Steam explosion method for improving tobacco stalk quality by using carbon dioxide as exogenous gas

A technology of exogenous gas and steam, applied in the direction of tobacco, application, treatment of tobacco, etc., can solve the problems of difficult separation of cellulose and lignin, loss of tobacco value of tobacco stems, and reduce the lignin gas and irritation of tobacco stems. , The effect of improving the quality of sucking food and increasing the content of aroma substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

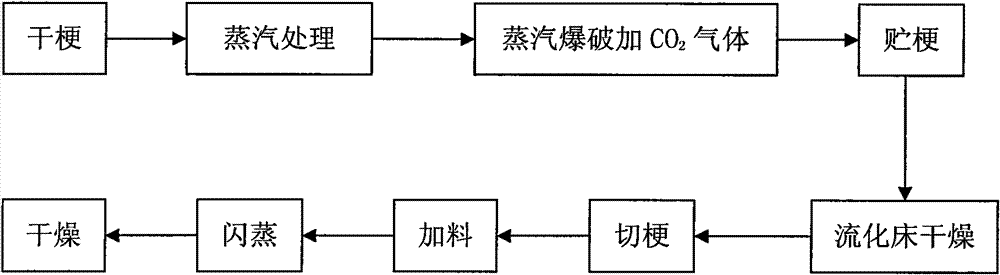

Method used

Image

Examples

Embodiment 1

[0028] (1) before the blasting of the tobacco stems, carry out the treatment of moistening the stems, let the tobacco stems soften naturally for 30 minutes, and control the moisture content at 30%;

[0029] (2) The moistened and softened tobacco stems are packed into the explosion cavity, and the filling amount is 2 / 3 of the volume of the explosion cavity;

[0030] (3) After sealing the upper cover of the explosion chamber, introduce CO 2 Exogenous gas, CO 2 After switching on, the pressure holding time is 20 seconds, and the CO is controlled 2 The inlet pressure is 0.4MPa; the CO is closed 2 After the intake valve, open the steam valve to introduce saturated water vapor;

[0031] (4) Close the steam valve after keeping the steam feeding time for 60 seconds, the saturated steam pressure is 0.6MPa, and blast the material;

[0032] (5) The explosive product is entered into the fluidized bed process for dehydration and drying, and the moisture content is reduced to about 30%;

Embodiment 2

[0035] (1) before the blasting of the tobacco stems, carry out the treatment of moistening the stems, and let the tobacco stems soften naturally for 30 minutes in the air, so that the moisture content is controlled at 35%;

[0036] (2) The moistened and softened tobacco stems are packed into the explosion cavity, and the filling amount is 2 / 3 of the volume of the explosion cavity;

[0037] (3) After sealing the upper cover of the explosion chamber, introduce CO 2 Exogenous gas, CO 2 After switching on, the pressure holding time is 20 seconds, and the CO is controlled 2 The inlet pressure is 0.5MPa; the CO is closed 2 After the intake valve, open the steam valve to introduce saturated water vapor;

[0038] (4) Close the steam valve after keeping the steam feeding time for 60 seconds, the saturated steam pressure is 0.8MPa, and blast the material;

[0039] (5) Carry out the explosion product into the fluidized bed process to carry out sequence dehydration and drying, and the

Embodiment 3

[0042] (1) before the blasting of the tobacco stems, carry out the treatment of moistening the stems, let the tobacco stems soften naturally for 30 minutes, and control the moisture content at 40%;

[0043] (2) The moistened and softened tobacco stems are packed into the explosion cavity, and the filling amount is 2 / 3 of the volume of the explosion cavity;

[0044] (3) After sealing the upper cover of the explosion chamber, introduce CO 2 Exogenous gas, CO 2 After switching on, the pressure holding time is 20 seconds, and the CO is controlled 2 The inlet pressure is 0.6MPa; the CO is closed 2 After the intake valve, open the steam valve to introduce saturated water vapor;

[0045] (4) Close the steam valve after keeping the steam feeding time for 60 seconds, the saturated steam pressure is 1.0MPa, and blast the material;

[0046] (5) Carry out the explosion product into the fluidized bed process to carry out sequence dehydration and drying, and the moisture content is reduc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap