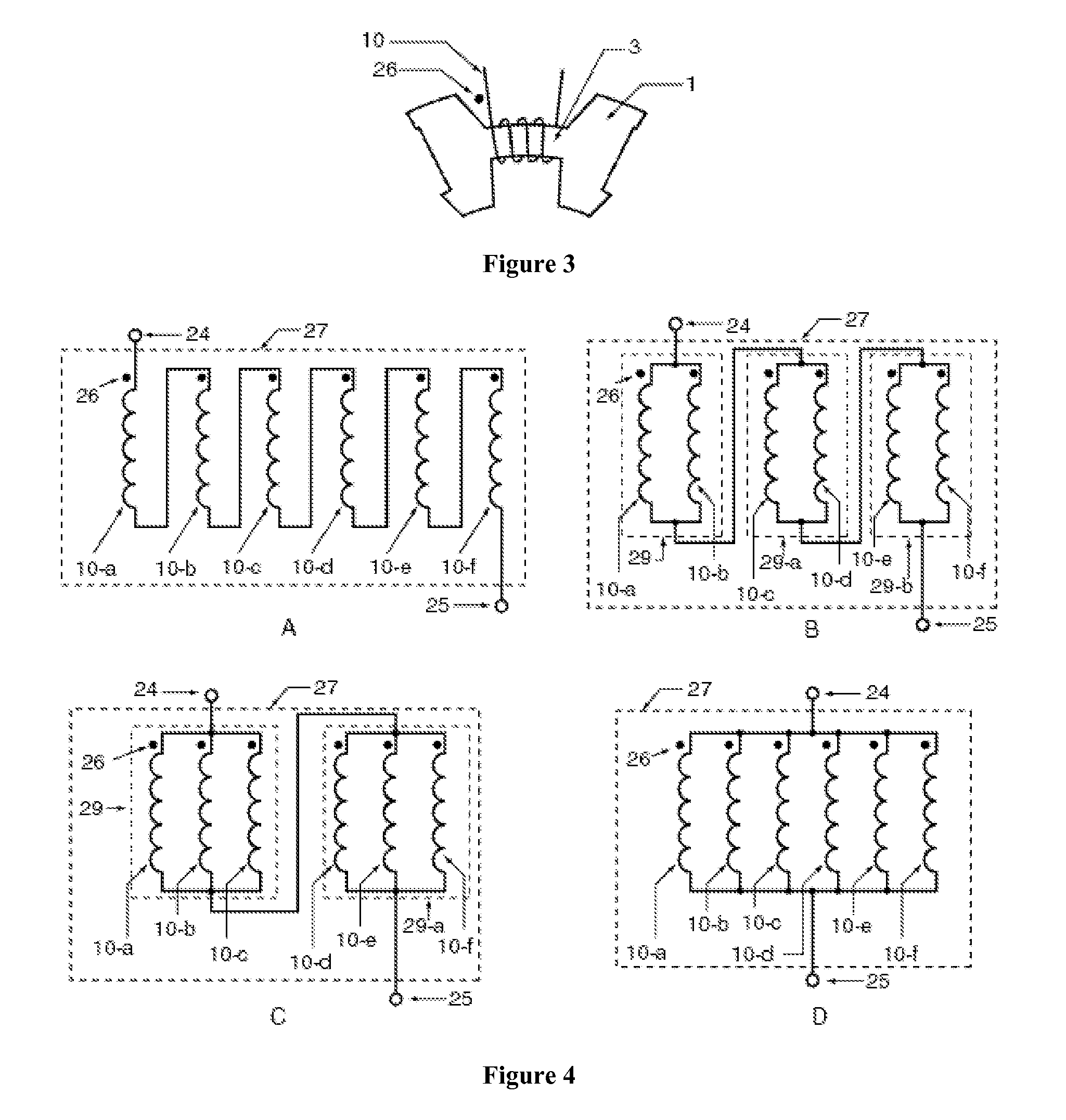

Permanent magnet electro-mechanical device providing motor/generator functions

InactiveUS20080272664A1DC commutatorSynchronous machines with rotating armatures and stationary magnetsMagnetic reluctanceCooling temperature

Owner:QM POWER

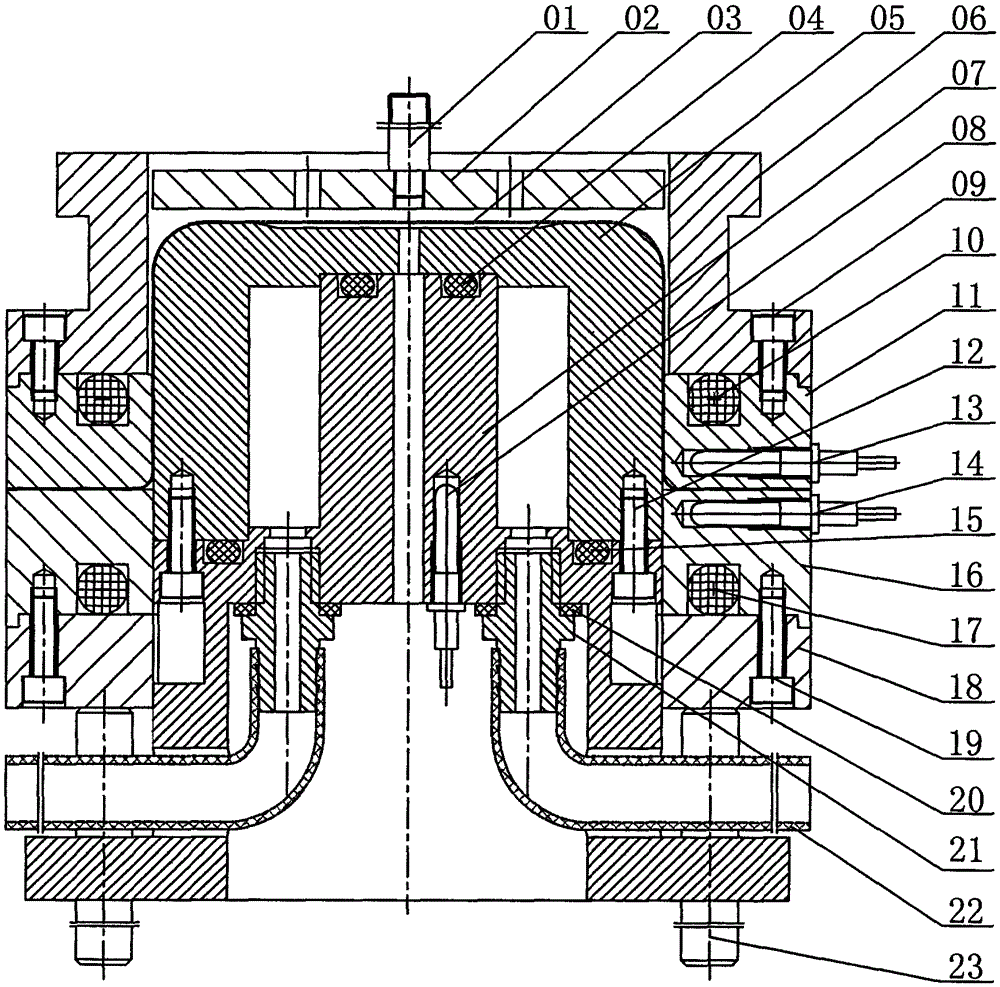

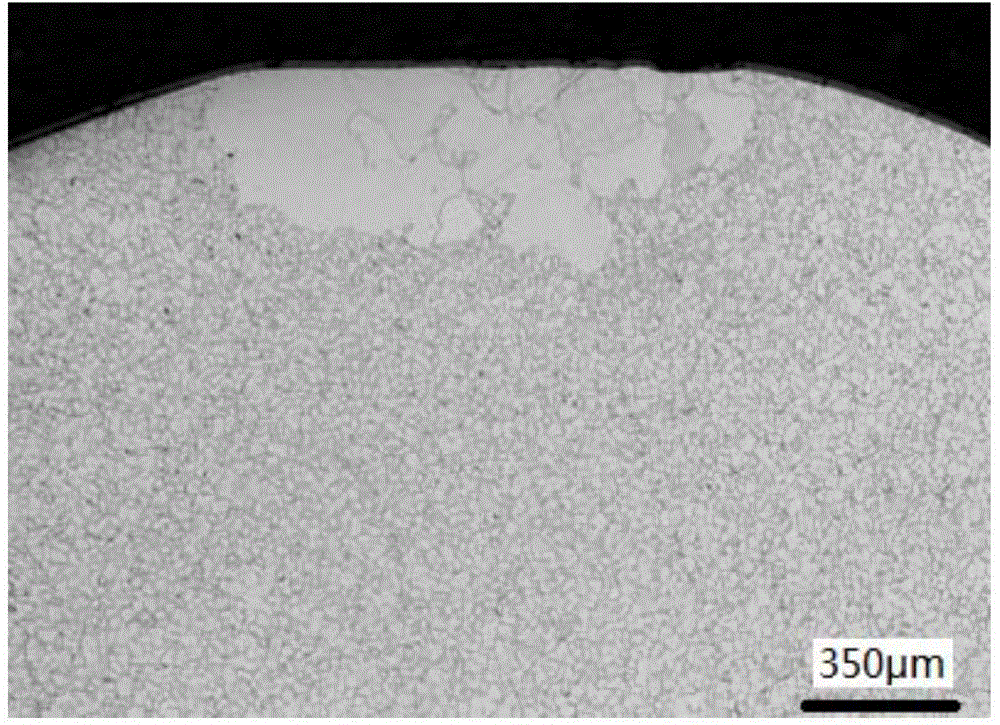

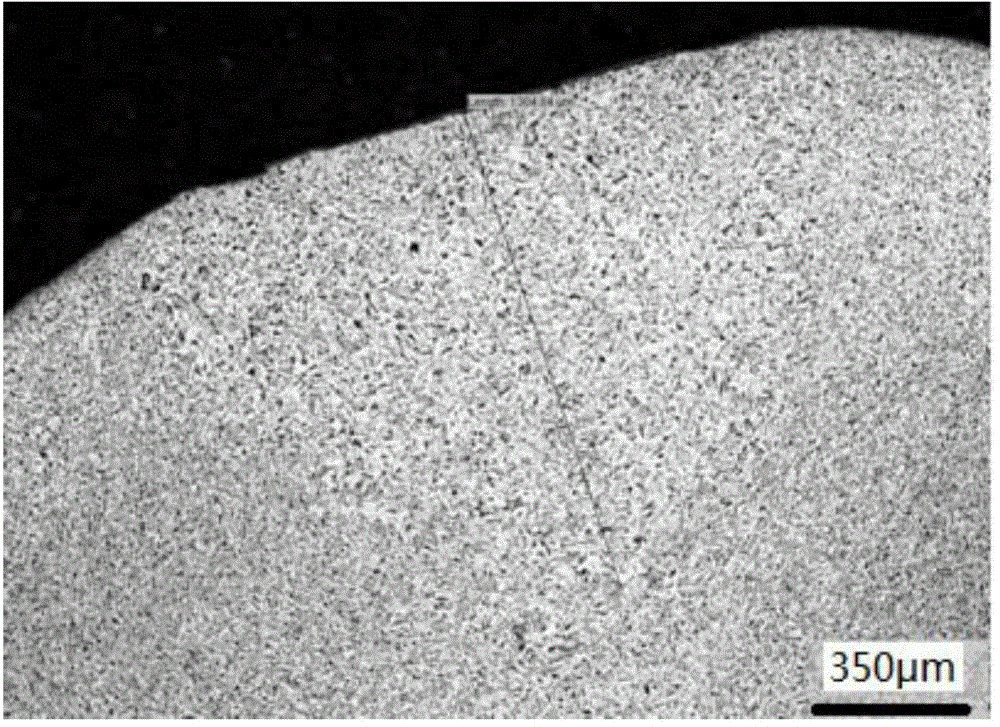

High-strength pipeline steel, steel pipe and manufacture method thereof

ActiveCN102953018AHigh elongationHigh uniform elongationTemperature control deviceCooling temperatureSteel tube

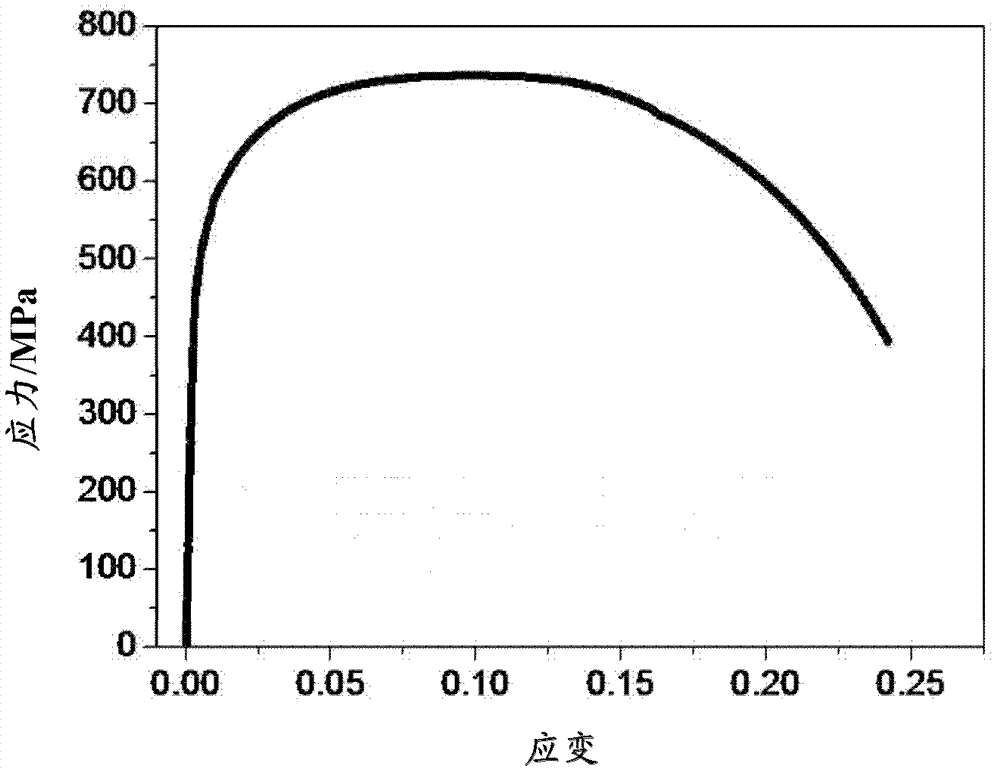

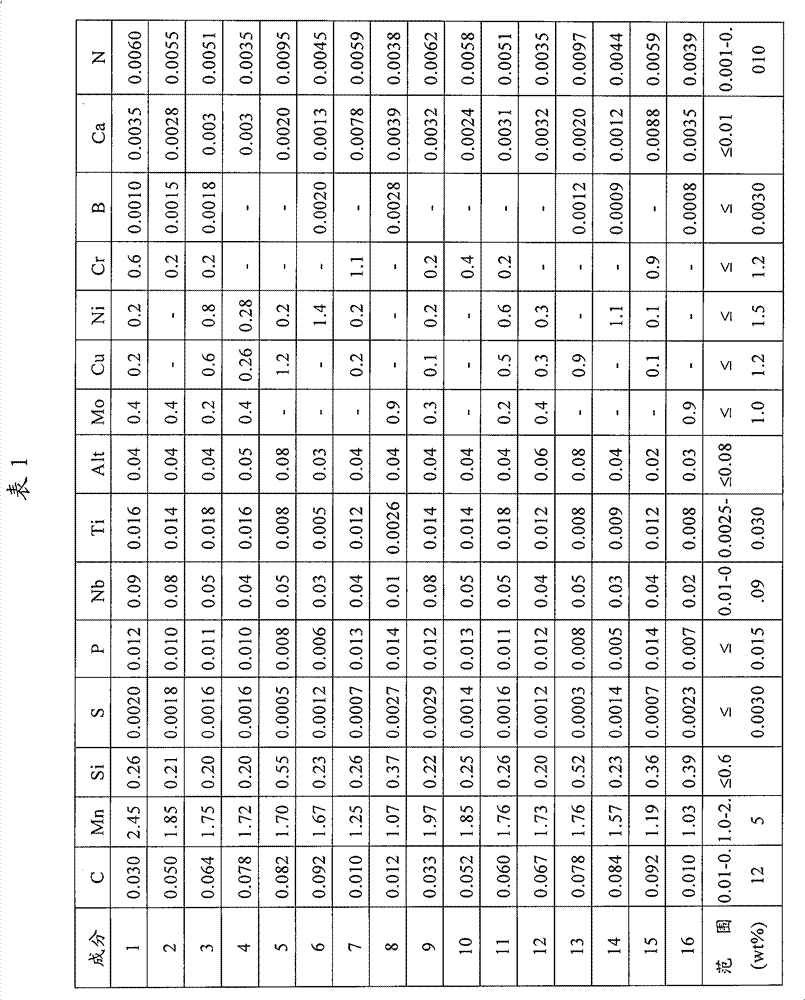

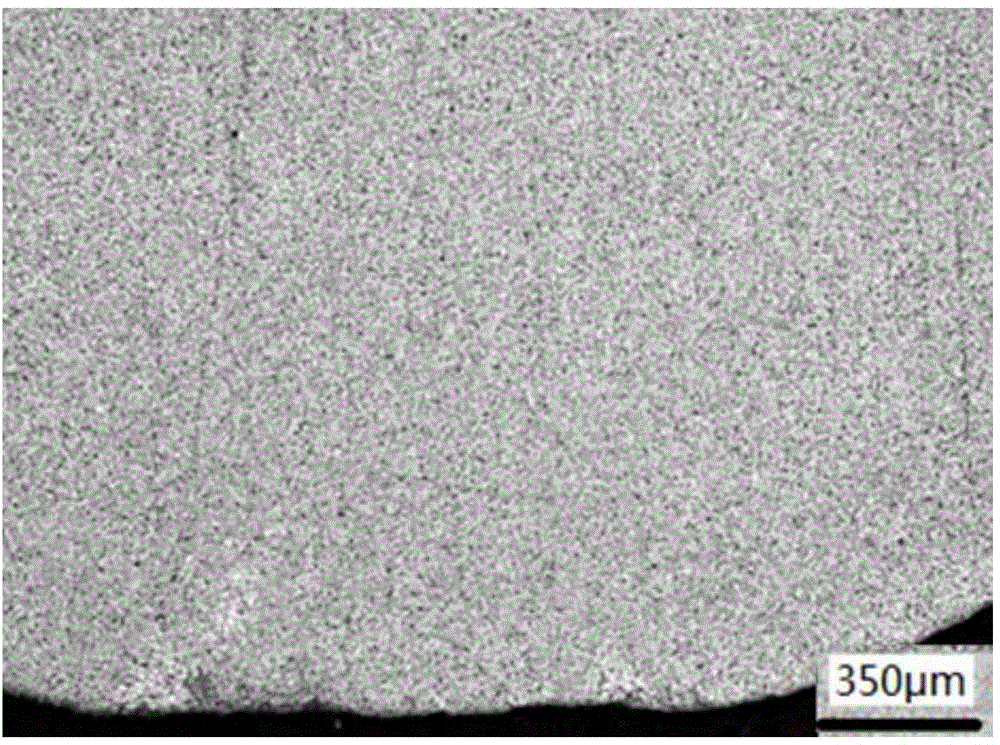

The invention relates to a high-strength pipeline steel which comprises the following chemical components by weight percent: 0.01-0.12 % of C, 1.0-2.5 % of Mn, less than or equal to 0.6 % of Si, less than or equal to 0.0030 % of S, less than or equal to 0.015 % of P, 0.01-0.09 % of Nb, 0.0025-0.030 % of Ti, less than or equal to 0.08 % of Alt, less than or equal to 1.0 % of Mo, less than or equal to 1.2 % of Cu, less than or equal to 1.5 % of Ni, less than or equal to 1.2 % of Cr, less than or equal to 0.0030 % of B, less than or equal to 0.01 % of Ca, 0.001-0.010 % of N, and the balance being iron and unavoidable impurities. The steel is polygonal ferrite and bainite duplex structure. A manufacture method of the high-strength steel pipe comprises heating slab with a temperature of 1100 to 1250 DEG C, rolling a non-recrystallization region with a starting temperature of 750 to 920 DEG C and a terminating temperature of 720 to 840 DEG C, two-stage cooling under control with an ACC terminating cooling temperature of 200 to 580 DEG C and a cooling rate of 5 to 30 DEG C per second, and manufacturing the pipe by using a UOE technology with a compression rate of 0.1 to 0.5 % and a diameter-expanding rate of 0.5 to 1.5 %. The obtained steel pipe can meet demands of low yield ratio and high uniform elongation.

Owner:BAOSHAN IRON & STEEL CO LTD

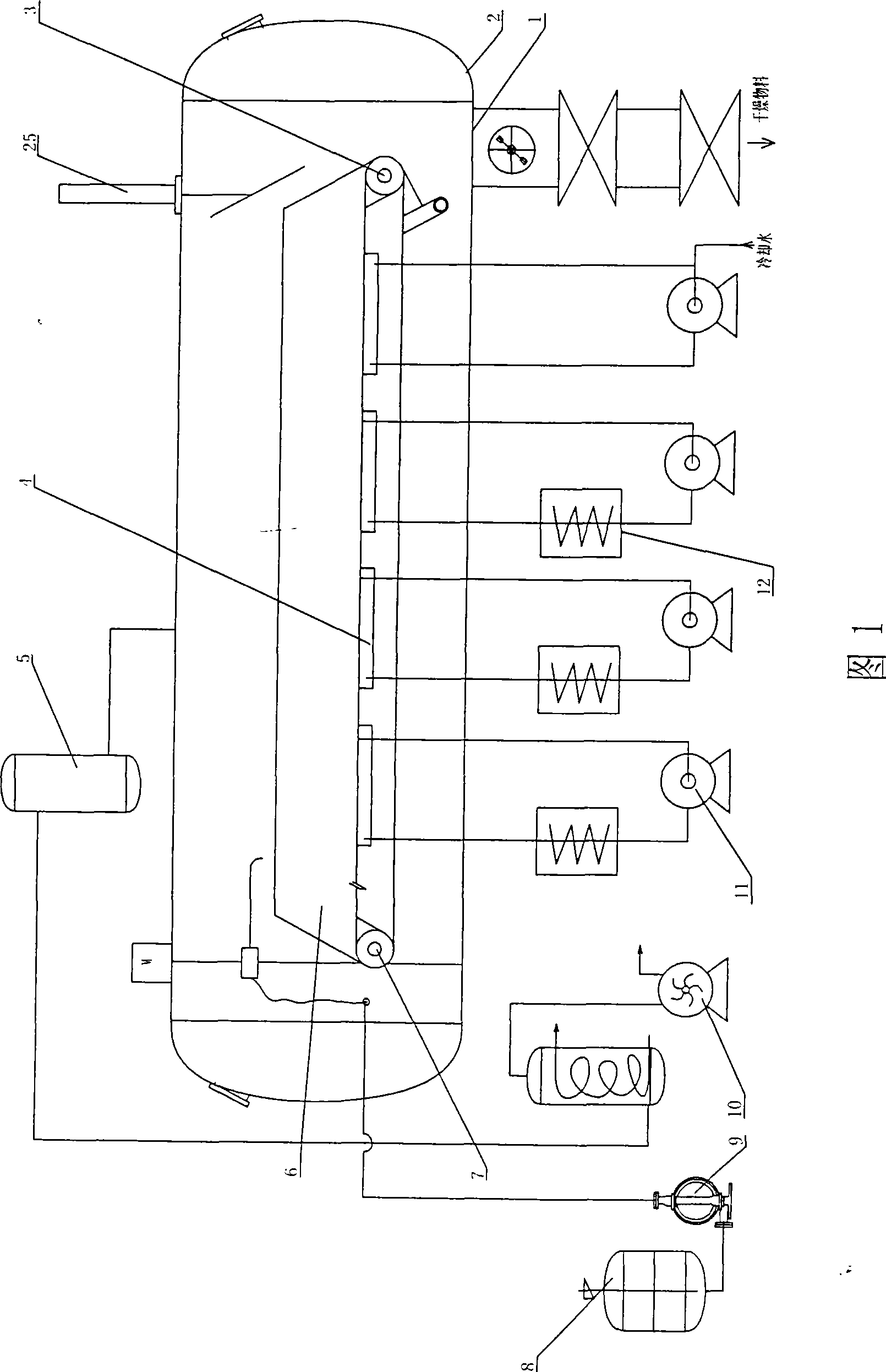

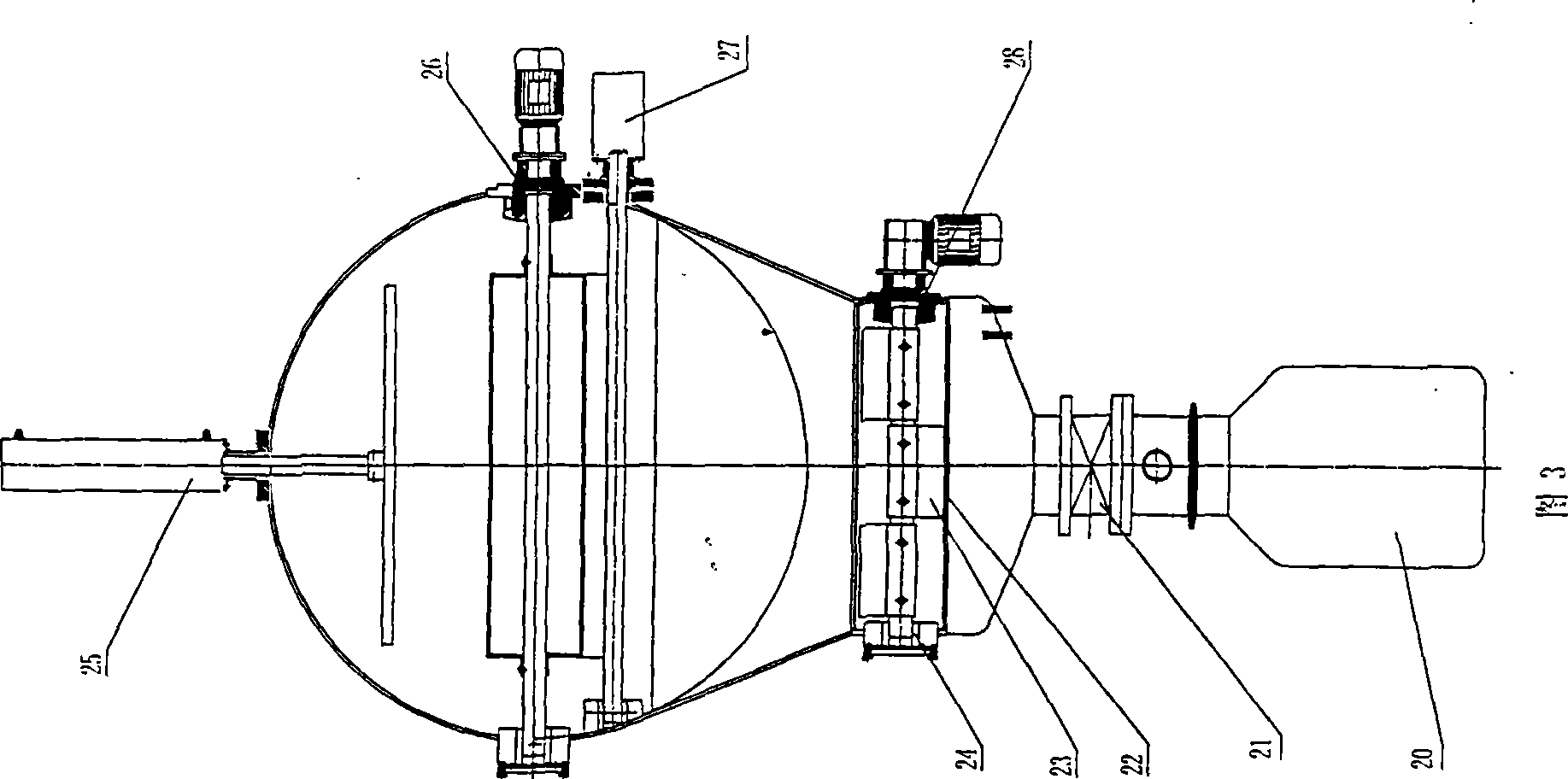

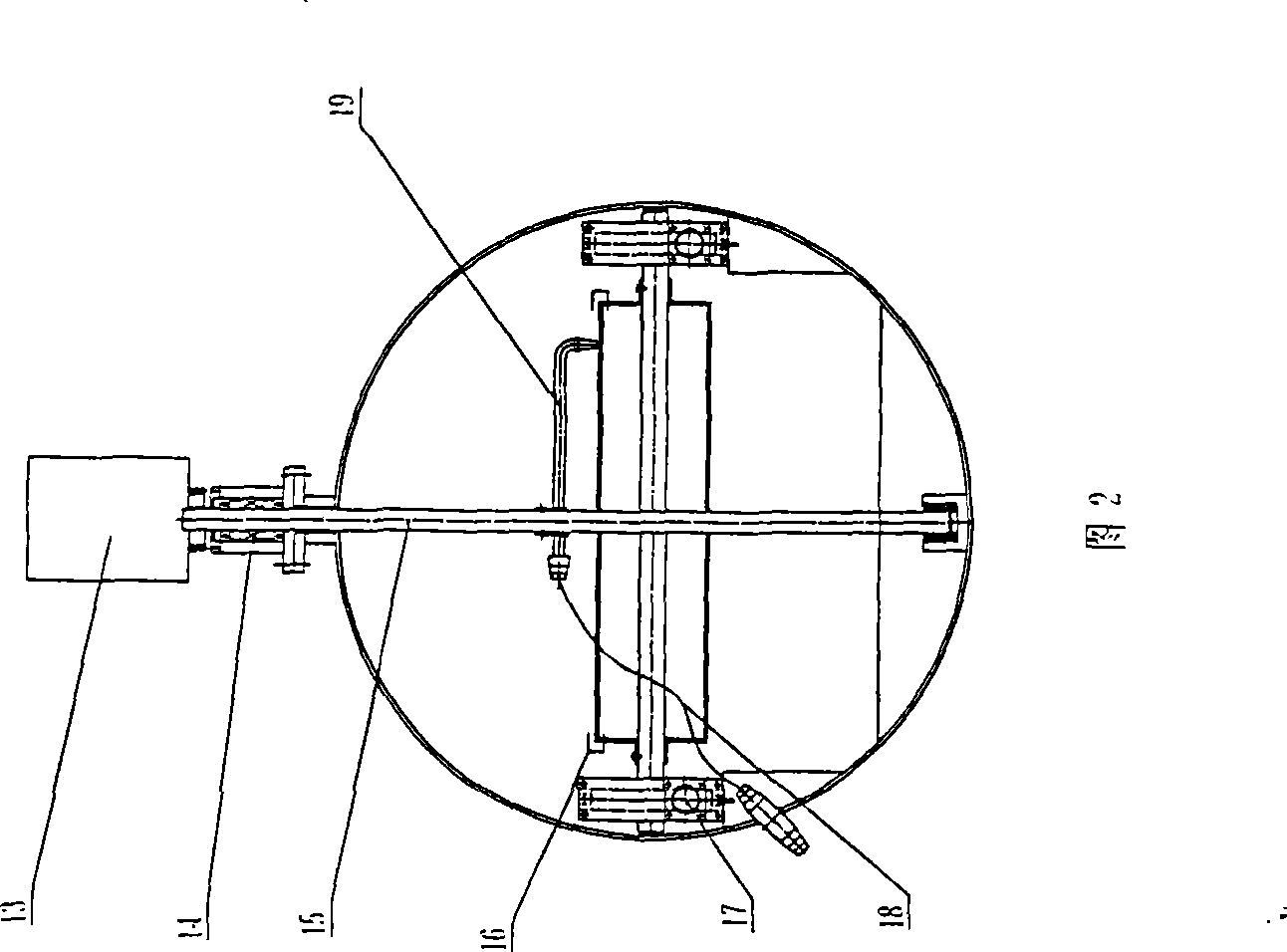

Vacuum belt type drying units

InactiveCN101368788ADrying machinesCooling temperatureHuman–machine interface

Owner:温州市金榜轻工机械有限公司

Intelligent electricity-saving control method for cooling towers in central air-conditioner monitoring system

InactiveCN107036231AHigh temperature regulation accuracyImprove dynamic performanceMechanical apparatusLighting and heating apparatusElectricityCooling tower

The invention relates to an intelligent electricity-saving control method for cooling towers in a central air-conditioner monitoring system. The intelligent electricity-saving control method is designed to solving the technical problem that in existing central air-conditioner monitoring systems, design of intelligent electricity-saving control methods for cooling towers is in lack of convenience. The intelligent electricity-saving control method is mainly characterized in that a temperature sensor on a pipe arranged between a cooling pump and a cooling water inlet valve of a refrigeration main machine is a cooling water returning temperature sensor; the cooling water returning temperature sensor is connected with temperature sensors at three positions, namely the temperature sensor arranged at the cooling water outlet position of water outlet of the refrigeration main machine, the temperature sensor arranged at the position where a cooling temperature difference of water inlet of the refrigeration main machine is generated and the temperature sensor arranged at the position where a cooling temperature difference of water outlet of the cooling pump is generated; two modes, namely the automatic mode and the intelligent modes, are arranged for the cooling water returning temperature sensor, and thus in the specific operation process of a central air-conditioner, by means of an intelligent algorithm in which the cooling towers are cut away, manual control over the number of the cooling towers is achieved; and by means of a touch screen end of cooling tower equipment, real-time monitoring is conducted, a real-time online sorting algorithm is adopted for operation time of the cooling towers, a time balanced control strategy is guaranteed, and for each time, the cooling tower which runs for the longest time is started and the tooling tower which runs for the shortest time is switched off.

Owner:HANGZHOU YUDA AUTOMATION TECH CO LTD

Method for controlling high speed wire rod surface clamp mark coarse grains

ActiveCN104785520AControlled rollingControl spinningRoll mill control devicesMetal rolling arrangementsWire rodEngineering

Owner:SHOUGANG CORPORATION

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap