Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Thermal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal resistance is a heat property and a measurement of a temperature difference by which an object or material resists a heat flow. Thermal resistance is the reciprocal of thermal conductance.

Smart chair for students

InactiveCN106263597AEasy to monitor in real timeEnsure good postureStoolsSchool benchesTemperature controlWireless transceiver

The present invention relates to the field of smart chairs, and in particular to a smart chair for students. The smart chair comprises a seat, a seat back, handrails, a head support device, a toolbox unit, and a smart camera. A central processor, a wireless transceiver, a temperature controller and a voice announcer are integrated in the seat back, thermal resistance wires are evenly distributed in the seat, the temperature controller is electrically connected with the thermal resistance wires, the head support device has a pressure sensor inside, the central processor is electrically connected with the smart camera, the wireless transceiver device, the temperature controller, the voice announcer and the pressure sensor. The central processor communicates with the mobile monitoring terminal through the wireless transceiver device. The invention has the advantages of strong function and can cool the seat in the cold days. The chair can ensure that the user's sitting position is correct and the user's eyesight and the health of the bones can be protected. The setting of the toolbox does not cause the desk to be disheveled by the tool; the smart camera captures the image video signal to facilitate the guardian or teacher to monitor the learning of the student in real time.

Owner:张佳琪

Method and device for quickly decreasing temperature

InactiveCN106325063ARealize automatic controlFast cooling rateCompression machinesThermometer testing/calibrationAutomatic controlEngineering

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Microchannel heat exchanger and air conditioner

InactiveCN105864888AImprove drainage efficiencyReduce heat transferCondensate preventionLighting and heating apparatusEngineeringHeat exchanger

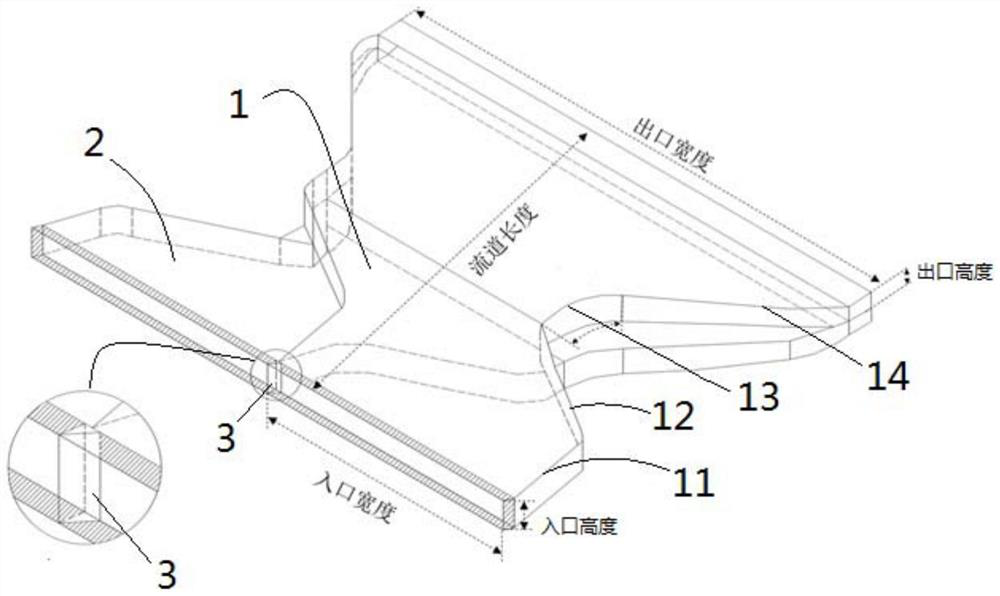

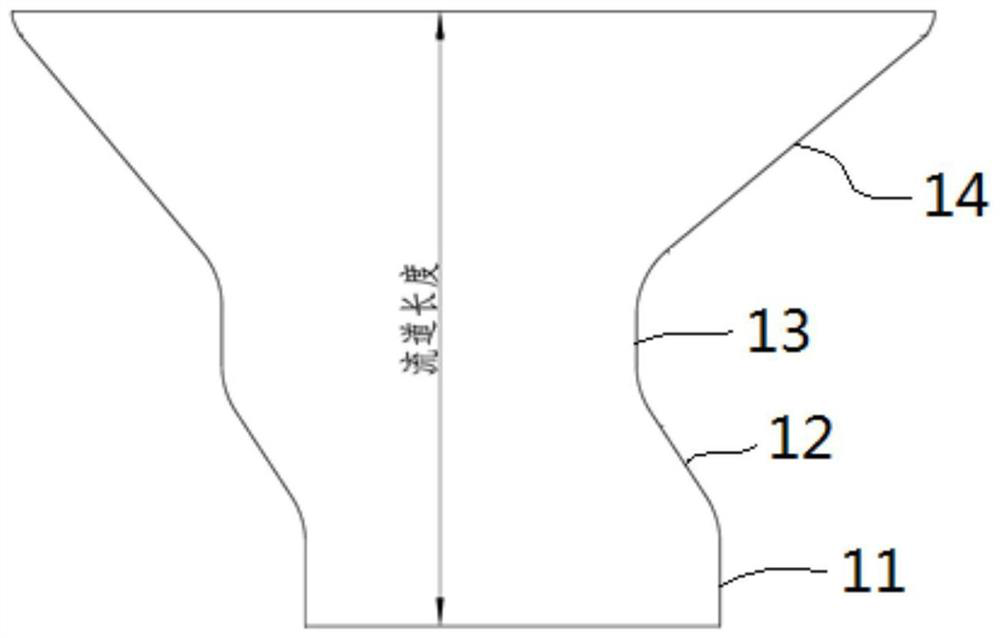

The invention discloses a microchannel heat exchanger and an air conditioner and relates to the technical field of air conditioners. The microchannel heat exchanger and the air conditioner are invented to solve the problem that in the prior art, heat exchange wind resistance and heat transfer resistance are increased due to the fact that condensate water or defrosted water at the roots of fins are not liable to be guided out. The microchannel heat exchanger comprises microchannel flat pipes arranged transversely. The upper surfaces of the microchannel flat pipes incline downwards from the windward side to the leeward side of the microchannel heat exchanger. The microchannel heat exchanger is used for conducting heat exchange with airflow.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

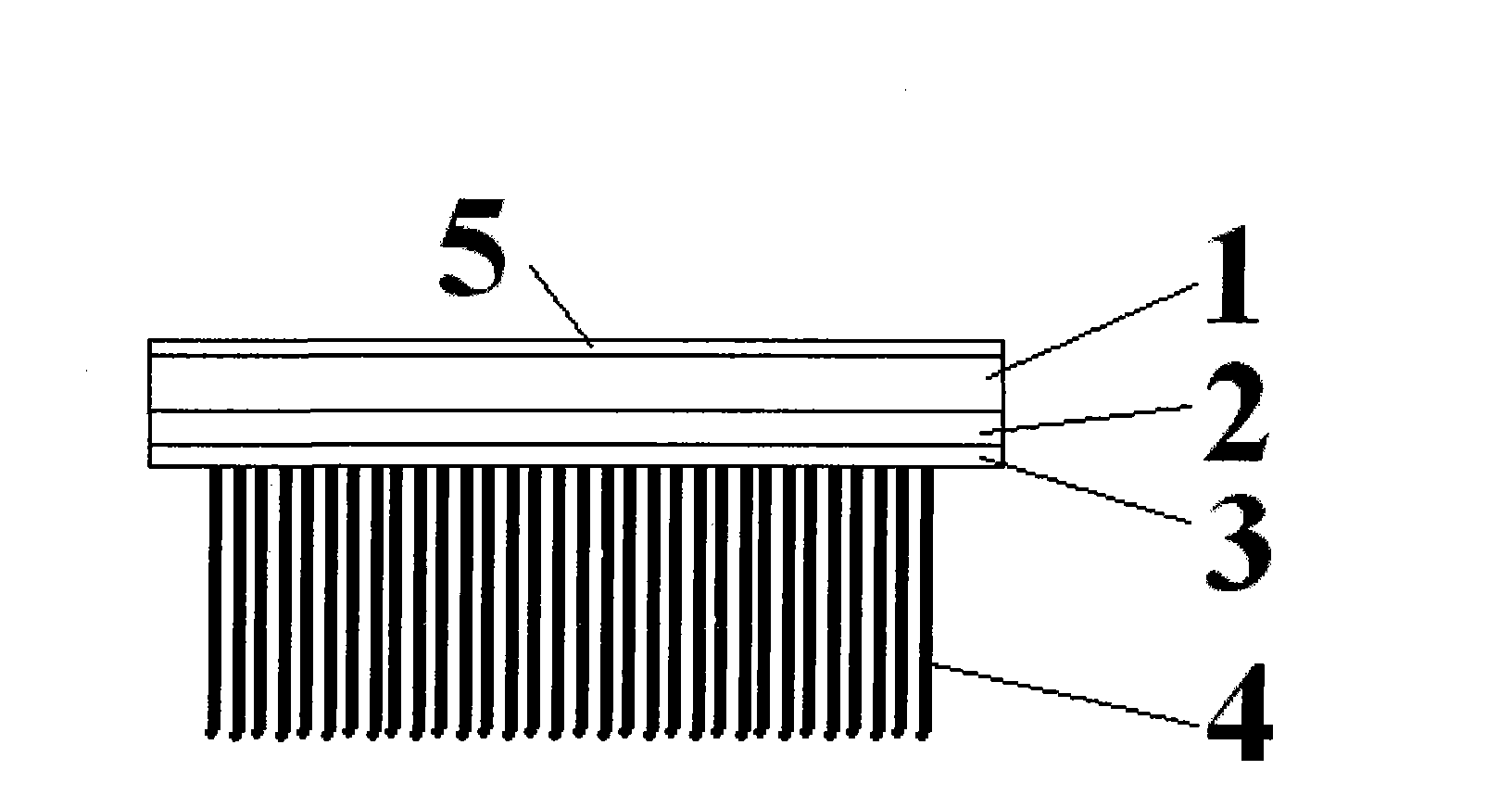

Method for preparing micro-system radiating device

InactiveCN101794753ASmall sizeLarge specific surface areaSemiconductor/solid-state device detailsSolid-state devicesCrystal structureThermal contact

Owner:NANTONG DAQING ENERGY SAVING TECH +1

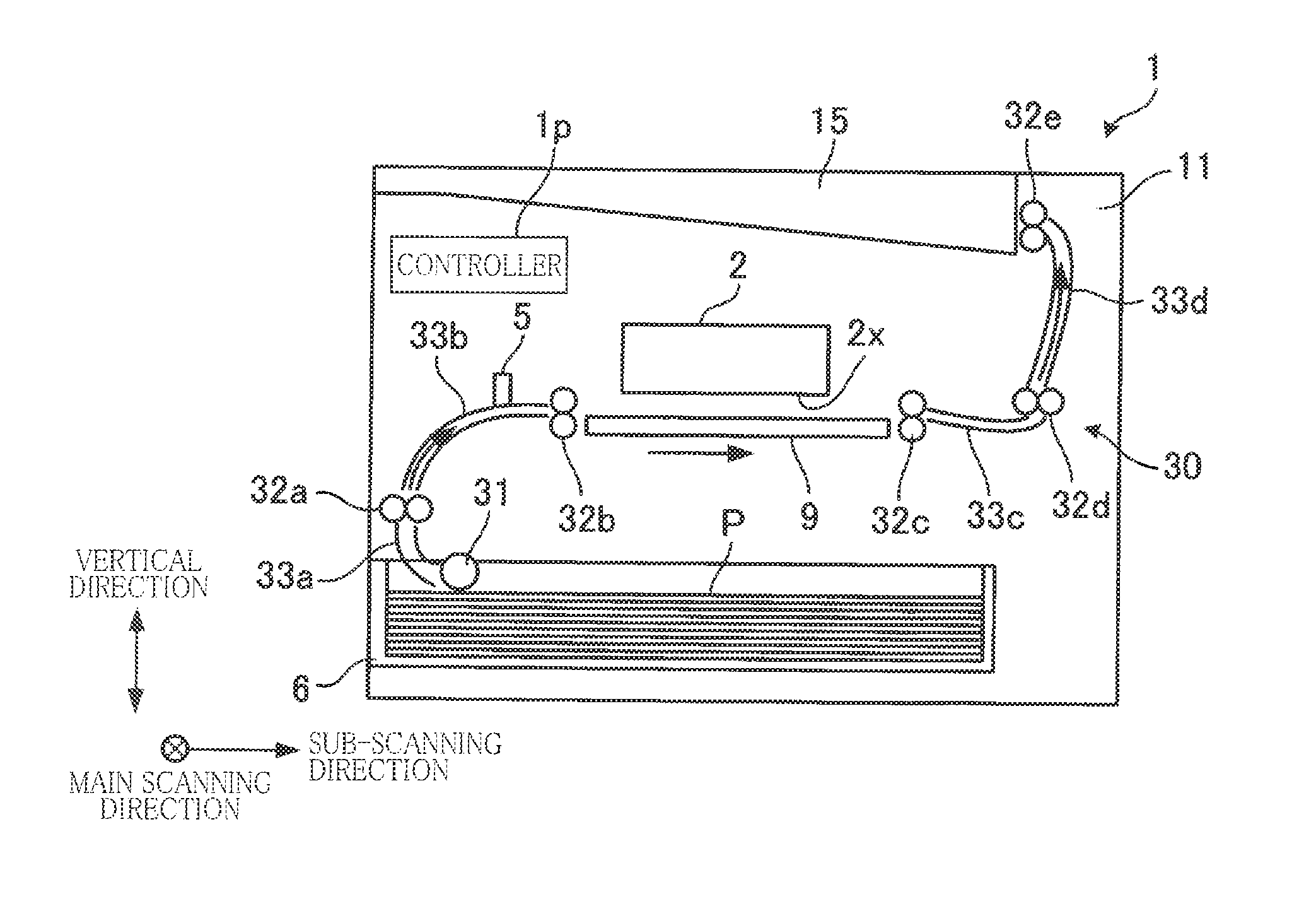

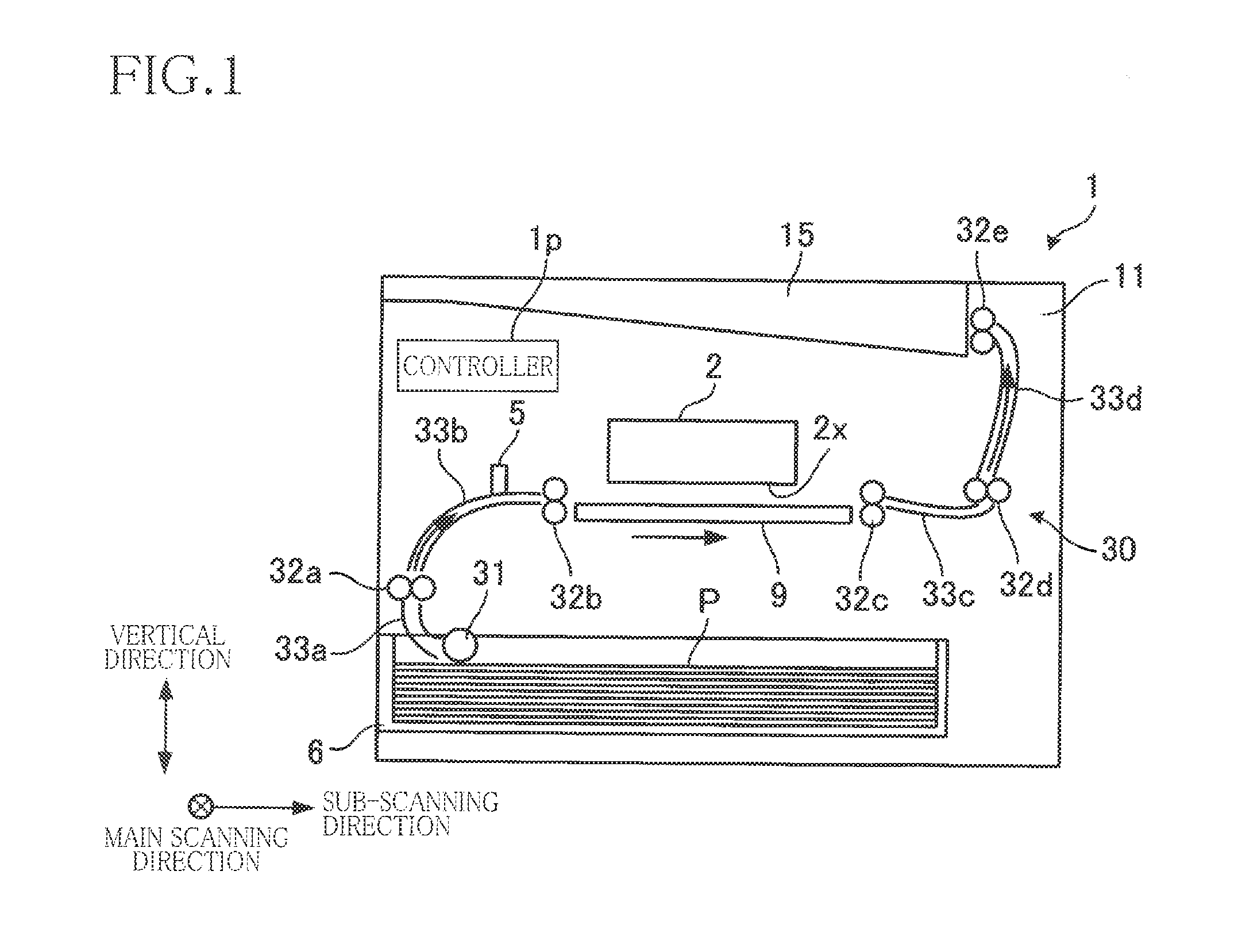

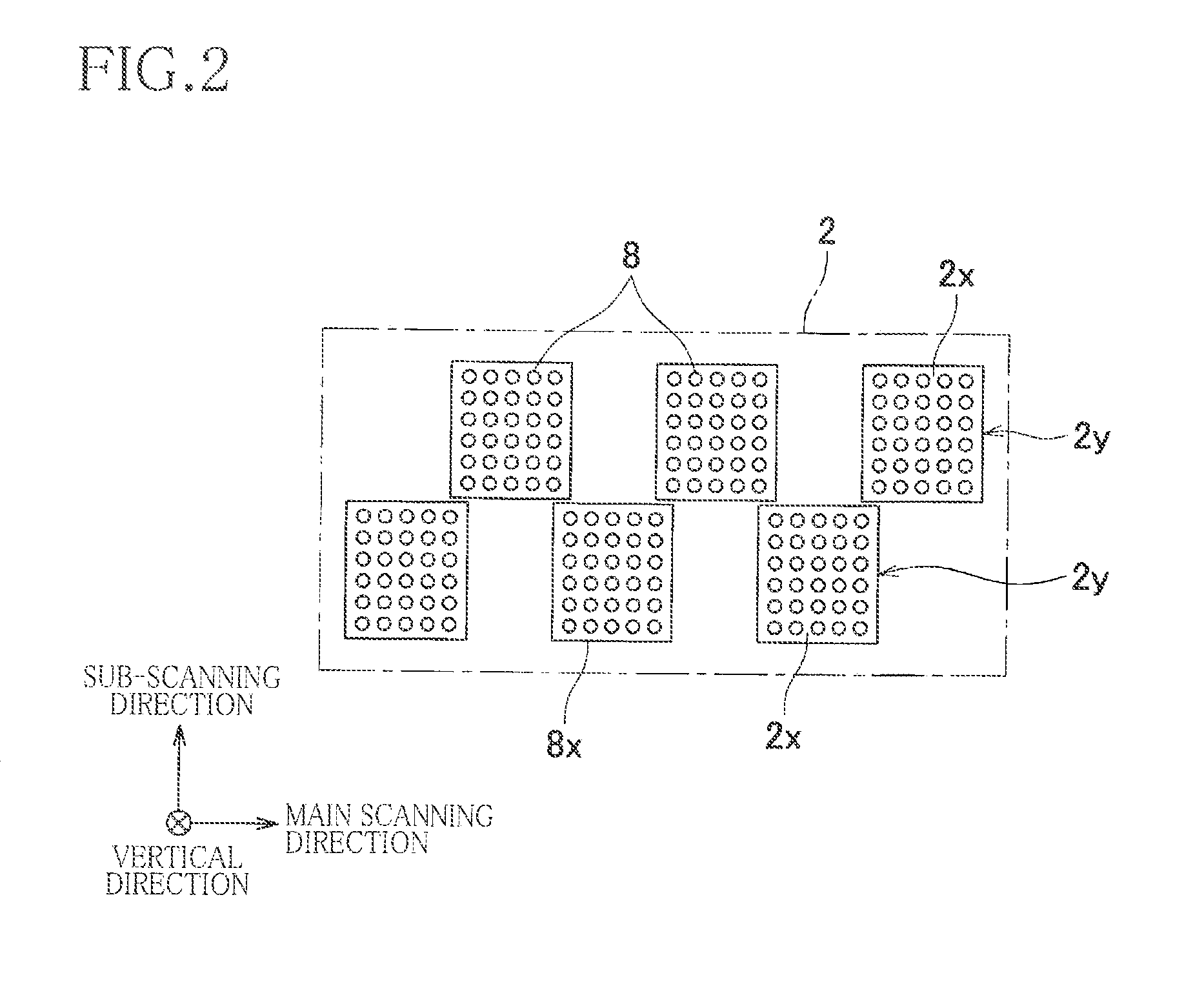

Liquid ejection apparatus

ActiveUS20140292887A1Reduce the differenceDeterioration can be suppressedInking apparatusOther printing apparatusHeat resistanceEngineering

Owner:BROTHER KOGYO KK

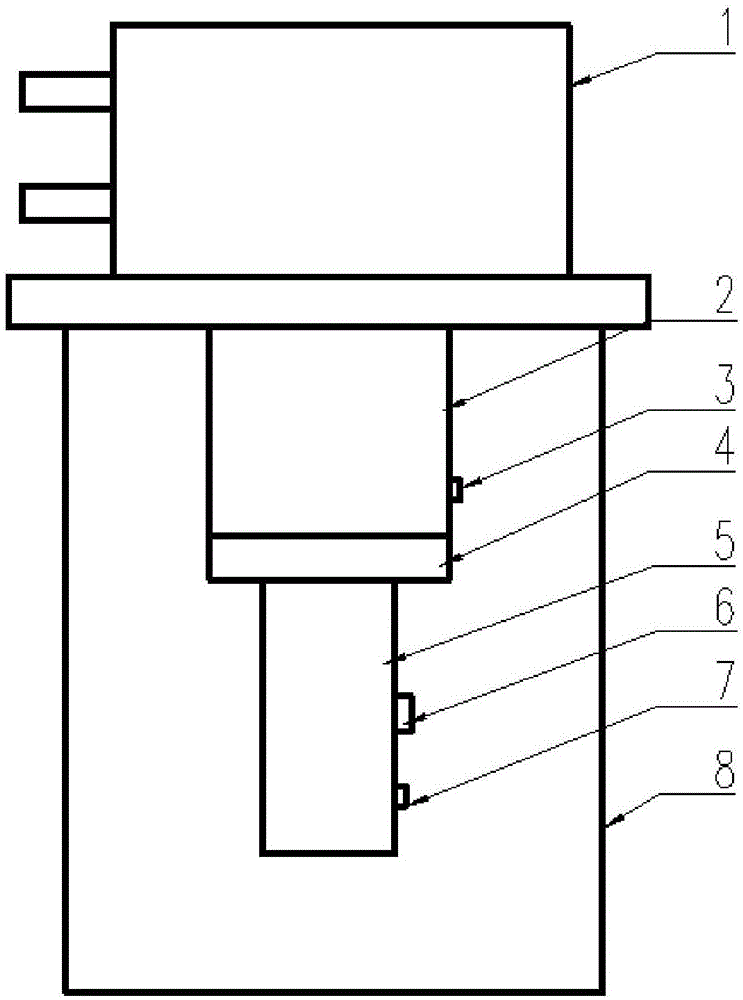

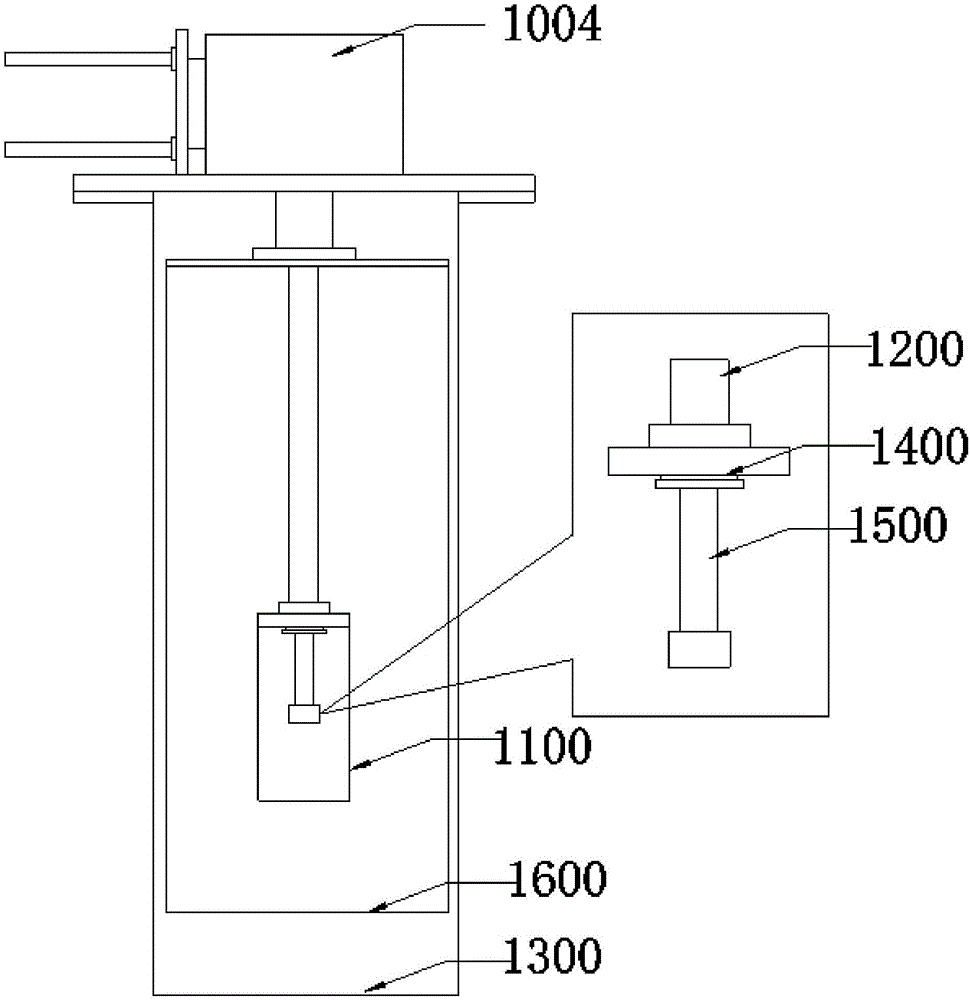

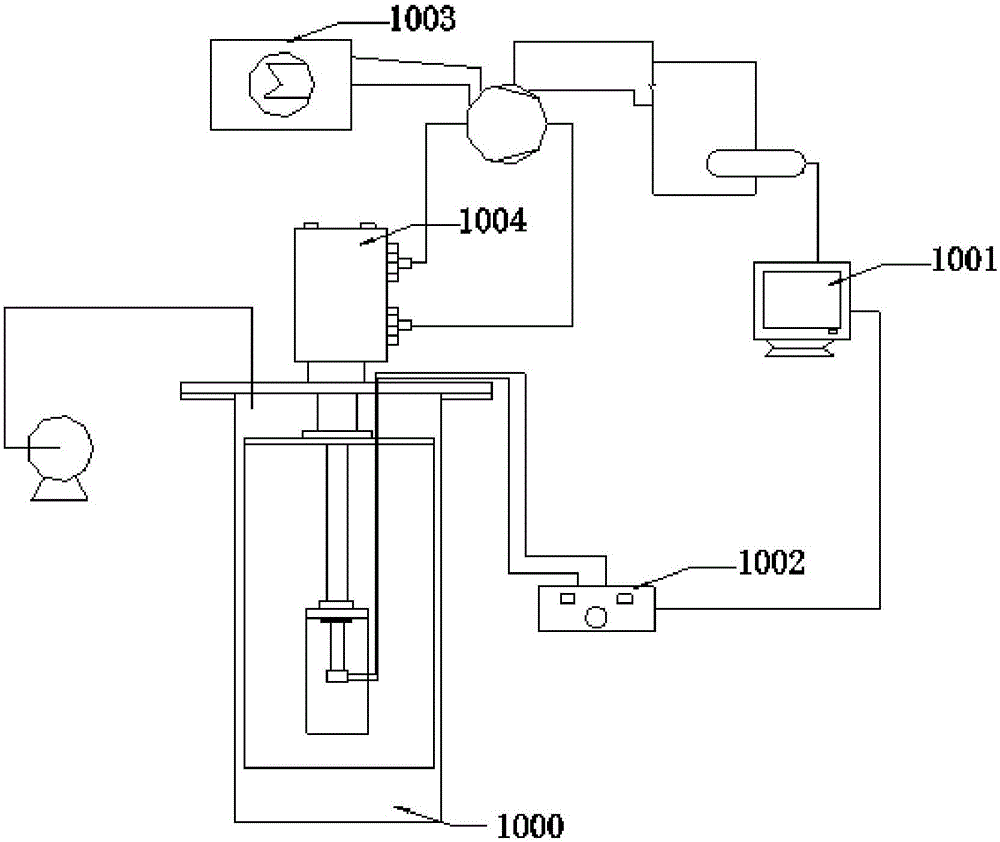

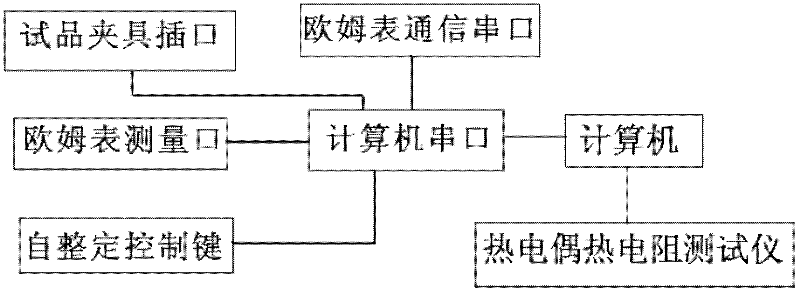

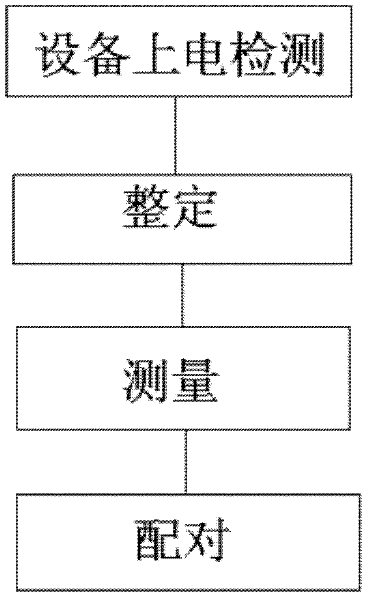

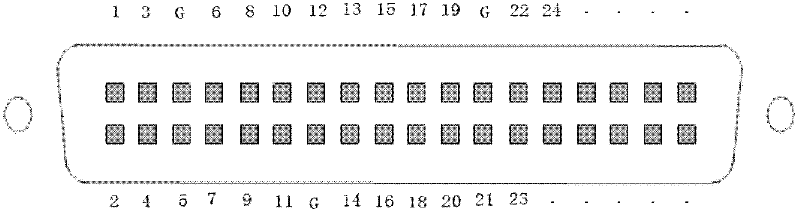

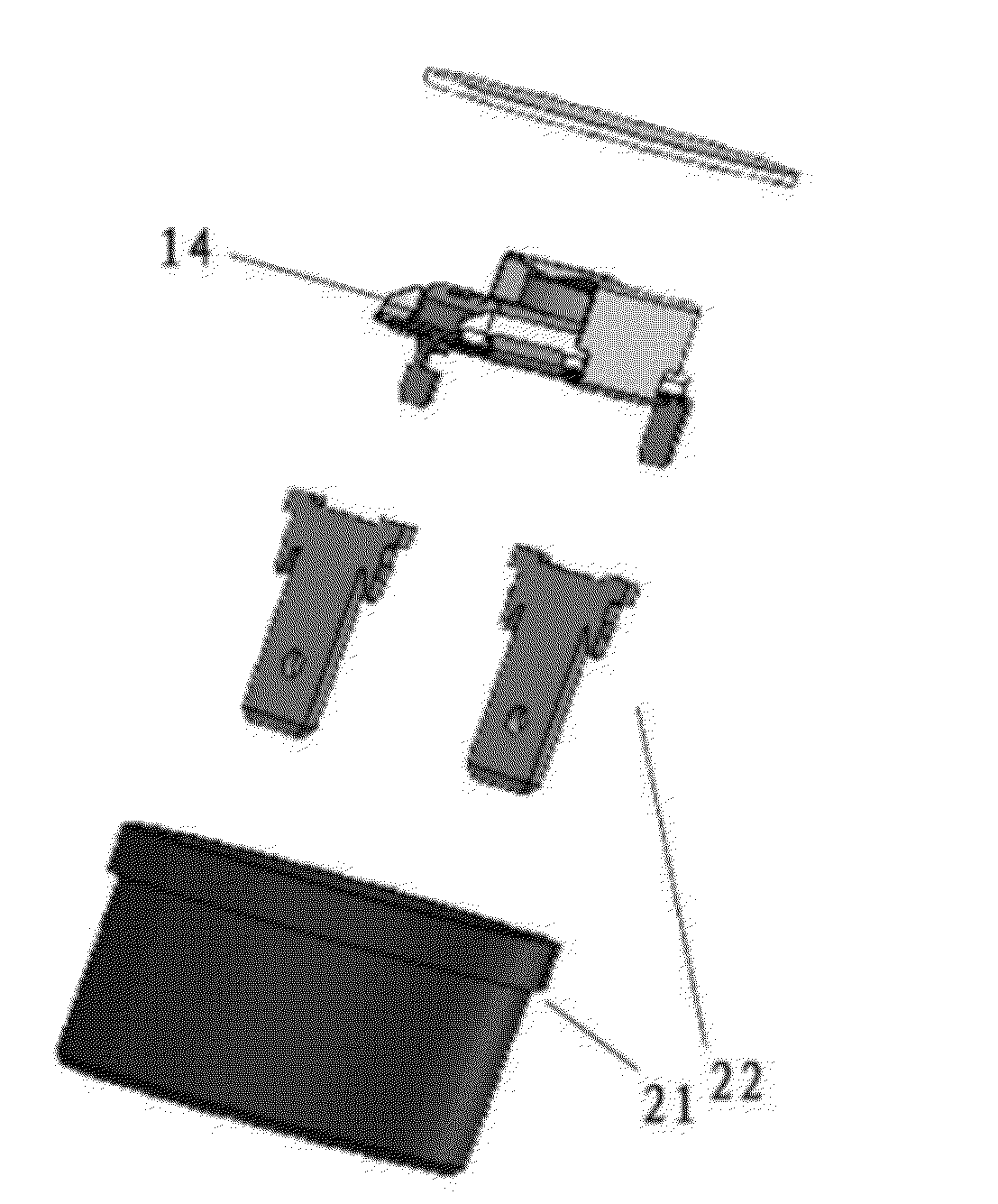

Test system of temperature sensor

ActiveCN102435351AAvoid duplication of effortFully automatedThermometer testing/calibrationElectricityEngineering

Owner:武汉海创电子股份有限公司

Method for manufacturing thermoelectric module having high-insulation thermal coupling surface, low thermal resistance and no brazing layer

ActiveCN101783386ASolve electrical connection problemsReduce work stepsThermoelectric device manufacture/treatmentThermoelectric device detailsMetal coatingThermoelectric element

The invention relates to a method for manufacturing a thermoelectric module having a high-insulation thermal coupling surface, low thermal resistance and no brazing layer. The method comprises the following steps: manufacturing an insulated frame which is embedded with at least two metal electric-connection terminals by an injection molding method; preparing thermoelectric elements; placing the thermoelectric elements in through holes of the insulated frame; respectively spraying metal coating on the upper ends and the lower ends of the thermoelectric elements; grinding the sprayed surfaces; and covering an alumina film layer on the grounded surfaces respectively, wherein the insulated frame is provided with a plurality of through holes in which thermoelectric elements are placed; grooves of which the number corresponds to that of the metal electric-connection terminals are formed in side frames of the insulated frame and are communicated with different through holes; the first end parts of the metal electric-connection terminals are respectively arranged in the grooves, while the second end parts are positioned outside the side frames of the insulated frame. The thermoelectric module manufactured by the manufacturing method has the high-insulation thermal coupling surface, the low resistance and no brazing layer, and has the characteristics of improvement on the reliability of the electric connection between the thermoelectric elements and an external system, simplification of operation steps, reduction of material cost, excellent performance, and suitability for large-scale generalization and application.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD +1

Heat-storage warm-keeping chinlon 6 short fiber and preparation method thereof

ActiveCN109402765AImprove dispersion uniformityLow viscosityMonocomponent polyamides artificial filamentArtifical filament manufactureFiberEmissivity

The invention relates to a heat-storage warm-keeping chinlon 6 short fiber and a preparation method thereof. The method includes: spinning a heat-storage warm-keeping chinlon 6 melt to prepare a heat-storage warm-keeping chinlon 6 short fiber, wherein the chinlon 6 is prepared from a mixture of caprolactam, a heat-storage powder coated with a catalyst, and water, and successively through a heat-storage powder surface chain growth reaction, a ring-opening pre-polycondensation reaction and a final-polycondensation reaction; wherein the heat-storage powder surface chain growth reaction is a reaction that the caprolactam on the surface of the heat-storage powder is polymerized to form a linear molecular chain under effect of the catalyst. A fabric, being 200-250 g / m<2> in gram weight and prepared from the fiber, is not less than 0.944 m<2>*K / W in thermal resistance, not less than 6.09 in Clo value, not less than 91.4% in warm-keeping rate, not less than 0.90 in far-infrared emissivity andnot less than 1.5 DEG C in far-infrared radiation temperature increasing value. The heat-storage warm-keeping chinlon 6 short fiber has good dispersion uniformity of the heat-storage powder and has excellent heat-storage and warm-keeping function.

Owner:WUXI MINGTE CHEM FIBER CO LTD

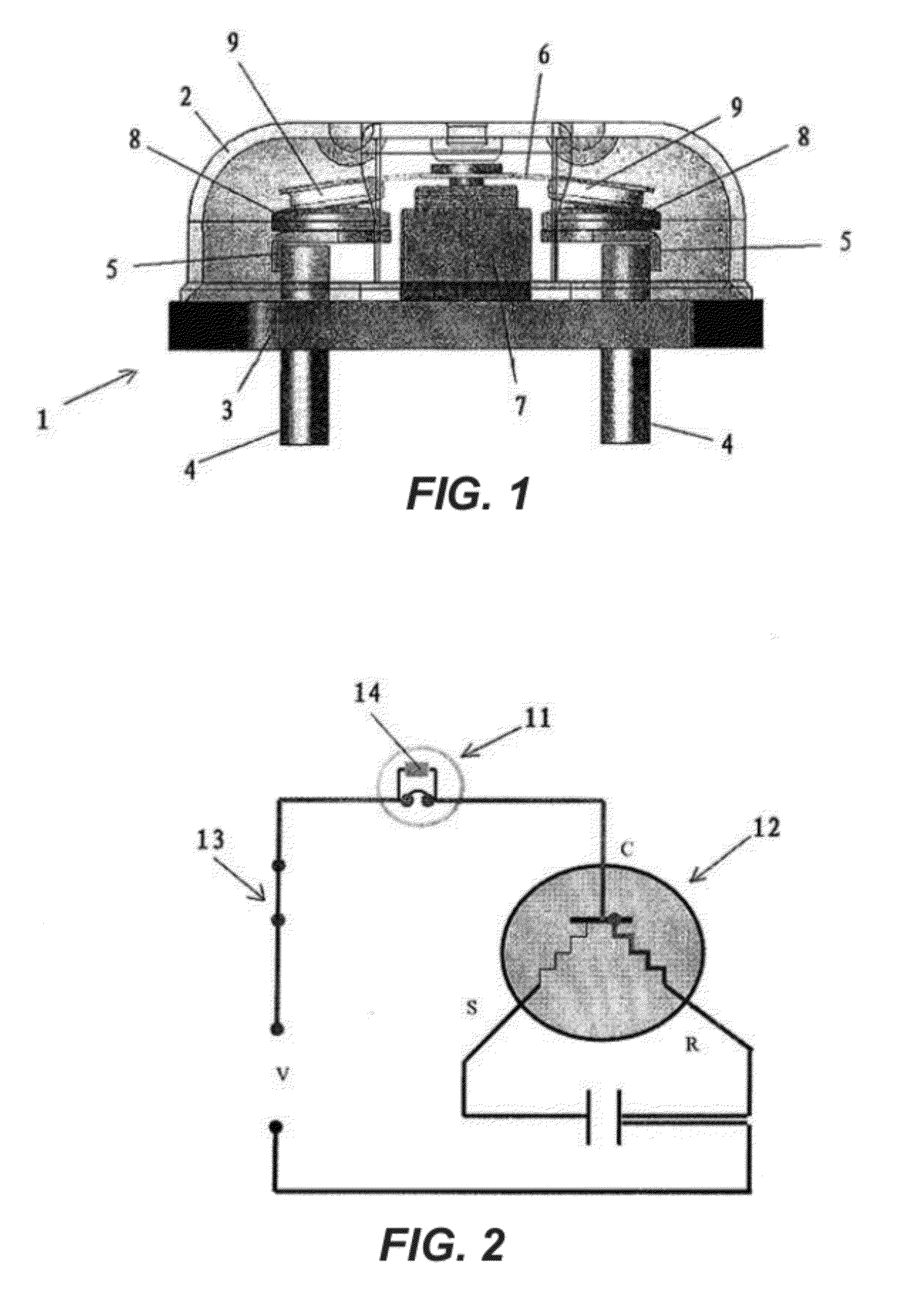

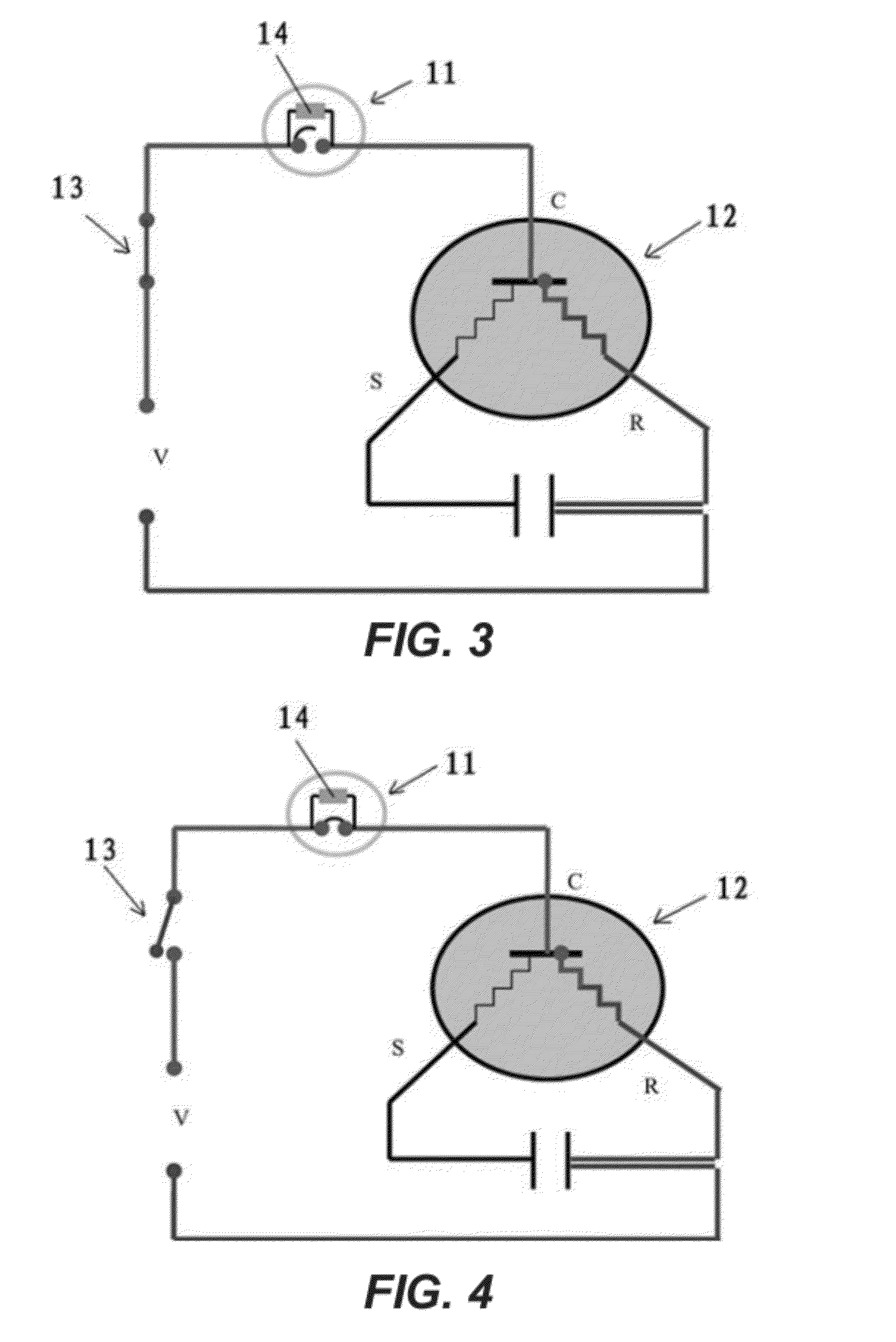

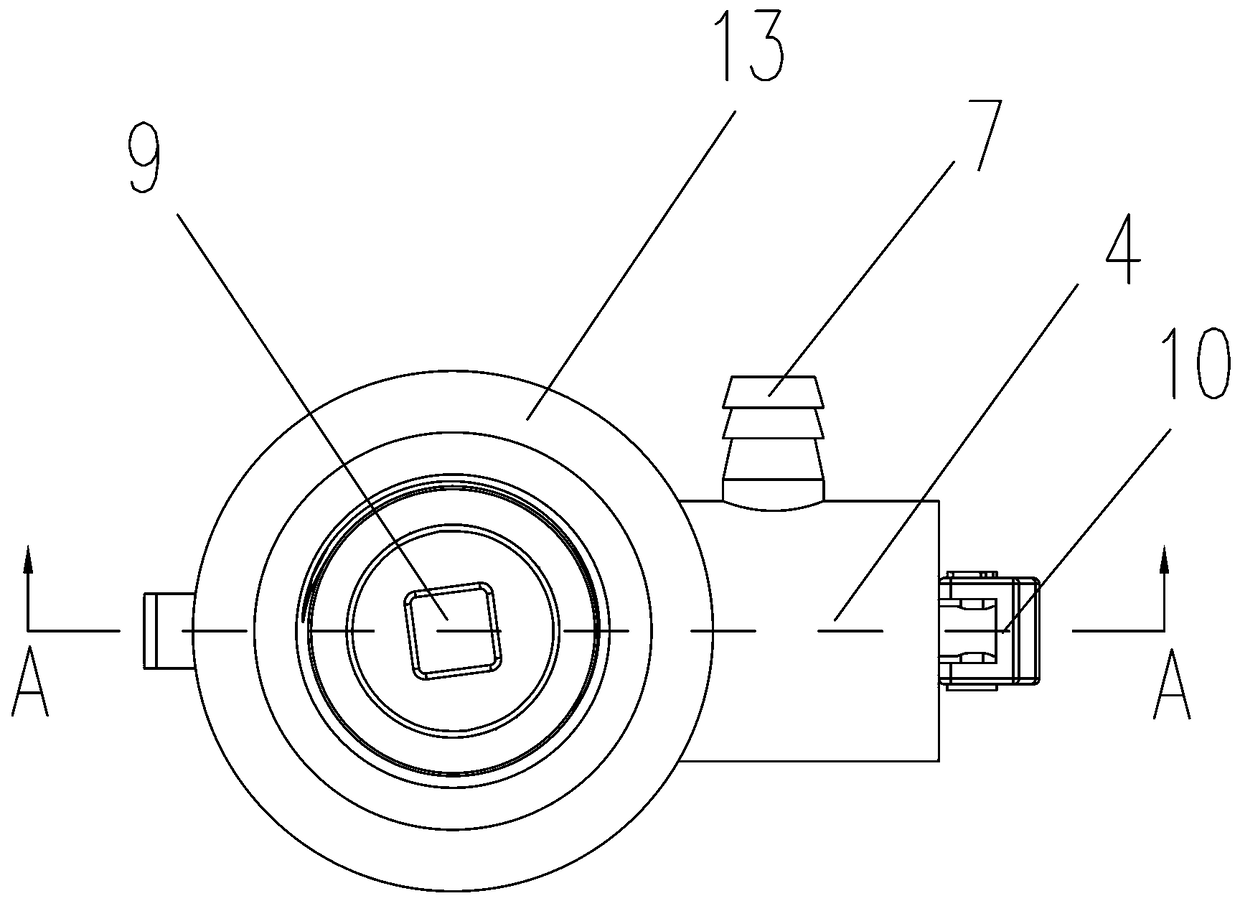

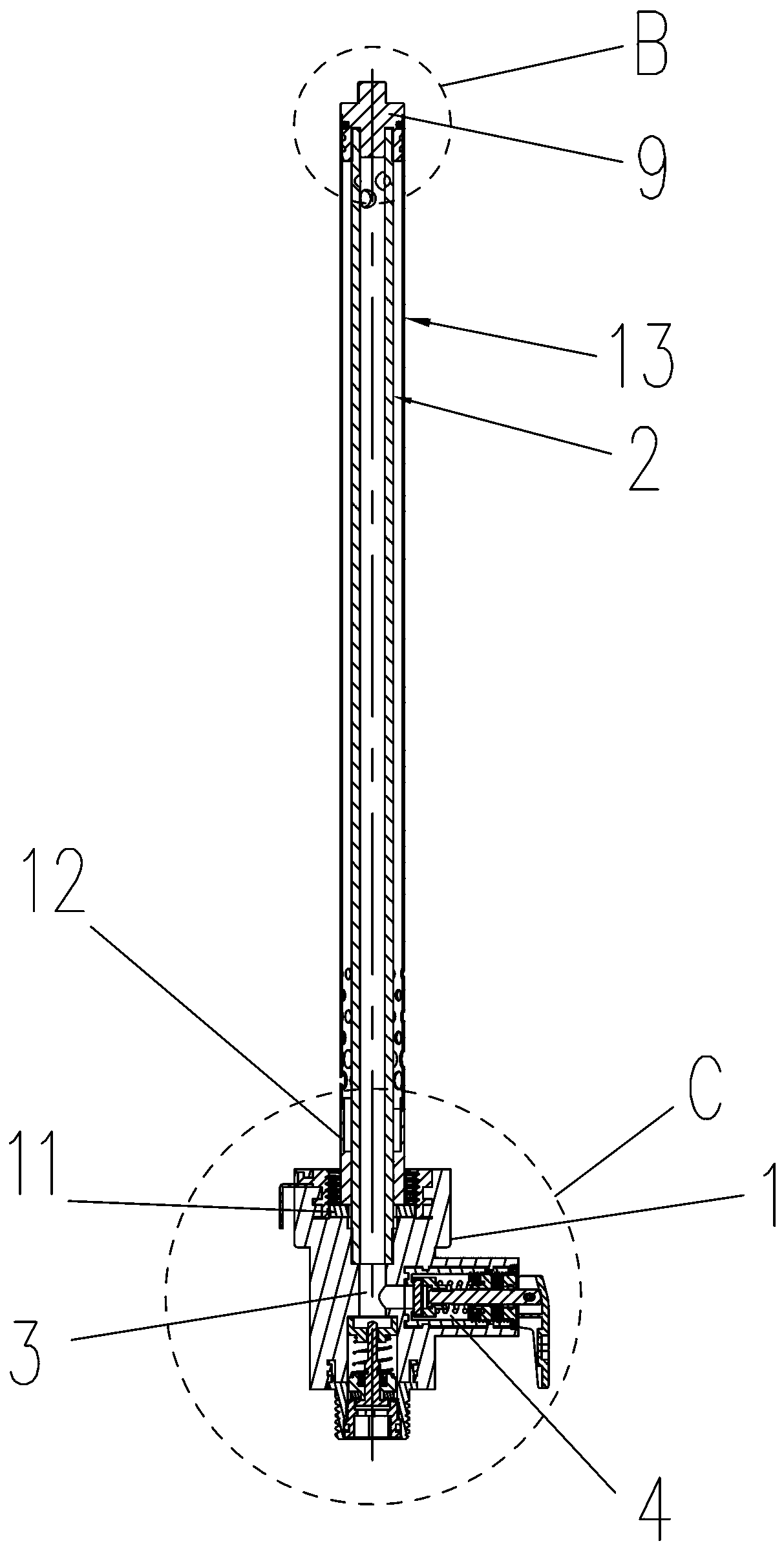

Compressor for an air-conditioner with a motor protector and an air-conditioner

InactiveUS20120236441A1Revolutionary improvement to long-term knowledgeExtended operating cycleEmergency protective circuit arrangementsMotor parameterEvaporatorThermal resistance

Owner:SESATA SCI & TECH CHANGZHOU CO LTD

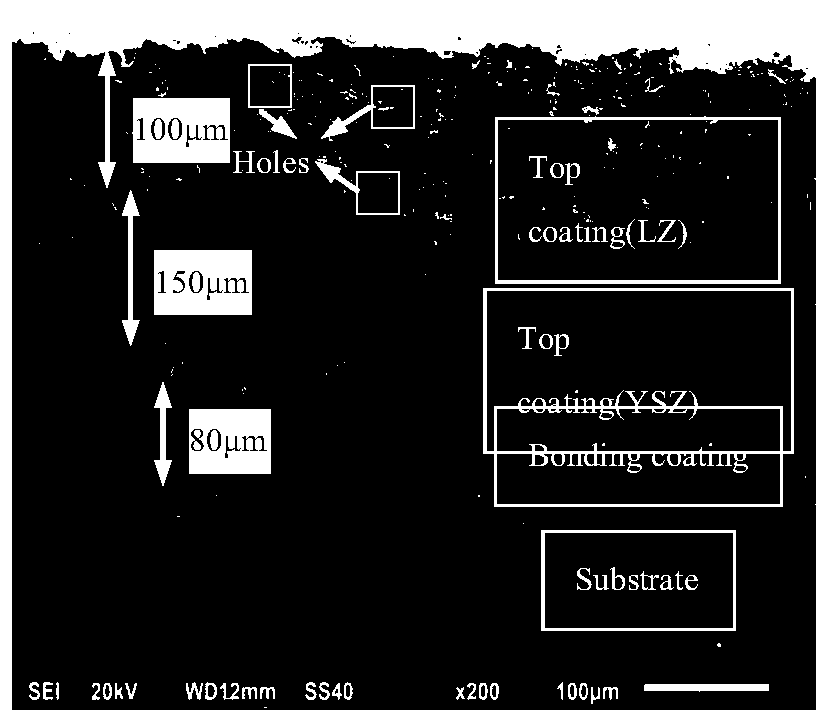

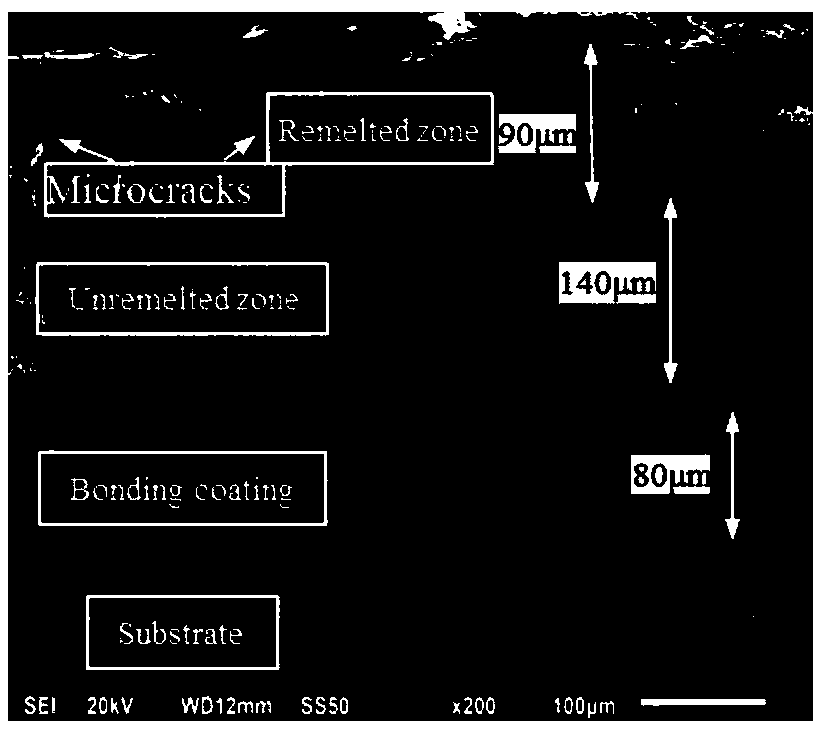

Preparation method for improving thermal shock resistance of double-ceramic-layer TBCs

InactiveCN110616394AImprove thermal shock resistanceImprove densification performanceMolten spray coatingSuperimposed coating processPre treatmentSuperalloy

Owner:HEBEI UNIV OF TECH

Composite material for ceramic sealing ring and preparation method thereof

Owner:HARBIN XINHUI SPECIAL CERAMIC

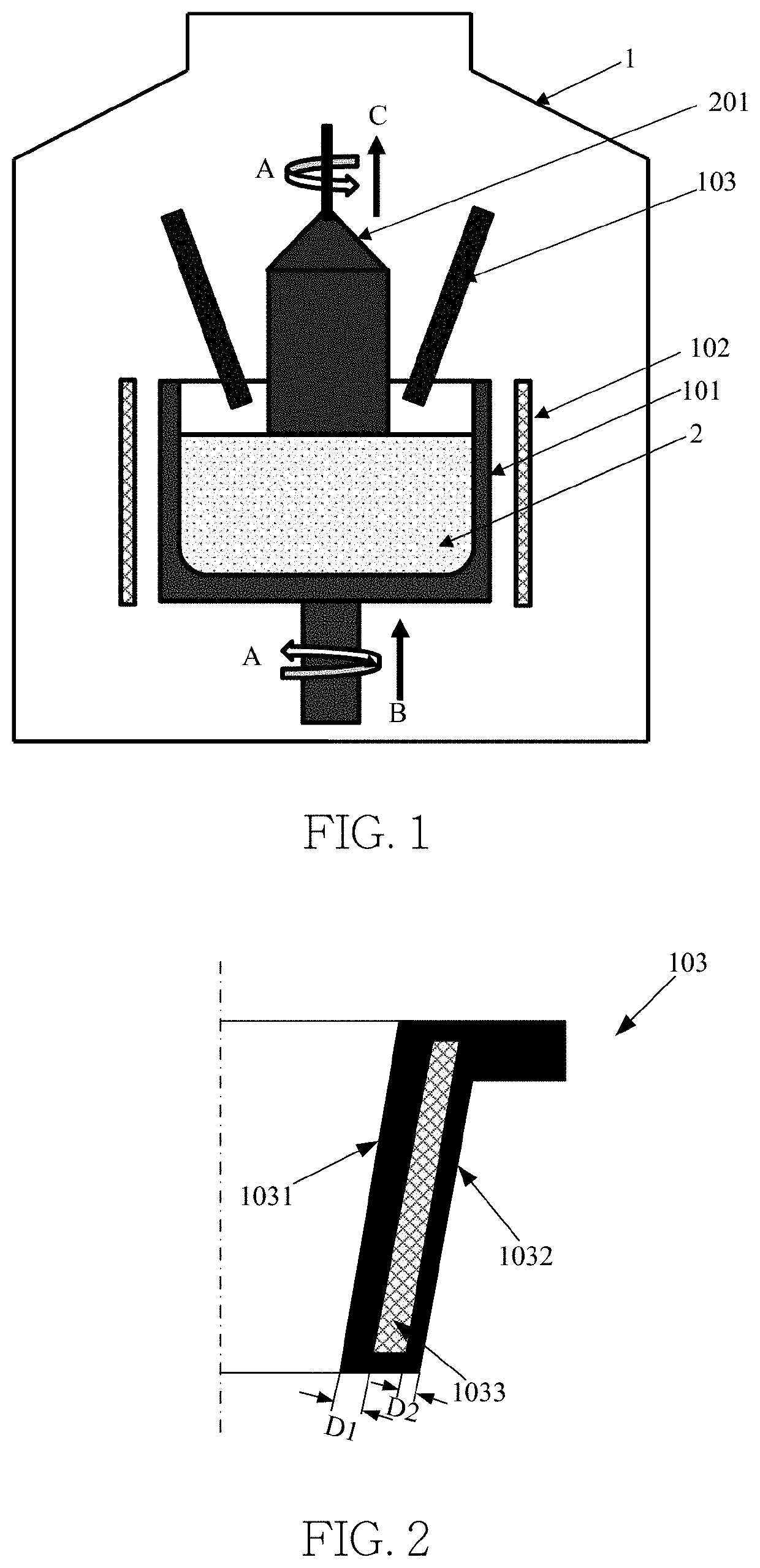

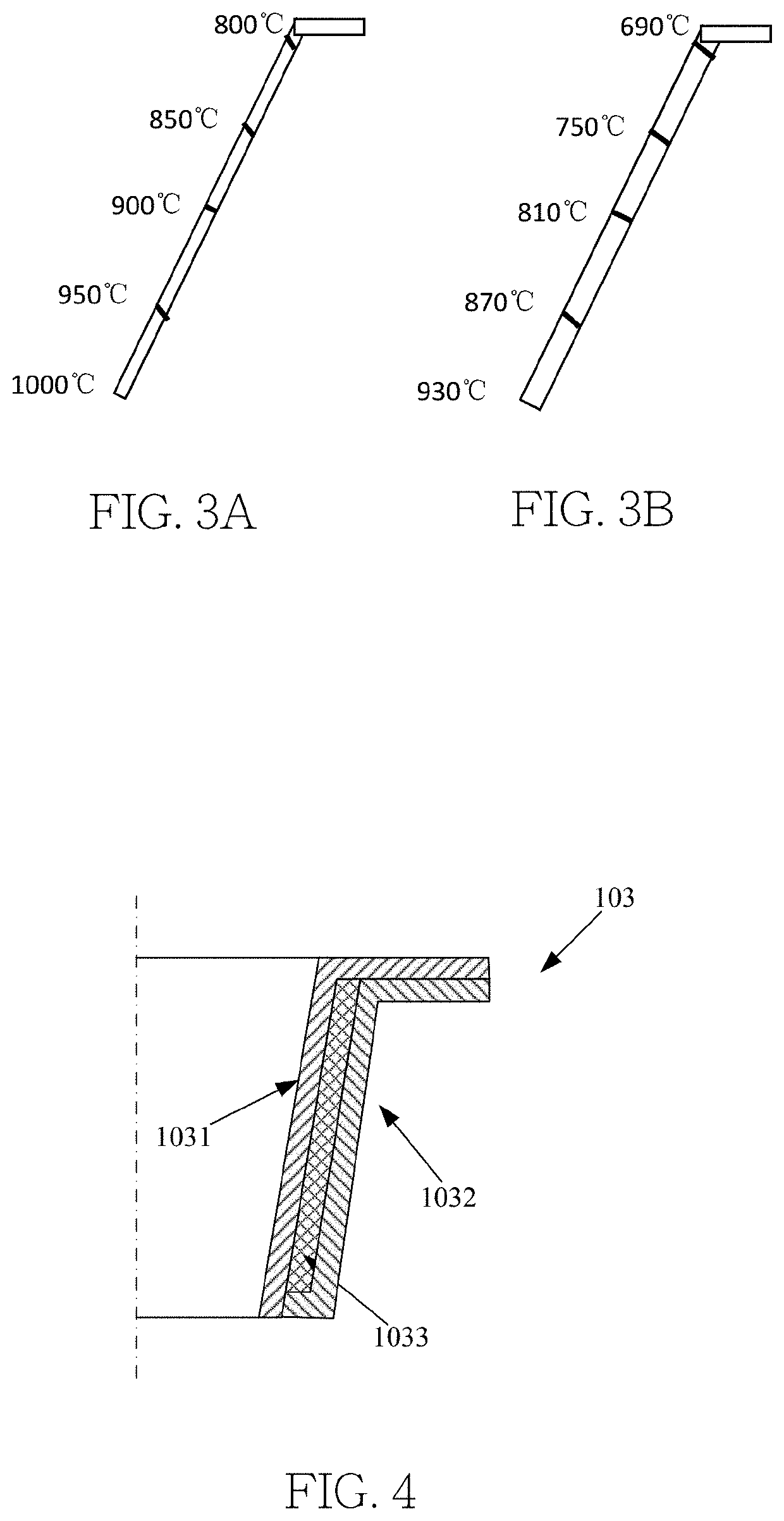

Draft tube of crystal growing furnace and the crystal growing furnace

InactiveUS20200255970A1Well formedPolycrystalline material growthBy pulling from meltEngineeringIngot

Owner:ZING SEMICON CORP

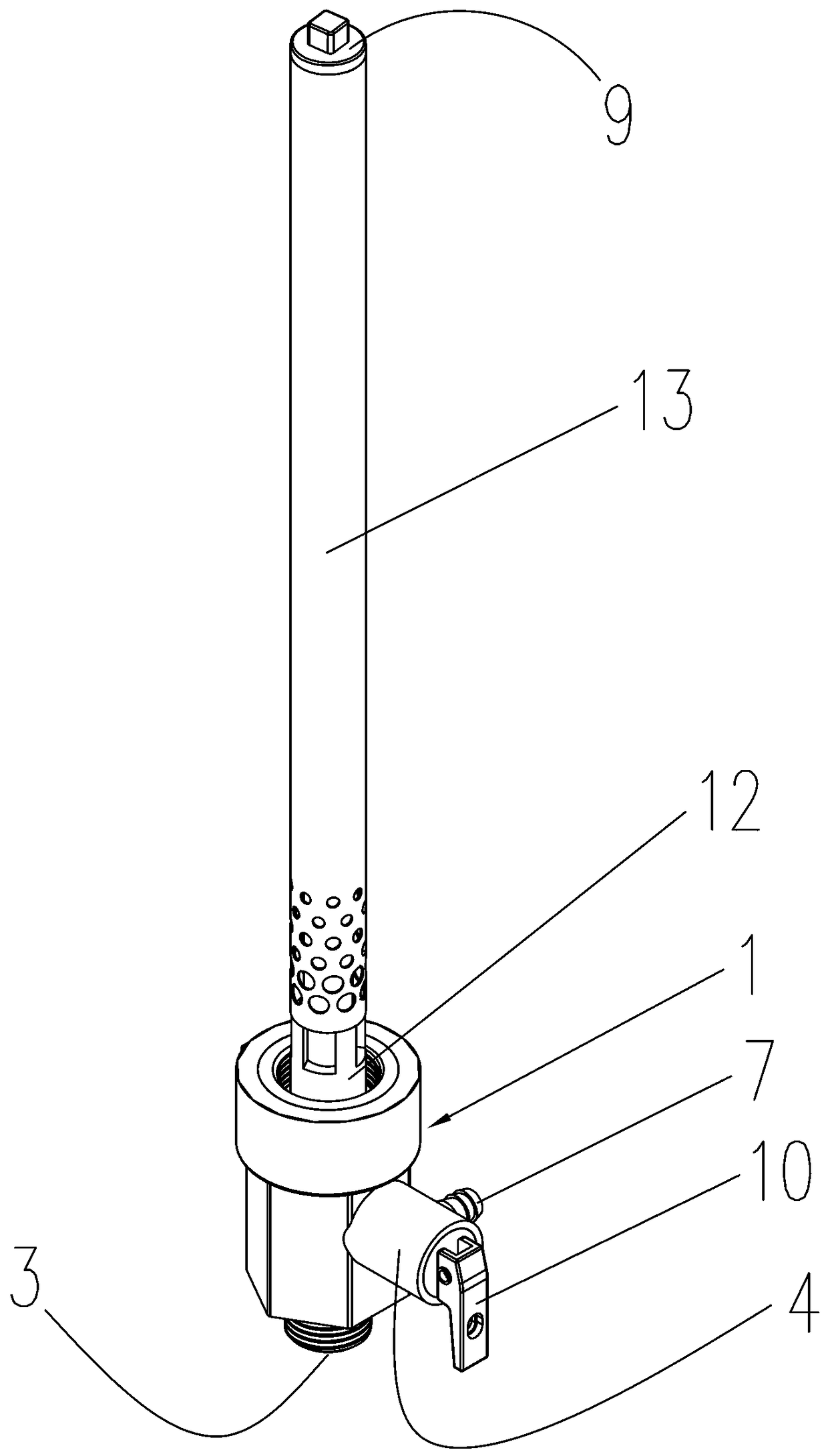

Safe pressure relieving and anti-creeping device for water heater

PendingCN108980429ALow thermal conductivityPlay a security functionFluid heatersEqualizing valvesInternal pressureElectricity

Owner:蒋琪峰

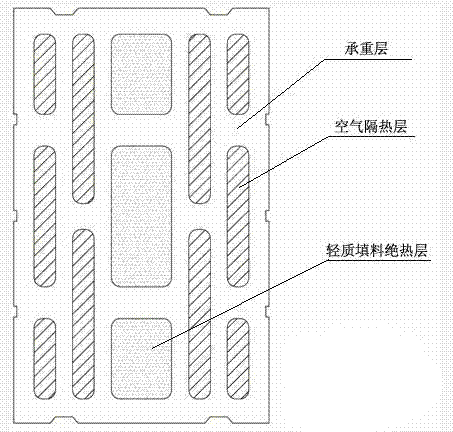

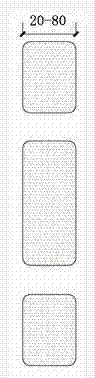

Composite thermal-insulating block of expanded and vitrified micro-bead

InactiveCN102828572AIncrease thermal resistanceMeet energy saving requirementsConstruction materialFireproofingMaterials science

Owner:江苏华伟佳建材科技有限公司

Preparation method of ablation-resistant low-thermal-conductivity composite material

Owner:XIAN MODERN CHEM RES INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap