Degradable filter material biogas slurry filter and filtering method thereof

A filtration method and filter technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of frequent backwashing of filter materials, poor filter applicability, cumbersome replacement of filter materials, etc., and achieve structural Simple, Accessible, Inexpensively Acquired Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

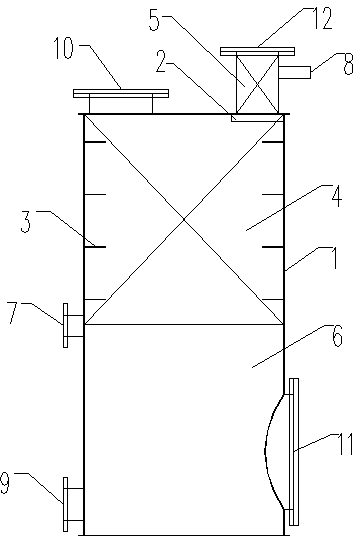

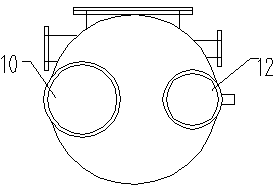

[0035] A biogas slurry filter with degradable filter material, comprising a box body 1, the top of the box body 1 is provided with a floating filter material filling port 10 and a fixed filter material filling port 12, the middle part is provided with a liquid inlet 7, and the bottom part is provided with a There is a slag outlet 9; the liquid inlet 7 divides the inner cavity of the box body 1 into a floating filter material chamber 4 at the upper part of the liquid inlet and a sedimentation chamber 6 at the lower part of the liquid inlet. The floating filter material chamber 4 is provided with a floating filter material, the slag outlet 9 communicates with the sedimentation chamber 6, the floating filter material filling port 10 communicates with the floating filter material chamber 4; the fixed filter material filling port 12 communicates with the floating filter material chamber 4 through the fixed filter material chamber 5, and communicates A grid 2 is arranged at the place, a

Embodiment 2

[0044] This embodiment is basically the same as the previous embodiment, the main difference is:

[0045] The ribs 3 are annular ribs, distributed in at least 4 layers in the floating filter material chamber 4, and the spacing is three times the width of the ribs 3. The width dimension of the rib plate 3 is 1 / 5 of the width of the box body. The volume of the floating filter material chamber 4 is 1 / 3 of the box volume; the volume of the sedimentation chamber 6 is 2 / 3 of the box volume; the volume of the fixed filter material chamber 5 is 1 / 50 of the box volume.

[0046] In this embodiment, the degradable filter material used has the characteristics of being able to settle and discharge out of the filter. It only needs to be regularly replenished according to the consumption of the filter material to run stably for a long time, and the quality of the filtered biogas slurry is stable and controllable.

Embodiment 3

[0048] This embodiment is basically the same as the previous embodiment, the main difference is:

[0049] The ribs 3 are annular ribs, distributed in at least 5 layers in the floating filter material chamber 4, and the spacing is 6 times of the width of the ribs 3 . The width dimension of the rib 3 is 1 / 50 of the width of the box body 1 . The volume of the floating filter chamber 4 is 2 / 3 of the volume of the casing 1; the volume of the sedimentation chamber 6 is 1 / 3 of the volume of the casing 1; the volume of the fixed filter chamber 5 is 1 / 300 of the volume of the casing 1 .

[0050] In this embodiment, each parameter is related to each other, and the change of one parameter will lead to the change of other parameters. Since there are many related parameters, it is impossible to obtain it through a limited number of tests, especially the relevant parameters of the ribs can ensure that the filter floats The water flow in the filter chamber is not short-circuited.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap