Tool mounting for a hand machine tool

a technology for power tools and tools, which is applied in the field of tool mounts for hand power tools, can solve the problems of high impact energy, special technical measures, and wear of the tool mounts, and achieve the effect of high degree of true running of the tool in the tool moun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

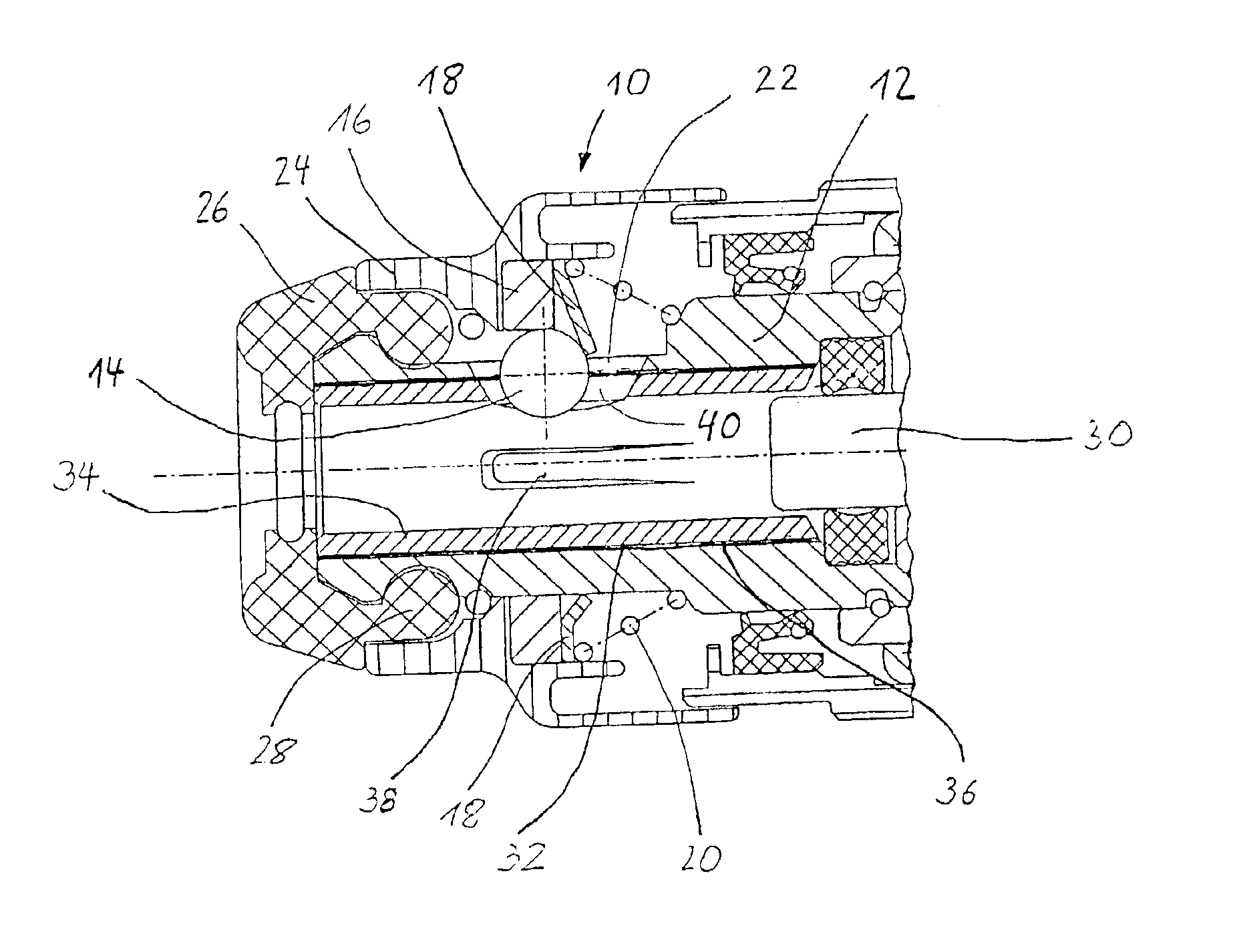

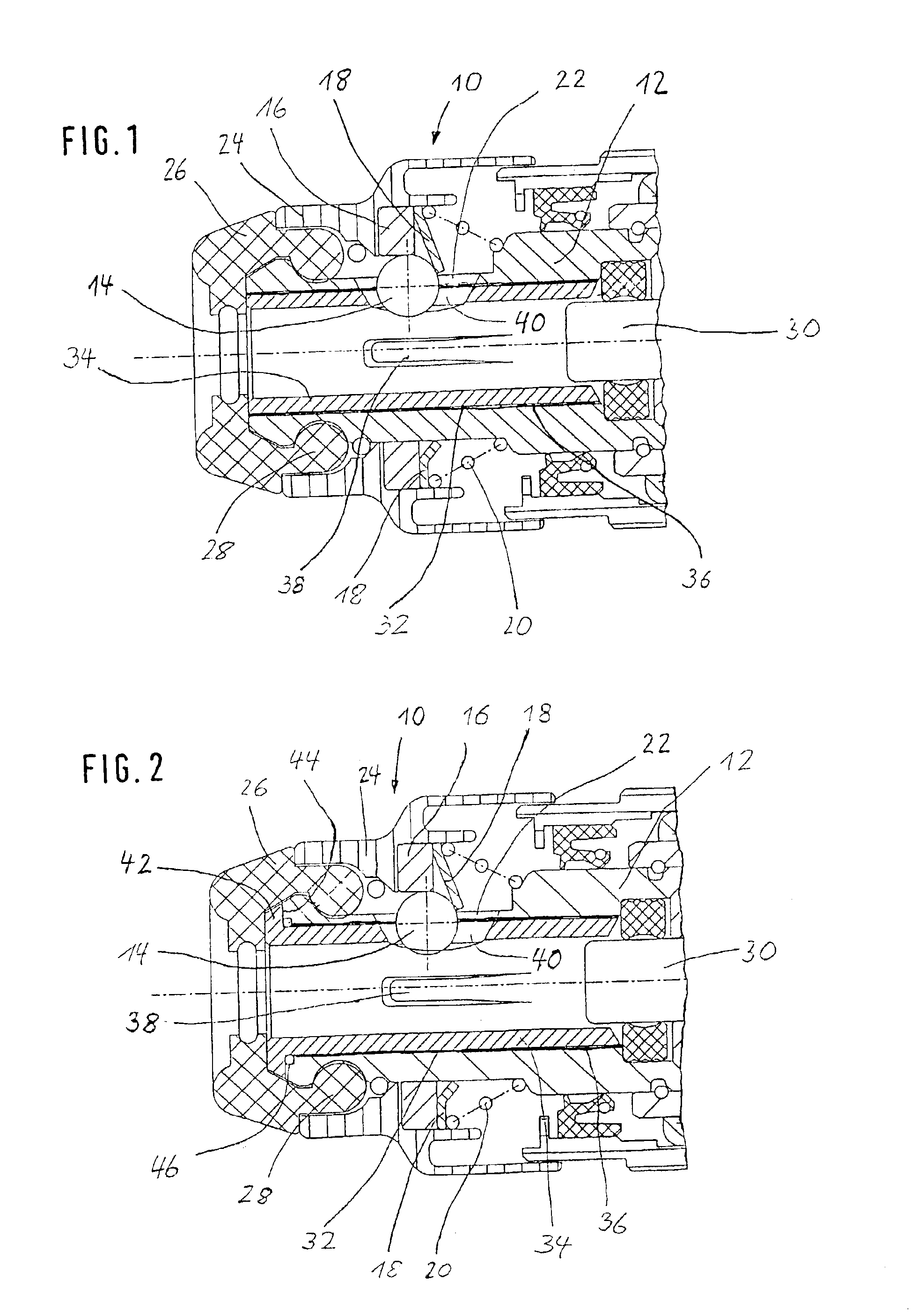

FIG. 1 shows sections of a cross section through a tool mount 10 that is located on a rotating and / or impacting hand power tool. This tool mount 10 is used to mount tools with grooves. The tool mount 10 has a body 12 in which a radially displaceable clamping body—a clamping ball 14 in the exemplary embodiment—is supported. This clamping ball 14 is capable of being guided into a groove located on the shank end of the tool (not shown in the drawing), and it is held in its clamped position by a retaining sleeve 16 that can be moved axially within limits, and by a holding sleeve 16. The retaining sleeve 16 is loaded in the direction of its retaining position by a compression spring 20 via the holding sleeve 18. The compression spring 20 is supported, at the machine end, on the body 12. The retaining sleeve 16 is also supported on the body 12.

When the clamping ball 14 is in the clamped position, the retaining sleeve 16 covers the clamping ball 14 radially, and the holding sleeve 18 secure

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap