Method for pipe coupling encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

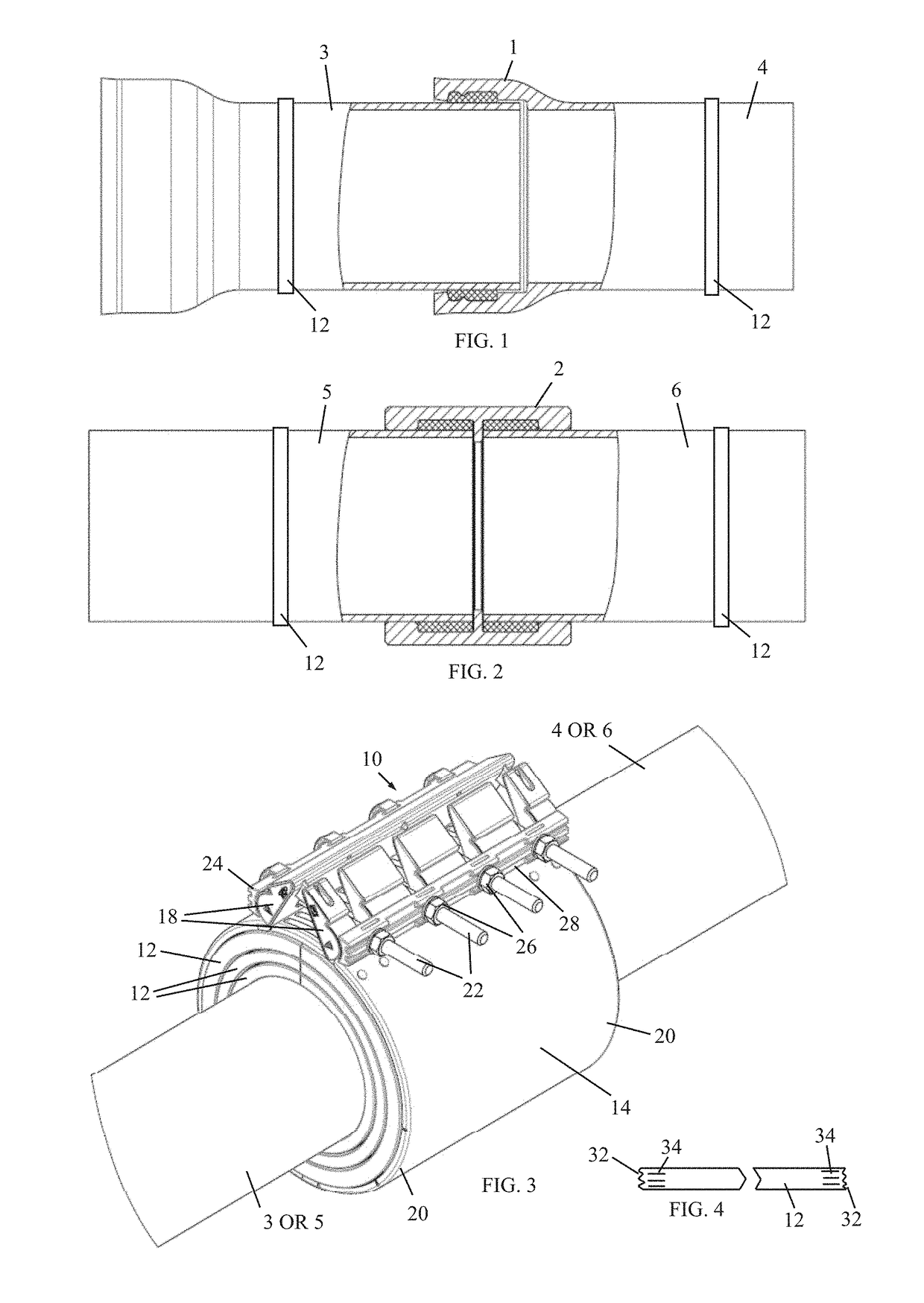

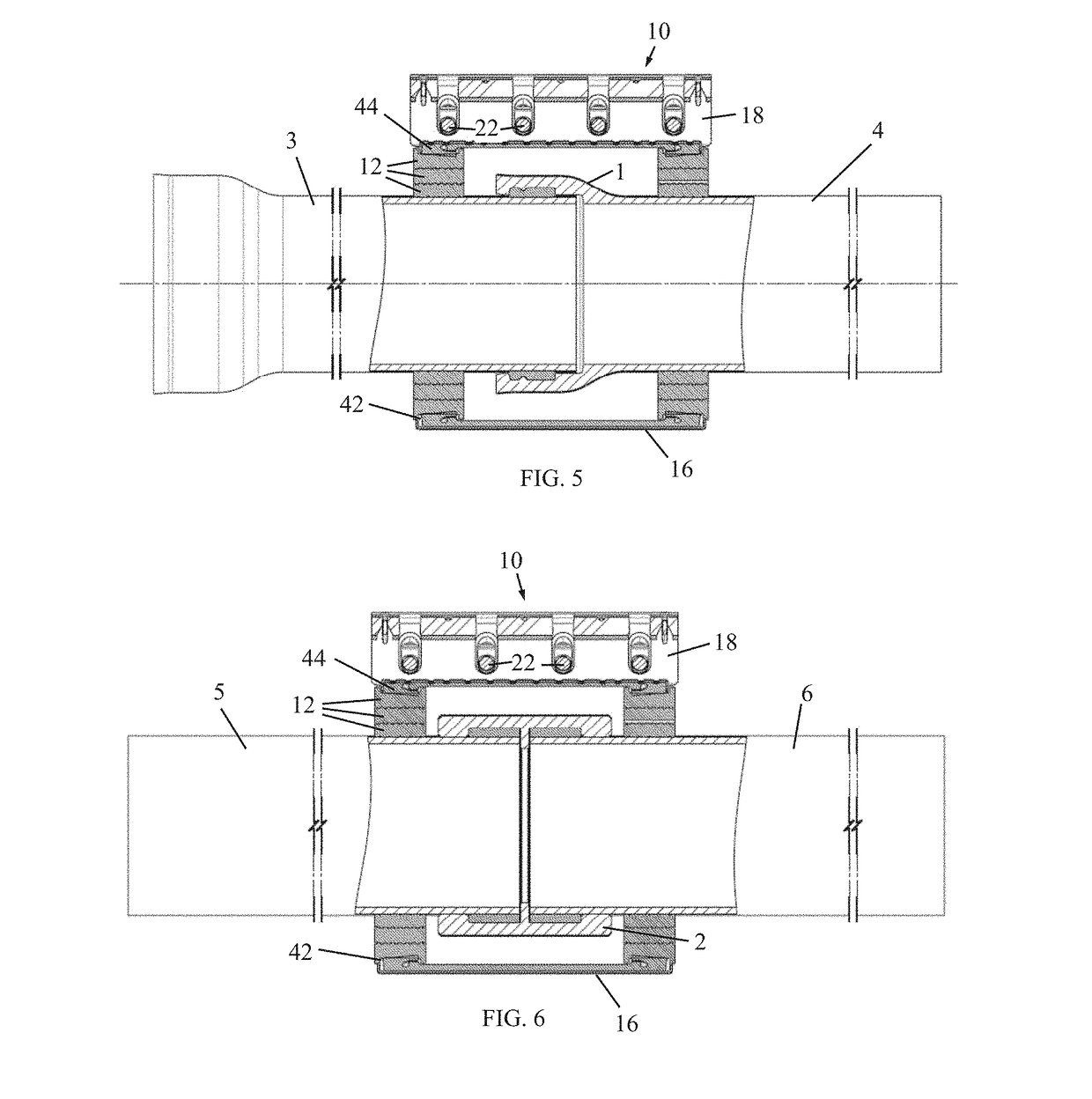

[0019]FIG. 1 illustrates a bell joint coupling 1, which has some leak. The bell joint coupling 1 is at the end of a pipe 4 and is connected to another pipe 3.

[0020]Similarly, FIG. 2 illustrates a sleeve joint coupling 2, which has some leak. The sleeve joint coupling 2 may be used to connect pipes 5 and 6.

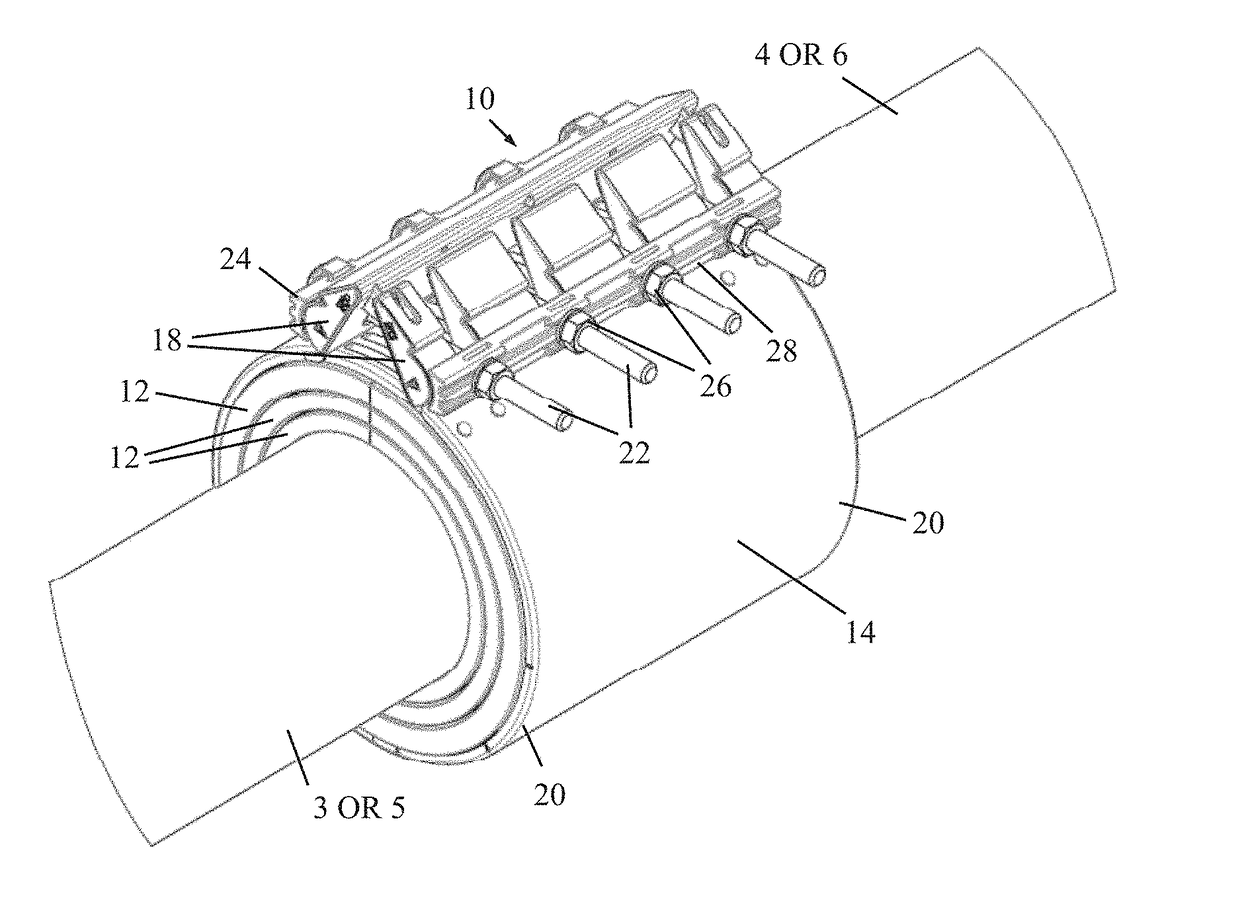

[0021]Reference is now made additionally to FIG. 3. In accordance with a non-limiting embodiment of the present invention, a pipe coupling encapsulation assembly 10 is provided to repair the leaking pipe joints, without having to interrupt flow through the pipes and joint couplings. The pipe coupling encapsulation assembly 10 includes two elastomeric partial rings 12, which may be made of natural or synthetic rubber or other suitable material. Each elastomeric partial ring 12 is wrapped or otherwise placed around one of the pipes on opposite sides of the leaking joint coupling (1 or 2), as shown in FIGS. 1 and 2.

[0022]If desired, each elastomeric partial ring 12 may be secured in p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap