Novel process for manufacturing leather shoes

A production process and new process technology, applied in the direction of footwear, other household appliances, household appliances, etc., to achieve the effect of improving the bonding strength and increasing the strength of the stitching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

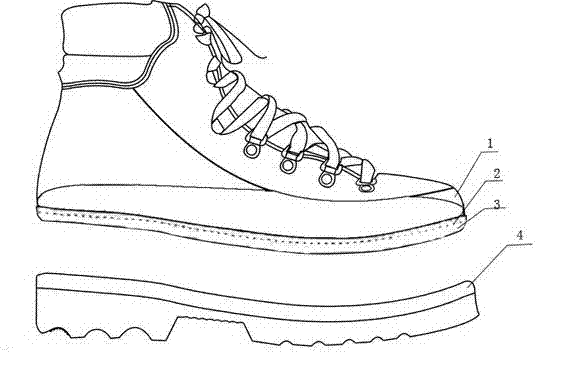

[0009] like figure 1 A new process of making leather shoes is shown, including stretching last - fluffing - brushing glue - putting the film in the mold cavity - injection pressure - vulcanization molding. - Raising - brushing glue - putting the film in the mold cavity - injection pressure - vulcanization molding.

[0010] In the present invention, another glue brushing process is added between the two processes of glue brushing and putting the film in the mold cavity.

[0011] The present invention is different from the traditional molding method in that the rubber 3 and the upper surface 1 are sewn together through the suture 2 after brushing, and then the rubber is brushed and vulcanized, and the rubber in the mold cavity 4 after vulcanization is fused with the rubber of the original suture to form a One, and through the bonding effect of the adhesive, the strength of the suture is increased, and the bonding strength between the upper surface and the rubber sole is greatly im

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap