Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Machinability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machinability is the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost. Materials with good machinability (free machining materials) require little power to cut, can be cut quickly, easily obtain a good finish, and do not wear the tooling much. The factors that typically improve a material's performance often degrade its machinability. Therefore, to manufacture components economically, engineers are challenged to find ways to improve machinability without harming performance.

Shoulder wedge composite material and manufacturing method thereof

The invention discloses a shoulder wedge composite material and a manufacturing method thereof. The shoulder wedge composite material consists of the following raw materials in part by weight: 100 parts of natural rubber, 10 to 50 parts of carbon series nano thermal conducting filler, 10 to 35 parts of coarse particle size carbon black, 2 to 6 parts of octyl phenolic resin, 2 to 4 parts of surfactant, 1 to 8 parts of silane coupling agent, 1.5 to 9 parts of vulcanizing agent and the balance of other common aids. The preparation method comprises the following steps of: plasticating the rubber in an internal mixer, adding the coarse particle size carbon black, the carbon series nano thermal conducting filler, the octyl phenolic resin, the surfactant and the other aids into the internal mixer, mixing and controlling the temperature to be between 80 and 120 DEG C; adding the silane coupling agent into the mixture, controlling the temperature to be between 120 and 160 DEG C, and discharging the sizing material; adding a master batch and the vulcanizing agent into the internal mixer and discharging products until the temperature is 80 to 120 DEG C, wherein if the other aids contain scorch retarder, the scorch retarder and the vulcanizing agent are added together. The shoulder wedge composite material provided by the invention meets the requirements of mechanical properties, and is low in themogenesis, high in thermal conductivity, and excellent in machinability.

Owner:BEIJING UNIV OF CHEM TECH +1

550MPa-grade steel plate and manufacturing method of 550MPa-grade steel plate

The invention provides a 550MPa-grade steel plate and a manufacturing method of the 550MPa-grade steel plate. The 550MPa-grade steel plate is prepared from the chemical components of, by mass, 0.08 to0.1 percent of C, 0.25 to 0.35 percent of Si, 1.78 to 1.88 percent of Mn, 0 to 0.015 percent of P, 0 to 0.005 percent of S, 0.017 to 0.027 percent of Als, 0.23 to 0.33 percent of Cr, 0.05 to 0.07 percent of V, 0.05 to 0.06 percent of Nb, 0.001 to 0.0025 percent of Ca, 0.01 to 0.02 percent of Ti, and the balance iron and inevitable impurities. Through the technical scheme provided by the invention, the 550MPa-grade steel plate is added with a small number of valuable alloy elements such as Nb, V and Ti, so that the production cost is low, and the machinability is favorable.

Owner:BAOTOU IRON & STEEL GRP

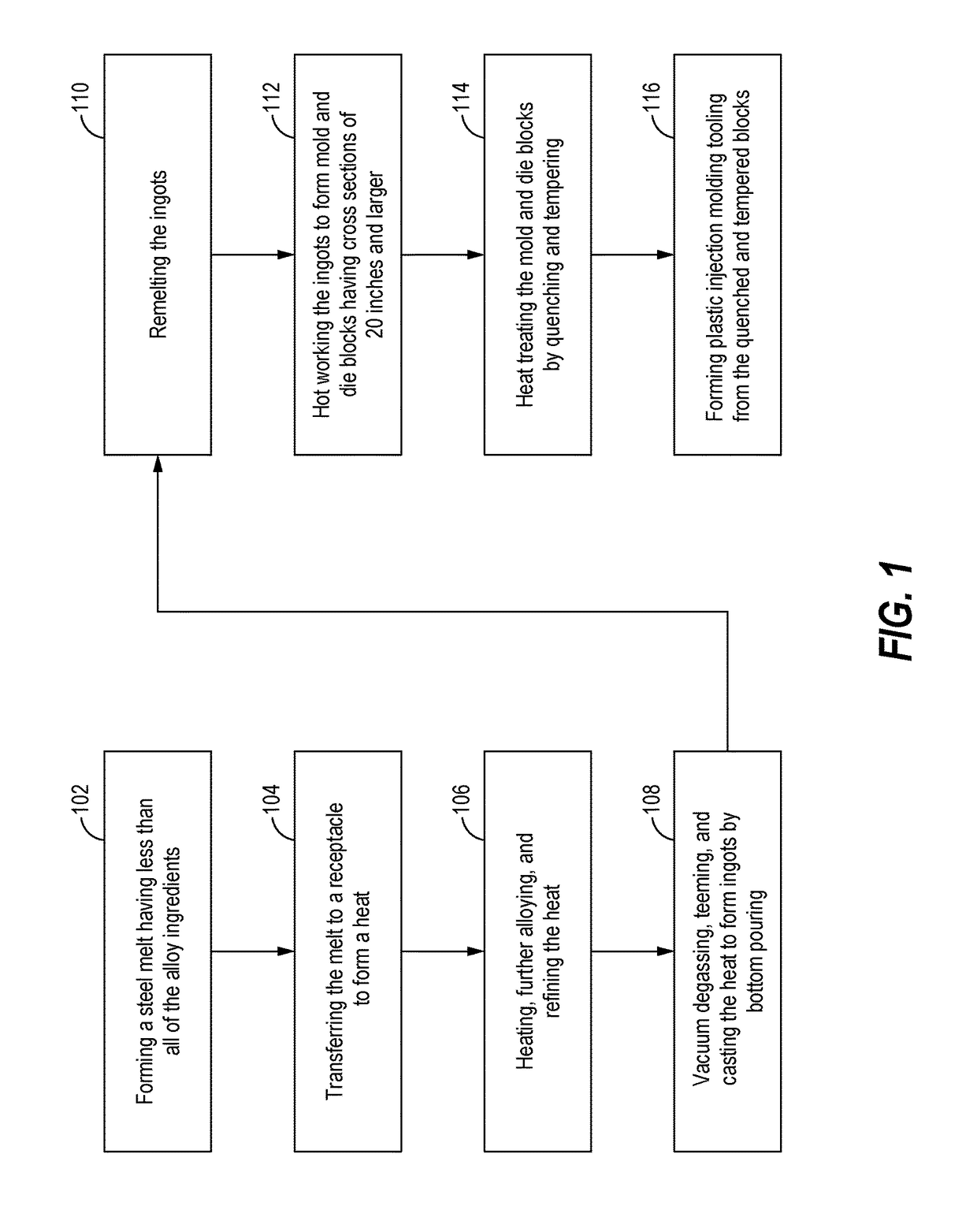

Plastic Injection Mold Tooling And A Method Of Manufacture Thereof

Owner:A FINKI & SONS

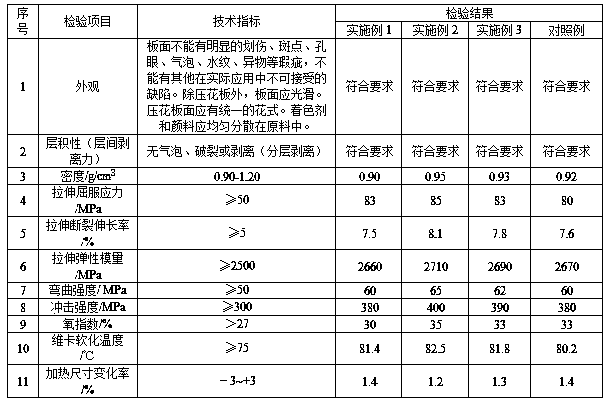

PVC (polyvinyl chloride) decoration plate prepared from acidification modified white ash

ActiveCN107686612AExcellent performance index dataExcellent extrusion lamination performanceParaffin oilsMachinability

The invention discloses a PVC (polyvinyl chloride) decoration plate prepared from acidification modified white ash and belongs to the field of PVC materials. The plate comprises the following ingredients in parts by weight: 100 parts of PVC, 40-70 parts of acidification modified white ash compound lead salt, 5-10 parts of acidification modified white ash compound basic lead phosphite, 5-8 parts ofMBS (methyl methacrylate-butadiene-styrene), 4-6 parts of CPE (chlorinated polyethylene), 4-6 parts of ACR (acrylate), 1-4 parts of paraffin and 2-3 parts of barium stearate. The acidification modified white ash compound lead salt and acidification modified white ash compound basic lead phosphite substitute tribasic lead sulfate and dibasic lead phosphite for manufacturing the PVC decoration plate; comprehensive utilization of a white ash slag resource is achieved; and the plate has a high economic value added, is clean, environment-friendly and good in product performance, exceeds technicalindex requirements of the like products, is better in extrusion and lamination performance, machinability and stability and has a wide application value in an aspect of interior decoration.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

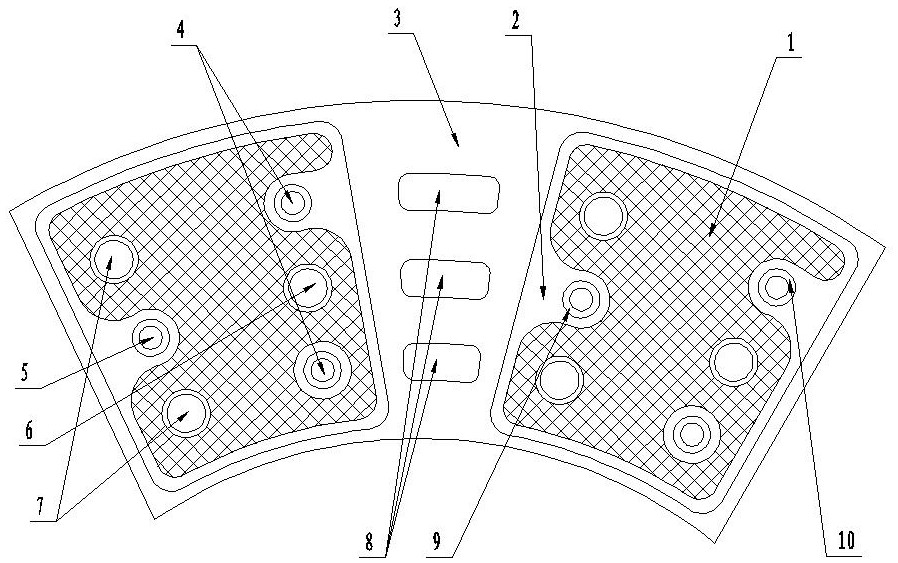

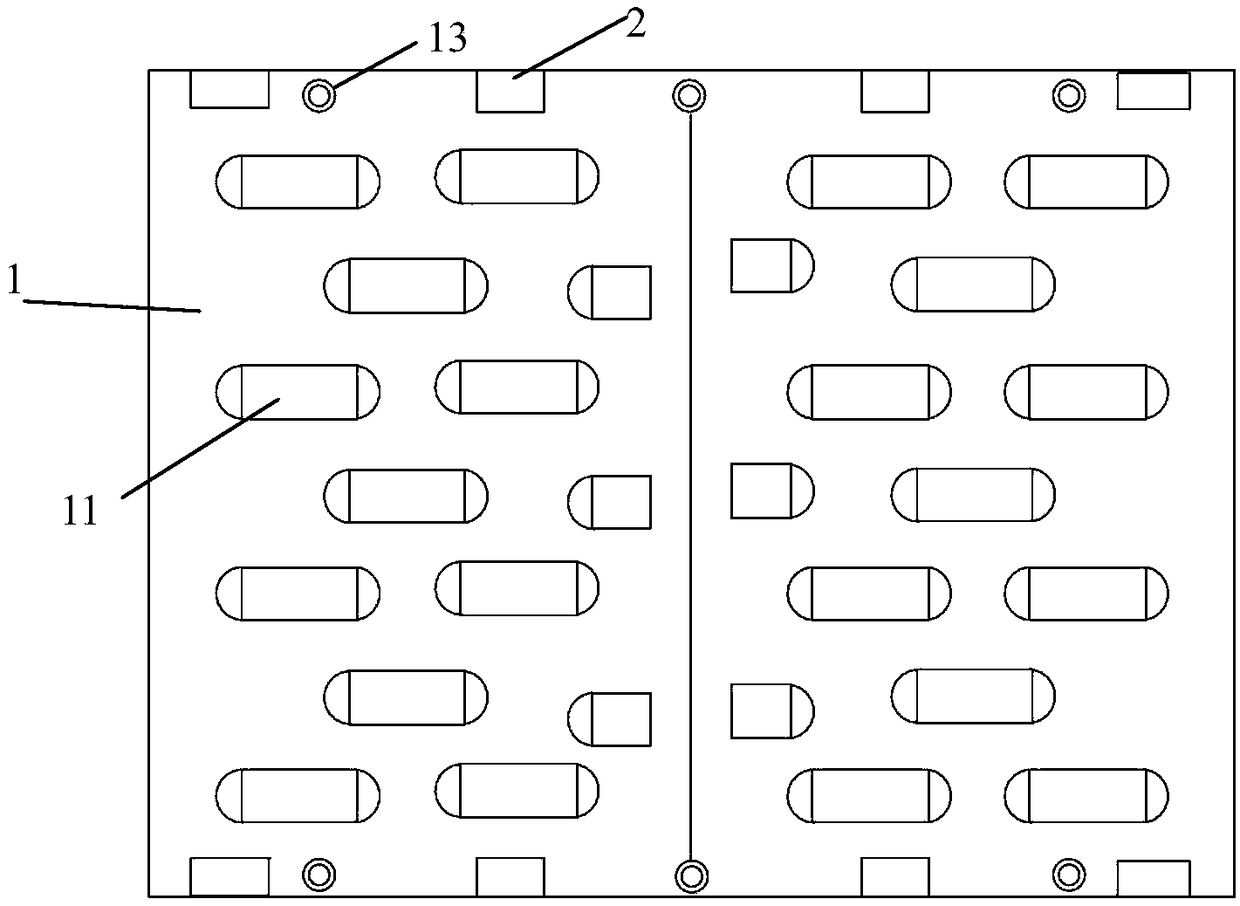

Novel AMT friction plate assembly of riveted structure

PendingCN113417955ASimple structureReduce manufacturing costFriction clutchesFriction liningMachinabilityMetal substrate

Owner:GUILIN FUDA

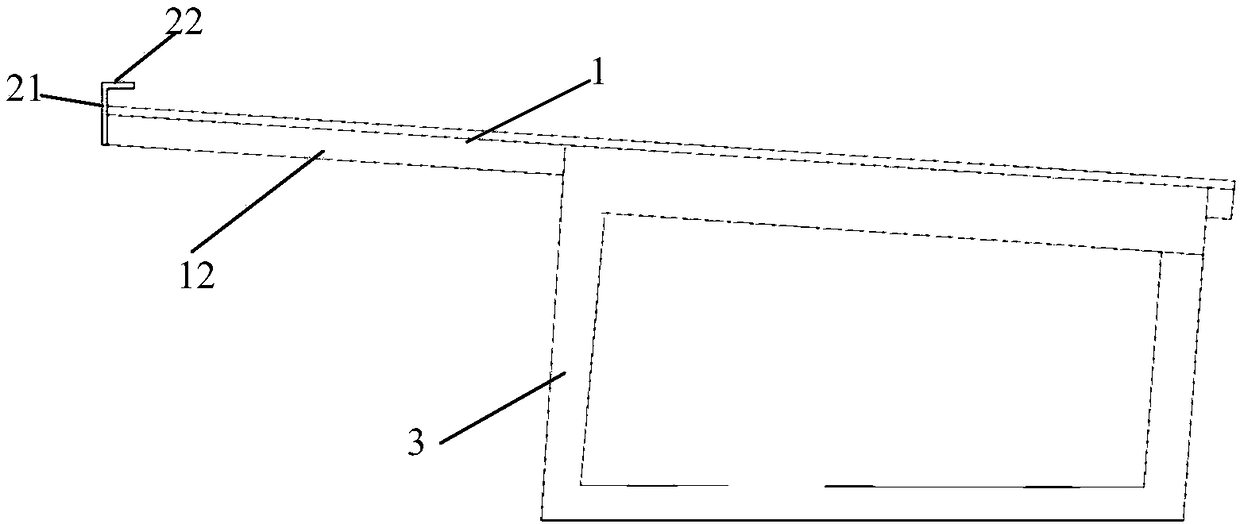

Alloy type silver mirror backboard, reflector, solar power generation reflector and manufacturing method

PendingCN109239822APrecise positioningImprove stabilitySolar heating energyMirrorsThermal expansionSolar power

Owner:TIANJIN BINHAI LIGHT & HEAT REFLECTING TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap