Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Synthetic rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A synthetic rubber is any artificial elastomer. These are mainly polymers synthesized from petroleum byproducts. About fifteen billion kilograms (thirty-three billion pounds) of rubbers are produced annually, and of that amount two thirds are synthetic. Global revenues generated with synthetic rubbers are likely to rise to approximately US$56 billion in 2020. Synthetic rubber, like natural rubber, has uses in the automotive industry for tires, door and window profiles, hoses, belts, matting, and flooring.

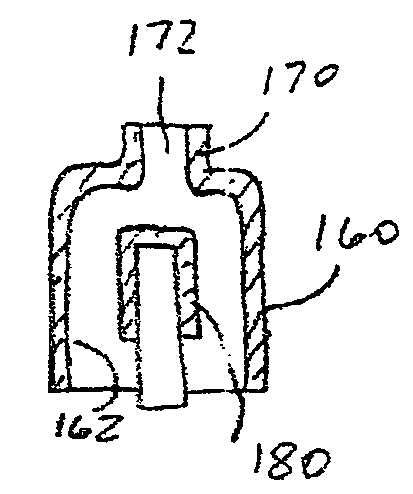

Waterproofing Membrane

InactiveUS20100196648A1Improve adhesionGood anti-sag performanceAdhesive articlesCoatingsLow-density polyethylenePolymer science

Owner:GCP APPL TECH INC

Device for removing loose pet hair strands and method thereof

Owner:STRAUB KELLY C +1

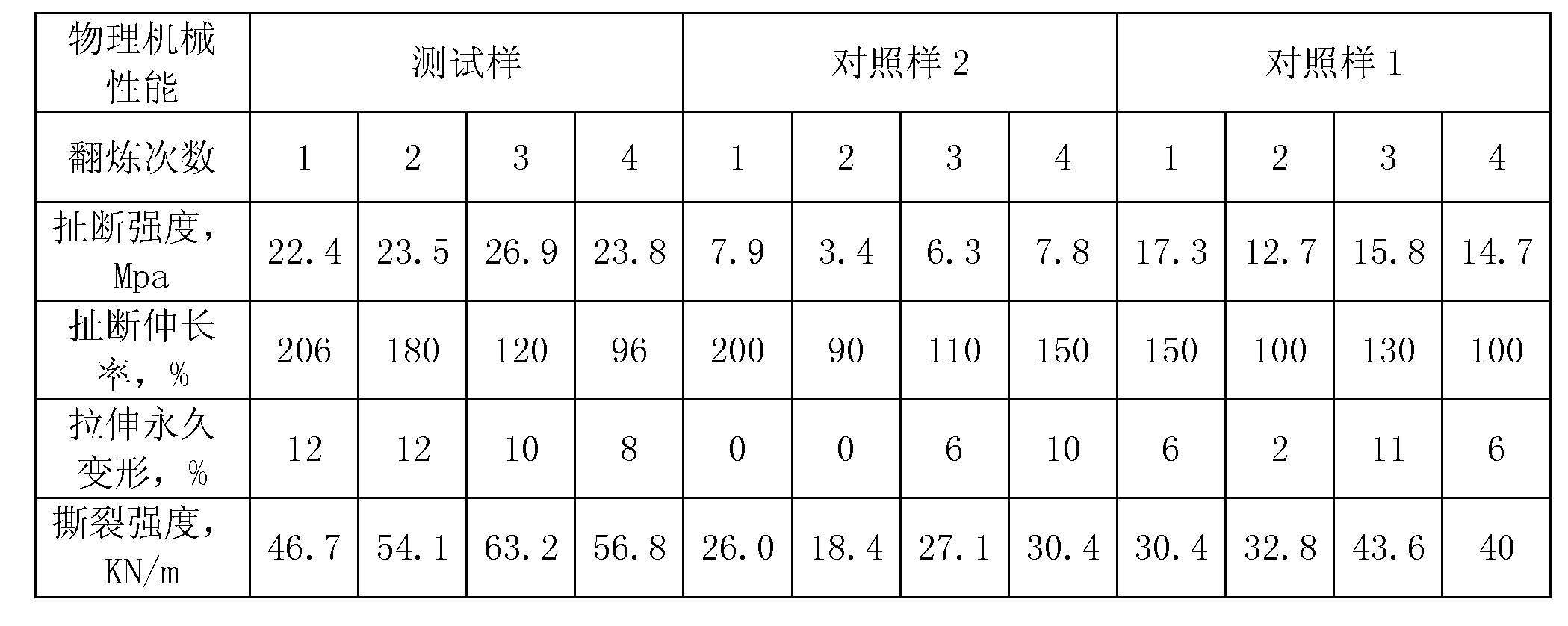

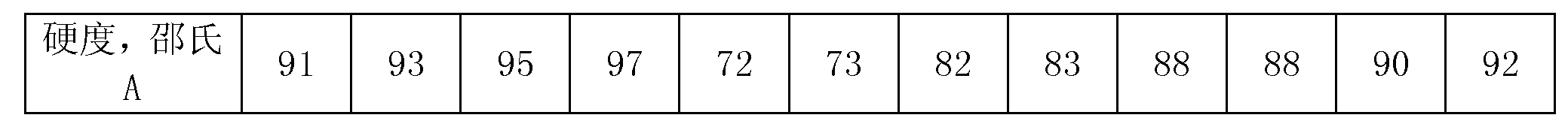

Processing method for preparing modified plastic rubber through utilizing waste plastic and waste rubber

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap