Temperature difference deep drawing die for stainless steel products

A technology of temperature difference deep drawing and stainless steel, which is applied in the field of mechanical processing and stamping, can solve problems such as deep drawing, and achieve the effect of low mold cost, high efficiency and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

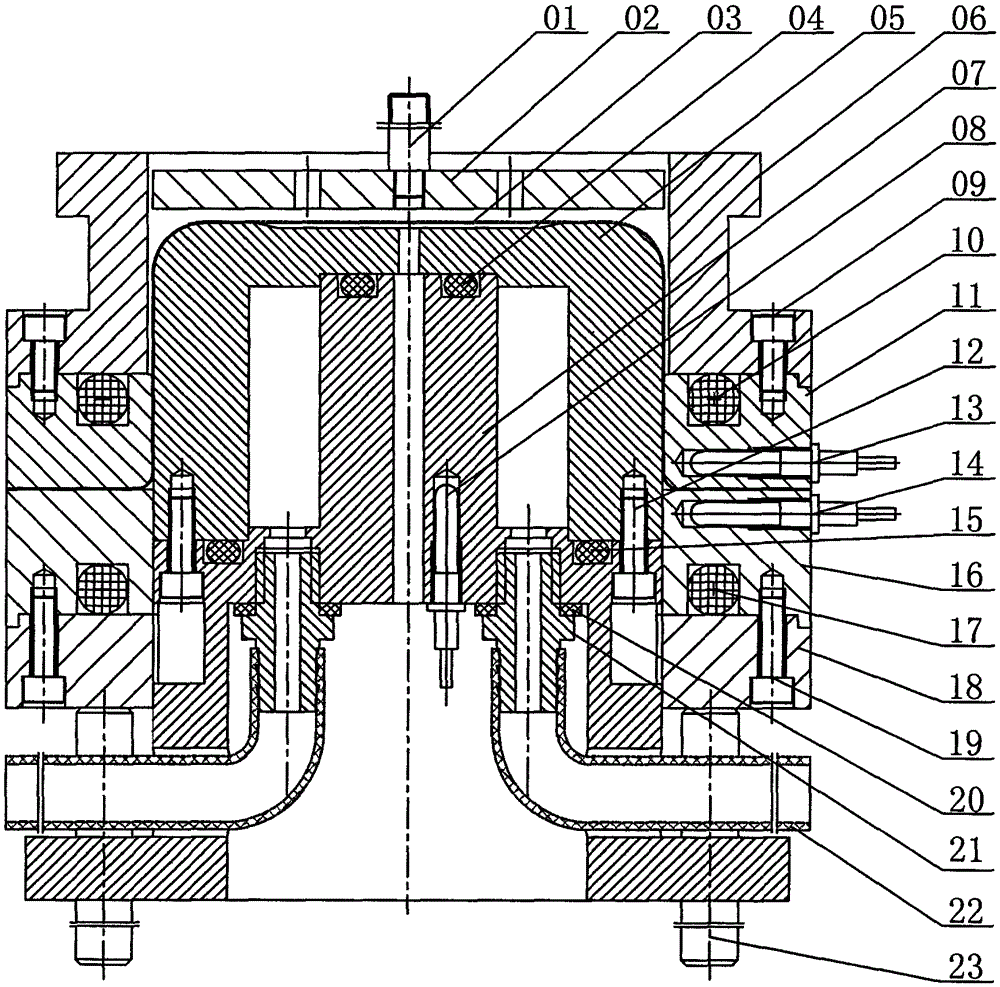

[0018] The present invention will be further described below in conjunction with the drawings.

[0019] Such as figure 1 As shown, a temperature difference drawing die for stainless steel products includes: push rod 01, push plate 02, stainless steel parts 03, upper seal ring 04, punch 05, concave mold seat 06, mold core 07, punch temperature sensor 08 , Die seat screw 09, Die electric heating tube 10, Die 11, Die core screw 12, Die temperature sensor 13, Pressure ring temperature sensor 14, Lower sealing ring 15, Pressure material ring 16, Pressure material ring electric heating tube 17. Support plate 18, support plate screw 19, water pipe joint gasket 20, water pipe joint 21, cooling water pipe 22, and top rod 23.

[0020] This embodiment is used in a double-acting hydraulic machine. The die seat 06 is mounted on the movable beam, the mold core 07 is mounted on the worktable, and the ejector rod 23 is mounted on the ejector plate of the lower cylinder.

[0021] The push rod 01 is co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap