Catalyst for removing hydrogen sulfide in biogas and preparation and usage methods thereof

A biogas and hydrogen sulfide technology, applied in the fields of energy and environment, can solve the problems of increasing impurities, lack of deep purification technology, and reducing the calorific value of biogas, and achieve the effect of increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] Example 1

[0044] In Example 1 of the present invention, the preparation method of the catalyst includes the following steps:

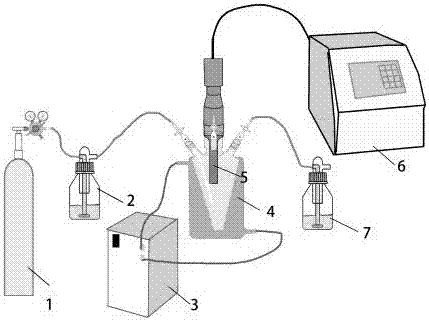

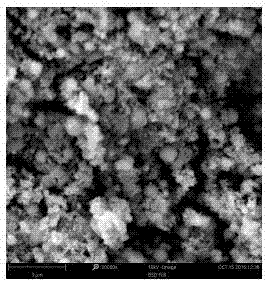

[0045] (1) Weigh 10 mmol of iron acetylacetonate and 30 mmol of elemental sulfur, put them into 500 mL of tetraethylene glycol dimethyl ether, add 0.25 mL of distilled water, and mix well to obtain a suspension; After the ethylene glycol dimethyl ether was deoxygenated, argon was continuously bubbled into the solvent at 200 mL / min for 30 minutes.

[0046] (2) Ultrasound the obtained suspension for 5h, the ultrasonic frequency is 20 kHz, the ultrasonic reaction temperature is 40°C, the amplitude is 96μm, the pulse mode is adopted, the pulse start time is 3 seconds, the pulse stop time is 1 second, the ultrasonic process Pass in 100 mL / min of argon humidified at room temperature and isolate the air.

[0047] (3) After the end of the ultrasound, add 100 ml of n-hexane, leave it to stand for 60 hours, and centrifuge the obtained product to wash and dry.

Example Embodiment

[0049] Example 2

[0050] In Example 2 of the present invention, the preparation method of the catalyst includes the following steps:

[0051] (1) Weigh 6 mmol of iron acetylacetonate and 20 mmol of elemental sulfur, put them into 500 mL of decalin, add 2.5 mL of distilled water, and mix well to obtain a suspension; the decalin is subjected to deoxygenation treatment, Continuously bubbling argon into the solvent at 250 mL / min for 30 minutes.

[0052] (2) The obtained suspension was ultrasonically processed for 20 hours, the ultrasonic frequency was 20 kHz, the ultrasonic reaction temperature was 10°C, the amplitude was 72 μm, the pulse mode was adopted, the pulse start time was 4 seconds, and the pulse stop time was 1 second. The ultrasonic process Pass in 100 mL / min of argon humidified at room temperature and isolate the air.

[0053] (3) After the ultrasound is over, add 100 ml of n-hexane and let it stand for 60 hours. The resulting product is washed by centrifugation and dried.

Example Embodiment

[0055] Example 3

[0056] In Example 3 of the present invention, the preparation method of the catalyst includes the following steps:

[0057] (1) Weigh 15 mmol of iron acetylacetonate and 50 mmol of elemental sulfur, put them into 500 mL of decalin, add 10 mL of distilled water, and mix well to obtain a suspension; the decalin is subjected to deoxygenation treatment to Continuously bubbling argon into the solvent at 100 mL / min for 60 minutes.

[0058] (2) Ultrasound the obtained suspension for 24h, the ultrasonic frequency is 20 kHz, the ultrasonic reaction temperature is 5℃, the amplitude is 120μm, and the pulse mode is adopted. The pulse start time is 6 seconds, and the pulse stop time is 3 seconds. The ultrasonic process 200mL / min of argon humidified at room temperature was passed through, and the air was isolated.

[0059] (3) After the ultrasonic wave is over, add 200 ml of n-hexane, let it stand for 120 hours, and centrifuge the obtained product to wash and dry. The washing s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap