Process for converting a liquid feed material into a vapor phase product

a technology of liquid feed and product, which is applied in the direction of feed devices, hydrocarbon oil treatment, thermal non-catalytic cracking, etc., can solve the problems of liquid feed loss, increased mass and heat transfer rate, and other problems, to achieve the effect of high solids-to-oil ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

application case 1

12. Application Case 1—Application to the Upgrading of Heavy Oil

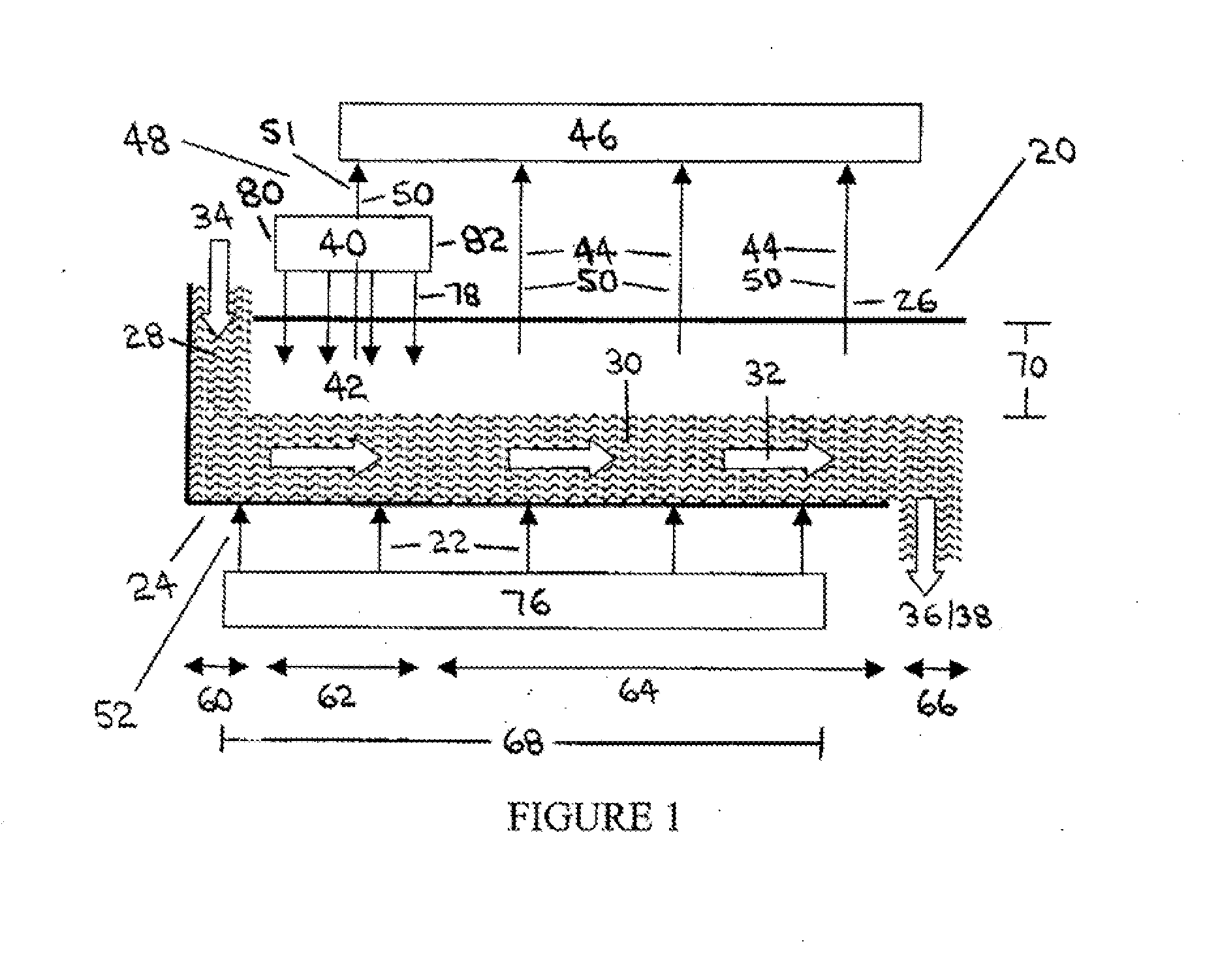

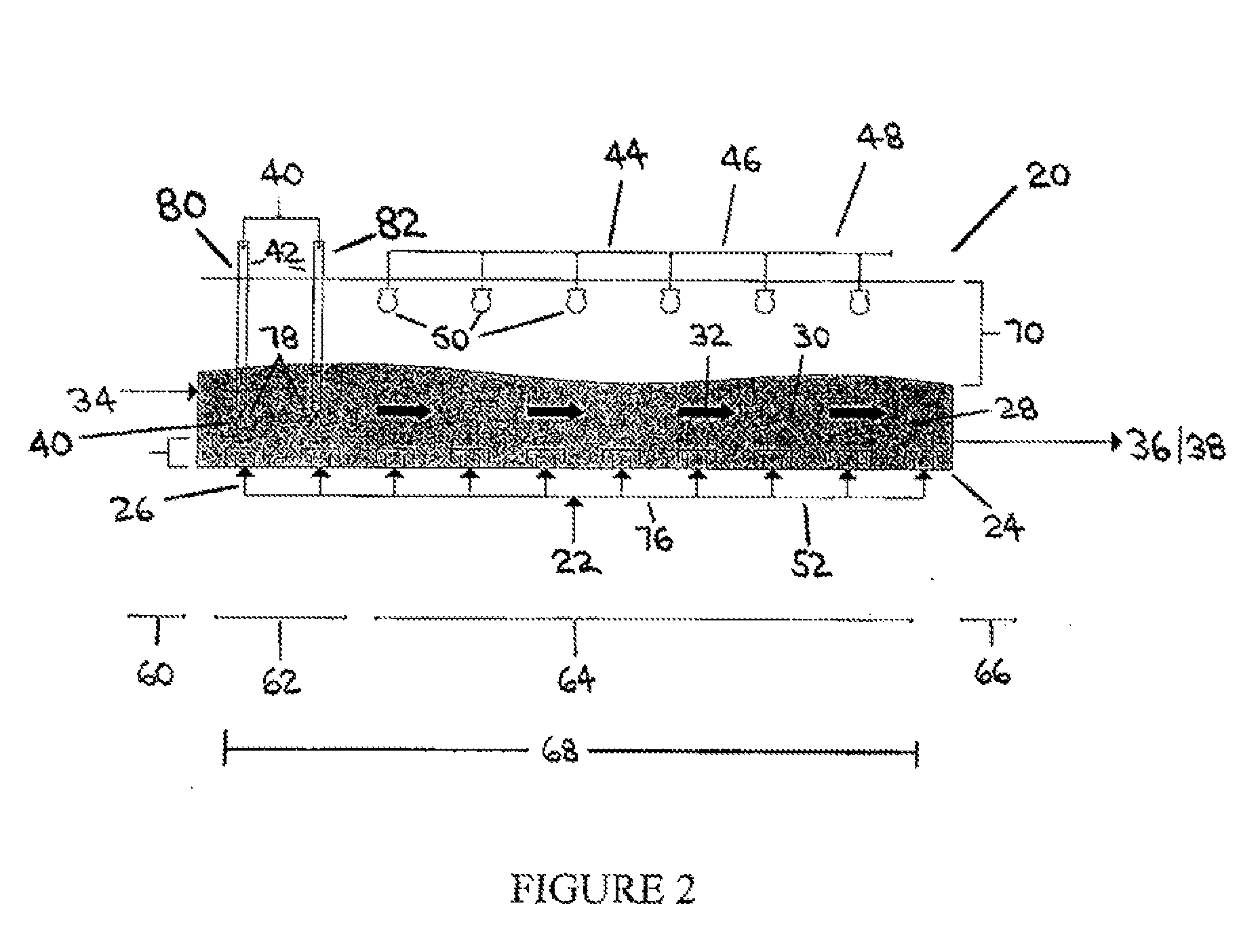

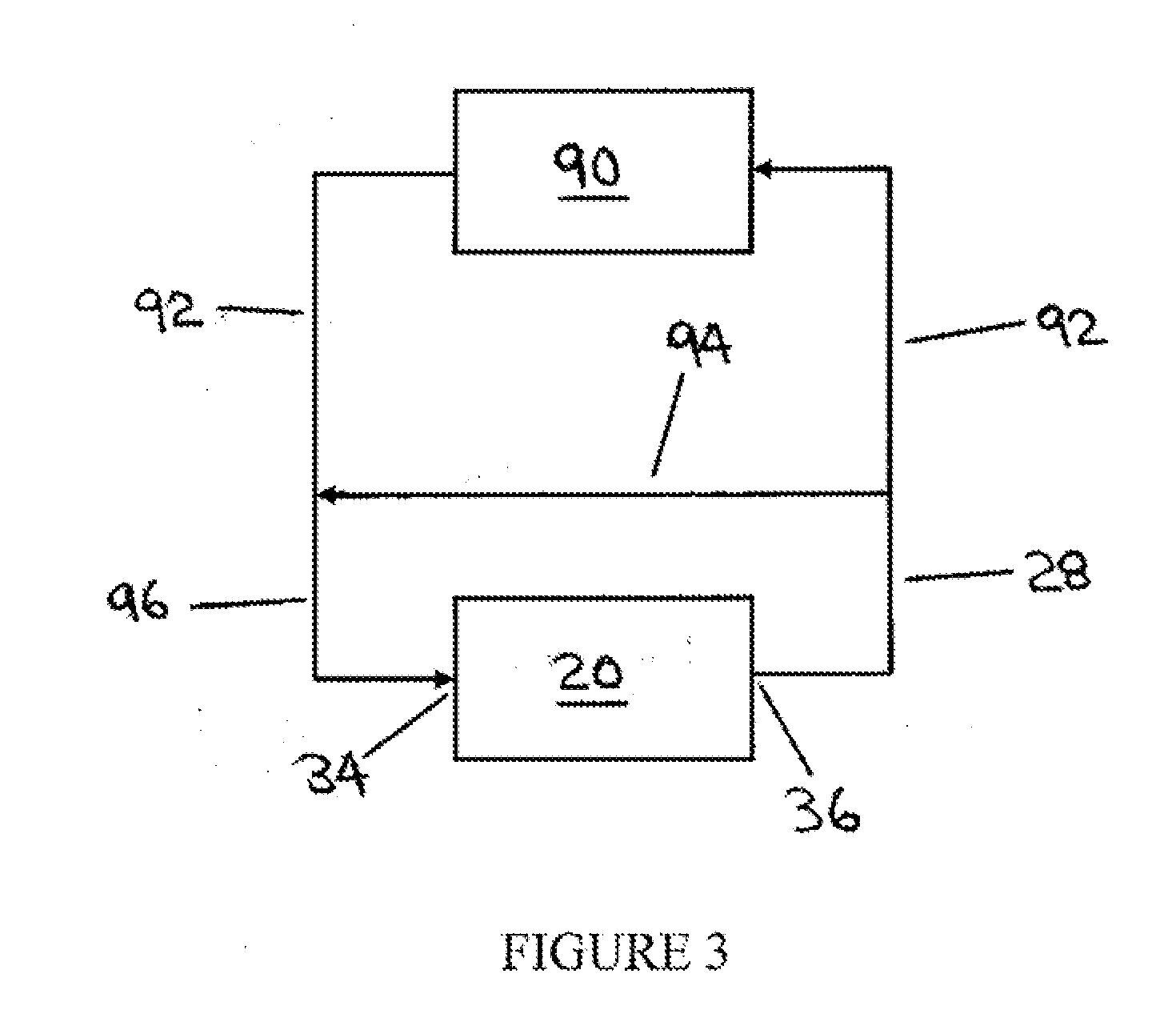

[0172]The following description describes a theoretical design of a specific application of the invention for the upgrading of a heavy oil, such as Athabasca bitumen. In this application, four reactor units are used in series (i.e. the solid particles (28) will flow from one reactor (20) into the next). Each unit has been designed to process feed at a rate of 250 bbl / day making the total capacity 1000 bbl / day. The design specifications and operating conditions for this application are listed in Table 1. The specifications listed in Table 1 are for a single reactor unit, and are based on an extensive piloting exercise designed for this purpose. The following is a brief explanation of the rationale behind the numbers in Table 1.

TABLE 1Operating Condition and Design Ranges for a Single Reactor UnitSpecific to Bitumen Where the Goal is to Maximize Liquid YieldSuitablePreferredOptimalReactor Length3 m-6 m4 m-5 m4.2mReactor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap