Double Wall Duct Connector

a technology of double wall ducts and connectors, which is applied in the direction of mechanical equipment, lighting and heating apparatus, heating types, etc., can solve the problems of bending or loss of shape at the connection, melting or dripping of sealant, and difficult to provide a good connection between ducts having different cross-sectional dimensions or diameters, etc., to achieve the effect of convenient use for installers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Objective:

[0038]To compare the leakage of a SPIRALMATE® connection with inner ring (attached with BNGASKET) to a standard SPIRALMATE® connection (without inner ring) to determine if BNGASKET is an acceptable attachment method. This will be achieved over several tests required.

Overview:

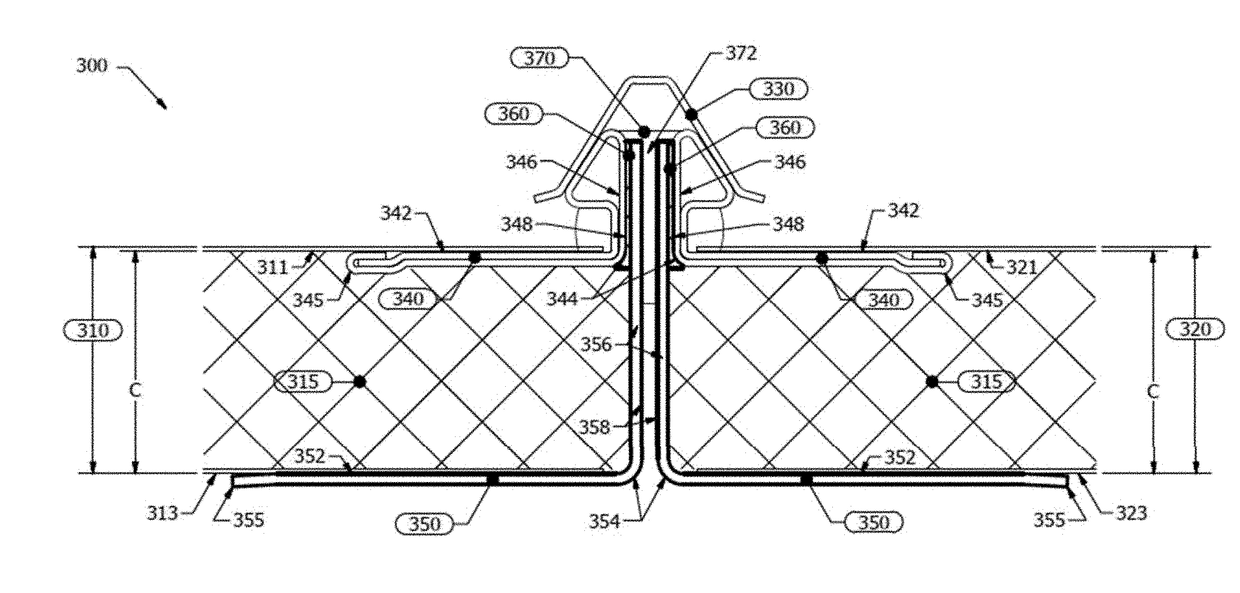

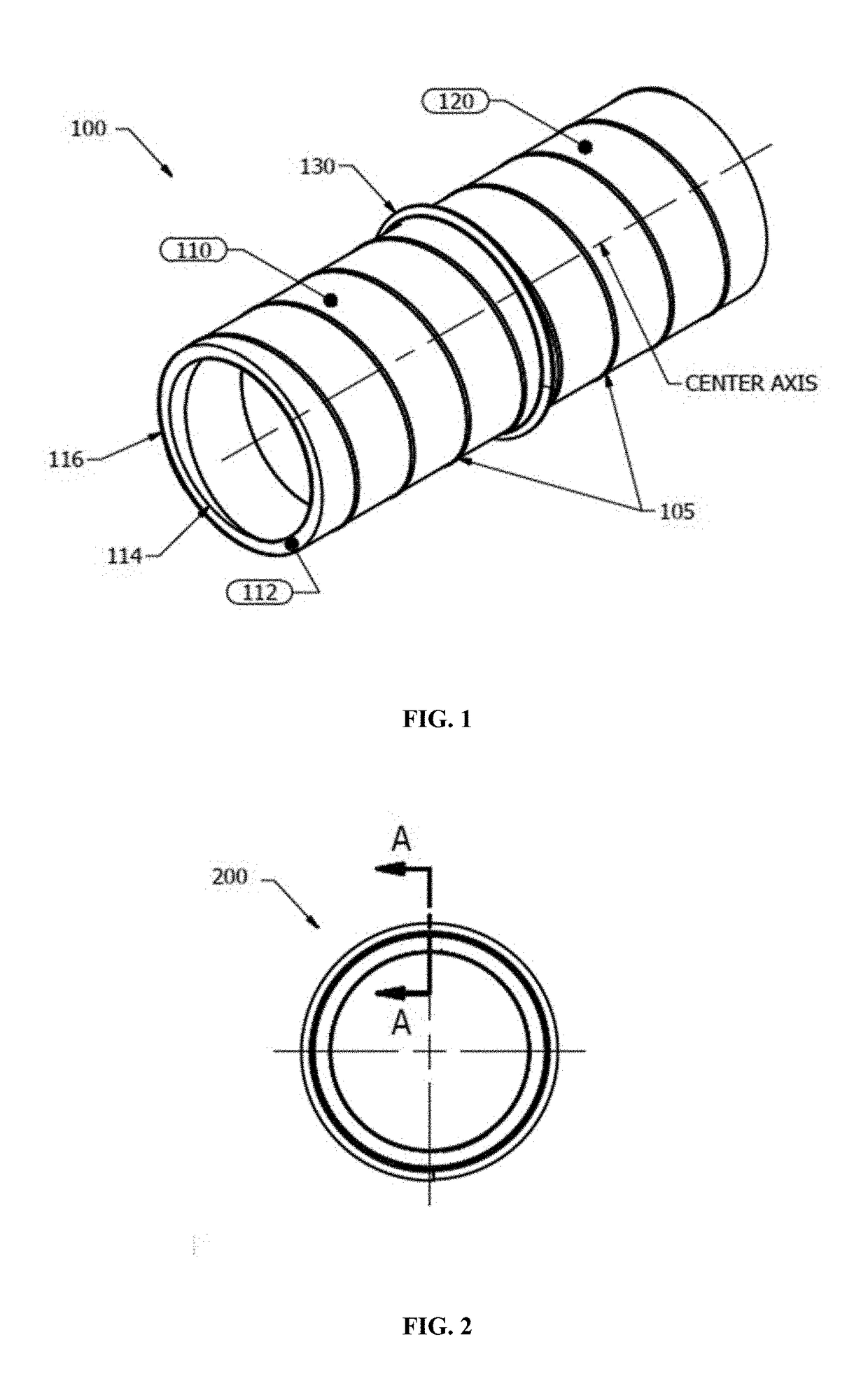

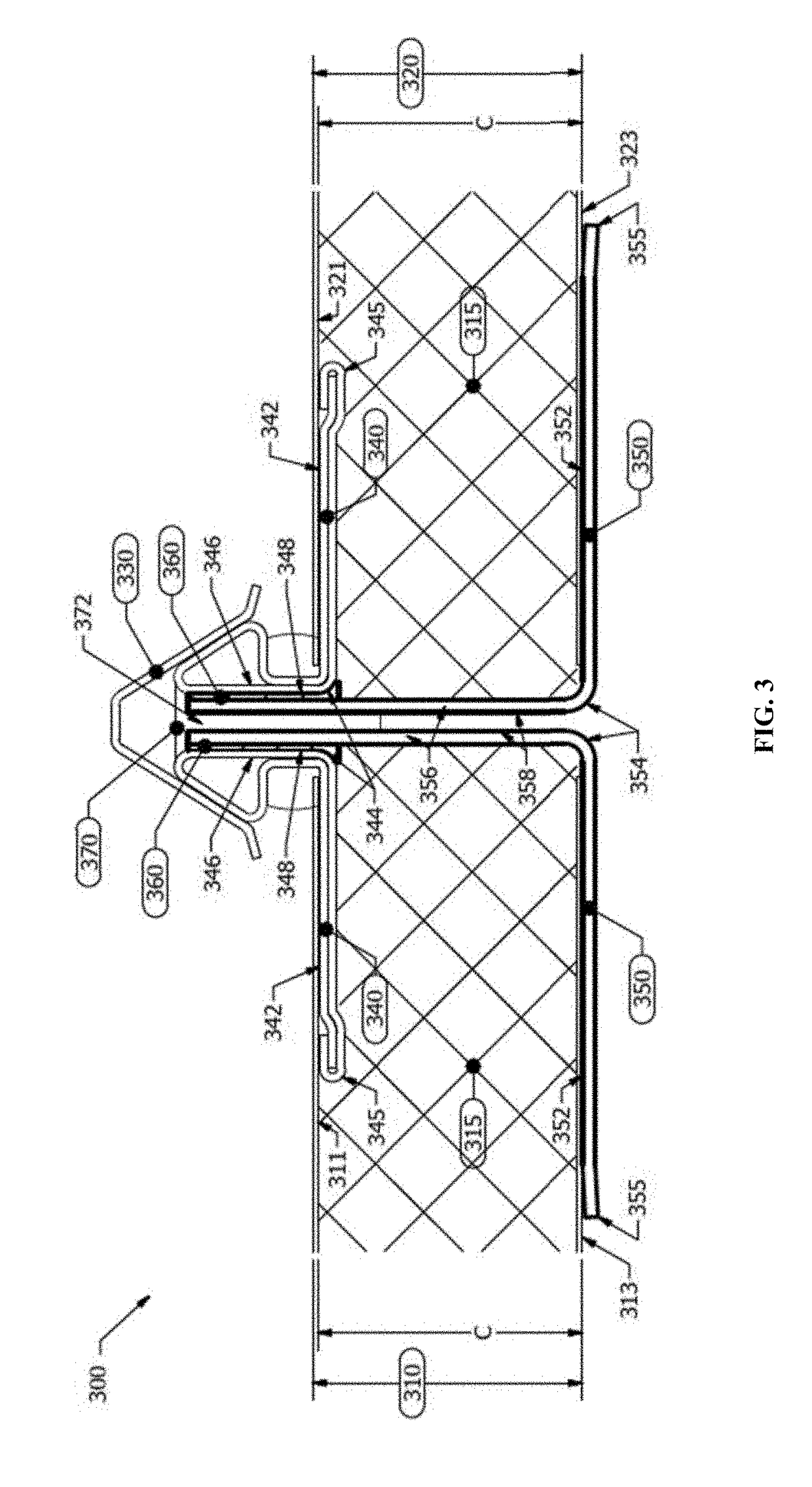

[0039]All tests will be done with a two connection system per SMACNA requirements. The tests performed will be leakage trials for Standard SPIRALMATE® connection and Standard SPIRALMATE® connection with inner ring connected with double-sided tape / gasket. This will be trialed for both small and large profile SPIRALMATE® connections.

Materials & Instrumentation:

[0040]The following material and instrumentation were used:[0041](3×) 10″ Dia×2′ Long, round spiral pipe[0042](3×) 40″ Dia×2′ Long, round spiral pipe[0043]Cadillac Products blower unit, Model: HP33P[0044]Meriam laminar flow element, Model: 50MC2-2, Range: 0-20 psi[0045]Extech Differential Pressure Manometer, Model: HD700, Range: 0-2 psi[0046]Retrote

example 2

Objective:

[0065]There are two primary objectives to this series of tests. First is to compare the leakage of a SPIRALMATE® connection with centered inner rings (attached with ½″ PSA Tape) using double-wall duct to a similar connection with non-centered inner rings. Second is to compare the leakage of a SPIRALMATE® connection using double-wall duct where flange and inner ring splices are misaligned vs. aligned.

Overview:

[0066]All tests will be done with a one-connection system. The tests performed will be leakage trials for a standard SPIRALMATE® connection with inner rings attached (concentric vs. non-concentric & aligned vs. misaligned splices) using ½″ double-sided tape / gasket. Only large profile SPIRALMATE® connections will be used, due to the diameter of duct being tested. The application of the inner rings on large diameter double-wall duct will also be trialed for determining difficulty.

Materials & Instrumentation:

[0067]The following material and instrumentation were used:[0068]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap