Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Rubber sheet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

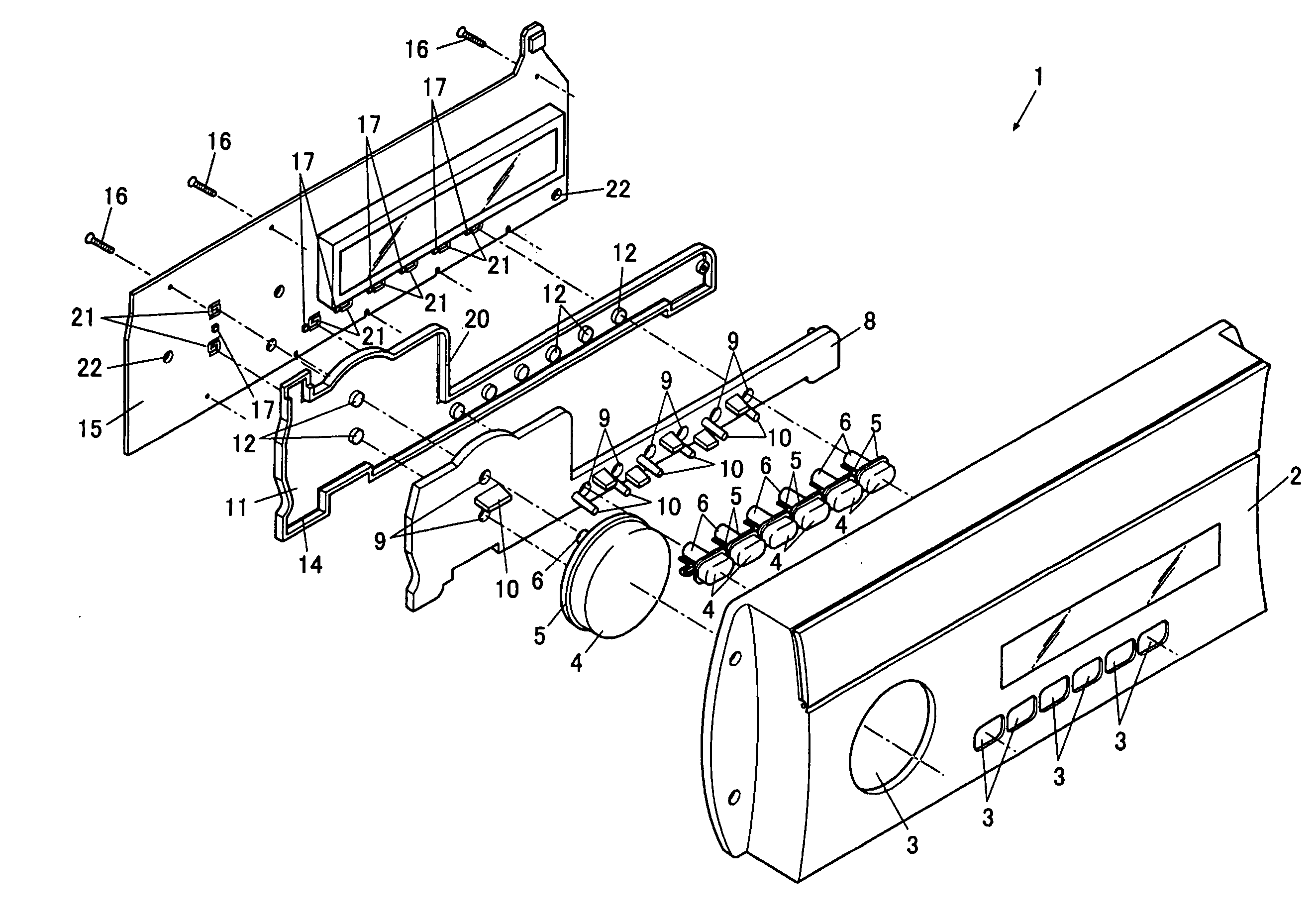

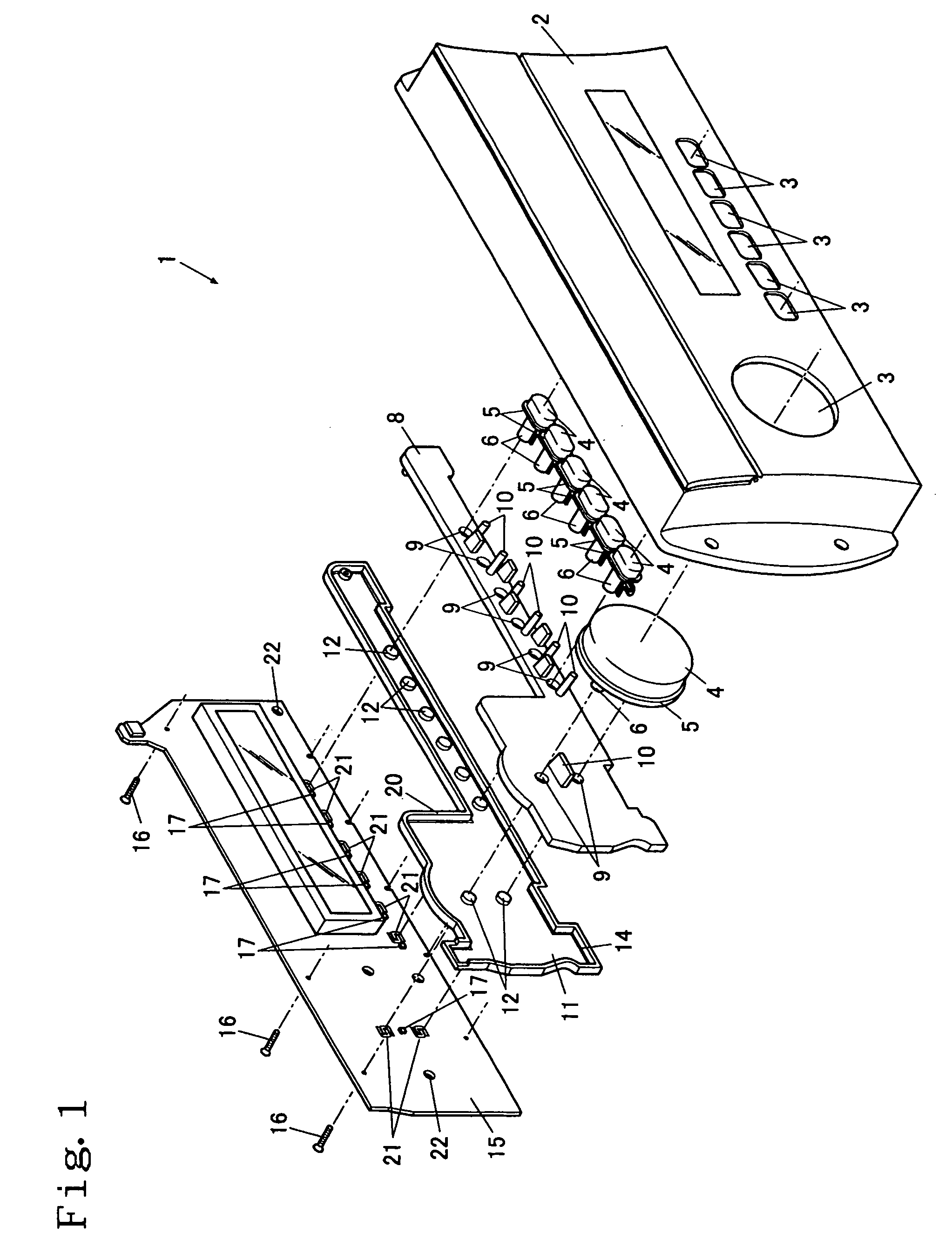

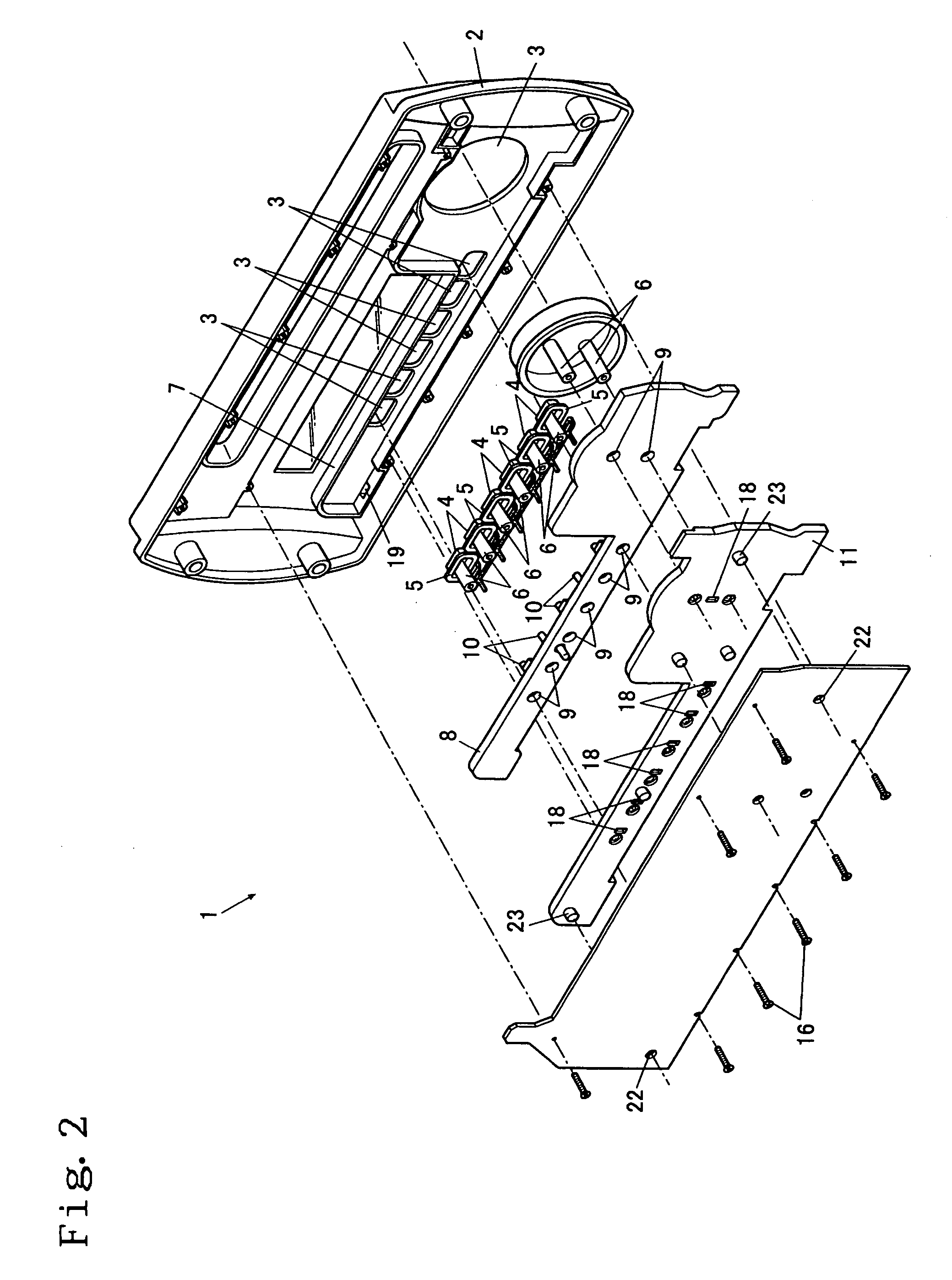

Button waterproofing structure

Owner:JVC KENWOOD CORP A CORP OF JAPAN

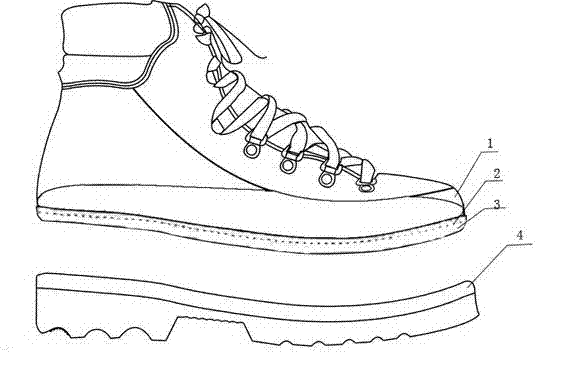

Novel process for manufacturing leather shoes

Owner:JIHUA 3515 LEATHER & SHOES

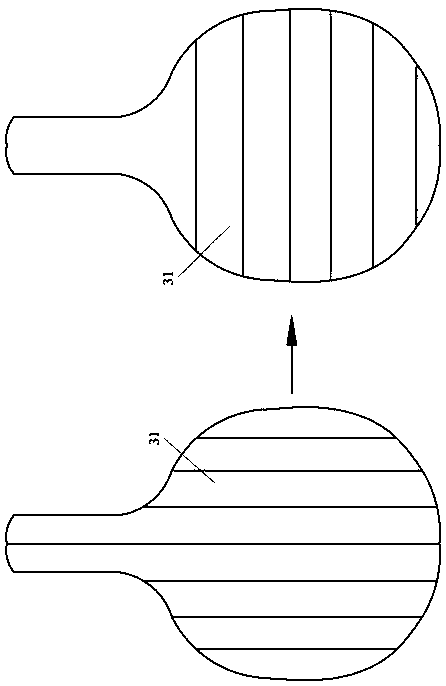

Ultra-light amorphous reinforced carbon fiber table tennis bat and preparation method thereof

ActiveCN111420375ASolve poor ball control performanceSolve the weakness of poor hand feelingSynthetic resin layered productsLaminationFiberCarbon fibers

Owner:广东嘉明体育用品有限公司

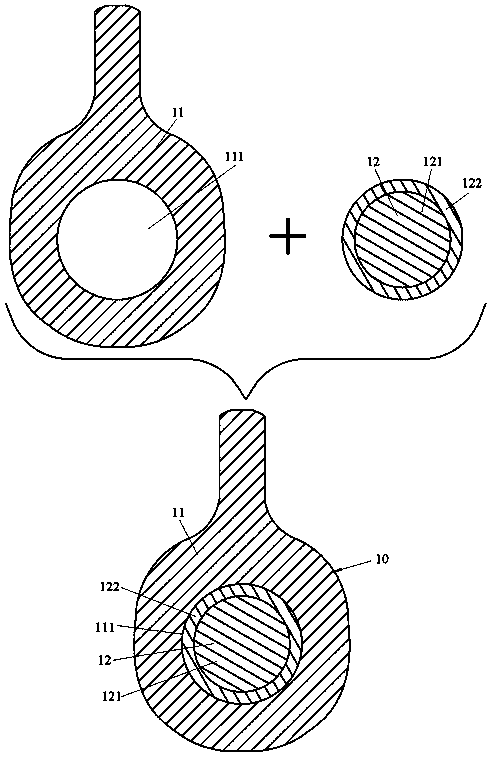

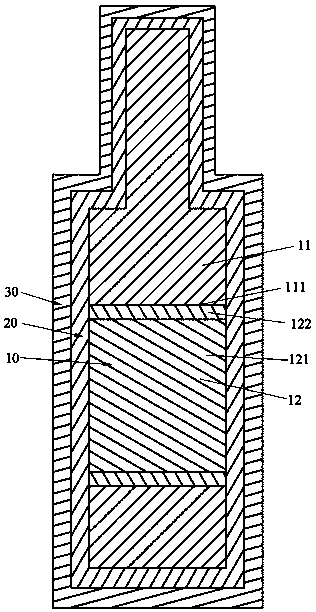

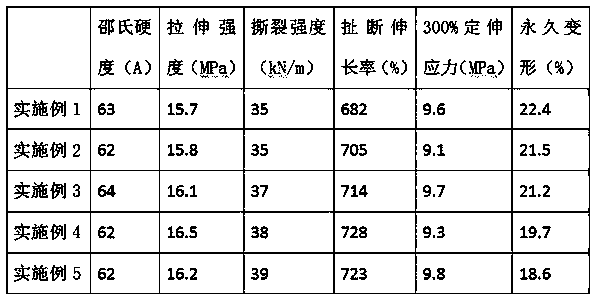

Preparation method of high-strength tire curing bladder

InactiveCN110698776AStrong responsivenessImprove adhesionDomestic articlesPolymer scienceActive agent

Owner:YONGYI RUBBER CO LTD

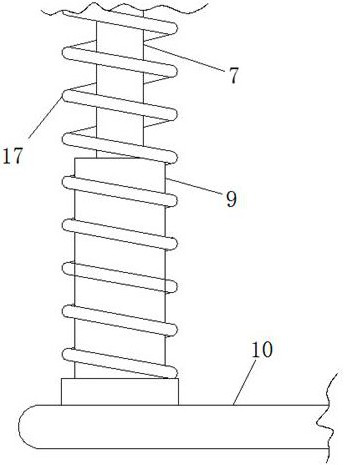

Universal wind power generation device

InactiveCN114320740AStable outputPlay the role of filtering windMachines/enginesWind energy generationMetal frameworkRubber sheet

Owner:赵冬云

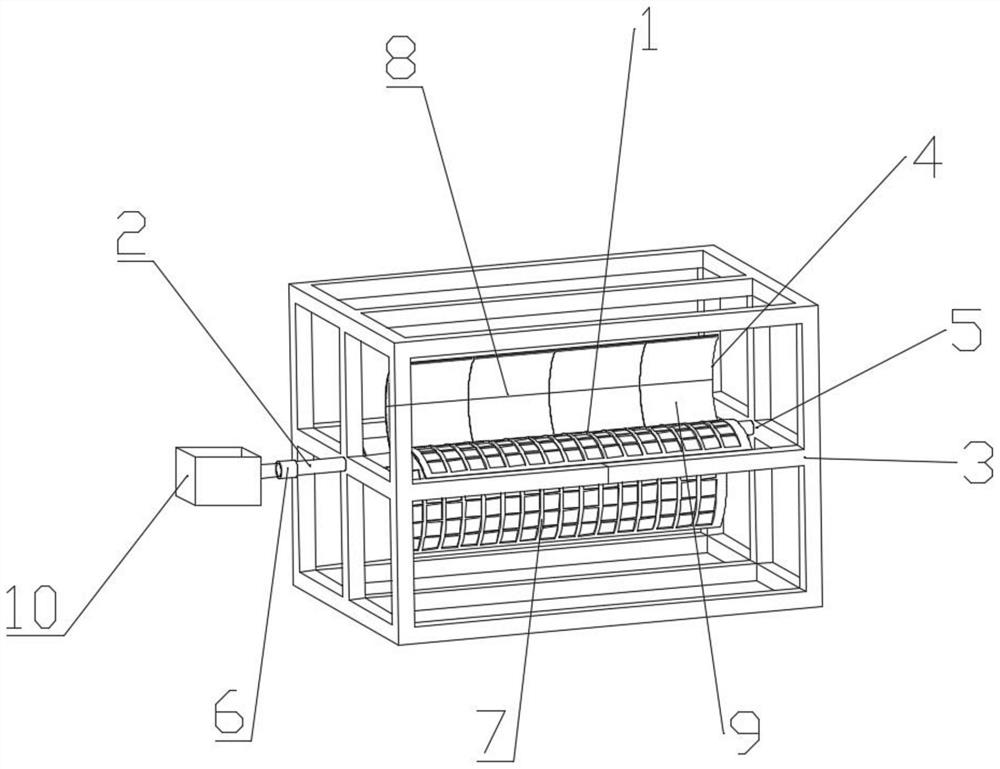

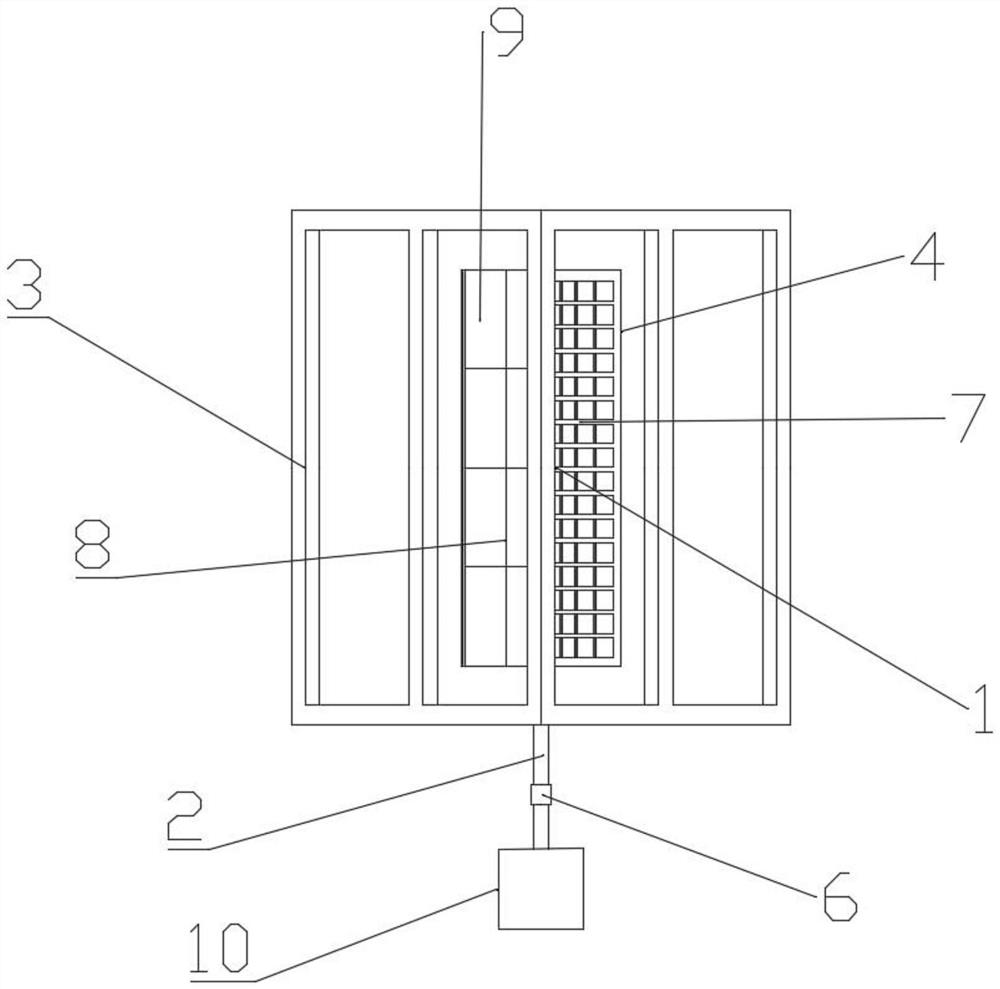

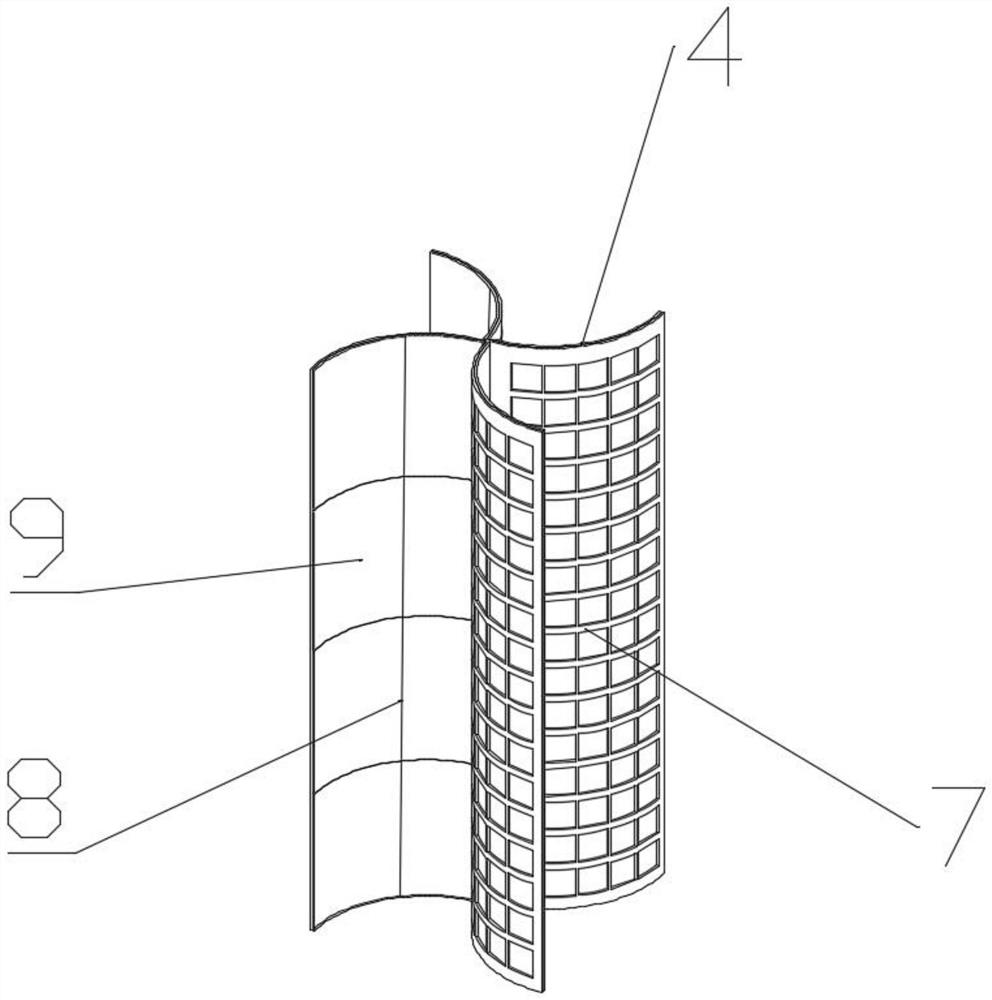

Bottom thread machine for automatic embroidery and use method thereof

InactiveCN113337971AAvoid scratchesAvoid stuckEmbroidering machines apparatusStructural engineeringRubber sheet

The invention discloses a bottom thread machine for automatic embroidery. The bottom thread machine comprises a bottom thread machine body; a thread inlet groove is formed in the top of the bottom thread machine body; a stock bin is installed at the top of the bottom thread machine body; rotating discs are arranged in the stock bin at intervals; shuttle pegs are arranged at the tops of the rotating discs; baffles are evenly installed on the outer walls of the circumferences of the rotating discs; rubber plates are installed on the side, away from the rotating discs, of the baffles and connected with the inner wall of the stock bin; and the baffles are matched with the shuttle pegs. According to the bottom thread machine for automatic embroidery, the bottom thread machine body can be protected by forming the thread inlet groove, meanwhile, the discharging speed of the shuttle pegs can be increased conveniently through a first conveying groove and a second conveying groove, and selective use can be achieved according to different discharging requirements.

Owner:GUANGDONG HAIDI ORIENTAL FINE EMBROIDERY IND CO LTD

High toughness cable for aviation and preparation method thereof

The invention discloses a high toughness cable for aviation and a preparation method thereof. The preparation method comprises 1) stirring to mix fibers, nano-calcium carbonate, tetrahydrofuran and ethanol in a nitrogen protective atmosphere at a temperature of 120-140 DEG C and collecting precipitates M1, 2) mixing neoprene and butadiene rubber to obtain mixed rubber M2, 3) mixing the precipitates M1, the mixed glue M2, a phosphate, a rare earth oxide and an antioxidant and pressing the mixture to obtain rubber sheet blanks M3, 4) mixing the rubber sheet blanks M3 and a vulcanizing agent and carrying out vulcanization to obtain rubber sheets M4, and 5) coating the rubber sheets M4 with metal wires to obtain the high toughness cable for aviation. The high toughness cable has high toughness, greatly-prolonged service life, improved use performances, and widened cable application field.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

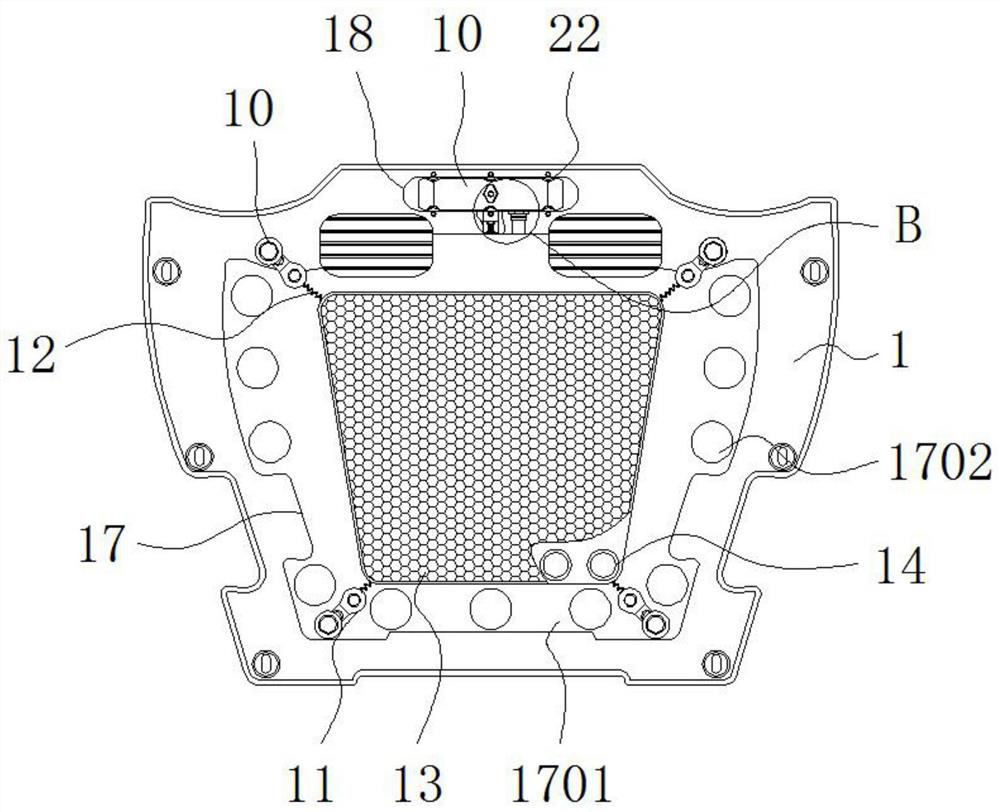

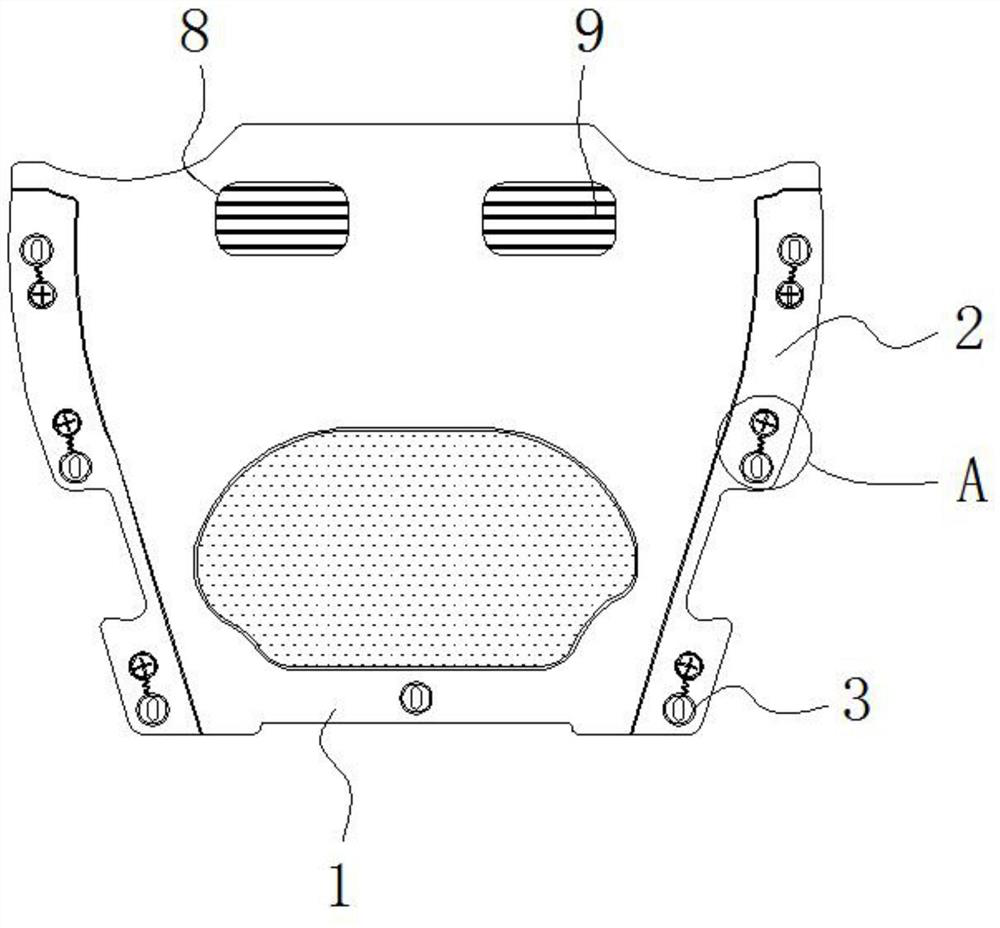

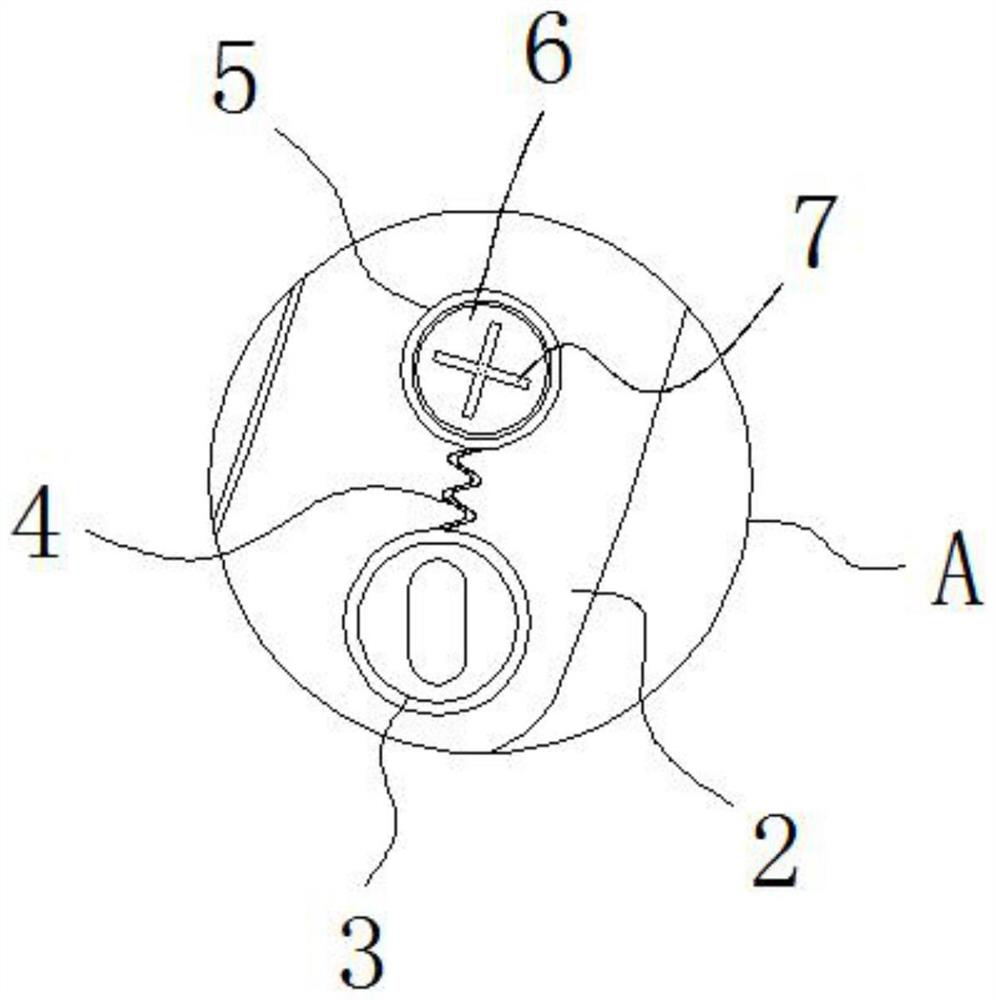

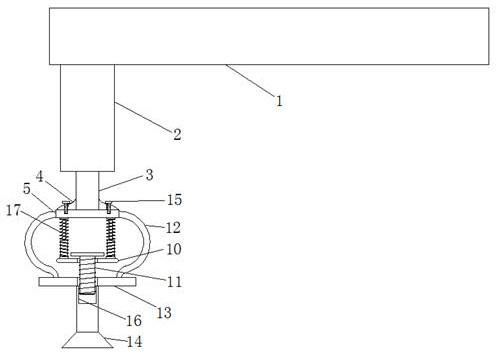

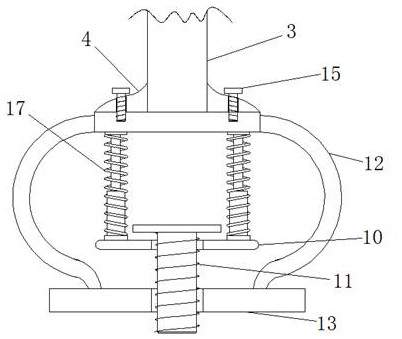

New energy automobile bottom protection plate

PendingCN113619498AEasy to installAvoid Corrosion Damaged SituationsPropulsion coolingNew energyRubber sheet

Owner:JIANGSU HUAMAN COMPOSITE MATERIALS TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap