Pipe fitting clamping device

A clamping device and pipe clamp technology, applied in workpiece clamping devices, shearing devices, accessories of shearing machines, etc., can solve the problems of difficult control of clamping force, taking a lot of time, and inability to realize automatic clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments.

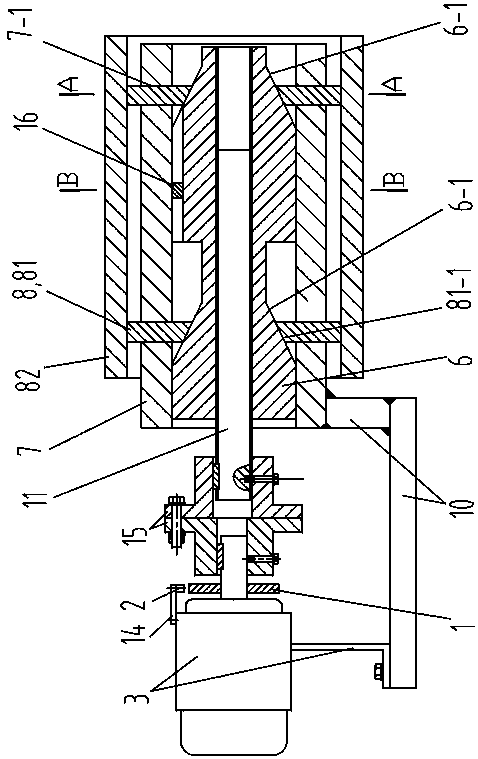

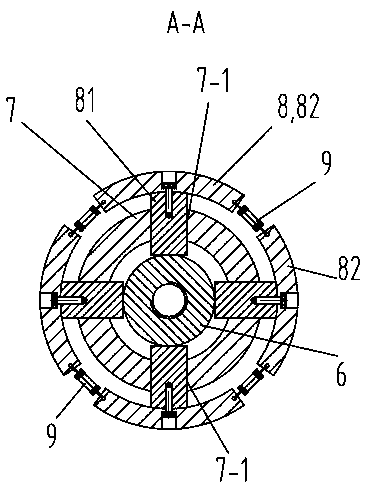

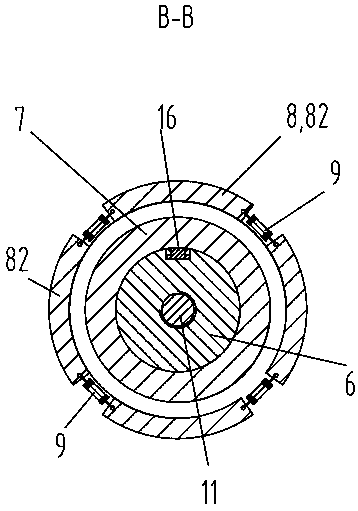

[0017] Such as Figure 1 to Figure 4 As shown, a clamping device for pipe fittings includes a magnetic ring 1, a sensor 2, a tensioning motor 3, a main controller 4, a motor driver 5, a mandrel 6, an expansion block mounting seat 7, an expansion block mechanism 8, a pull Spring 9, frame 10, screw mandrel 11, first switch 12 and second switch 13; Among the present embodiment, magnetic ring 1 selects the two pairs of pole magnetic rings produced by Jiangsu Xinxu Magnetic Technology Co., Ltd. The sensor 2 selects the Hall sensor of model MT4401. The tensioning motor 3 is a servo motor whose model is TLSM04-M00330. The main controller 4 is a PLC programmable controller, and the Mitsubishi FX2NC-PLC programmable controller is selected, and the motor driver 5 is a DC motor drive board whose model is LMD 18200T. Both the first switch 12 and the second sw

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap