Method for treating organic waste gas by using plasma fluidized bed

A technology of plasma and organic waste gas, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as human health hazards, atmospheric environmental quality degradation, and national economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

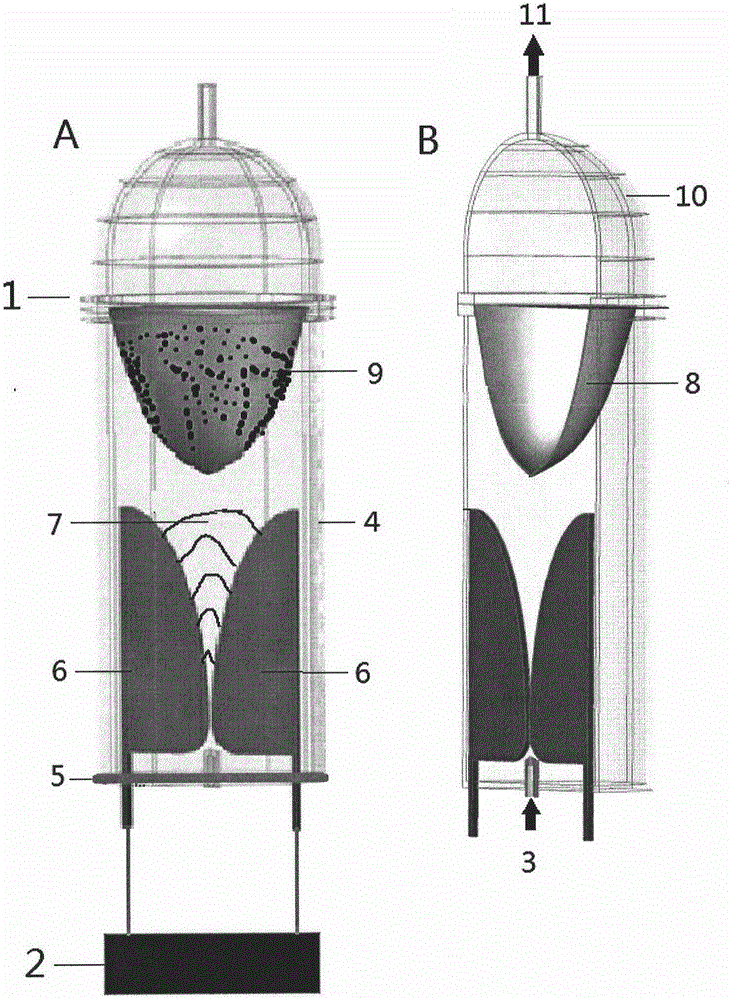

[0011] As shown in the accompanying drawings, the plasma device of the present invention comprises a plasma fluidized bed 1 and a high voltage power supply 2; electrode 6, conical stainless steel mesh 8, granular activated carbon 9, quartz cover 10 and exhaust port 11; Two knife-shaped stainless steel electrodes 6 are symmetrically fixed on the tetrafluoroethylene base 5, and are connected to the high-voltage power supply 3 through a high-voltage line. The air inlet 3 is placed at the center of the tetrafluoroethylene base 5; the conical stainless steel mesh 8 is placed in the quartz container 4 At the central axis of the top and fixed directly above the electrode 6, the granular activated carbon 9 is placed in the conical stainless steel mesh 8.

[0012] In this example, benzene simulated waste gas is selected as the organic waste gas to be treated, and the initial concentration of waste gas is 15000 mg / m 3 , airflow 13m 3 / h. 1) will be processed 13m 3 / h toluene wast

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap