Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Coarse particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coarse particles are the relatively large airborne particles mainly produced by the mechanical break-up of even larger solid particles.

Shoulder wedge composite material and manufacturing method thereof

The invention discloses a shoulder wedge composite material and a manufacturing method thereof. The shoulder wedge composite material consists of the following raw materials in part by weight: 100 parts of natural rubber, 10 to 50 parts of carbon series nano thermal conducting filler, 10 to 35 parts of coarse particle size carbon black, 2 to 6 parts of octyl phenolic resin, 2 to 4 parts of surfactant, 1 to 8 parts of silane coupling agent, 1.5 to 9 parts of vulcanizing agent and the balance of other common aids. The preparation method comprises the following steps of: plasticating the rubber in an internal mixer, adding the coarse particle size carbon black, the carbon series nano thermal conducting filler, the octyl phenolic resin, the surfactant and the other aids into the internal mixer, mixing and controlling the temperature to be between 80 and 120 DEG C; adding the silane coupling agent into the mixture, controlling the temperature to be between 120 and 160 DEG C, and discharging the sizing material; adding a master batch and the vulcanizing agent into the internal mixer and discharging products until the temperature is 80 to 120 DEG C, wherein if the other aids contain scorch retarder, the scorch retarder and the vulcanizing agent are added together. The shoulder wedge composite material provided by the invention meets the requirements of mechanical properties, and is low in themogenesis, high in thermal conductivity, and excellent in machinability.

Owner:BEIJING UNIV OF CHEM TECH +1

Pre-separation process of coal slime flotation

Owner:LIAONING TECHNICAL UNIVERSITY

Household garbage incineration fly ash source reduction treatment system and method

InactiveCN111905535AReduce productionReduce landfill volumeCombination devicesGas treatmentBottom ashFlue gas

The invention discloses a household garbage incineration fly ash source reduction treatment system and method, and the treatment system comprises a deacidification reaction tower, a classifier and a chelating agent atomization reactor which are sequentially communicated, the bottom of the deacidification reaction tower is connected with a circulating fan, and household garbage incineration flue gas enters the deacidification reaction tower for deacidification treatment; the bottom ash of the deacidification reaction tower enters the deacidification reaction tower again under the action of thecirculating fan to be circulated, the flue gas subjected to deacidification treatment is classified into fine-particle fly ash and coarse-particle fly ash through the classifier, and the fine-particlefly ash enters the chelating agent atomization reactor to be subjected to chelating stabilization treatment for the first time; and the treated fine-particle fly ash and the treated coarse-particle fly ash are converged and subjected to dust removal treatment and secondary chelating stabilization treatment in sequence. According to the method, the consumption of consumables in the flue gas purification process is reduced, the action efficiency of desulfurization and heavy metal fixing agents is improved, the fly ash yield and harmless treatment cost are reduced, and fly ash reduction and efficient stabilization treatment of heavy metals are realized.

Owner:BEIJING CAPITAL ENVIRONMENT TECH CO LTD

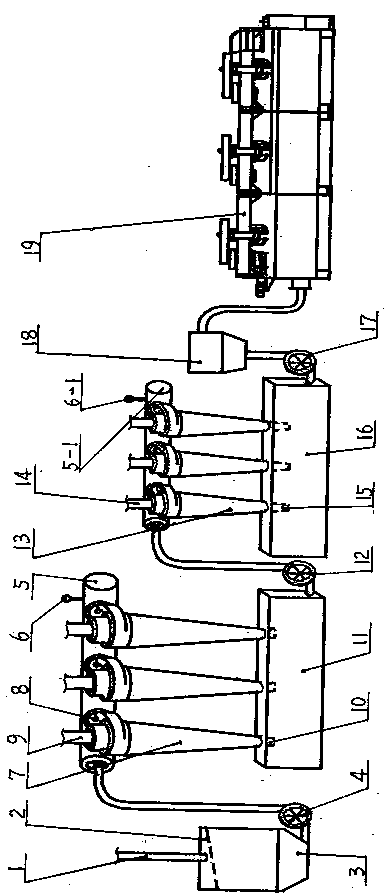

Small and medium sized fuel gas production device based on household refuse grading and flash pyrolysis and gasification

ActiveCN105907428AGasification processes detailsGranular/pulverulent flues gasificationFluidized bedIron removal

The invention provides a small and medium sized fuel gas production device based on household refuse grading and flash pyrolysis and gasification. The small and medium sized fuel gas production device comprises an iron-removal pulverizer, a riser, a circulating fluidized bed, a gas distributor, an ash discharging pipe, a gas inlet pipe, a feed inlet, a first-stage gas and solid separator, a coarse ash circulating pipe, a back feeder, a second-stage gas and solid separator, a fine ash circulating pipe, an entrained-flow bed, a fuel gas outlet, an air heat-exchanger and the like. The iron-removal pulverizer and the riser are arranged at the front end of the circulating fluidized bed sequentially; the gas distributor and the ash discharging pipe are arranged at the bottom of the circulating fluidized bed; the entrained-flow bed is arranged at the position which is 1000-2000 mm away from the bottom of the circulating fluidized bed; an oil gas inlet is arranged at the position which is 500-3000 mm away from the entrained-flow bed; the second-stage gas and solid separator is arranged at the top of the circulating fluidized bed; a coarse-particle ash circulating pipe of the first-stage gas and solid separator is connected to the bottom of the circulating fluidized bed, and a fine-particle ash circulating pipe of the first-stage gas and solid separator is connected to the entrained-flow bed through the back feeder; and a gas outlet is connected with the fuel gas outlet through the air heat exchanger.

Owner:田原宇

Preparation method of ceramic tile applicable to wireless charging and ceramic tile

ActiveCN108484154AHigh dimensional accuracyImprove charging efficiencyTransformersTransformers/inductances coils/windings/connectionsMetallurgyAdhesive

The invention provides a preparation method of a ceramic tile applicable to wireless charging and the ceramic tile. The preparation method comprises the following steps: S1, sintering a soft ferrite core or a magnetic block; S2, crushing the sintered soft ferrite core or magnetic block into particles with different particle sizes, and dividing the particles with different particle sizes into coarse particles and fine particles; S3, uniformly mixing an adhesive for use; S4, strongly mixing the coarse particles, the fine particles and the uniformly mixed adhesive to obtain a uniformly mixed fluid; S5, by a vacuum and high pressure die casting technology, pressing the uniformly mixed fluid into a ceramic tile blank; S6, sintering and curing the ceramic tile blank into the ceramic tile applicable to wireless charging. A magnetic separating piece required for high-power wireless charging, which is produced from the ceramic tile, has the characteristics of large area, integration, good surface flatness and high dimensional accuracy; a produced charging device is impact-resistant, is adaptable to superhigh power and is high in charging efficiency.

Owner:SHENZHEN KRY-SCN TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap