Biogas carbon reduction coupled biogas slurry pollution reduction device and method based on biogas circulating fermentation

A circulating biogas technology, applied in the field of environment and energy, can solve the problems of poor treatment effect, poor biodegradability, and low mass transfer efficiency, and achieve the effects of improving electrolysis efficiency, increasing the calorific value of biogas, and increasing methane content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

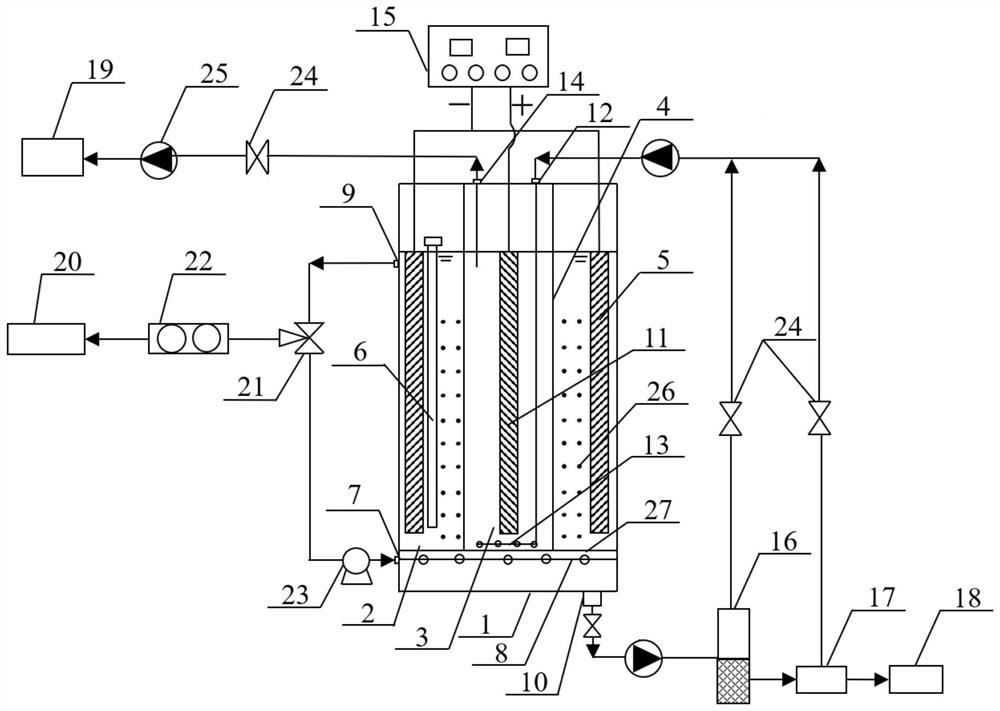

[0078] The method of biogas carbon reduction coupled with biogas slurry pollution reduction based on biogas cyclic fermentation mainly includes the following steps:

[0079] (1) Start-up stage: Inoculate digested sludge in a substrate with a 7:3 VS mixing ratio of kitchen waste and fungus chaff, so that the VS ratio of digested sludge to substrate is 1:1 to 2:1. The mixture was added to the cathode chamber 2 through the liquid-sealed feed port 6, and nitrogen was introduced to maintain the system under anaerobic conditions, and anaerobic fermentation was carried out at a temperature of 50-55 °C until the high-temperature digestion reaction cycle ended. The fermentation residue enters the solid-liquid separation unit through the fermentation residue discharge port 10;

[0080] (2) The fermentation residue is separated by the mechanical dehydration device 16 to obtain biogas slurry, which is uniformly injected into the bottom of the anode chamber 3 through the biogas slurry liquid

Embodiment 2

[0085] The difference between this example and Example 1 is that the biogas generated by the anaerobic digestion of the mixed substrate of kitchen waste and fungus chaff is cyclically injected into the lower biogas through the biogas outlet 9, the three-way diverter valve 21 and the air pump 23 in the upper part of the cathode chamber. The air inlets 7 are evenly distributed in the cathode chamber 2 through the air distribution pipes 8 with holes. During the continuous operation period of anaerobic fermentation during the biogas cycle, the CO in the biogas 2 The active hydrogen produced by the cathode is converted into methane under the action of hydrogenophilic methanogens, and the H passing through the anode chamber + It also participates in the biochemical conversion reaction; real-time monitoring of the methane concentration in the biogas, when the methane concentration in the biogas reaches more than 90%, it can enter the purified biogas storage tank 20 through the three-way

Embodiment 3

[0087] The difference between this embodiment and Embodiment 1 is that the biogas residue hydrothermal carbon 26 is made into a block with a certain shape and mechanical strength, and is filled into the cathode chamber 2 as a biological carrier (also serving as a cathode conductor), The hydrogen methanogens are attached to these hydrothermal carbon carriers through immobilized culture in advance; when the circulating biogas bubbles pass through the hydrothermal carbon layer, the flow rate of biogas decreases, which is beneficial to the CO in the biogas 2 More is dissolved and adsorbed on the hydrothermal char, where it is converted into methane by hydrogenophilic methanogens.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap