High power impatt diode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

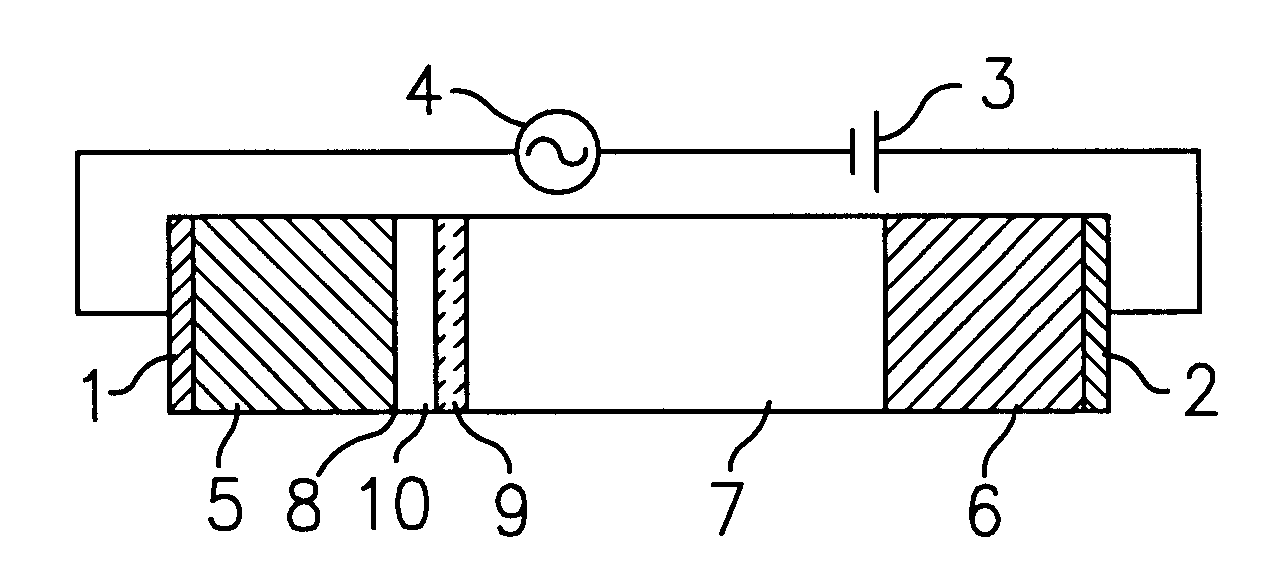

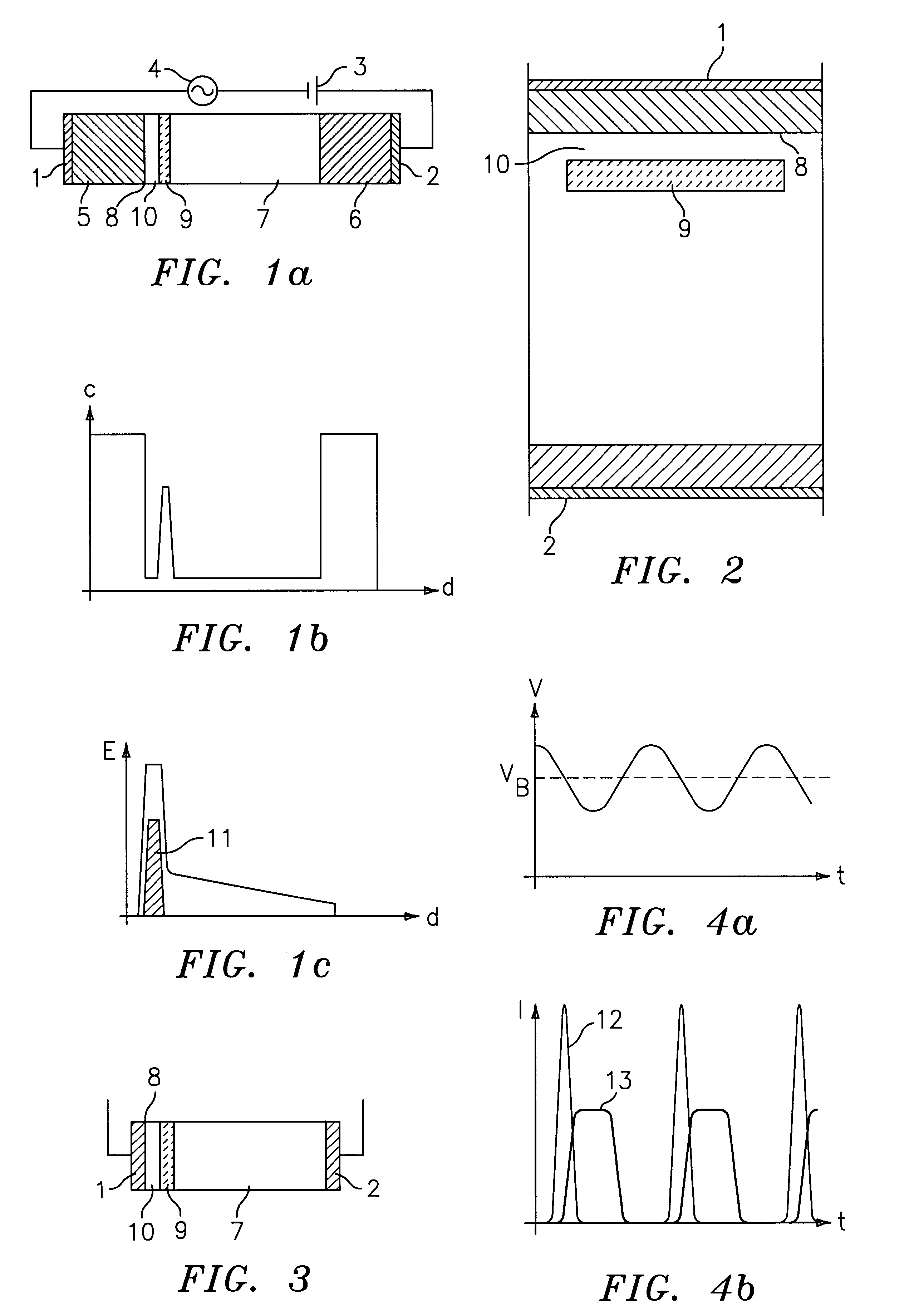

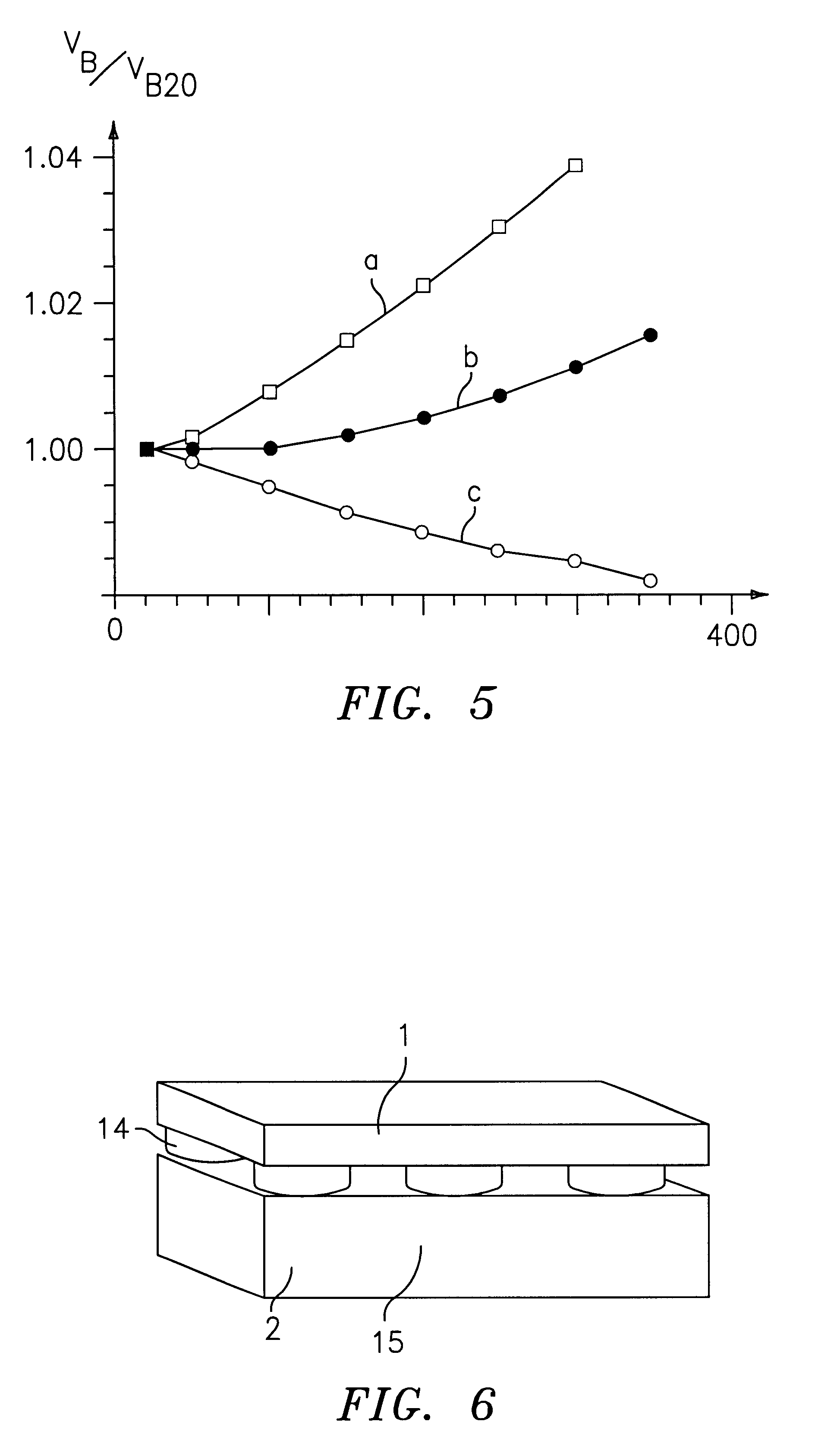

FIG. 1 illustrates a high power IMPATT (Impact Ionisation Avalanche Transit Time) diode for generation of power signals with a frequency above 30 GHz. This diode has two electrodes, namely a cathode 1 and an anode 2, adapted to be connected to a direct voltage source 3 and positioned in a microwave cavity 4 designed so as to have the resonance at desired microwave frequency. A semiconductor layer of crystalline SiC is arranged between the two electrodes and has a highly doped p-type layer 5 in contact with the metal cathode 1, a highly doped n-type layer 6 in contact with the metal anode 2, and a low doped n-type drift layer 7 interconnecting the layers 5 and 6. The layers 5 and 7 forms a pn-junction 8, which is reverse biased by the direct voltage of the direct voltage source 3. Furthermore, a thin n-type layer 9 with a substantially higher doping concentration than the drift layer is arranged in the drift layer 7 at a short distance from the highly doped p-type layer 5. The thin l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap