Process for removing a composite coating present on the surface of a gas cartridge

a gas cartridge and composite coating technology, applied in the field of process for removing a composite coating present on the surface of a gas cartridge, can solve the problems of not being able to directly recycle the liner as a gas container, not being able to optimize the recycling operation, and increasing standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0040]In order to demonstrate the effectiveness of the process of the invention, trials have were carried out under the following conditions.

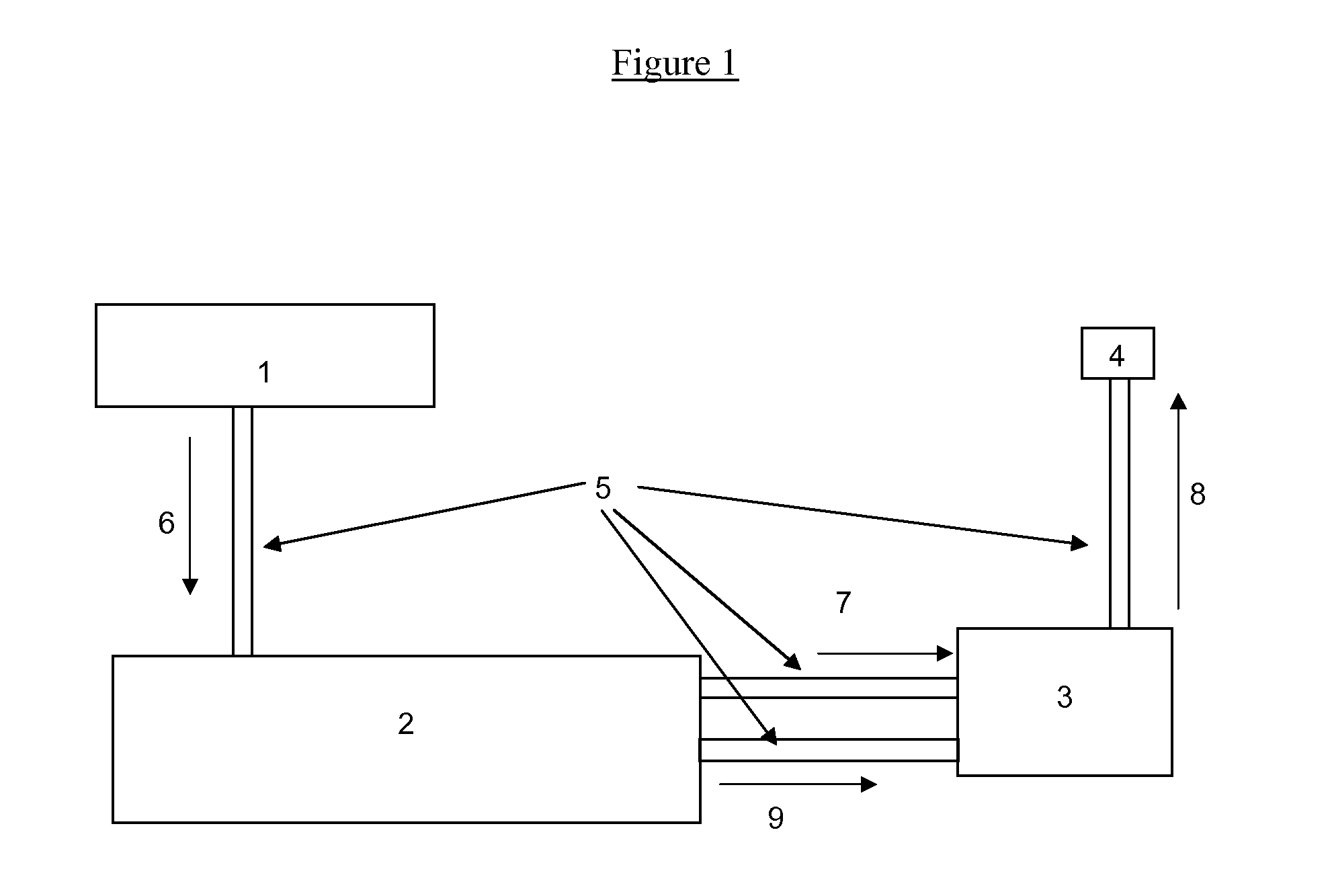

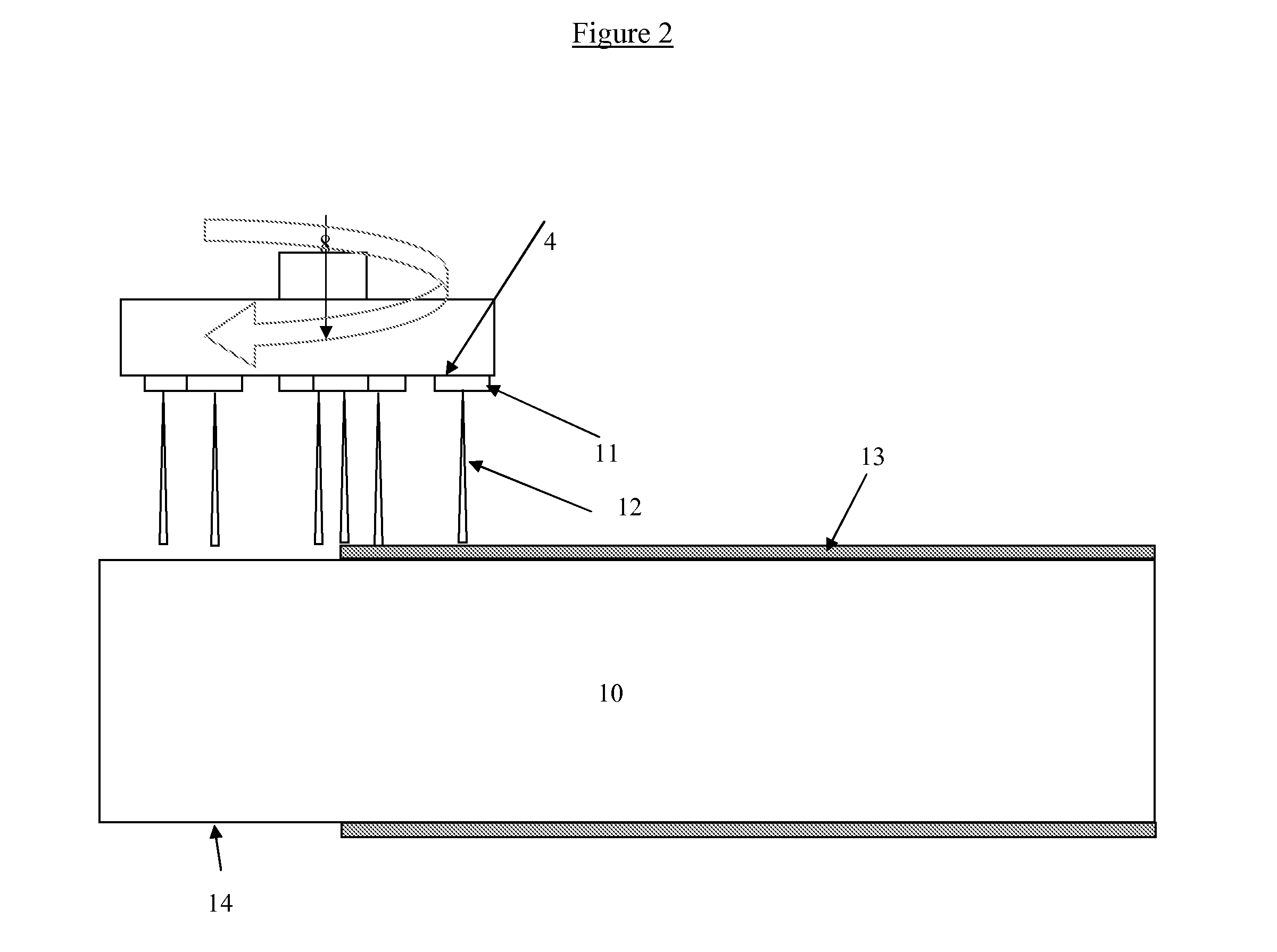

[0041]A cylindrical gas bottle 1.68 m in height and 0.23 m in diameter, the steel or aluminum body of which was covered in a surface-coating layer of 10 mm of a KEVLAR / epoxy composite, was treated with liquid-nitrogen jets at 3200 bar and at a temperature of −155° C. Said nitrogen jets were ejected by a rotating tool having a number of nozzles, such as that in FIG. 2. The jets traced a 0.054 m strip. The rate of advance of the rotating tool was 1 m / min. When the entire length of the bottle had been processed over a width of 0.054 m, the bottle was rotated by 0.053 m (1 mm overlap).

[0042]The trial results showed that the composite “skin” or surface coating came off very easily from the body under the effect of the high-pressure liquid-nitrogen jets. The bodies of the bottles were stripped in about 18 to 20 minutes.

[0043]Moreover, the throughput

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap