Universal wind power generation device

A technology for wind energy power generation and wind blades, which is applied in wind energy power generation, wind turbines, motors, etc., can solve the problems of wind non-directionality, etc., and achieve the effect of high practical value and promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A universal wind energy generating device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

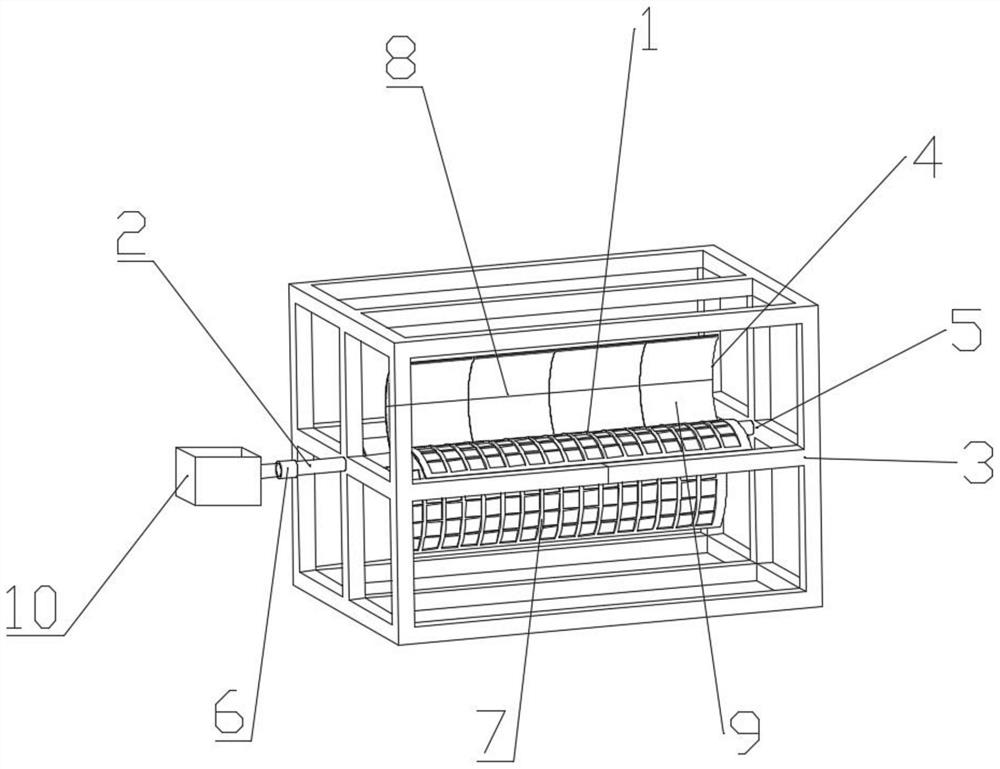

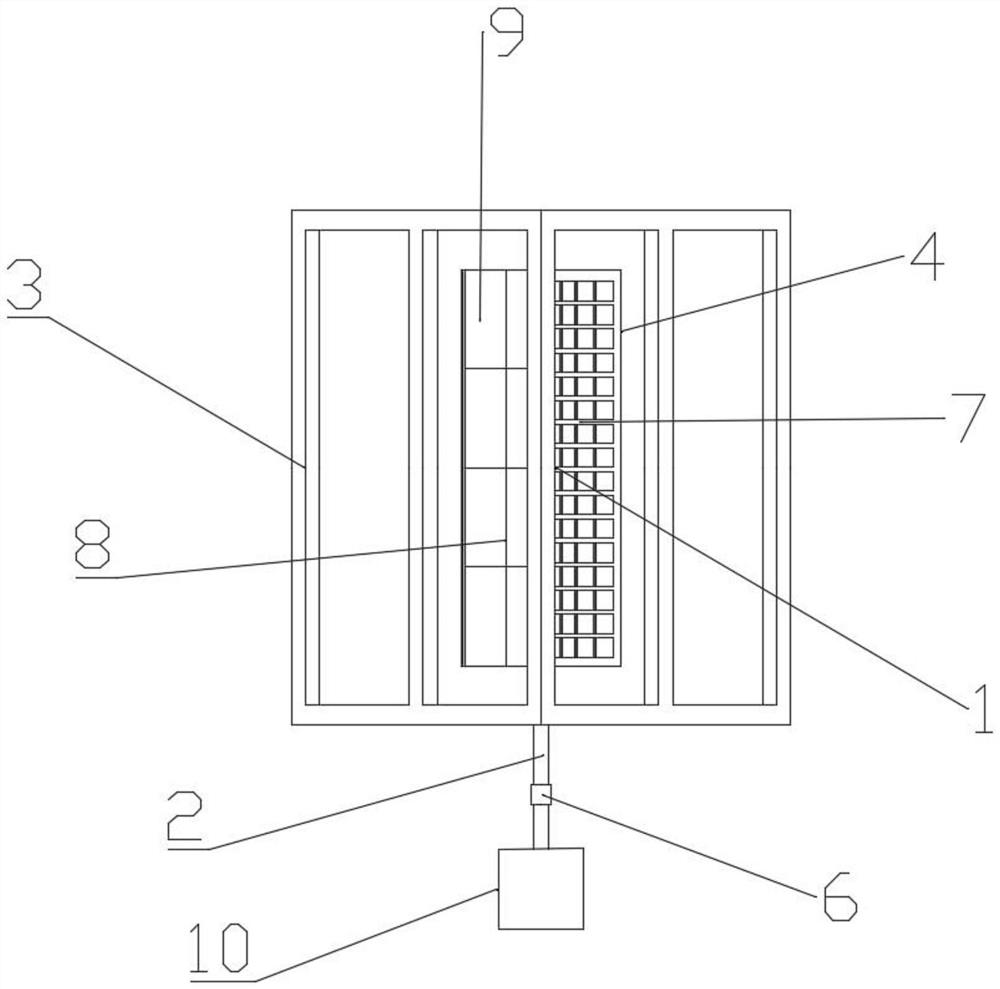

[0016] combined with Figure 1 to Figure 3 , a universal wind power generation device, comprising a fan blade rotating part 1, the fan blade rotating part 1 includes a rotating shaft 2 and a metal frame 3, the rotating shaft 2 is evenly provided with a number of arc-shaped blades 4, and the arc-shaped blades 4 It is fixedly connected with the rotating shaft 2; the rotating shaft 2 is rotationally connected with both ends of the metal frame 3 through bearings 5, and a transmission connecting piece 6 is provided at one end of the rotating shaft 2.

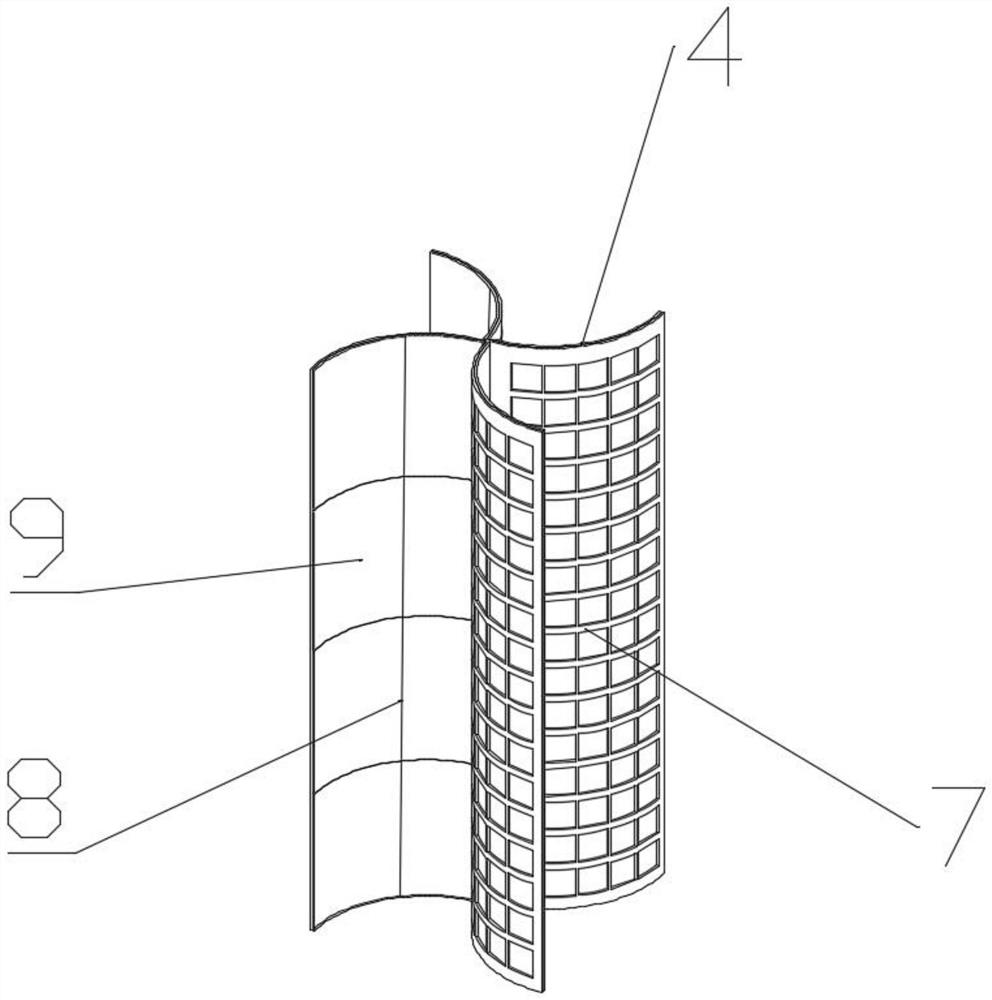

[0017] The number of said curved blades 4 is four, and said curved blades 4 are of double-layer structure, including metal mesh leaves 7 and a soft rubber layer 8, said soft rubber layer 8 is located on the concave side of the curved blades 4, said The metal mesh leaf 7 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap