Permanent magnet dropping pill sampling pharmacy production line with function of data monitoring

A data monitoring and assembly line technology, applied in water supply devices, sanitary equipment for toilets, devices that make medicines into special physical or ingestible forms, etc., can solve the problem of high temperature in the upper part, low production efficiency, and affecting product quality And other problems, to achieve the effect of improving the balance, high production efficiency, and good disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

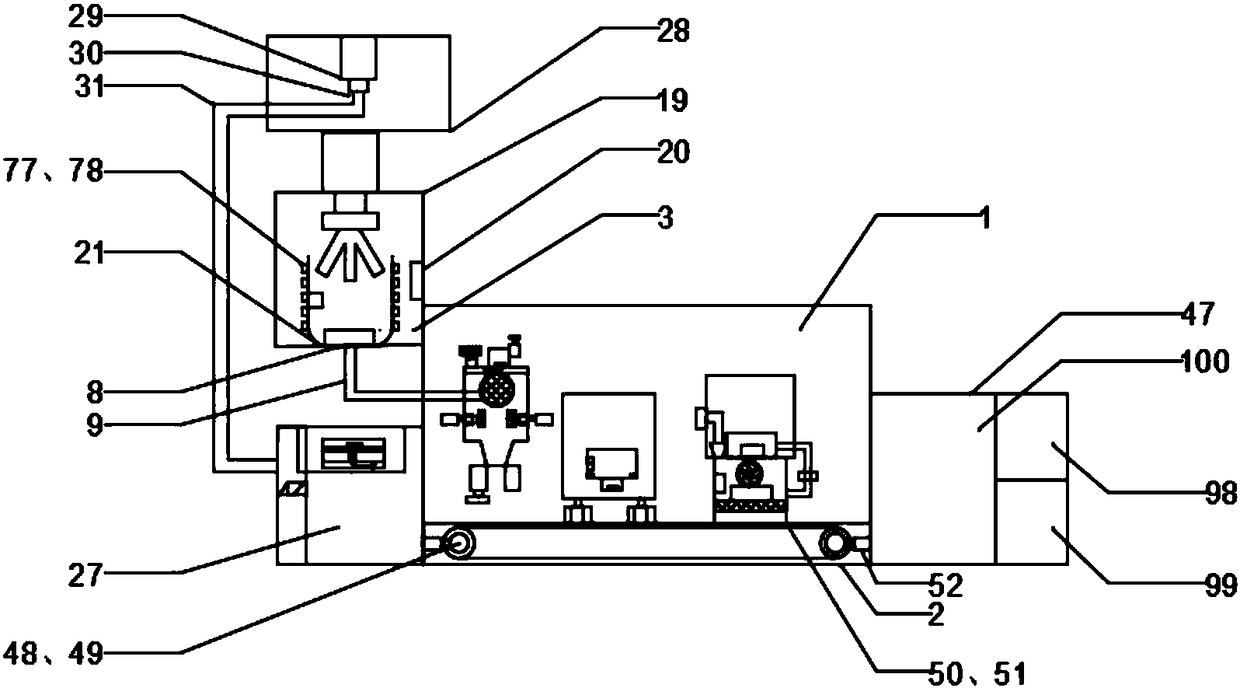

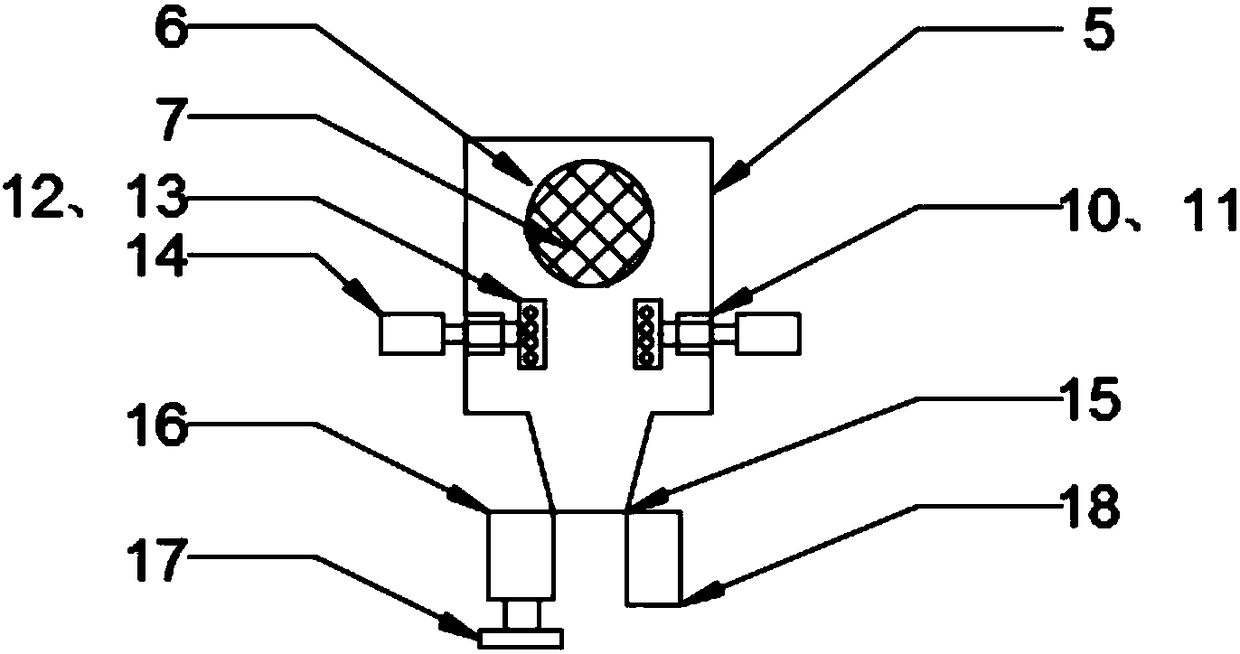

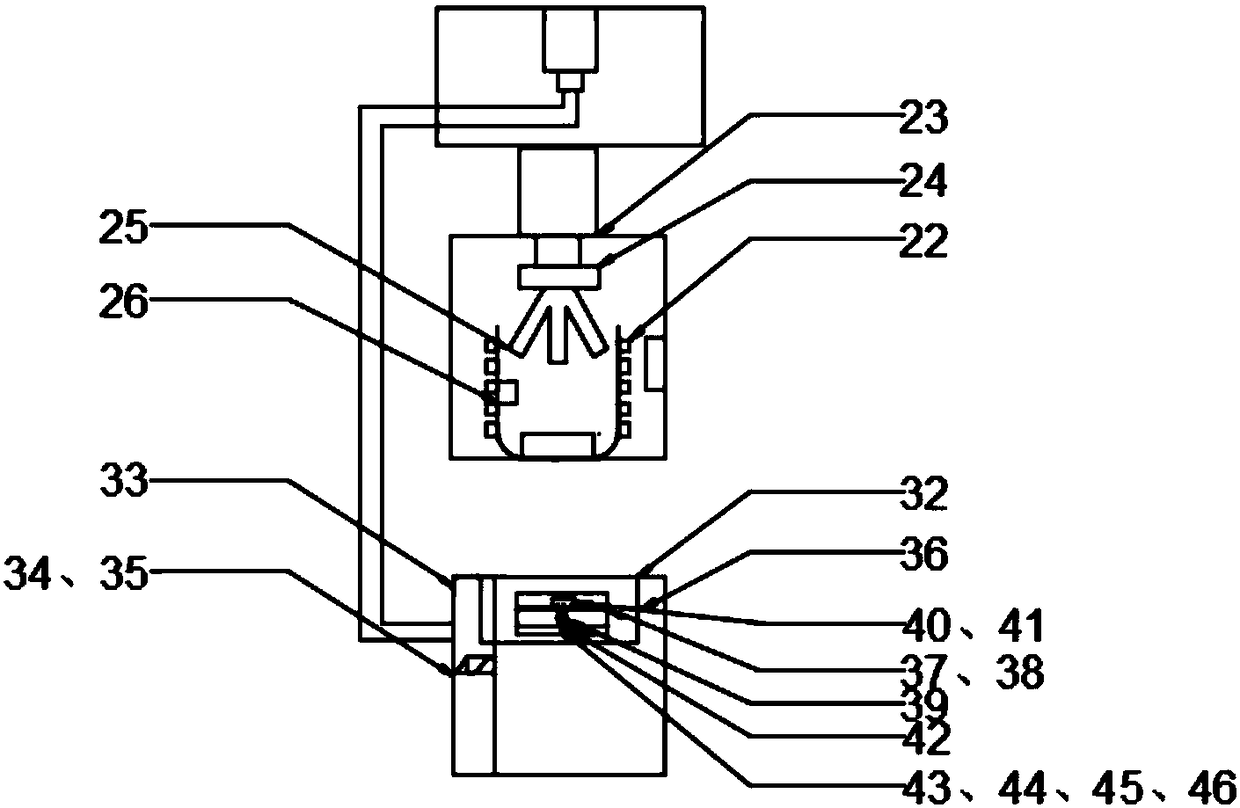

[0021] The present invention will be described in detail below with reference to the drawings, such as Figure 1-6 As shown, a data-monitored permanent magnetic dropping pill sampling pharmaceutical assembly line is provided. The upper surface of the base 1 is provided with a through slot 2 along its length, and the through slot 2 is provided with a transmission mechanism. 1 The upper surface is provided with a steam sterilization mechanism, a drip pill filling mechanism, a cap hot-pressing sealing mechanism, and a medicine sampling device in sequence along its length. The drip pill filling mechanism is fixedly installed on the ground on both sides of the base 1 from the bottom. The upper frame 3, the pharmaceutical box 5 fixedly embedded in the rack 4, the circular hole 6 opened at the center of the upper surface of the pharmaceutical box 5, the pharmaceutical granule spray head 7 fixedly embedded in the circular hole 6, one end and The suction pump 8 is fixedly connected and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap