Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27 results about "Biogas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biogas is the mixture of gases produced by the breakdown of organic matter in the absence of oxygen, usually consisting of certain quantities of methane and other constituents. Biogas can be produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste or food waste. Biogas is a renewable energy source. In India, it is also known as "Gobar Gas".

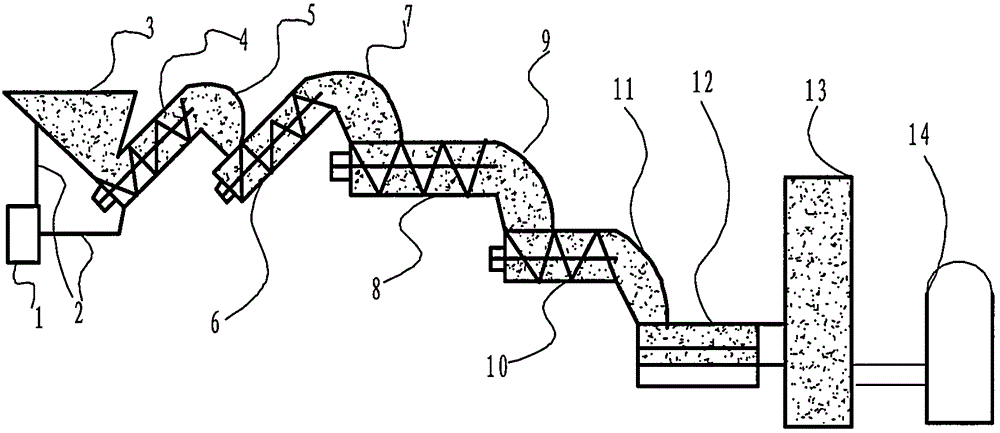

Degradable filter material biogas slurry filter and filtering method thereof

Owner:成都中农能源环境工程设计所有限责任公司

Method and device for comprehensively processing pig dung in large-scale pig farm

PendingCN110127970AEasy to handleSimple process conditionsBio-organic fraction processingSpecific water treatment objectivesPig farmsBiological filter

The invention discloses a method and a device for comprehensively processing pig manure in a large-scale pig farm. The method for comprehensively processing pig dung in the large-scale pig farm comprises the following steps: S1, the pig dung in pig houses is collected by a mechanical dung scraping facility, and is transported into a dung collecting tank; S2, the pig dung in the dung collecting tank is added into a fermentation tower by a screw conveyor, undergoes anaerobic dry fermentation to produce biogas, and then undergoes aerobic composting; S3, the biogas generated in the anaerobic dryfermentation process is introduced into and stored in a gas storage cabinet, odorous gas generated during the aerobic composting is introduced into a biological filter and is processed, the above produced organic fertilizer is transported to a curing workshop and is cured, and generated biogas slurry and leachate enter an anaerobic fermentation reactor by a pump, and are used to produce biogas; and S4, the biogas obtained in step S2 and step S3 is purified, and then used, the produced organic fertilizer is returned to the field, and the generated biogas slurry is used for irrigating crops after being discharged into an oxidation pond and processed. The method and the device have the advantage of good processing effect, simple process conditions, no secondary pollution and high economic benefits.

Owner:GUANGDONG GUANGKEN ANIMAL HUSBANDRY ENG RES INST CO LTD

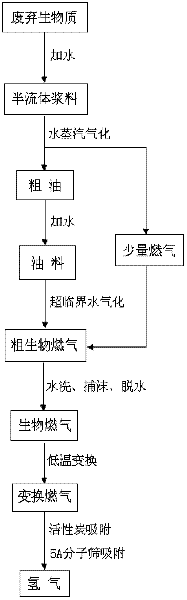

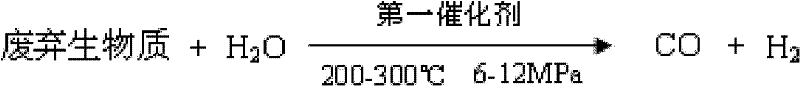

Method for preparing hydrogen by utilizing waste biomass

InactiveCN102653393AReduce pollutionReduce manufacturing costHydrogen separation using solid contactCombustible gas catalytic treatmentRare-earth elementWater vapor

Owner:北京雷恩新材料科技有限公司

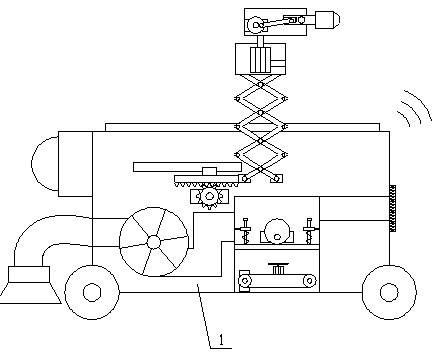

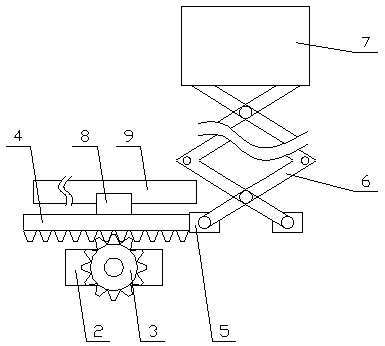

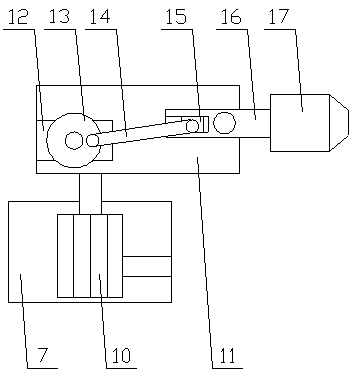

Agricultural machinery equipment with sterilizing and excrement recovering and treating functions

Owner:NANJING LENIAS PHOTOELECTRIC EQUIP

PVC composite material for biogas digester and preparation method of PVC composite material

ActiveCN104553171AImprove flame retardant performanceHigh smoke suppression effectLiquid surface applicatorsSynthetic resin layered productsPolyesterAging resistance

Owner:思嘉环保材料科技(上海)有限公司

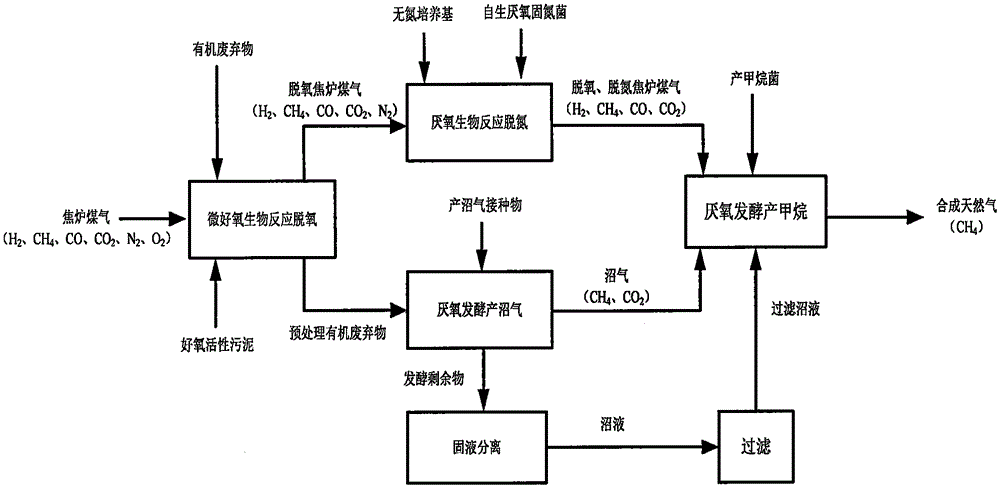

Method for biologically synthesizing natural gas from coke oven gas

ActiveCN105623761AHigh yieldGas production bioreactorsGaseous fuelsActivated sludgeBiogas production

Owner:CHENGDU ZHONGKE ENERGY & ENVIRONMENTAL PROTECTION CO LTD

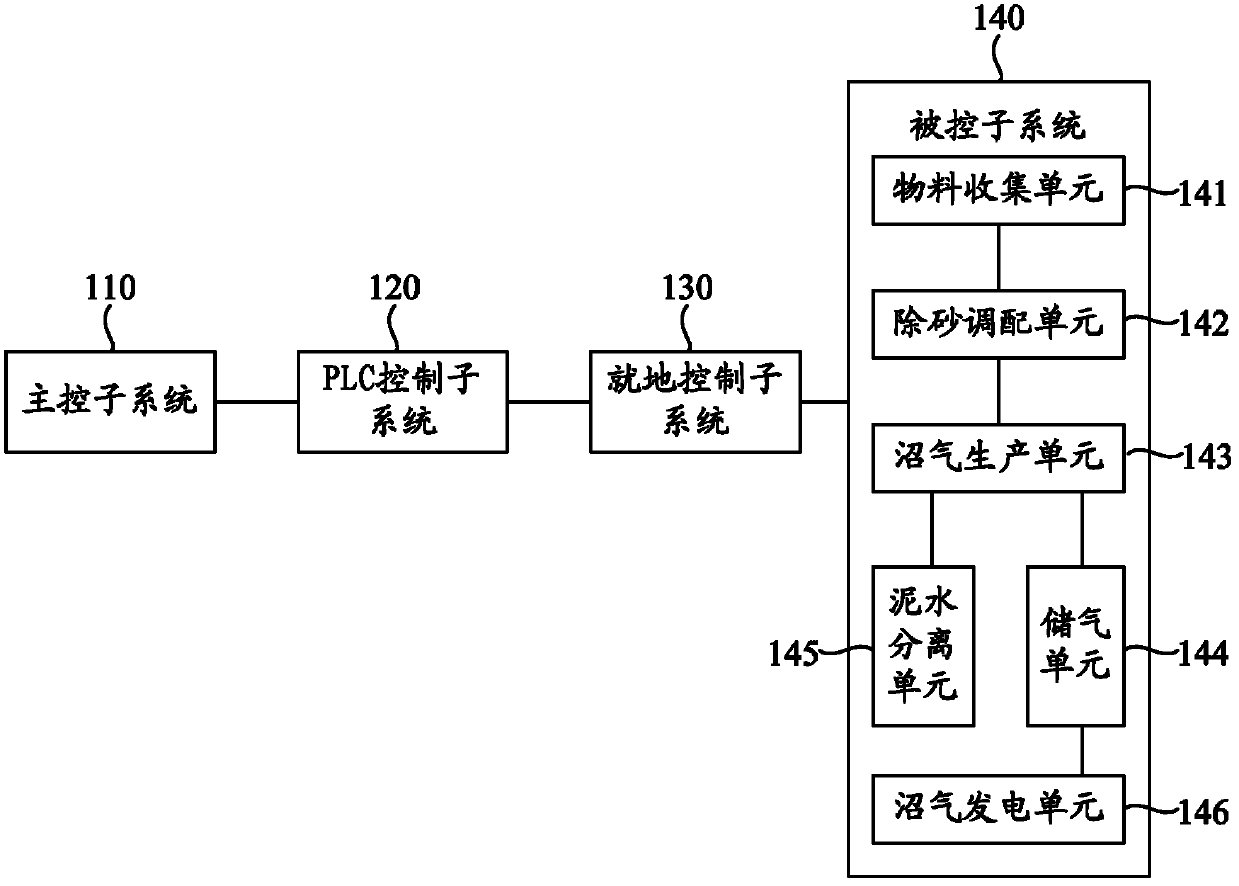

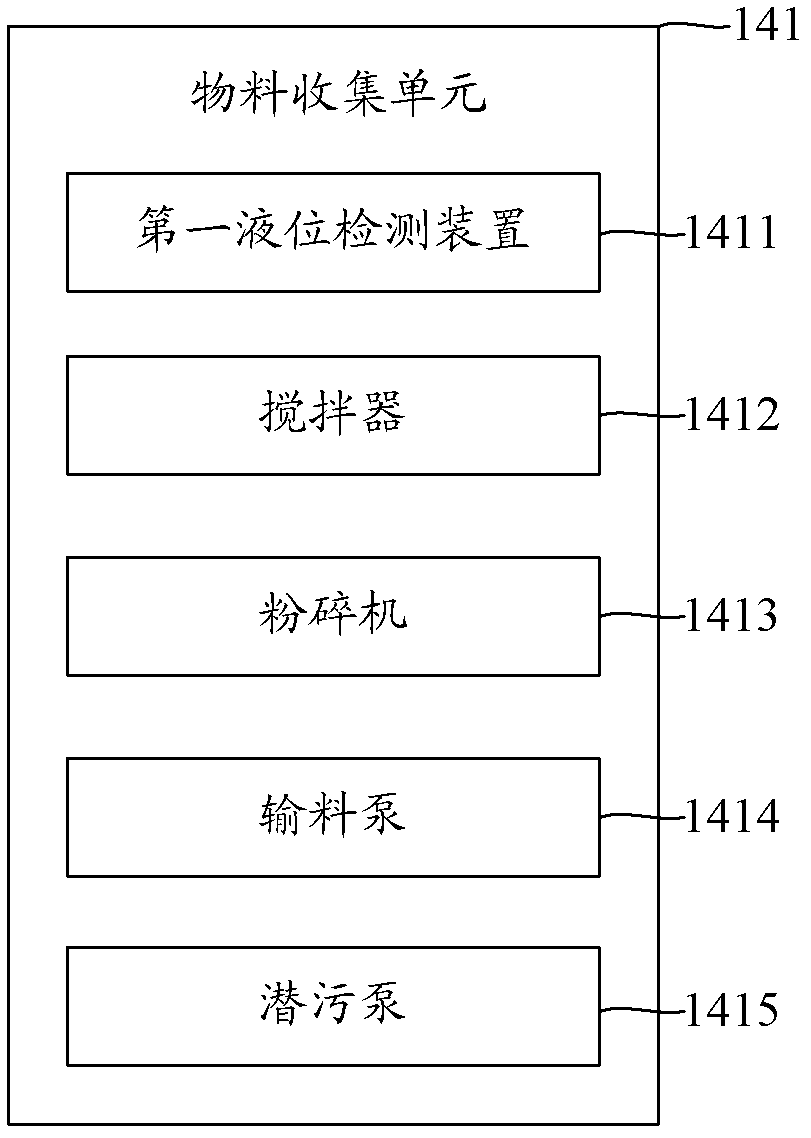

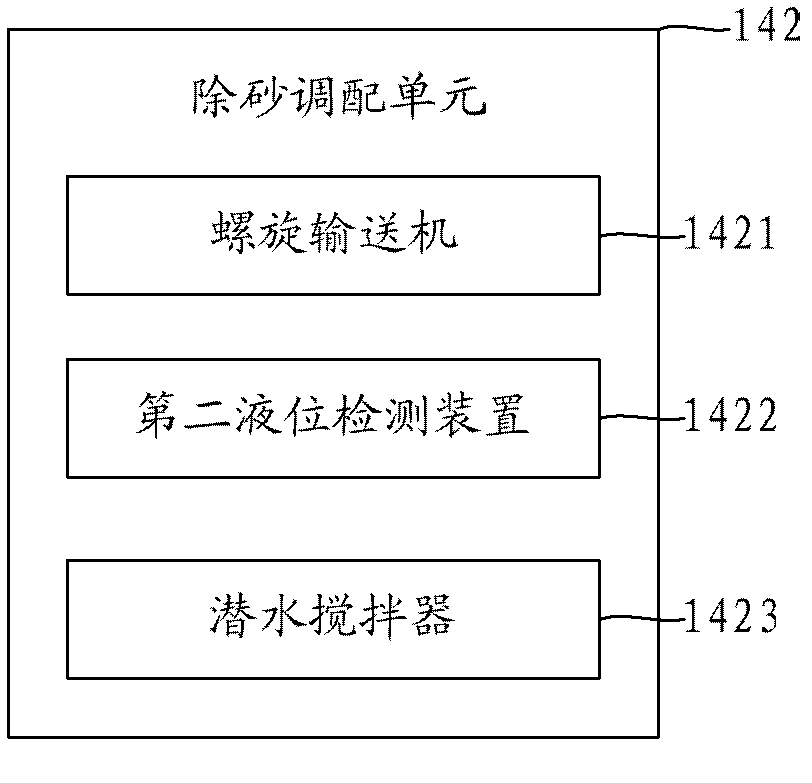

Biogas fermentation gas supply engineering control system

InactiveCN103305413AImprove real-time performanceImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlEngineering controls

Owner:北京愿景宏能源环保科技发展有限公司

Biochar-based organic fertilizer and production method thereof

InactiveCN110357727AReduce pollutionLight weightExcrement fertilisersNitrogenous fertilisersPotassiumSlurry

Owner:湖北金日生态能源股份有限公司

Rubbish treatment system and method

ActiveCN107008730AImplement preliminary processingAvoid cloggingSpecific water treatment objectivesSolid waste disposalSiphonLow speed

Owner:许国志

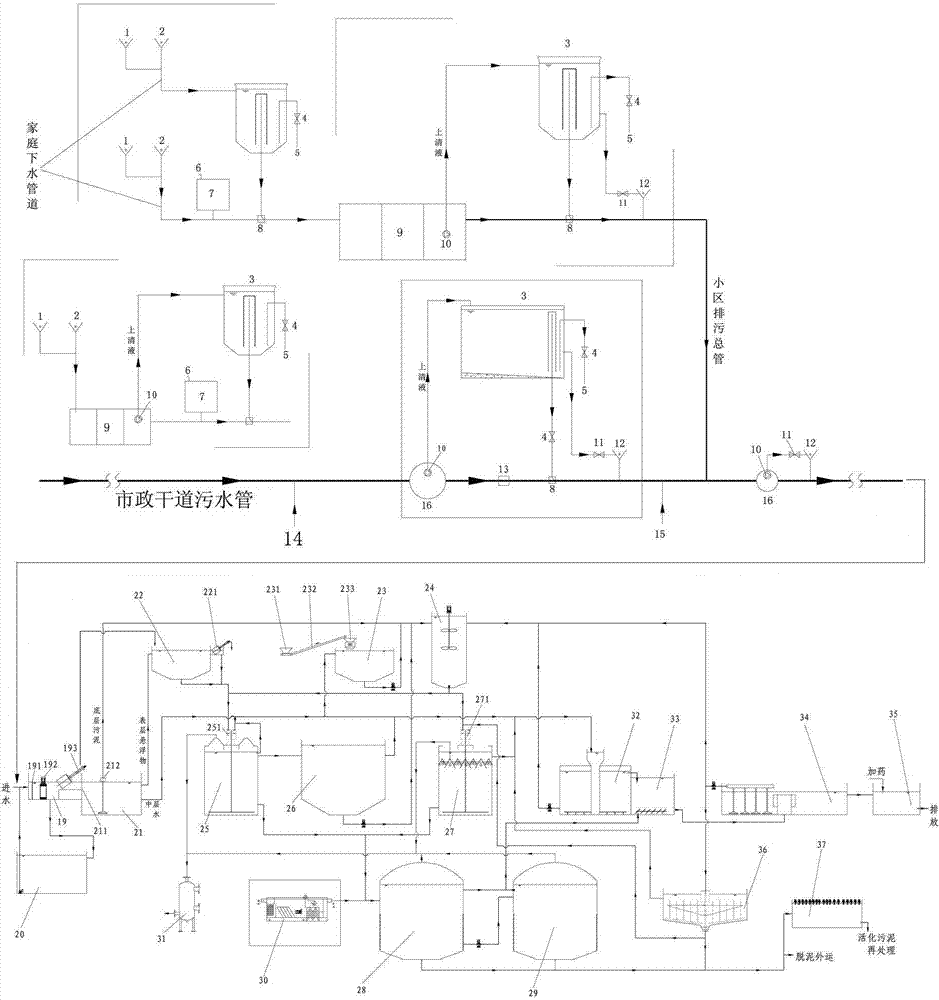

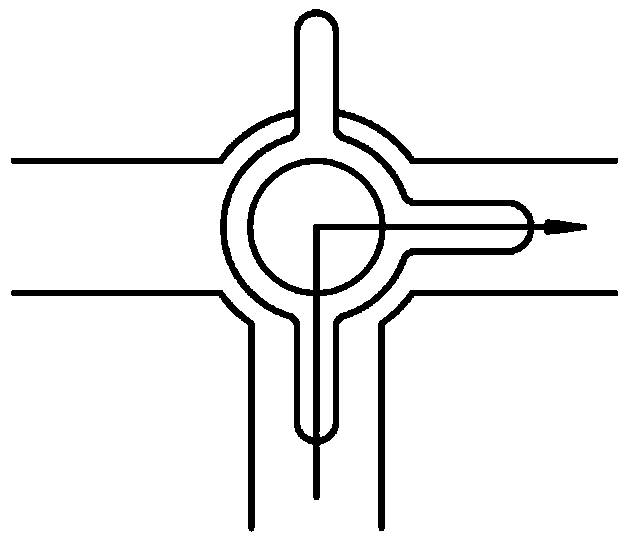

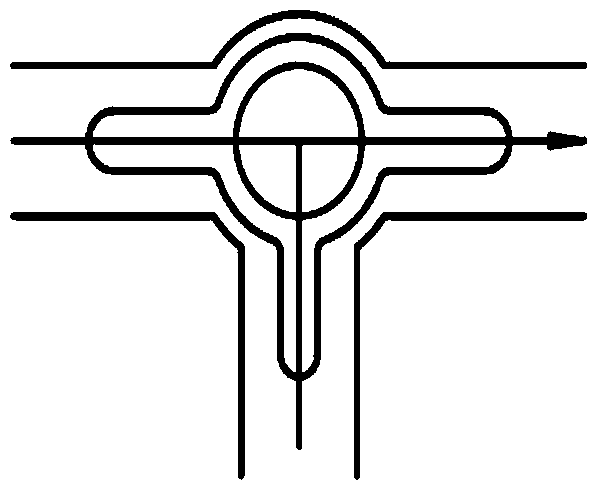

Expressway service area sewage comprehensive treatment device

InactiveCN106698659ALow construction cost and operation, maintenance and management costsLow water demandWaste based fuelTreatment with anaerobic digestion processesBiogasUrine

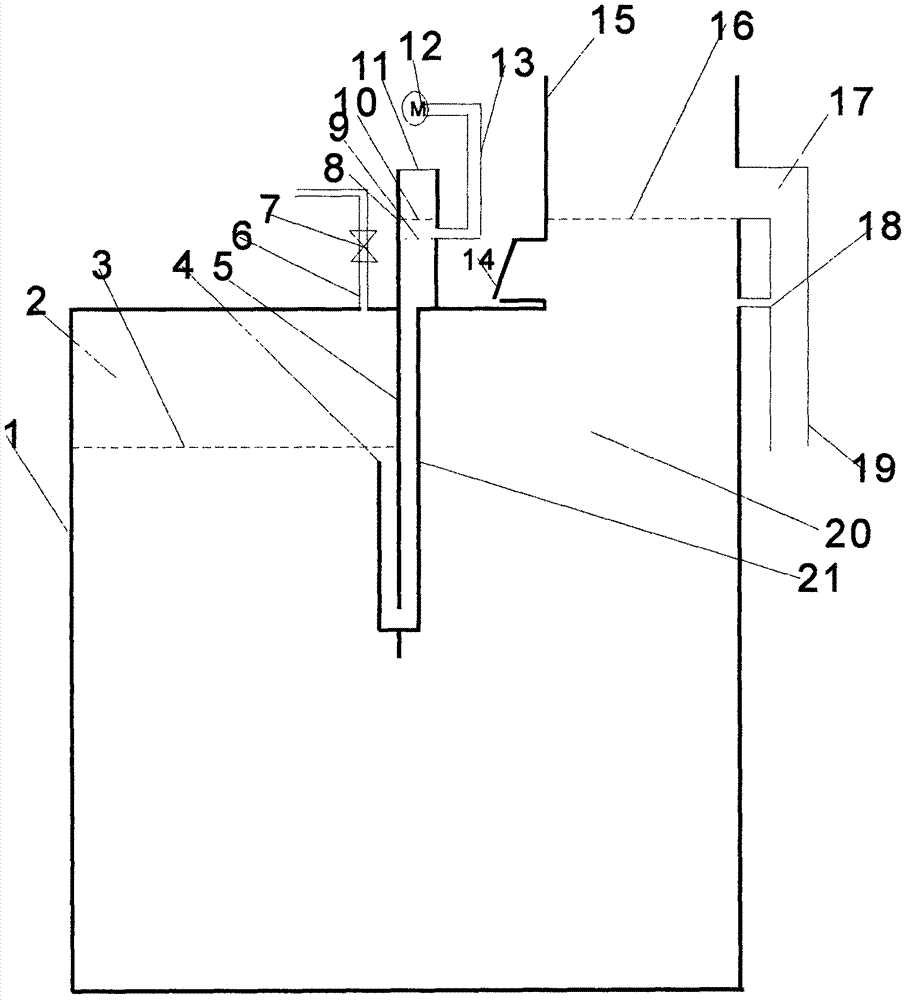

The invention belongs to the technical field of sewage treatment. An expressway service area sewage comprehensive treatment device is characterized by comprising a fermentation pool, a regulating pool, an aeration vertical flow wetland, a horizontal baffled flow wetland and a comprehensive biological pond; excrement of an excrement pool and catering sewage in an expressway service area are introduced into the fermentation pool through a Z-shaped first concealed pipe, and flushing sewage of a urine pool in the expressway service area is introduced into the regulating pool through a second concealed pipe; biogas residue at the bottom of the fermentation pool is discharged outside through a submersible sewage pump, and fermenting liquid in the fermentation pool overflows to the regulating pool through a Z-shaped concealed pipe; a submerged pump is arranged in the regulating pump and is connected with the aeration vertical flow wetland through a fourth concealed pipe, the aeration vertical flow wetland is connected with the horizontal baffled flow wetland through a fifth concealed pipe, the horizontal baffled flow wetland is connected with the comprehensive biological pond through an open channel, and the effluent of the comprehensive biological pond is discharged up to the standard or recycled. The expressway service area sewage comprehensive treatment device is simple in structure, low in energy consumption and suitable for high ammonia-nitrogen sewage characteristics and water quality and unstable water quantity in the expressway service area.

Owner:WUHAN UNIV OF TECH

Harmless treatment device of livestock and poultry died from diseases

Owner:JIANGSU LVHUI SUDONG IND CO LTD

Odourless high-valued biogas slurry fertilizer and preparation method thereof

InactiveCN110171994AEliminate odorNo change in fermentation characteristicsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAgricultural irrigationMicrobial agent

Owner:梁运祥

Technology for producing paper pulp from biogas residues of fast anaerobic fermentation of straw

InactiveCN109505187AExpand the scope of useReduce utilizationWaste based fuelFermentationFiberPapermaking

Owner:黑龙江徐盛农业科技有限公司

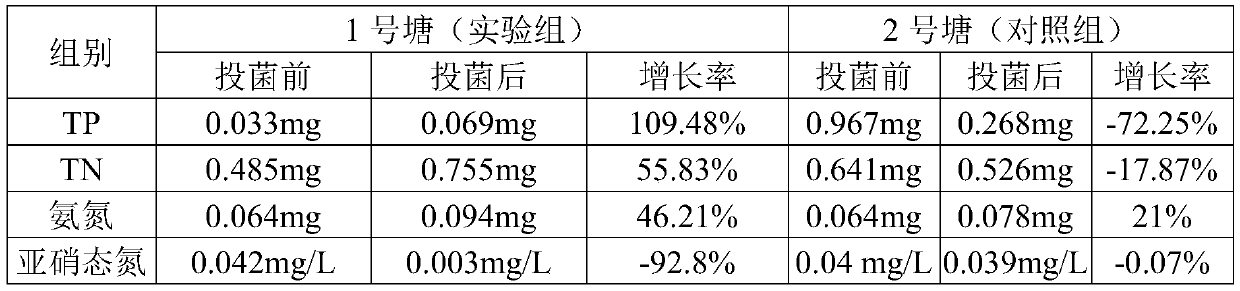

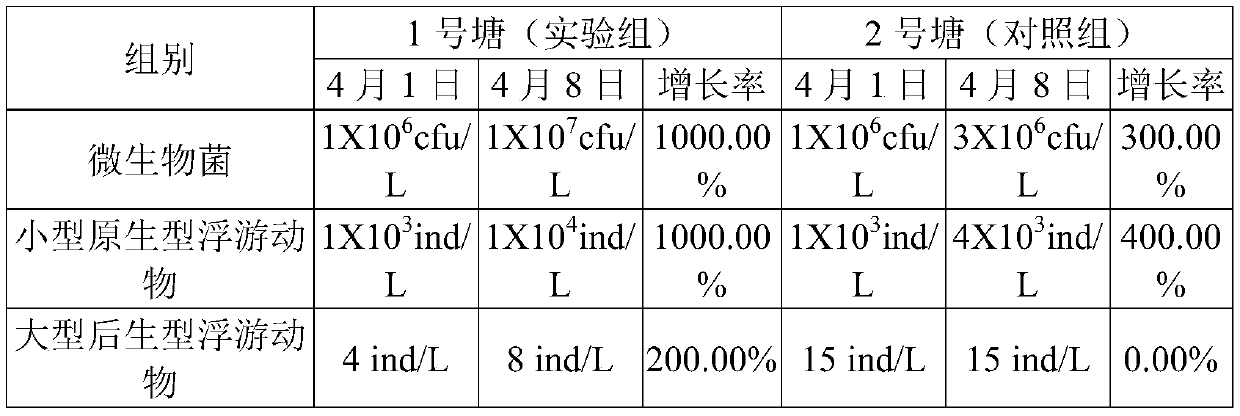

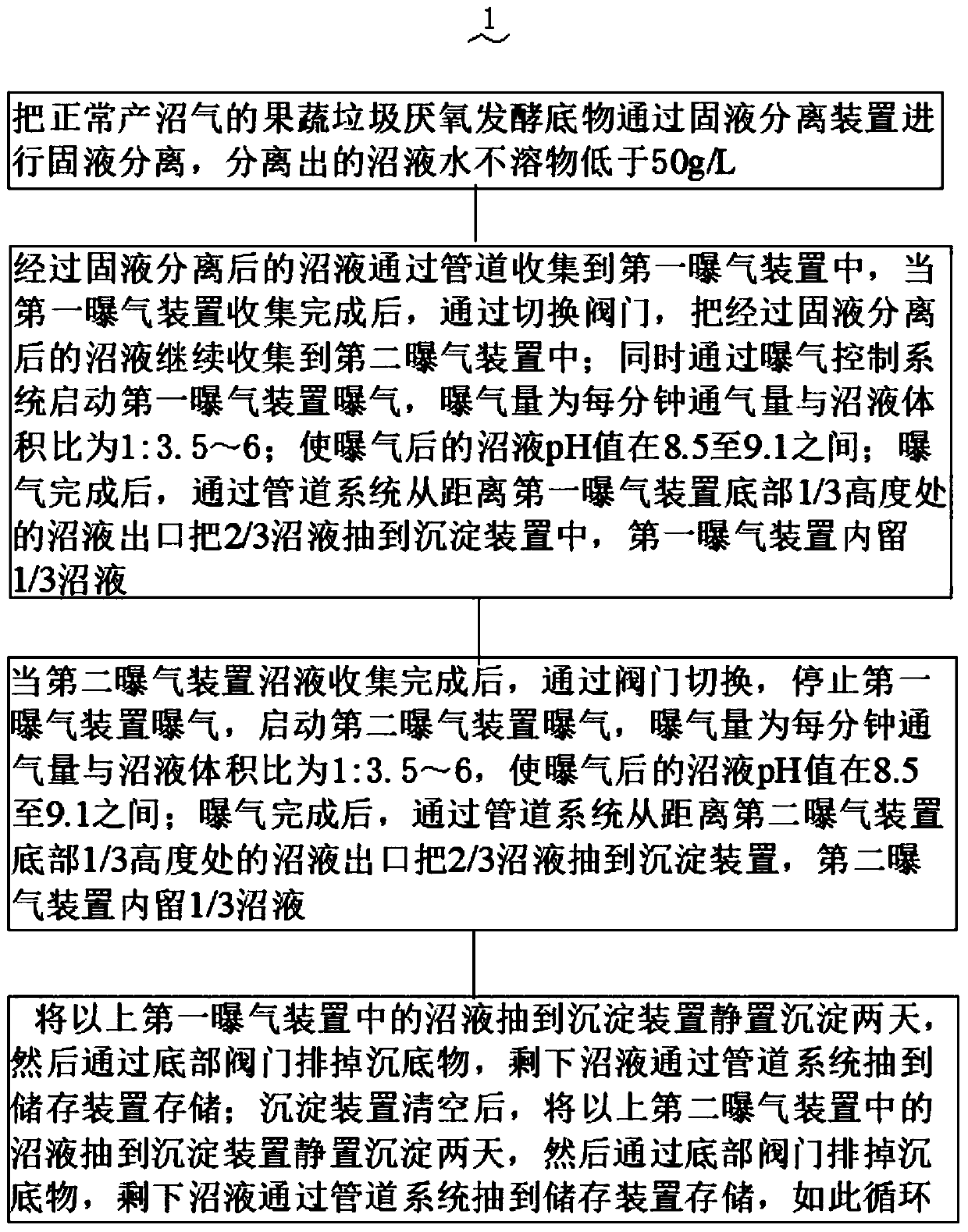

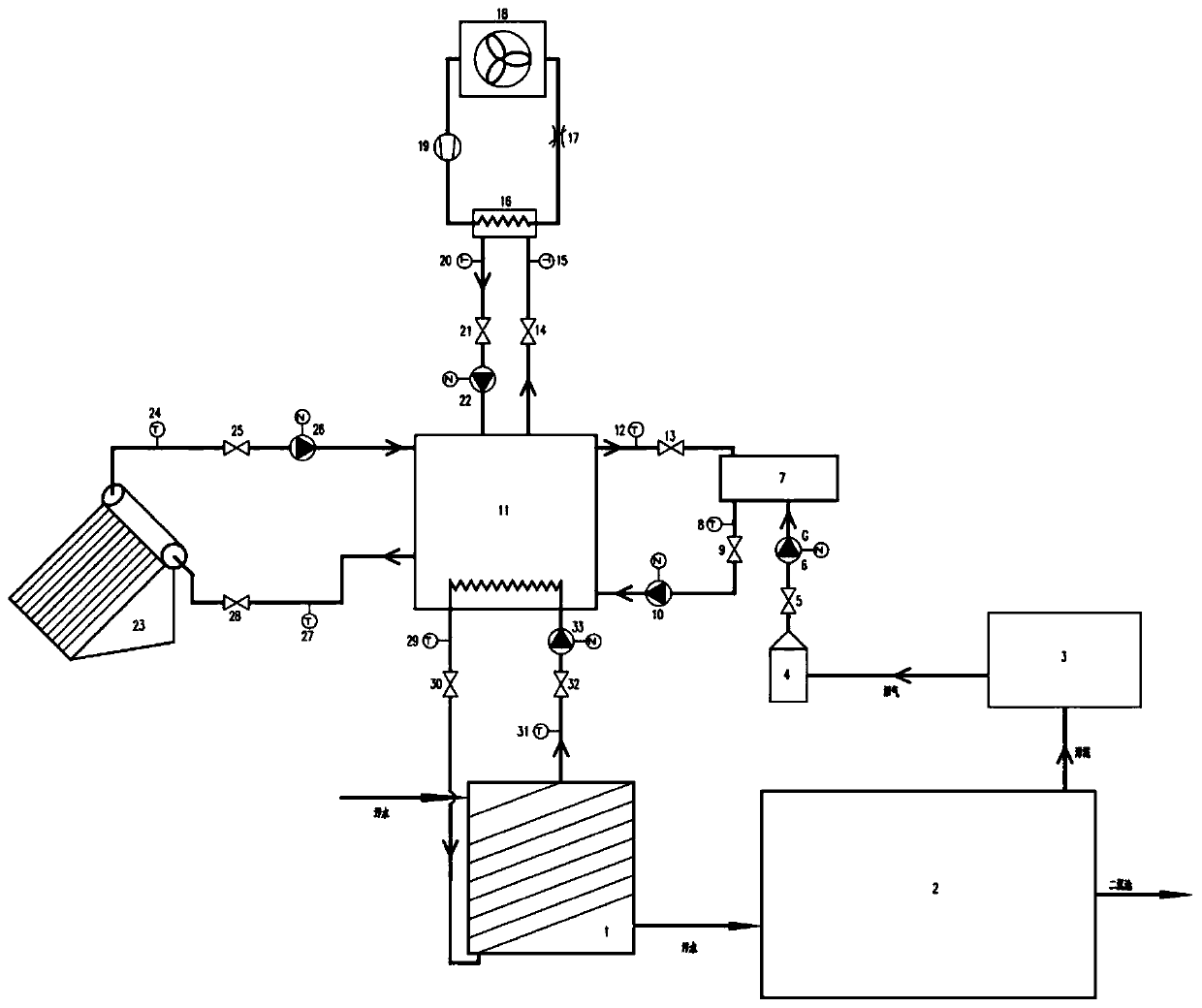

Fruit and vegetable waste anaerobic fermentation substrate efficient treatment method

InactiveCN111333444AImprove processing efficiencyReduce energy consumptionBio-organic fraction processingClimate change adaptationAeration rateSulfur dioxide

Owner:深圳市海吉星环保农业科技有限公司

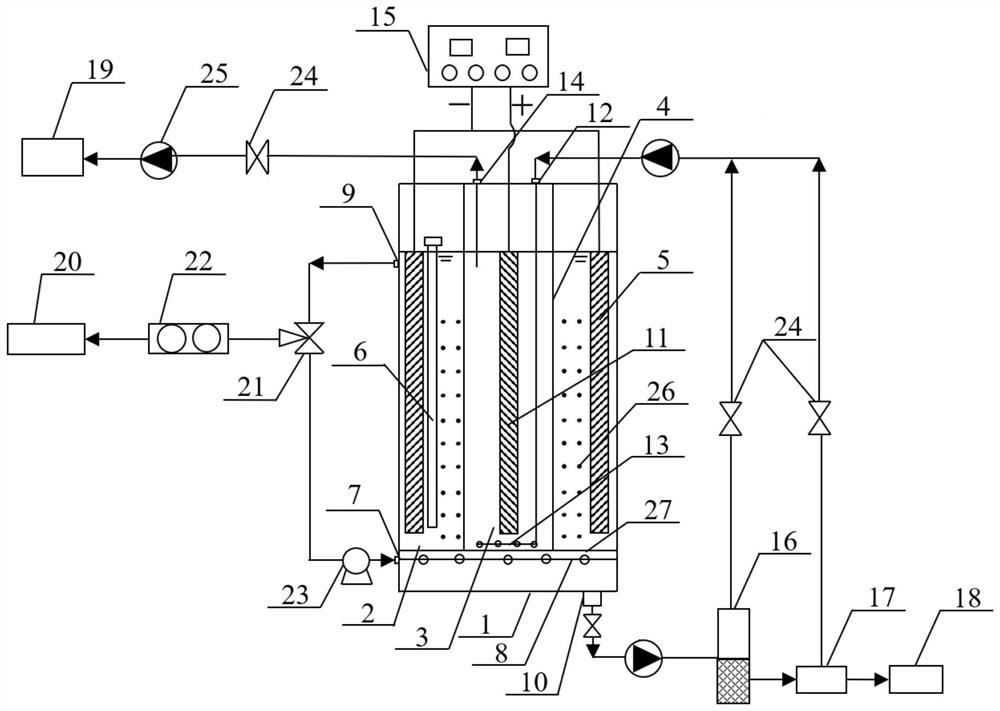

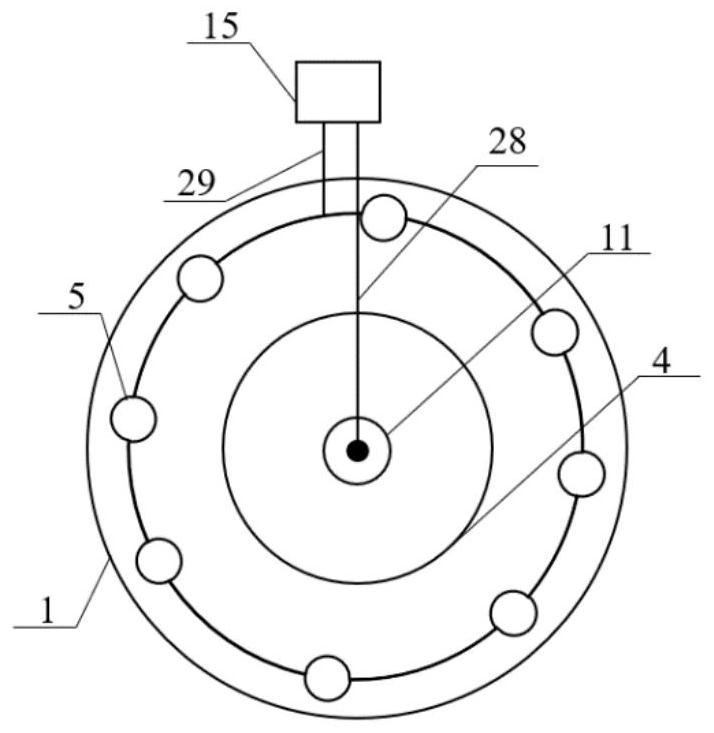

Anaerobic ammonia oxidation reactor stable operation system based on multi-energy complementation

InactiveCN111547845AEfficient and stable denitrificationMeet the requirements of water environment temperatureTreatment with anaerobic digestion processesSludgeEnergy coupling

Owner:SHIHEZI UNIVERSITY

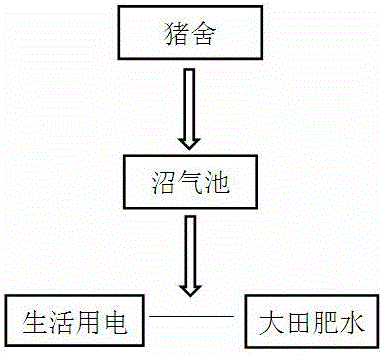

Hog house capable of easy cleaning and pollution discharge

InactiveCN106508693ARealize ecological recyclingReasonable structureWaste based fuelAnimal housingPig farmsEngineering

Owner:安顺市平坝区九九生态农业发展有限公司

Biogas carbon reduction coupled biogas slurry pollution reduction device and method based on biogas circulating fermentation

PendingCN114574329AHigh methane contentHigh calorific valueBioreactor/fermenter combinationsBiological substance pretreatmentsMethanobacterSorbent

Owner:UNIV OF SCI & TECH BEIJING +1

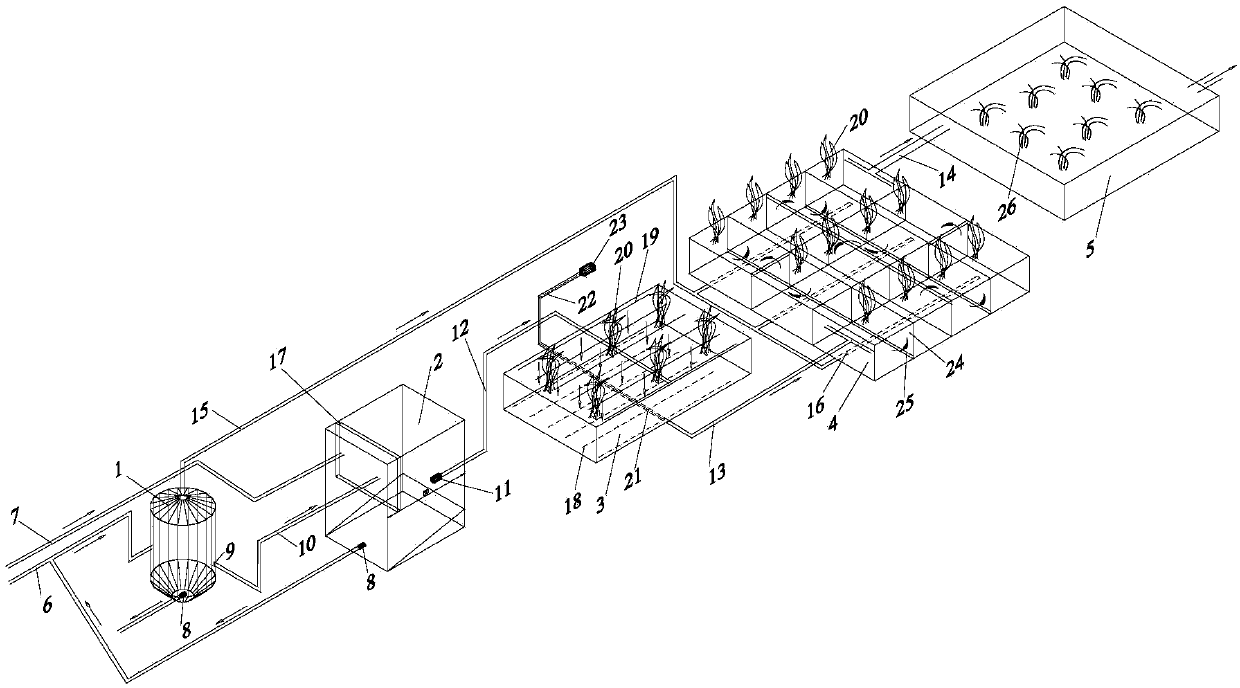

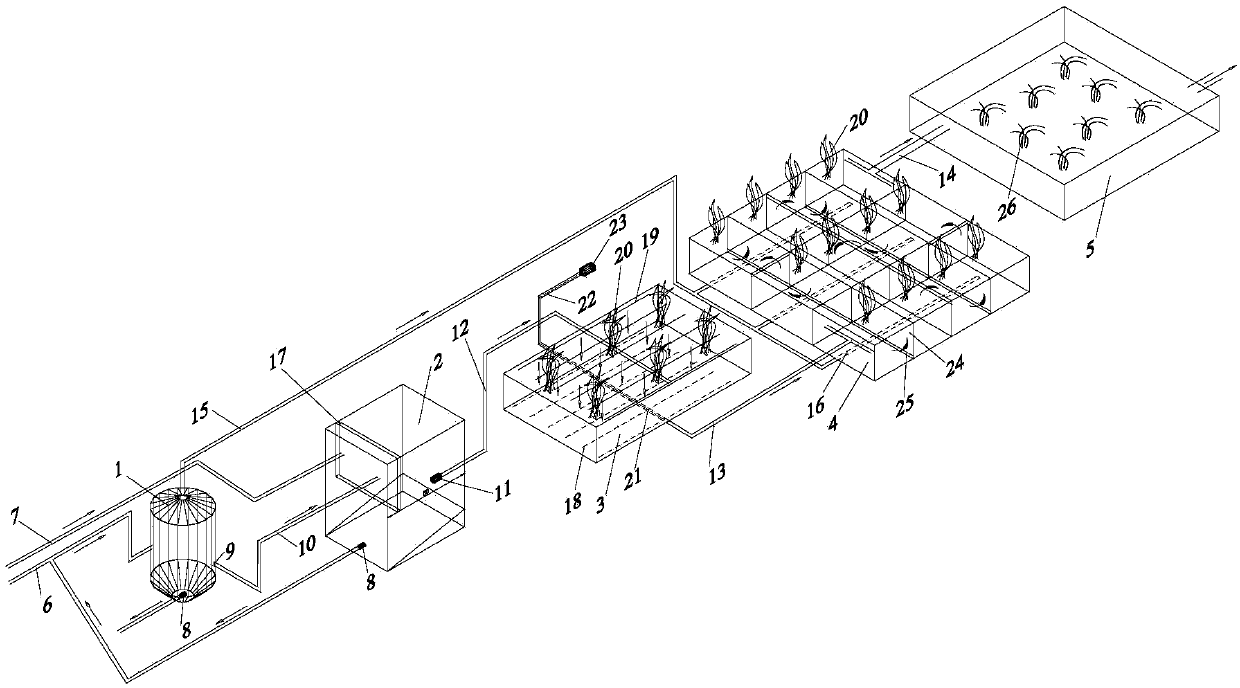

Narcissus soilless cultivation method

InactiveCN106561426AIncrease productionImprove qualityExcrement fertilisersBioloigcal waste fertilisersSlurryOrganic matter

Owner:陈海林

Fish feed prepared from biogas residue prepared from animal and human manure, and preparation method thereof

Owner:CHUZHOU YANGTZE RIVER FISHERIES PROFESSIONAL COOP

Matrix for Chinese orchid tissue culture

InactiveCN104969862AImprove survival rateReduce pests and diseasesHorticulture methodsPlant tissue cultureHuskCarbonization

The invention discloses a matrix for Chinese orchid tissue culture. The matrix comprises agar and is characterized by also comprising coconut shell flour, decomposed alcohol dregs, carbonized rick husk, and mud in the biogas generating pit. The living rate of Chinese orchid tissue cultured seedlings planted on the provided matrix can reach 85% or more, furthermore, the damage caused by diseases and insects is reduced, compared with the common tissue culture matrixes, the seedling time is shortened by 23%, and the rooting and exuberance time is reduced by 43%.

Owner:LIUZHOU TIANZI HORTICULTURE

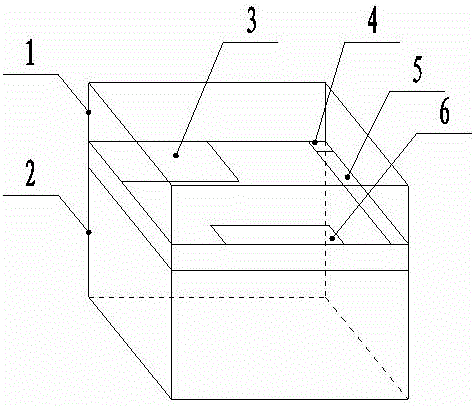

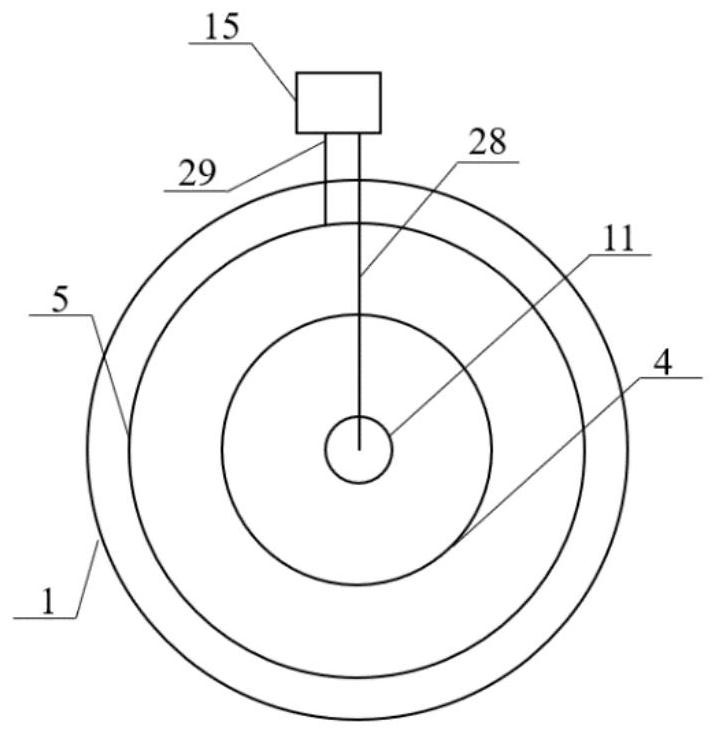

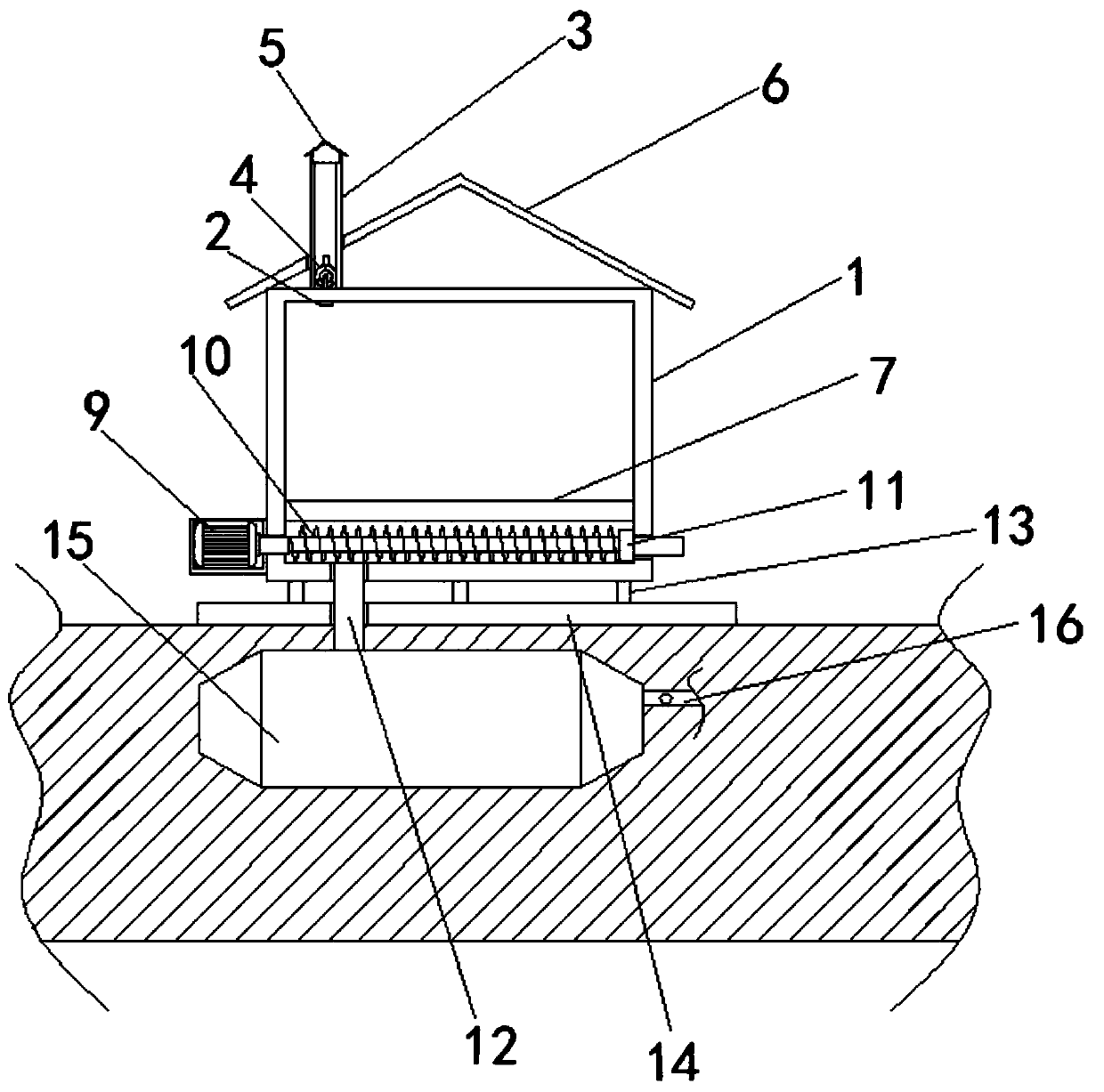

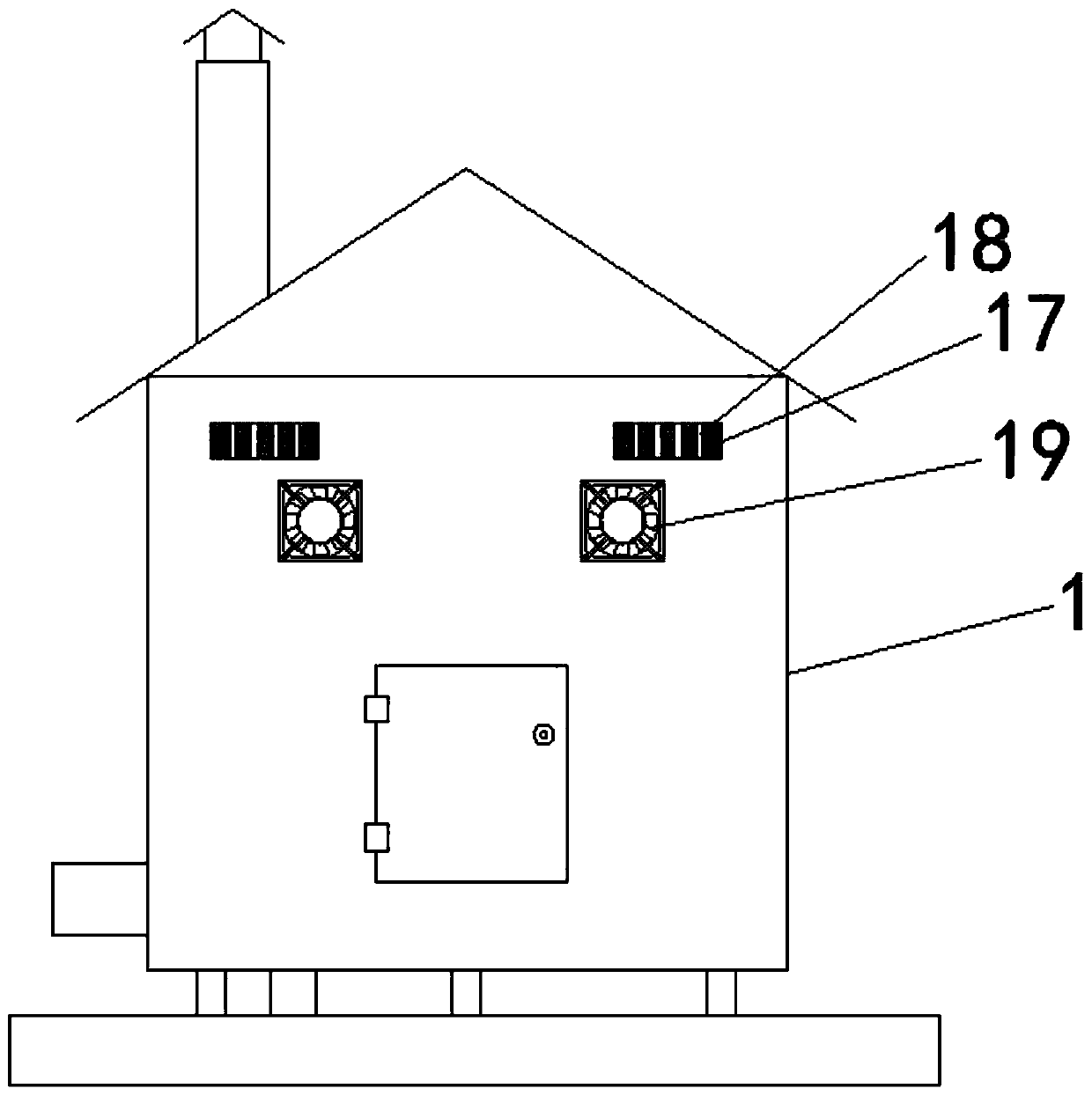

Semi-buried biogas mixed jacking fluffy soft body anaerobic fermentation system

InactiveCN110564591ADisperse operationEasy to clean with frictionBioreactor/fermenter combinationsBiological substance pretreatmentsVolumetric Mass DensityEngineering

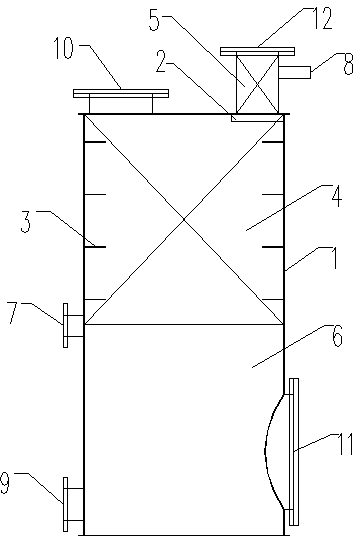

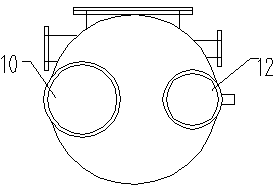

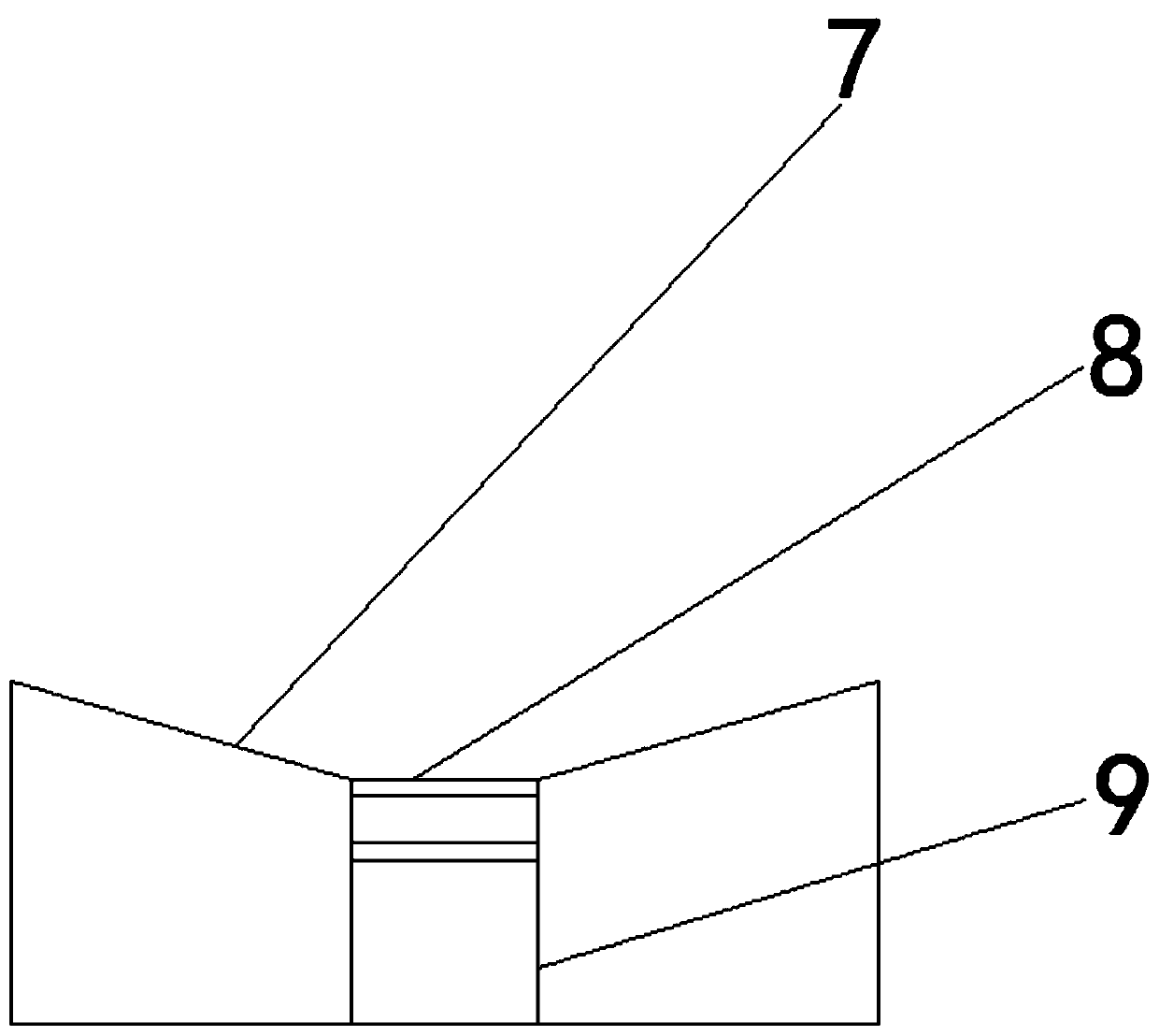

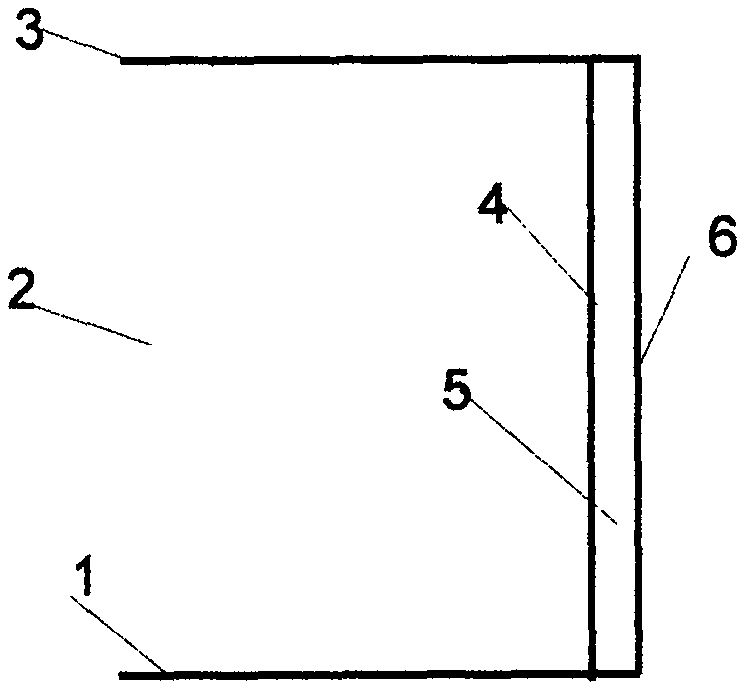

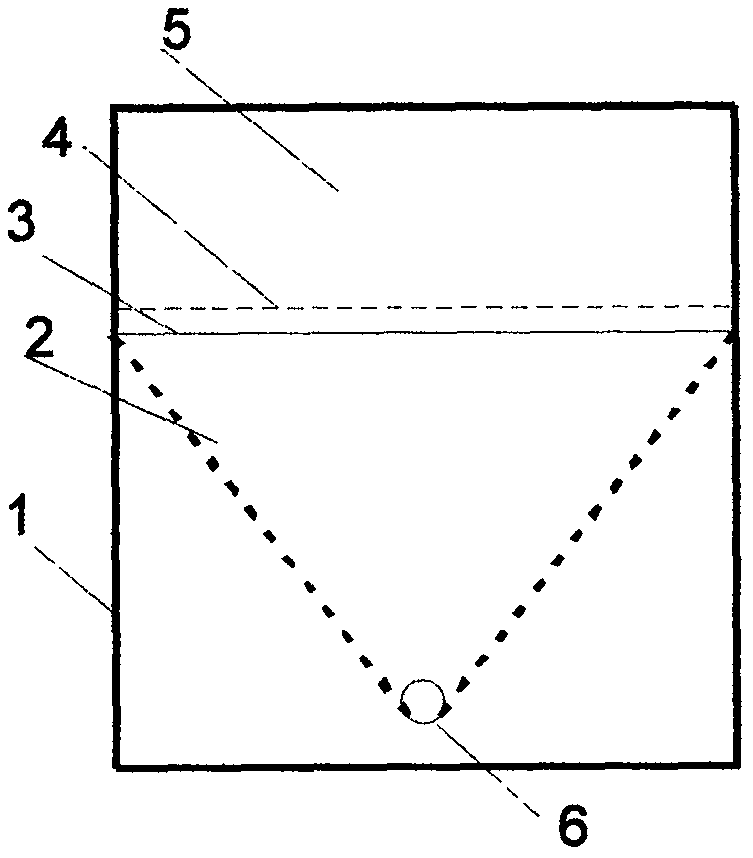

The invention discloses a semi-buried biogas mixed jacking fluffy soft body anaerobic fermentation system. The system structurally comprises a square box shell, an indication lamp post, a thin film pad, a thick soft body block, a vent pipe cavity, a gas storage cell box, an anaerobic fermentation tank and a biogas connecting pipe seat. According to the invention, a thick soft body block is matchedwith the vent pipe cavity, the jacking and lagging biogas effect is achieved, the bulking degree of the thick soft body block is increased, the effect of turning over a fluidized bed up and down is achieved to form an interval balloon type granular sensation fluctuation effect, a vibration screen left-and-right pushing output operation is formed through an overturning rack, a double-air-whirl effect is also formed for the circulation of upper and lower air flows, a negative pressure air chamber obtains slow pressure reduction and release of the lagging air flow, an effect of balancing a bottom biogas layer in an upper row is formed for an external air pressure value, a single super-density sealing compression phenomenon is conveniently swept by disturbance air flow when the soft body is turned over, the intermittent air exchange shearing hierarchical system processing operation is achieved, and the potential safety hazard of anaerobic fermentation equipment is controllable.

Owner:NANAN HANCHENFENG TRADING CO LTD

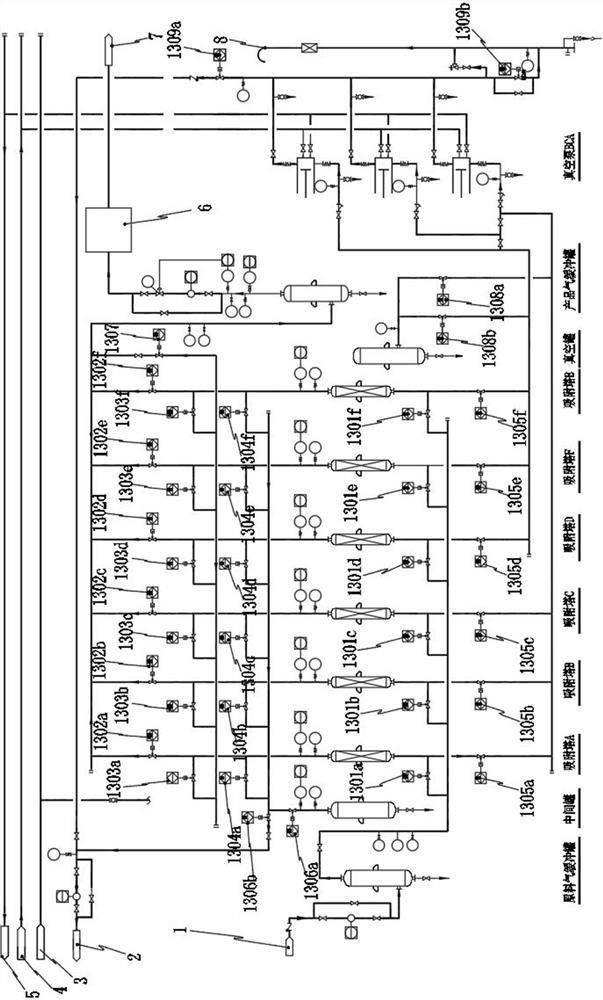

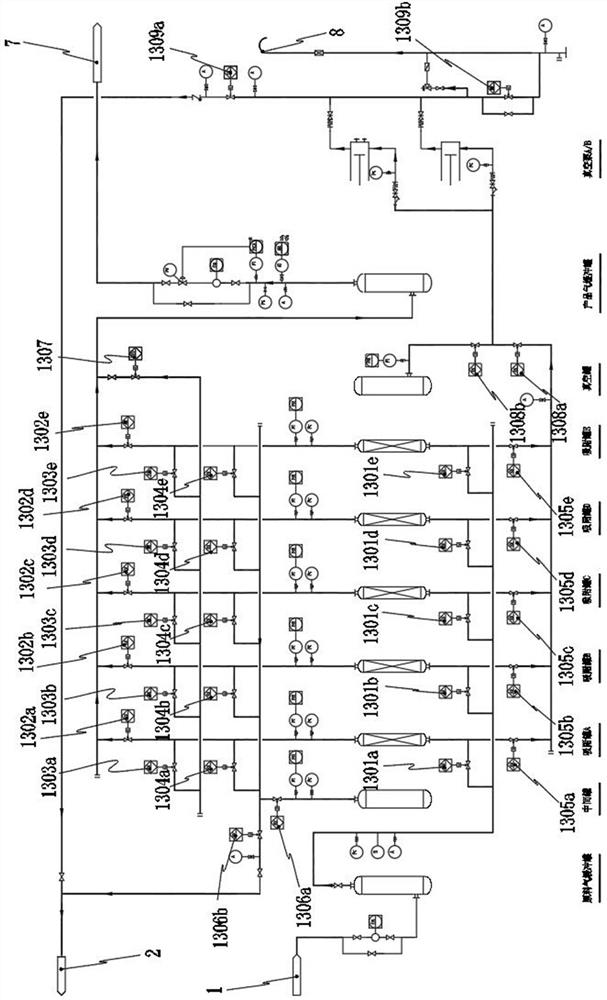

Tower switching method

Owner:山东红枫环境能源有限公司

Method for collecting gas sample and/or liquid sample in anaerobic fermentation system

InactiveCN103698165AEnsure anaerobic environmentSimple methodWithdrawing sample devicesInternal pressureExperimental research

Owner:CHINA AGRI UNIV

Simple and effective livestock feces treatment method

InactiveCN107382000AReasonable handlingCreate pollutionSludge treatment by de-watering/drying/thickeningWaste water treatment from animal husbandryFecesPre treatment

Owner:谈玉靓

Livestock breeding room with odor removal function

InactiveCN111357657AWith deodorizing functionWill not polluteWaste water treatment from animal husbandryAnimal housingCrop livestockLivestock breeding

Owner:刘伍旺

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap