Combined splicing tubular pile and pile splicing method

A technology for pipe piles and connecting casings, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve problems such as difficulty in operation, and achieve the effects of simple operation, shortened construction period, and easy access to piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Such as figure 1 It is a combined splicing pipe pile of the present invention, which includes two sequentially connected TSC pipe piles 10 and a steel cylinder 20;

[0030] The steel cylinder 20 is a hollow cylinder, which is arranged on the outer side of the junction of two adjacent TSC pipe piles 10 of the combined splicing pipe pile. The steel cylinder 20 is provided with several rows of circular plug welding holes 21 along the circumference, and two adjacent The plug welding holes 21 of the row are set in a staggered manner, and the steel cylinder 20 is welded to the TSC pipe pile 10 through the plug welding holes 21;

[0031] The joint of two adjacent TSC pipe piles 10 is set in the middle of the steel cylinder.

[0032] The preparation steps are as follows:

[0033] (1) Prepare two TSC pipe piles 10 and steel cylinder 20;

[0034] (2) Put one end of the steel cylinder 20 up along the end of one of the TSC pipe piles 10 until the end of the TSC pipe pile 10 reaches

Embodiment 2

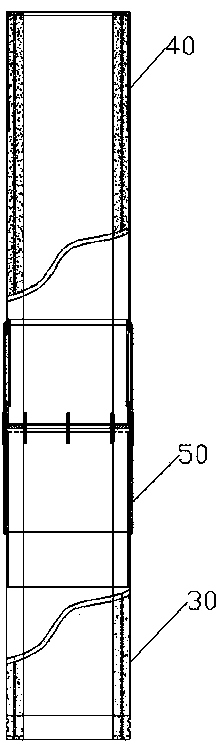

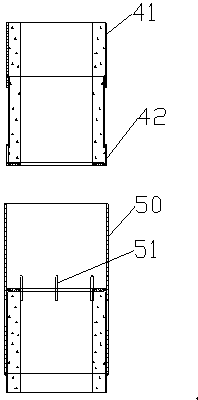

[0038] Such as figure 1 It is the combined splicing pipe pile of the present invention, which includes two sequentially connected PHC pipe piles 30, YTSC40 and a steel cylinder sleeved on the outer periphery of the connection between the PHC pipe pile 30 and the YTSC pipe pile 40;

[0039] The connection between the PHC pipe pile 30 and the YTSC pipe pile 40 is set in the middle of the steel cylinder 50, and the middle of the steel cylinder 50 is distributed along the circumferential direction with a row of strip-shaped plug welding holes 51 arranged parallel to the pile axis. The plug welding hole 51 straddles the connecting seam between the PHC pipe pile 30 and the YTSC pipe pile 40;

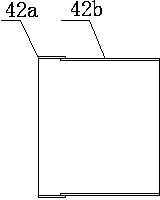

[0040] The YTSC pipe pile 40 includes a pile body 41 and a telescopic sleeve 42 arranged at the connection end of the YTSC pipe pile 40 and the PHC pipe pile 30. The length of the telescopic sleeve 42 is equal to or less than 1 / 2 of the height of the steel cylinder body 50. The telescopic sleev

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap