Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Ferrite core" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electronics, a ferrite core is a type of magnetic core made of ferrite on which the windings of electric transformers and other wound components such as inductors are formed. It is used for its properties of high magnetic permeability coupled with low electrical conductivity (which helps prevent eddy currents). Because of their comparatively low losses at high frequencies, they are extensively used in the cores of RF transformers and inductors in applications such as switched-mode power supplies, and ferrite loopstick antennas for AM radio receivers.

Fixing device

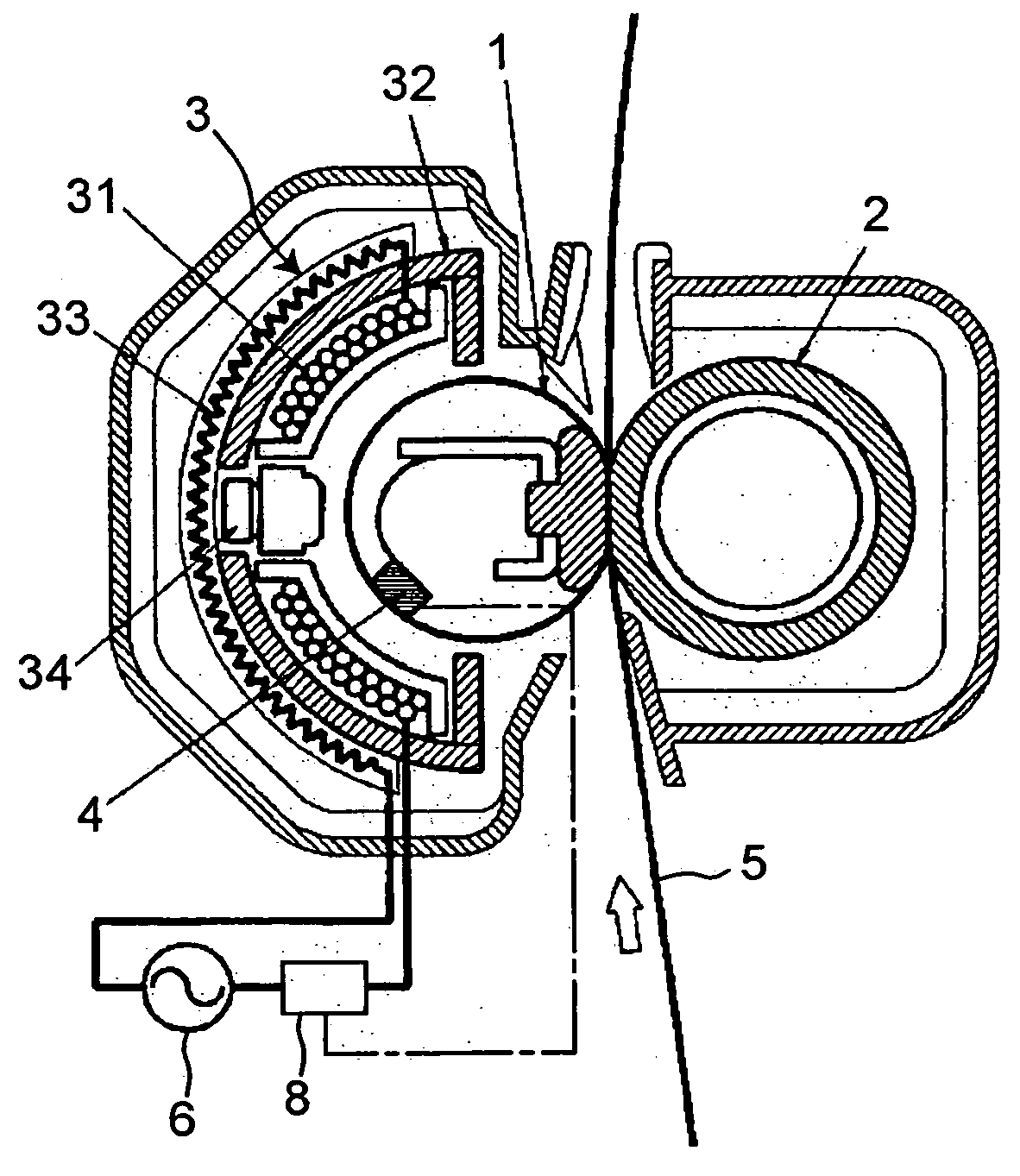

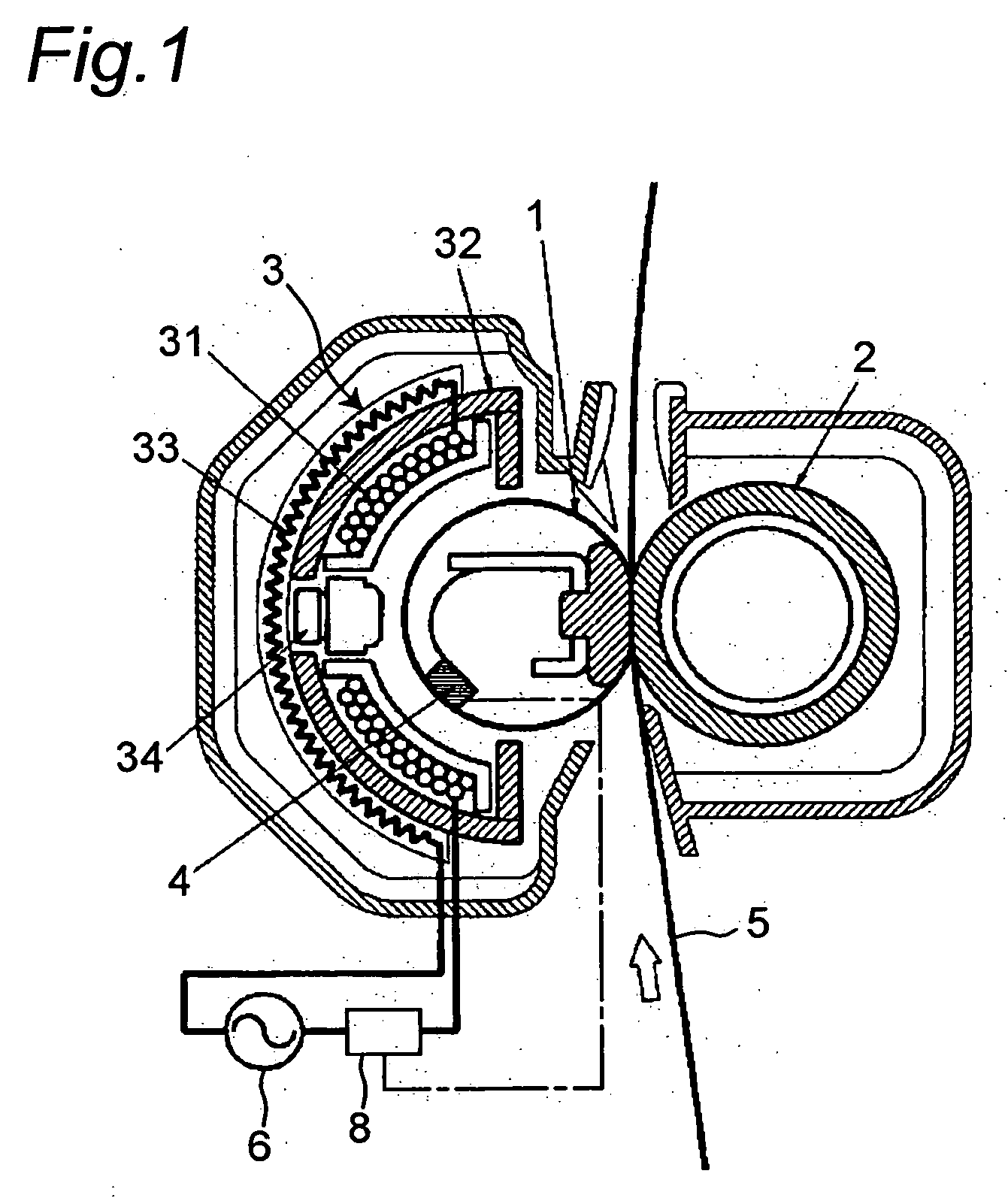

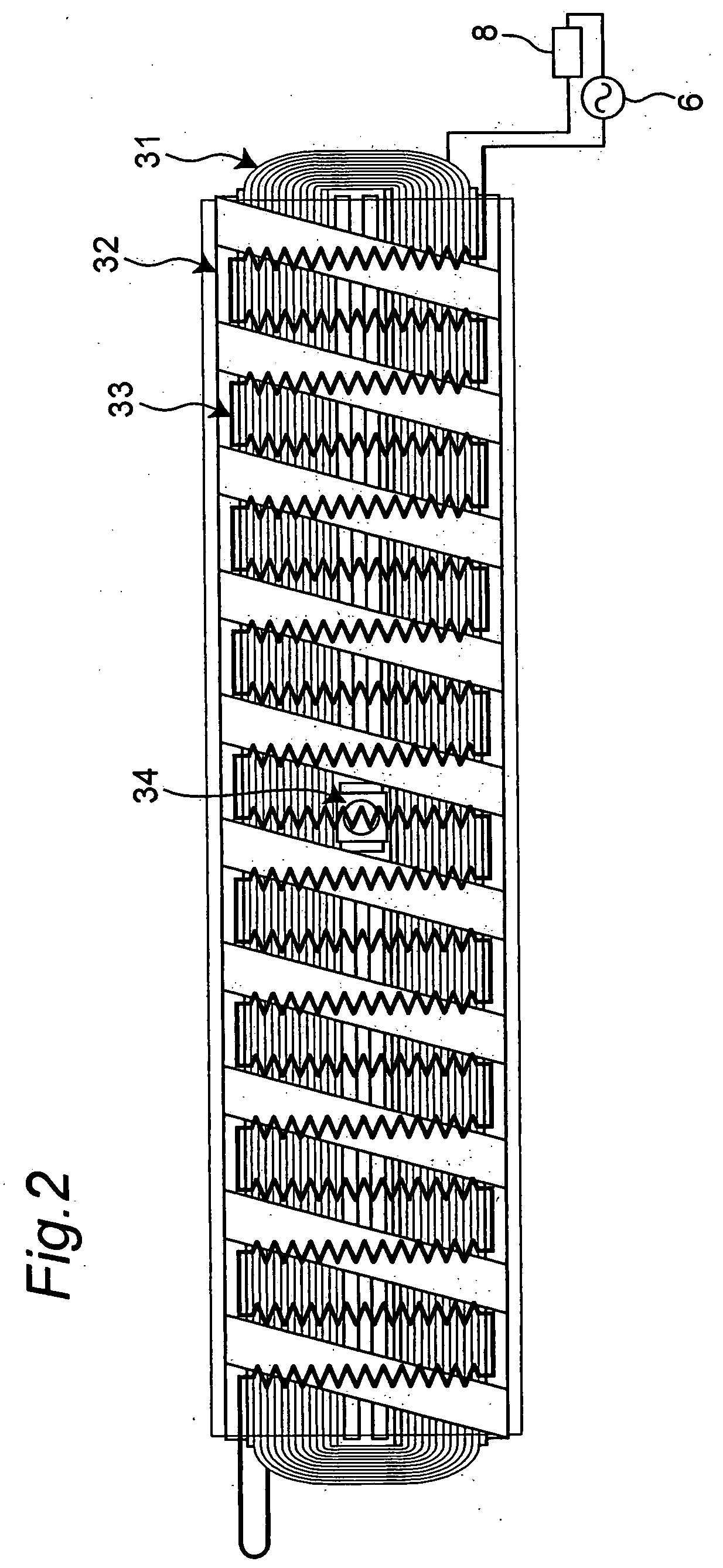

ActiveUS20060088324A1Electrographic process apparatusInduction heating apparatusSmoking startedSmoking starts

Owner:KONICA MINOLTA BUSINESS TECH INC

Tapered ferrite core, its production method and apparatus, and inductance device comprising it

ActiveUS20200135393A1High precisionProduce efficientlyRevolution surface grinding machinesTransformers/inductances coils/windings/connectionsEngineeringMechanical engineering

A tapered ferrite core having a solid or hollow cylindrical shape with larger length than outer diameter, and comprising a ground taper portion in at least one end portion, the taper portion having ground streaks extending in the longitudinal direction of the ferrite core, can be formed by centerless-grinding a rotating ferrite core by a rotating grinder.

Owner:PROTERIAL LTD

Preparation method of ceramic tile applicable to wireless charging and ceramic tile

ActiveCN108484154AHigh dimensional accuracyImprove charging efficiencyTransformersTransformers/inductances coils/windings/connectionsMetallurgyAdhesive

The invention provides a preparation method of a ceramic tile applicable to wireless charging and the ceramic tile. The preparation method comprises the following steps: S1, sintering a soft ferrite core or a magnetic block; S2, crushing the sintered soft ferrite core or magnetic block into particles with different particle sizes, and dividing the particles with different particle sizes into coarse particles and fine particles; S3, uniformly mixing an adhesive for use; S4, strongly mixing the coarse particles, the fine particles and the uniformly mixed adhesive to obtain a uniformly mixed fluid; S5, by a vacuum and high pressure die casting technology, pressing the uniformly mixed fluid into a ceramic tile blank; S6, sintering and curing the ceramic tile blank into the ceramic tile applicable to wireless charging. A magnetic separating piece required for high-power wireless charging, which is produced from the ceramic tile, has the characteristics of large area, integration, good surface flatness and high dimensional accuracy; a produced charging device is impact-resistant, is adaptable to superhigh power and is high in charging efficiency.

Owner:SHENZHEN KRY-SCN TECH CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap