Test system of temperature sensor

A temperature sensor and testing system technology, applied in thermometer testing/calibration, thermometers, instruments, etc., can solve the problems of low success rate of artificial combination matching, failure to achieve the best product matching, and inaccurate matching results, etc., to achieve switching and The effect of automating the measurement process, improving product quality, and avoiding repetitive labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

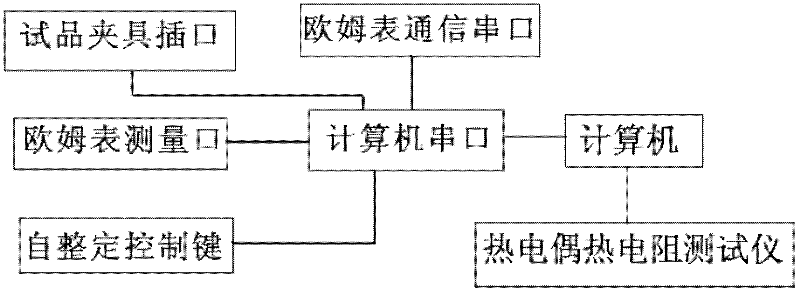

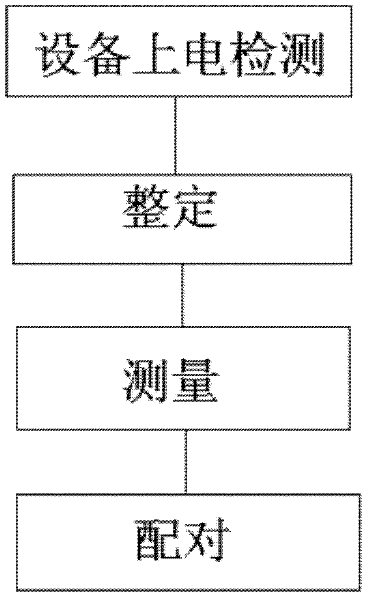

[0021] Such as figure 1 The temperature sensor test system shown includes a computer, a thermocouple thermal resistance tester and a temperature sensor test platform, wherein the computer and the thermocouple thermal resistance tester are connected through a serial port line, and the temperature sensor test platform includes multiple test objects Fixture socket, multiple ohmmeter measurement ports, self-tuning control key, computer serial port and ohmmeter communication serial port, the test fixture socket, ohmmeter measurement port, self-tuning control key and ohmmeter communication serial port are respectively connected to the computer through the serial port line connection, the temperature sensor test platform works according to the following steps (see figure 2 Shown): ① power-on detection of the temperature sensor measurement platform, detect the co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap