Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Sheet material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sheet Materials are engineered woods that are made by binding the timber material together with adhesives. The timber is typically formed into tiny strips and bound to create layers with wooden veneers sometimes used if appearances are important.

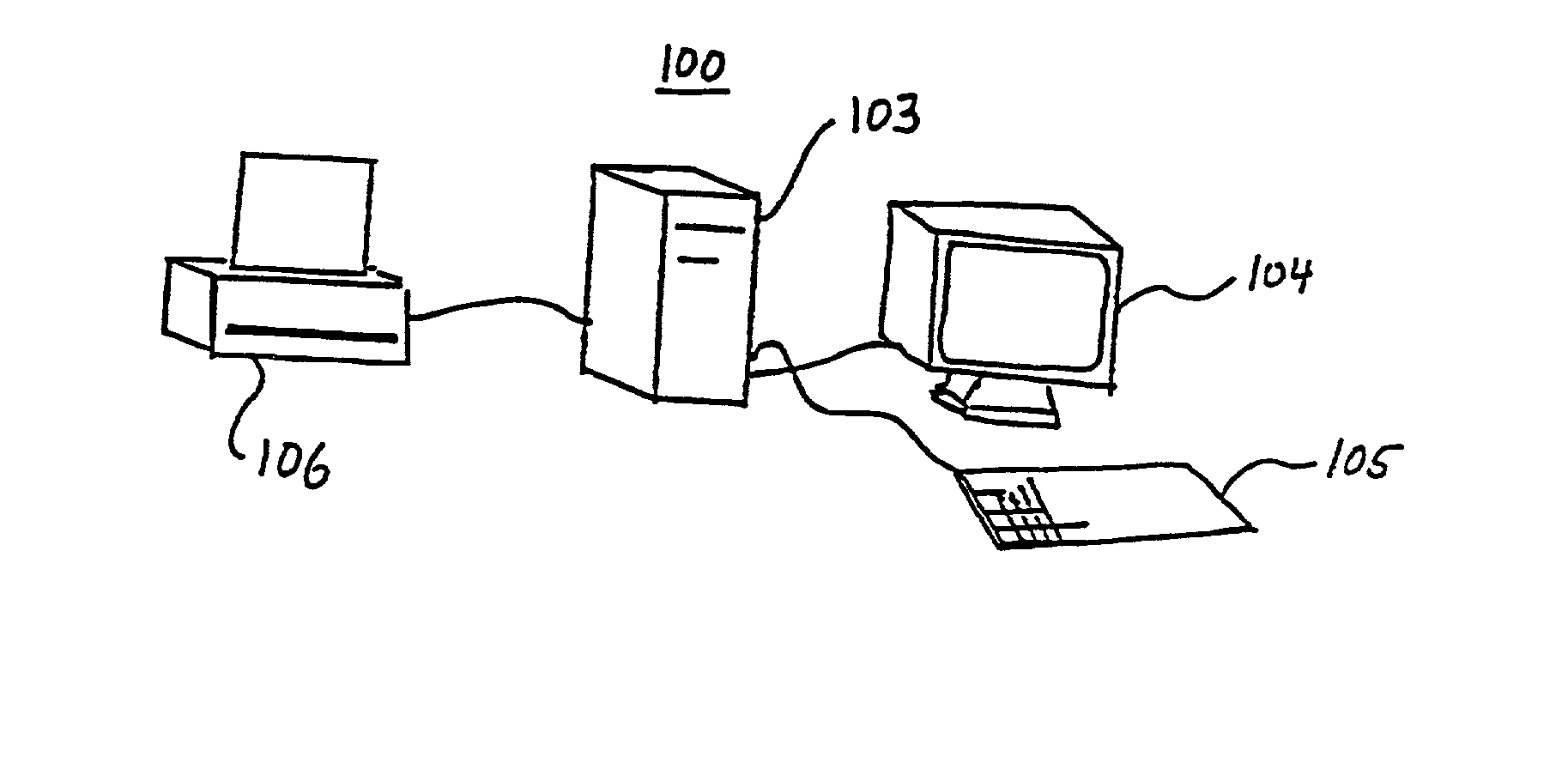

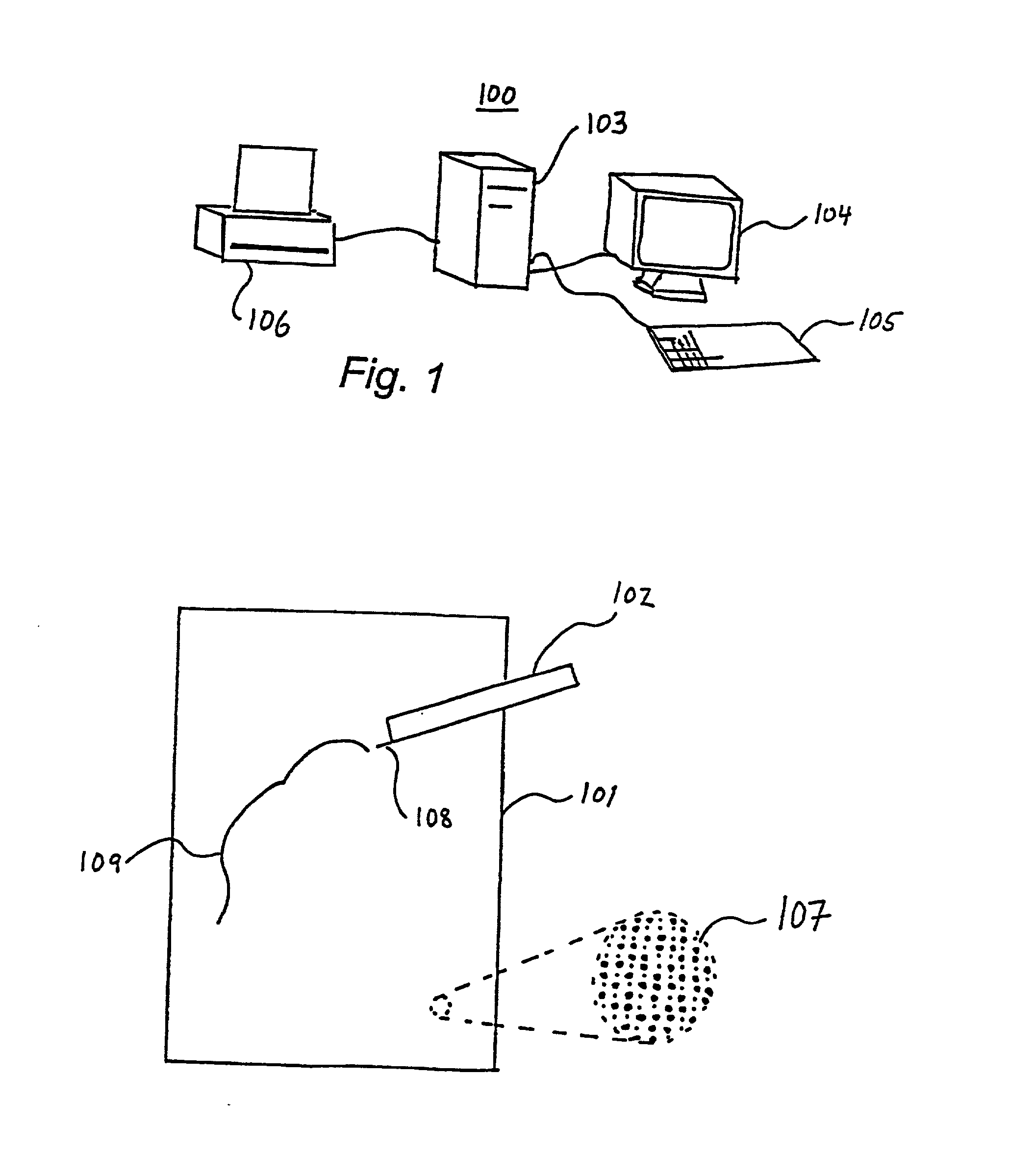

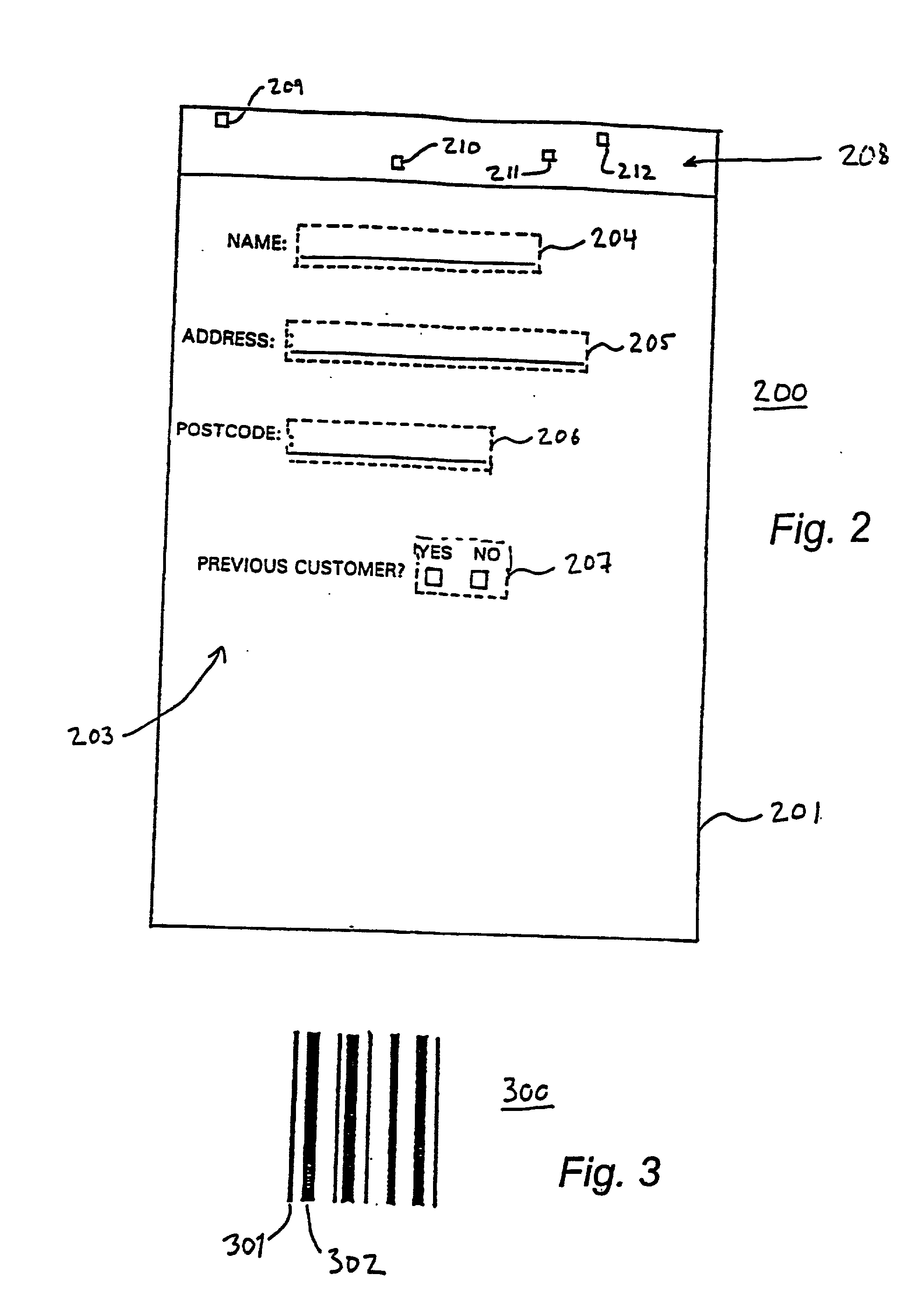

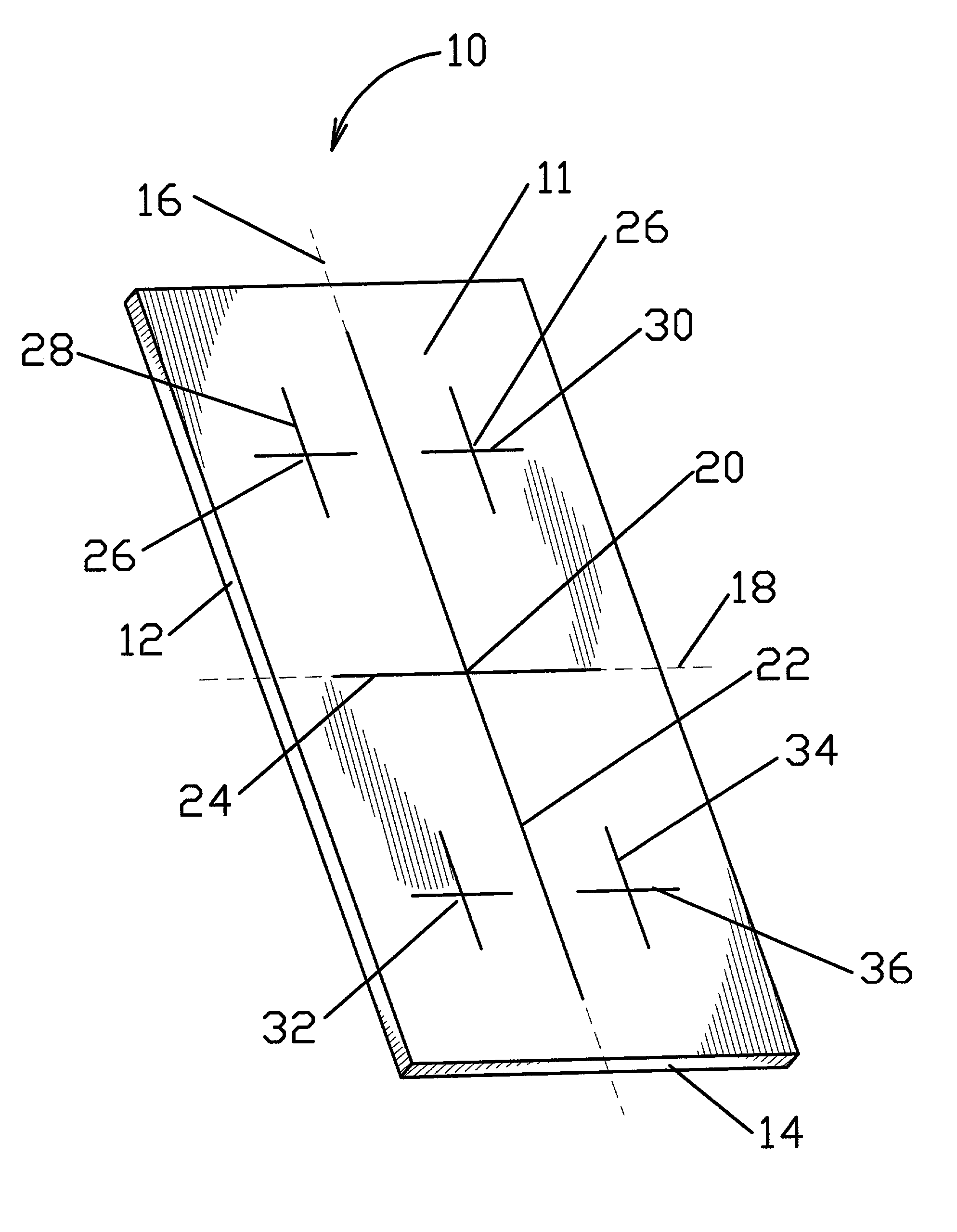

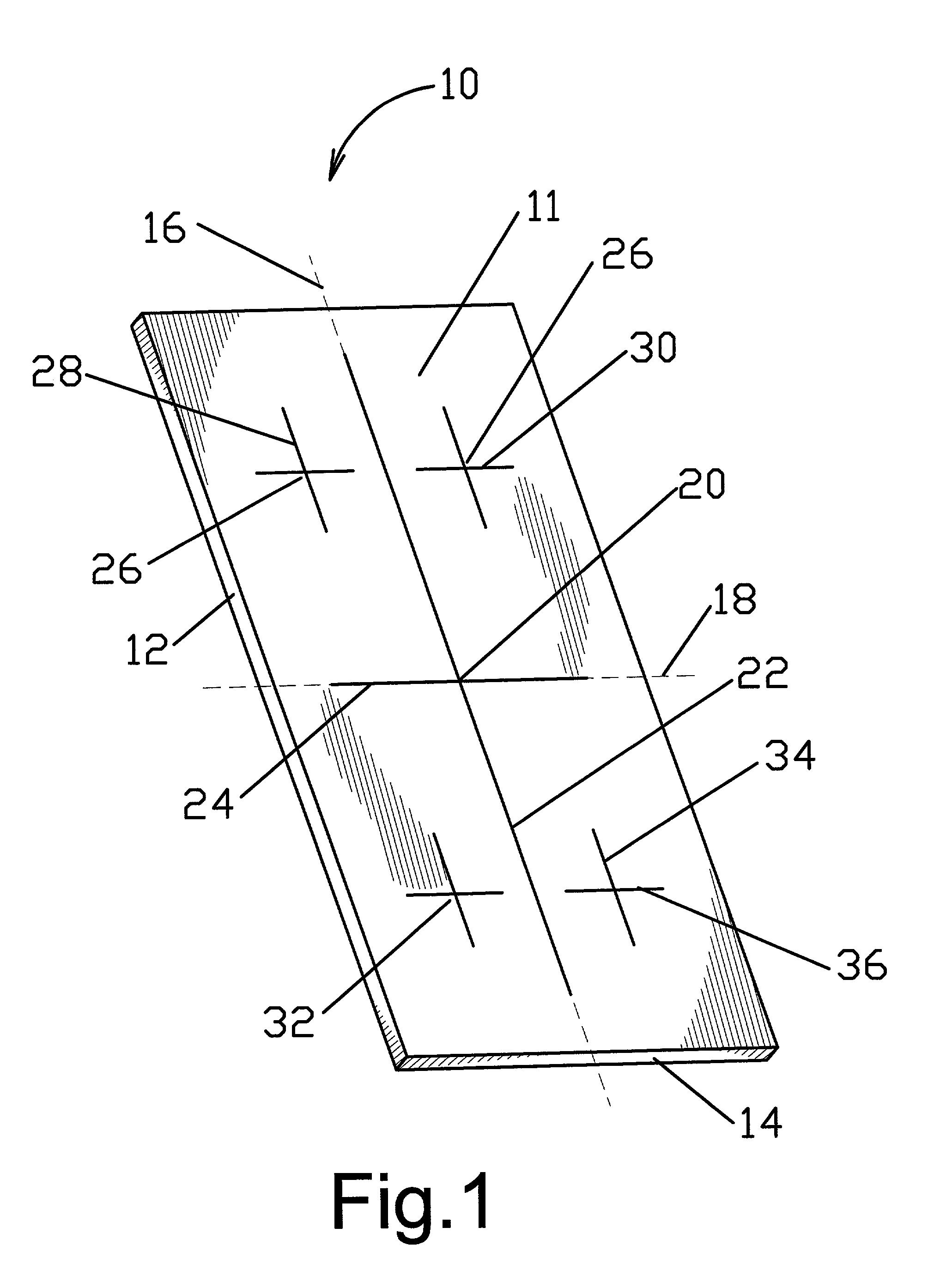

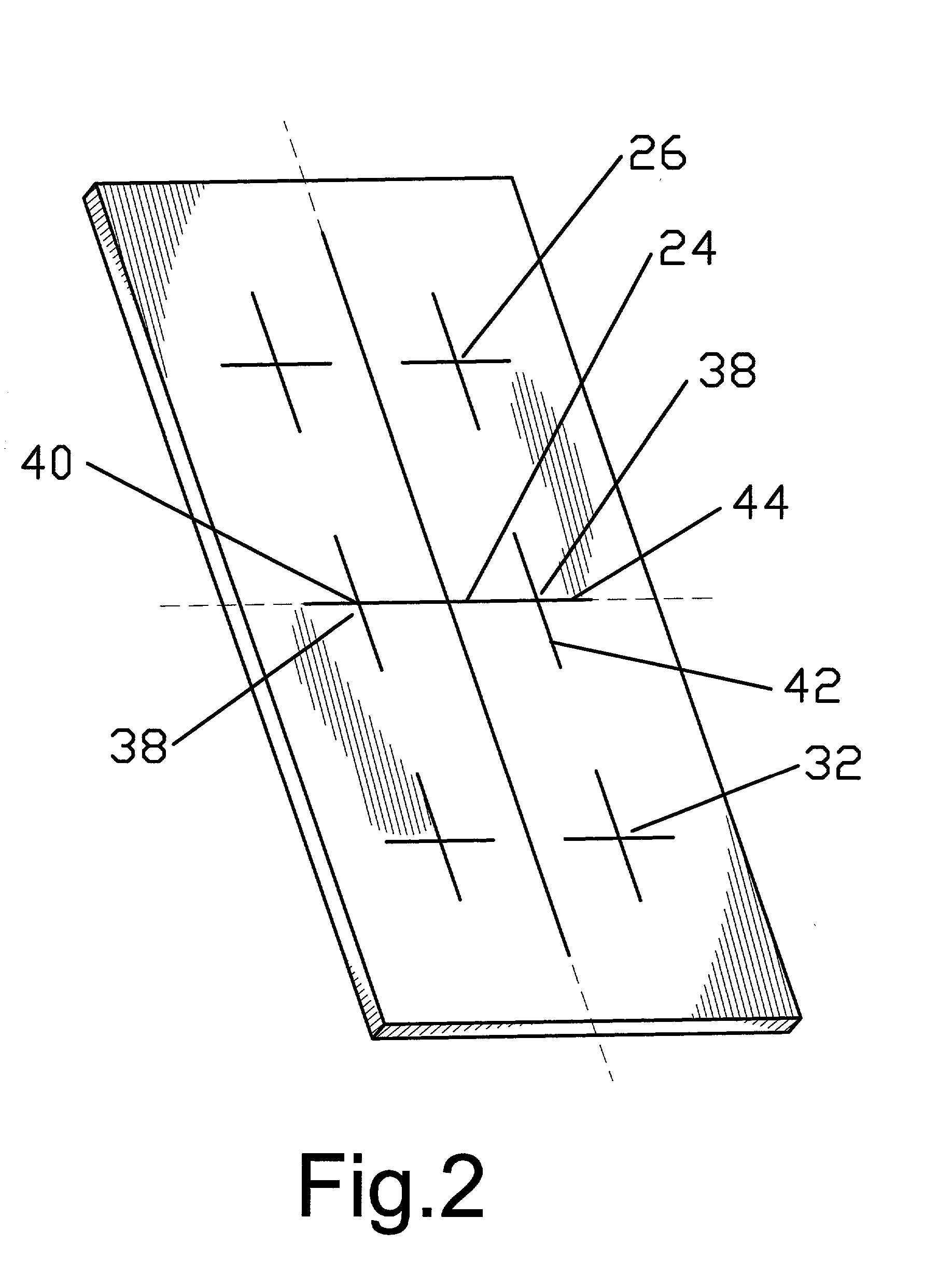

Data form having a position-coding pattern detectable by an optical sensor

InactiveUS20020050982A1High resolutionIncrease the areaCathode-ray tube indicatorsRecord carriers used with machinesDigital recordingEngineering

Owner:ANOTO AB

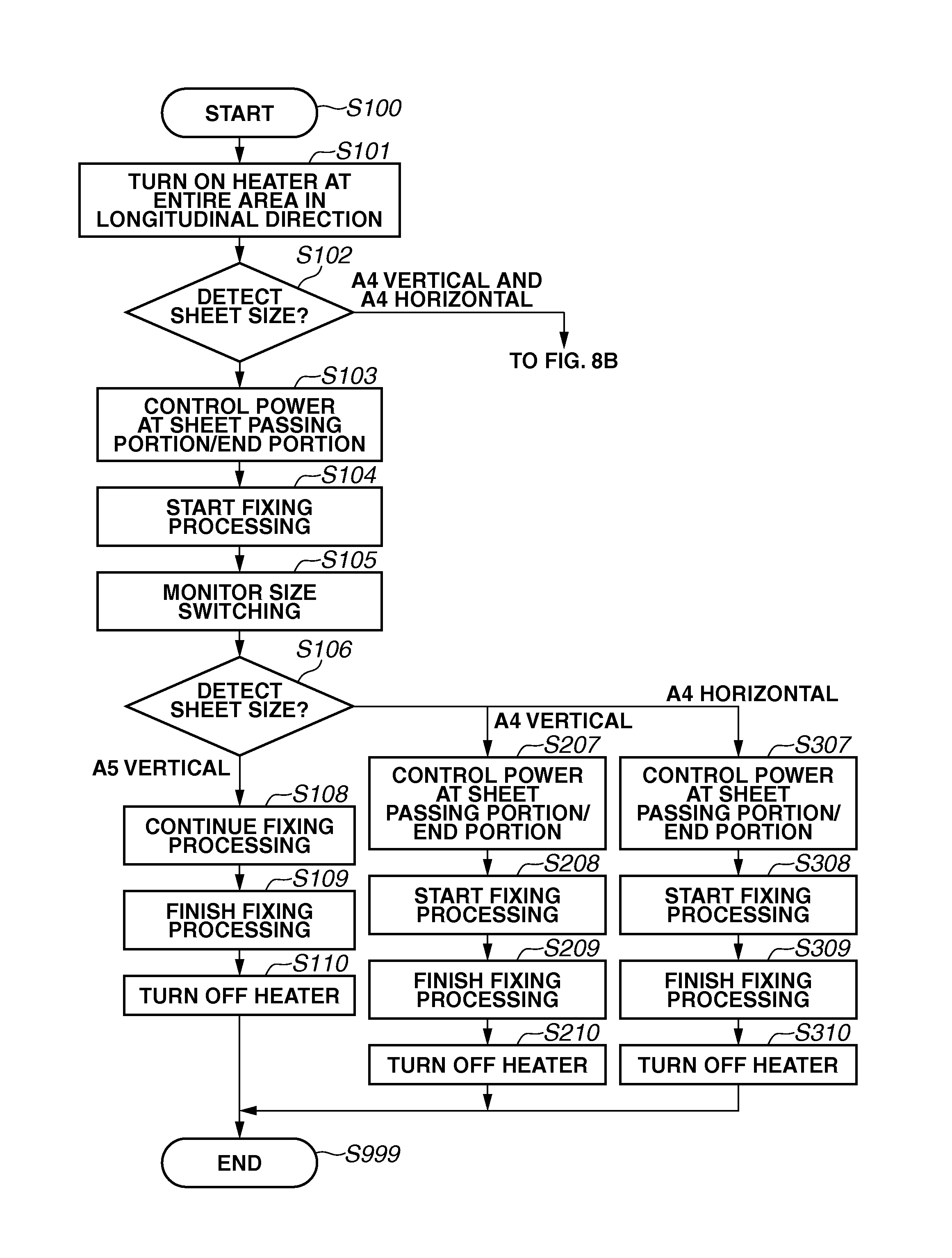

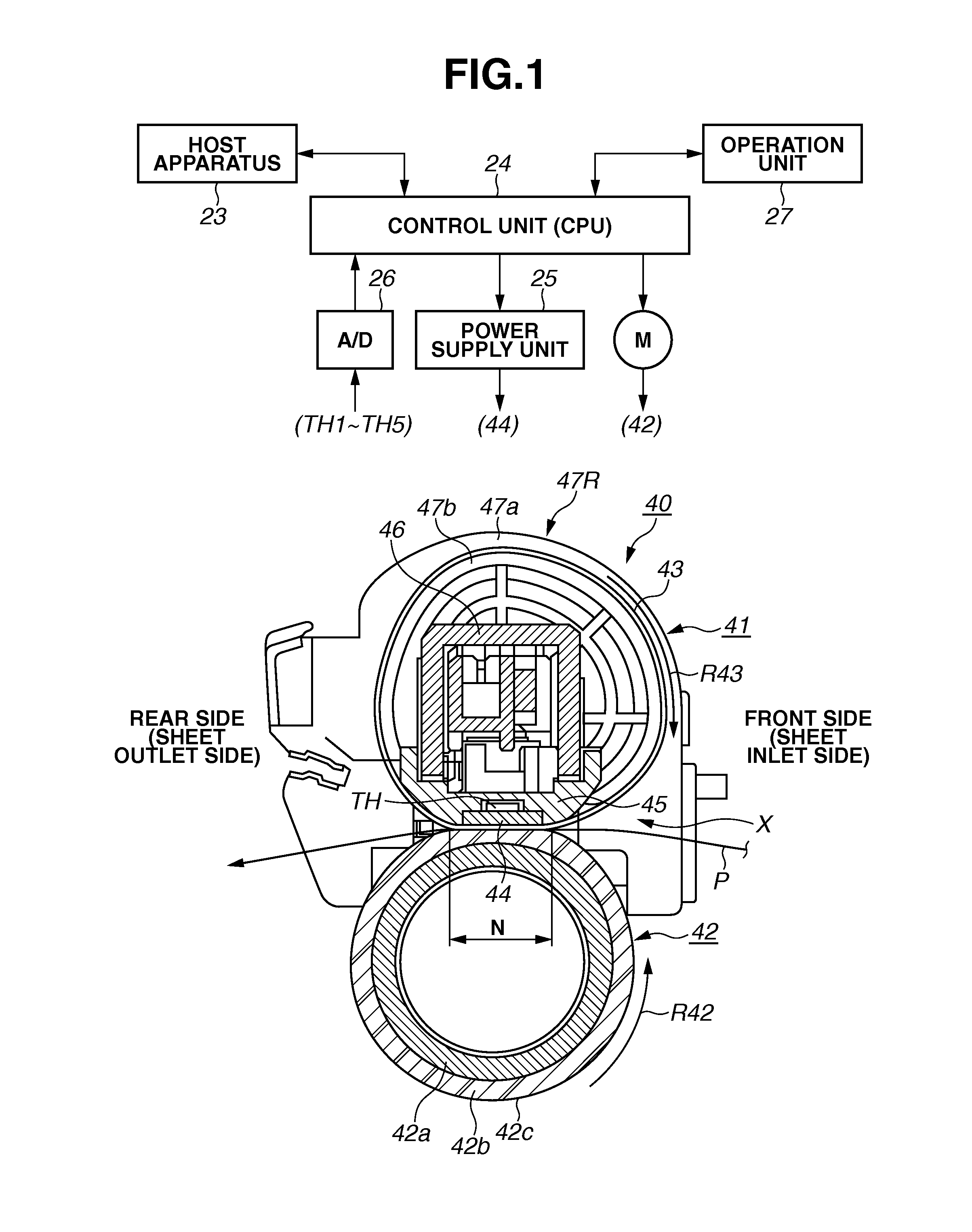

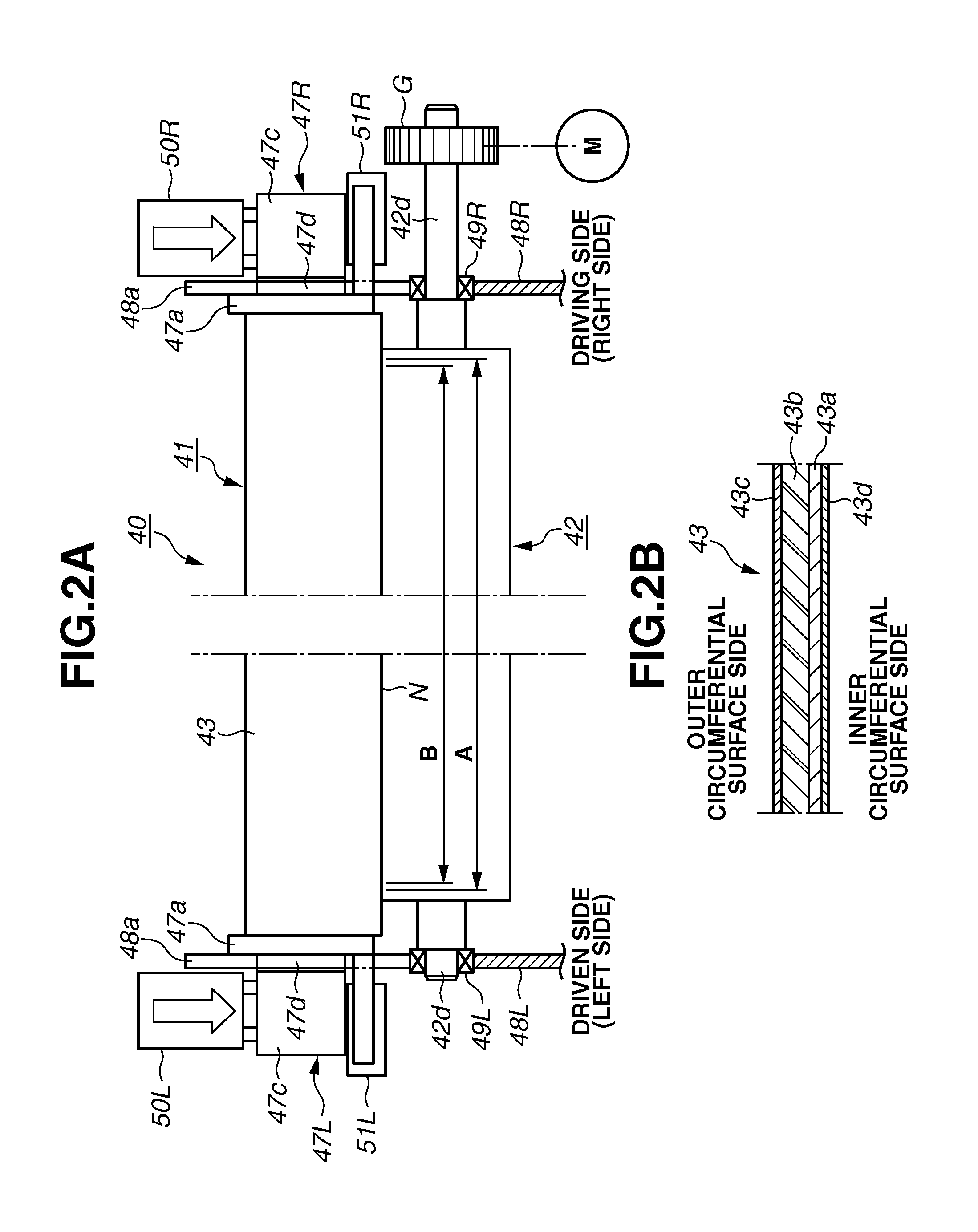

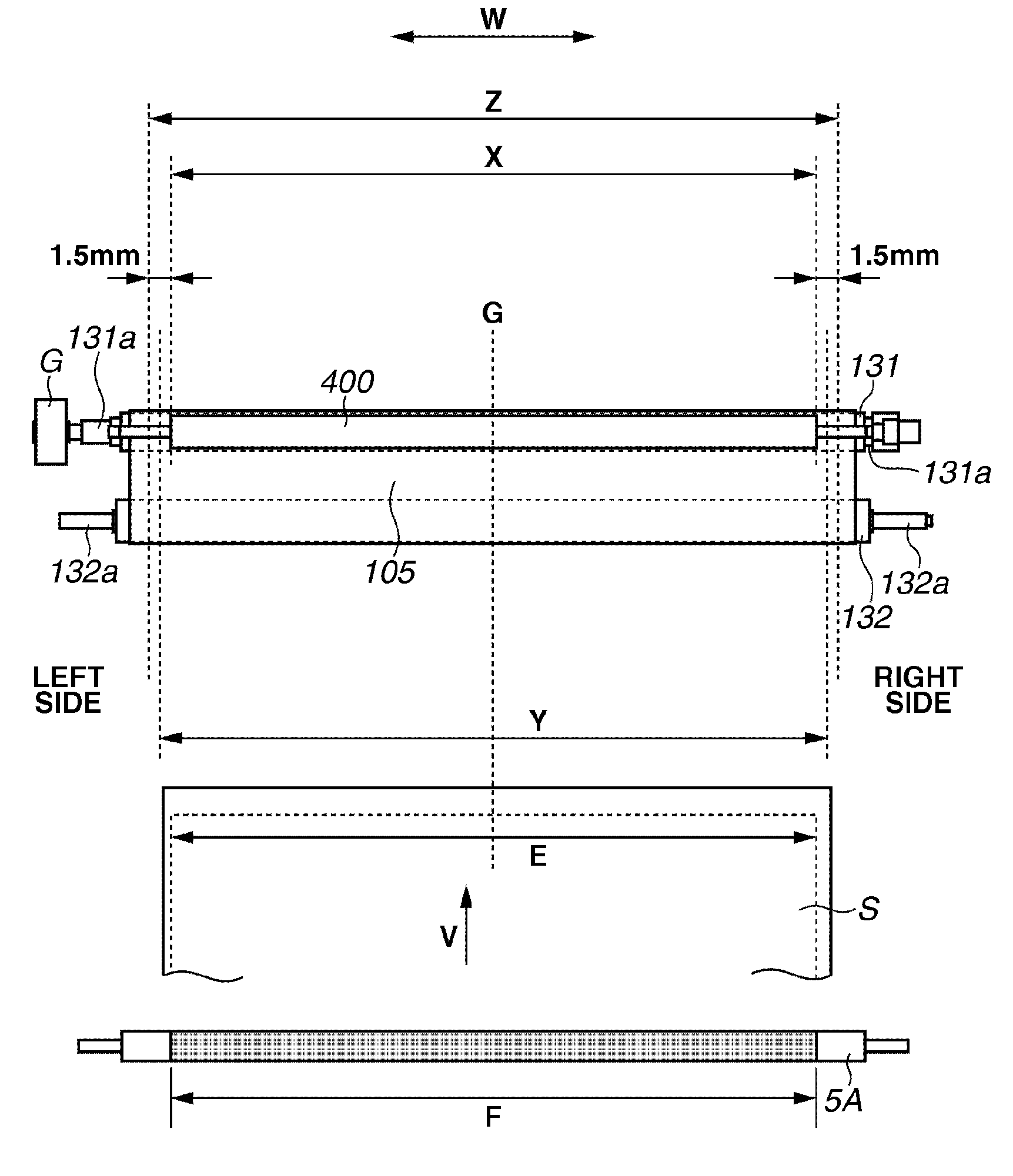

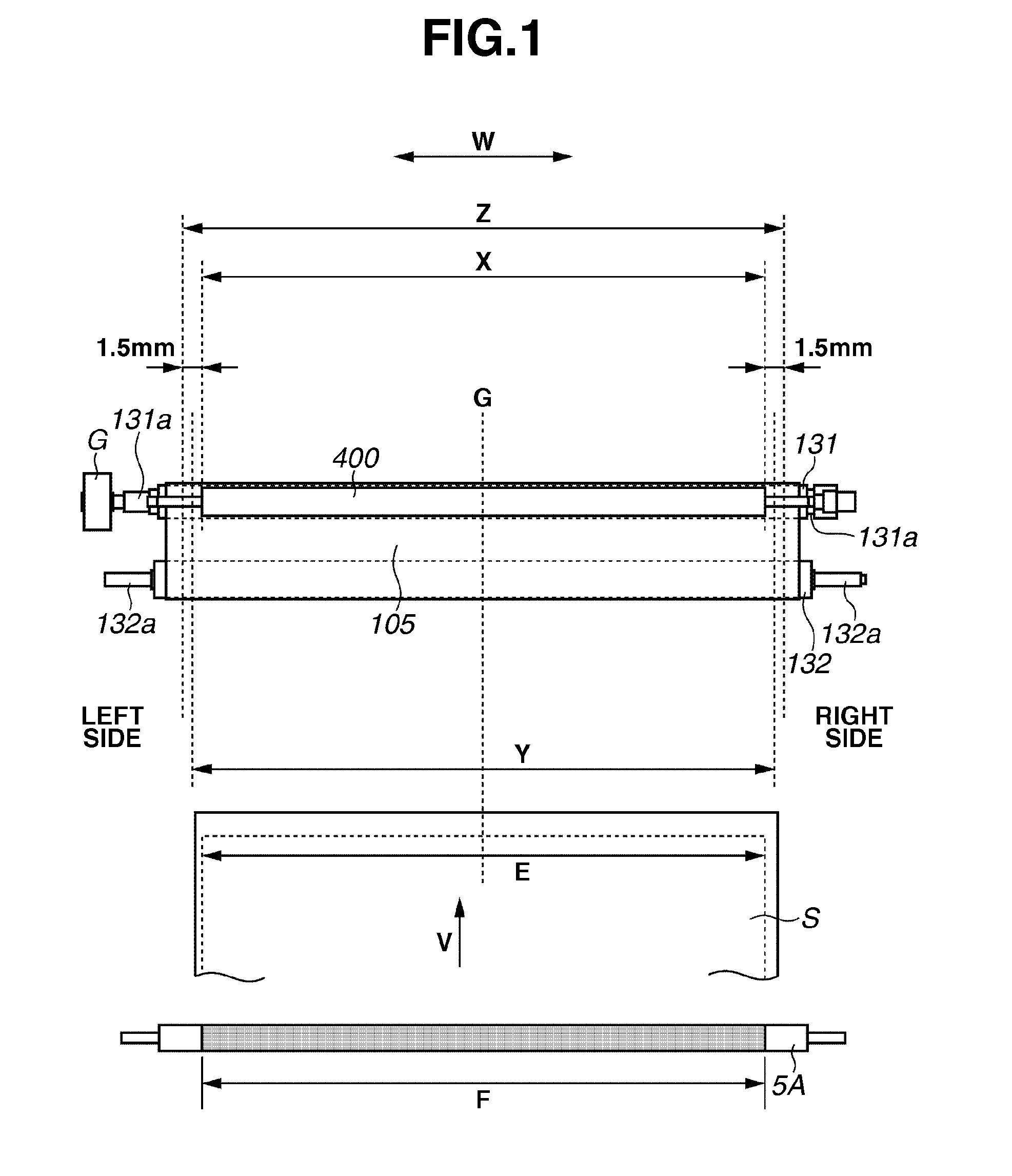

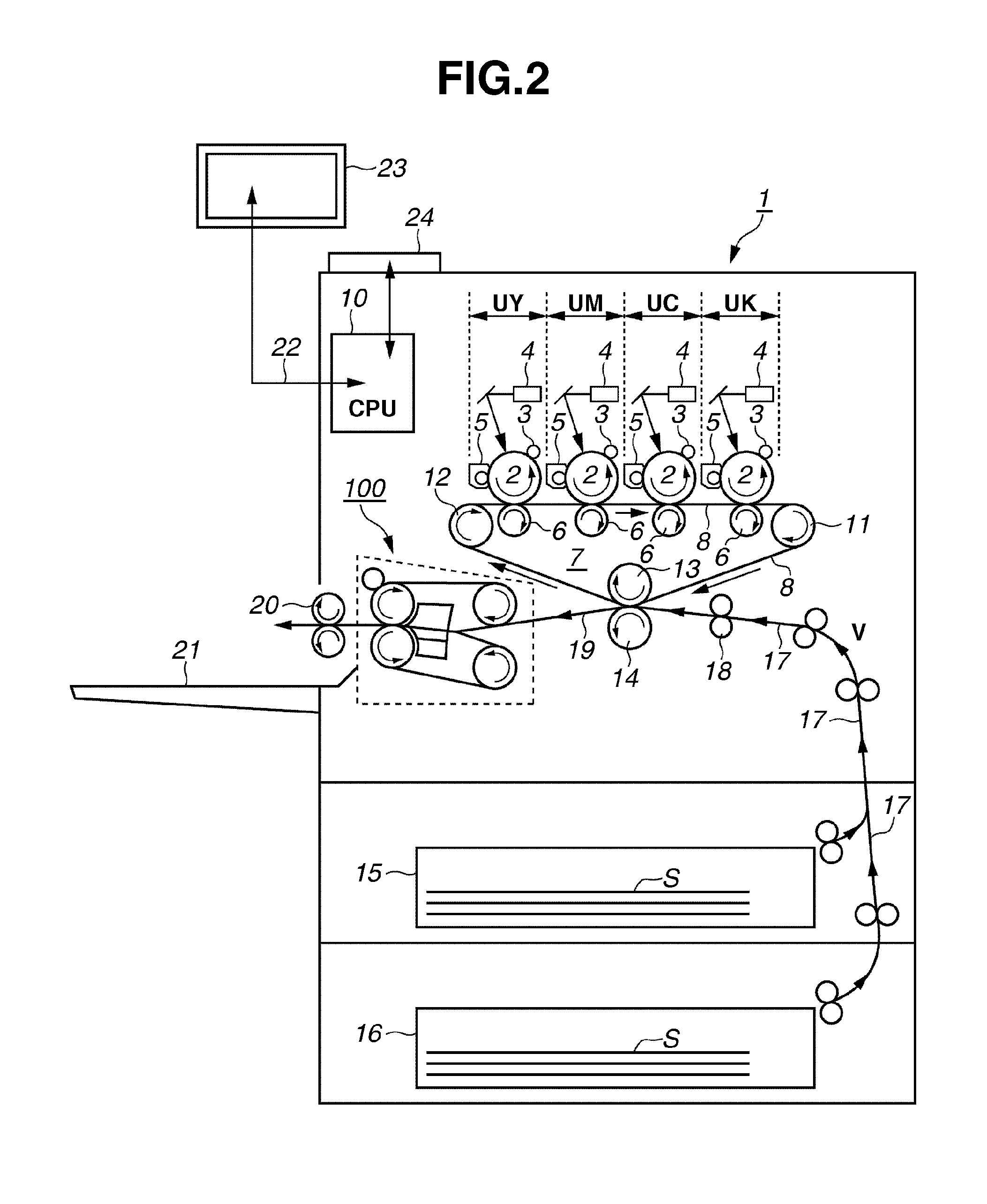

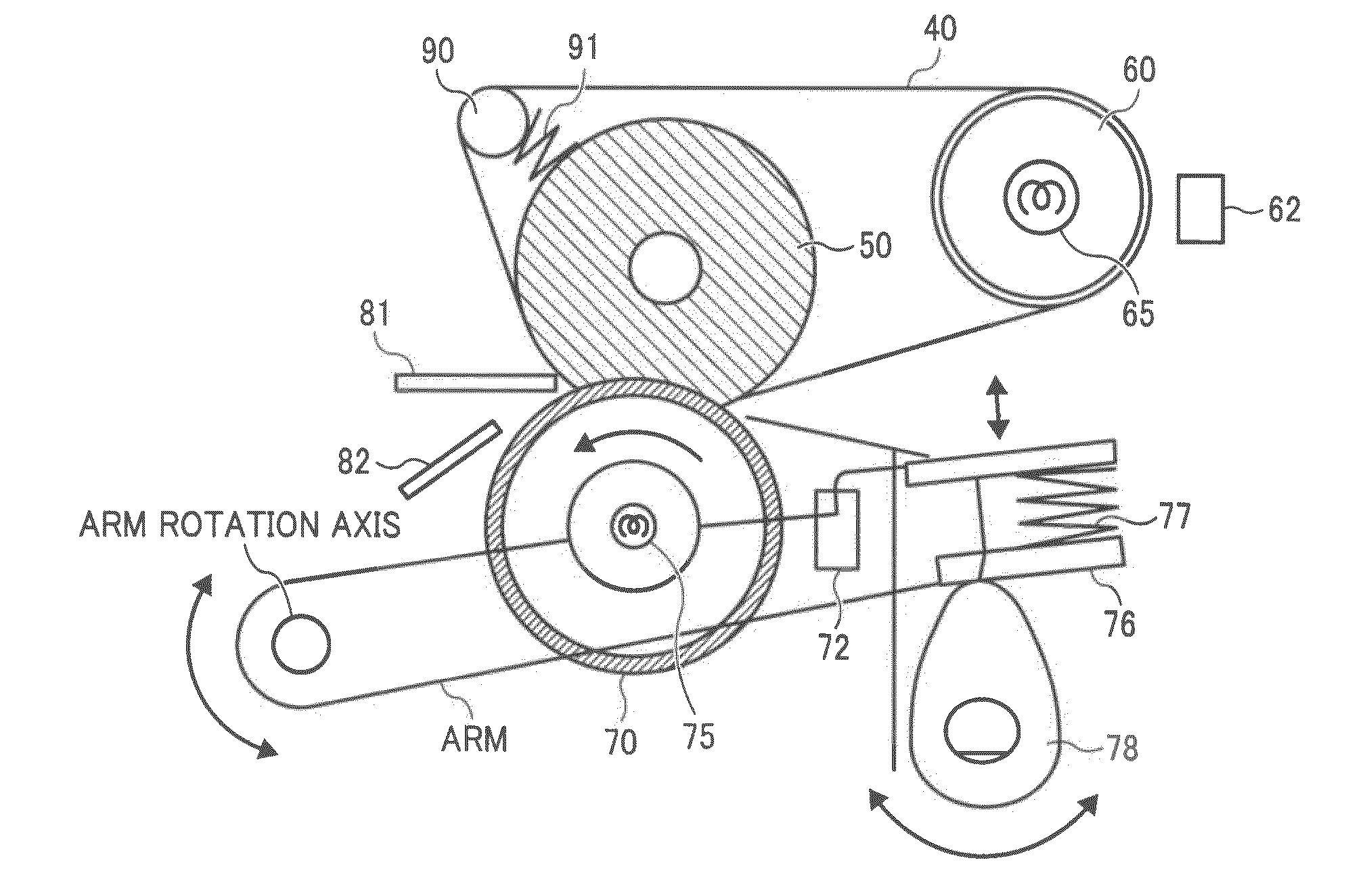

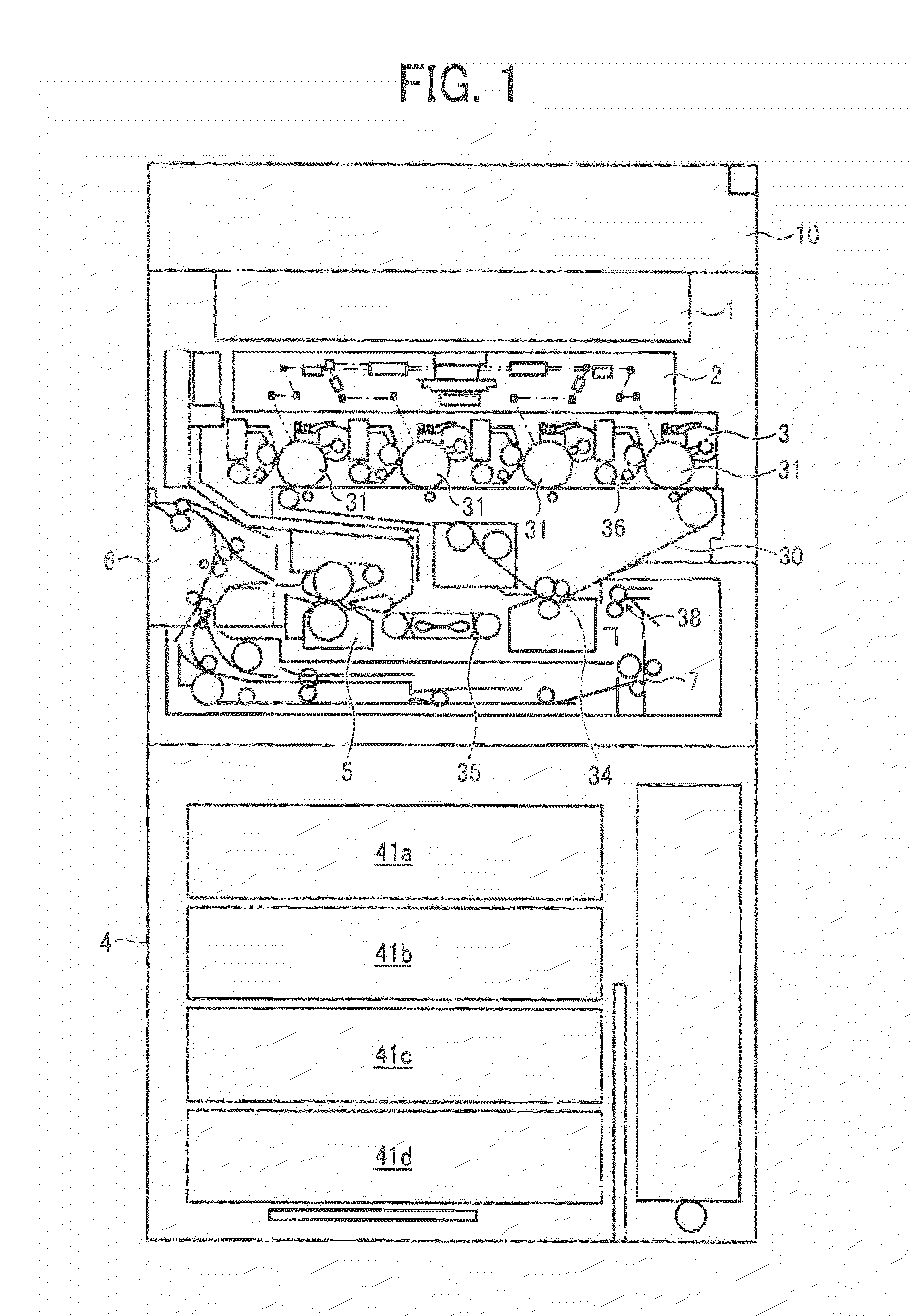

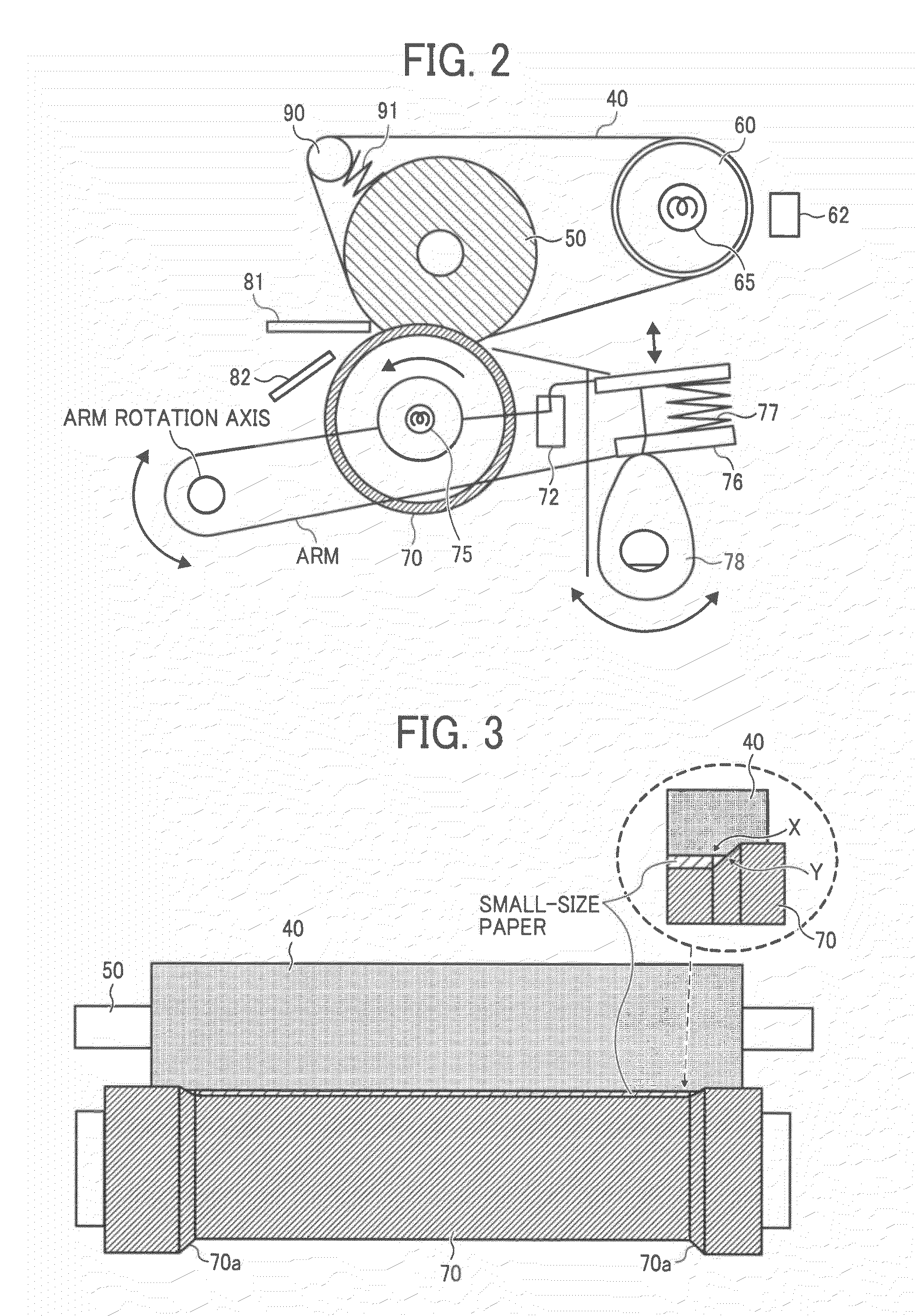

Image heating apparatus for heating toner image on sheet

ActiveUS20150037052A1Electrographic process apparatusElectrical and Electronics engineeringSheet material

Owner:CANON KK

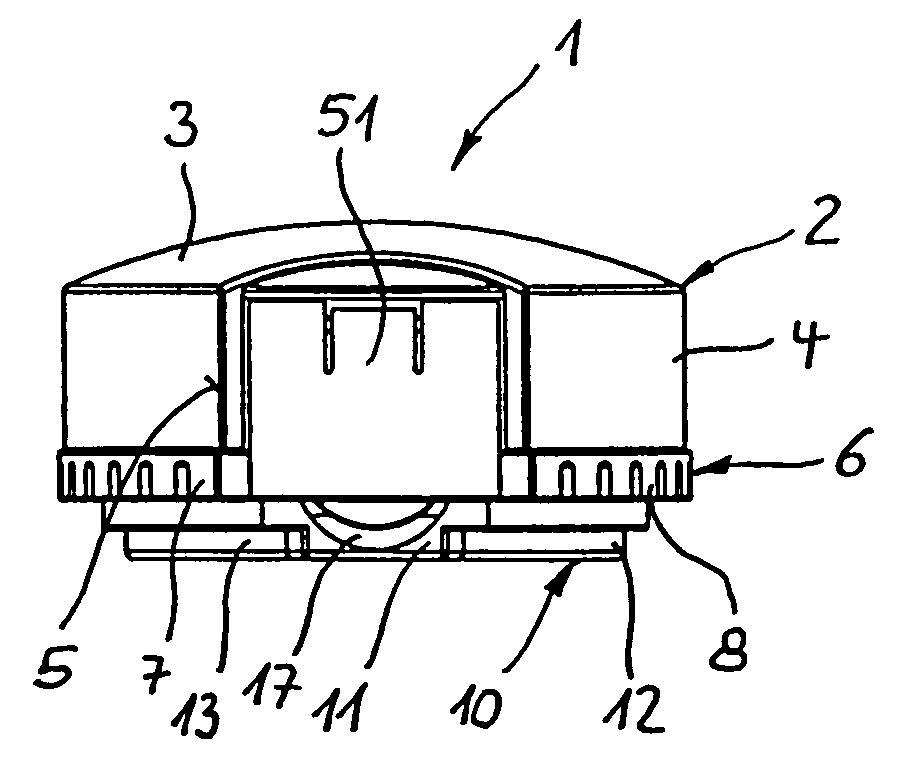

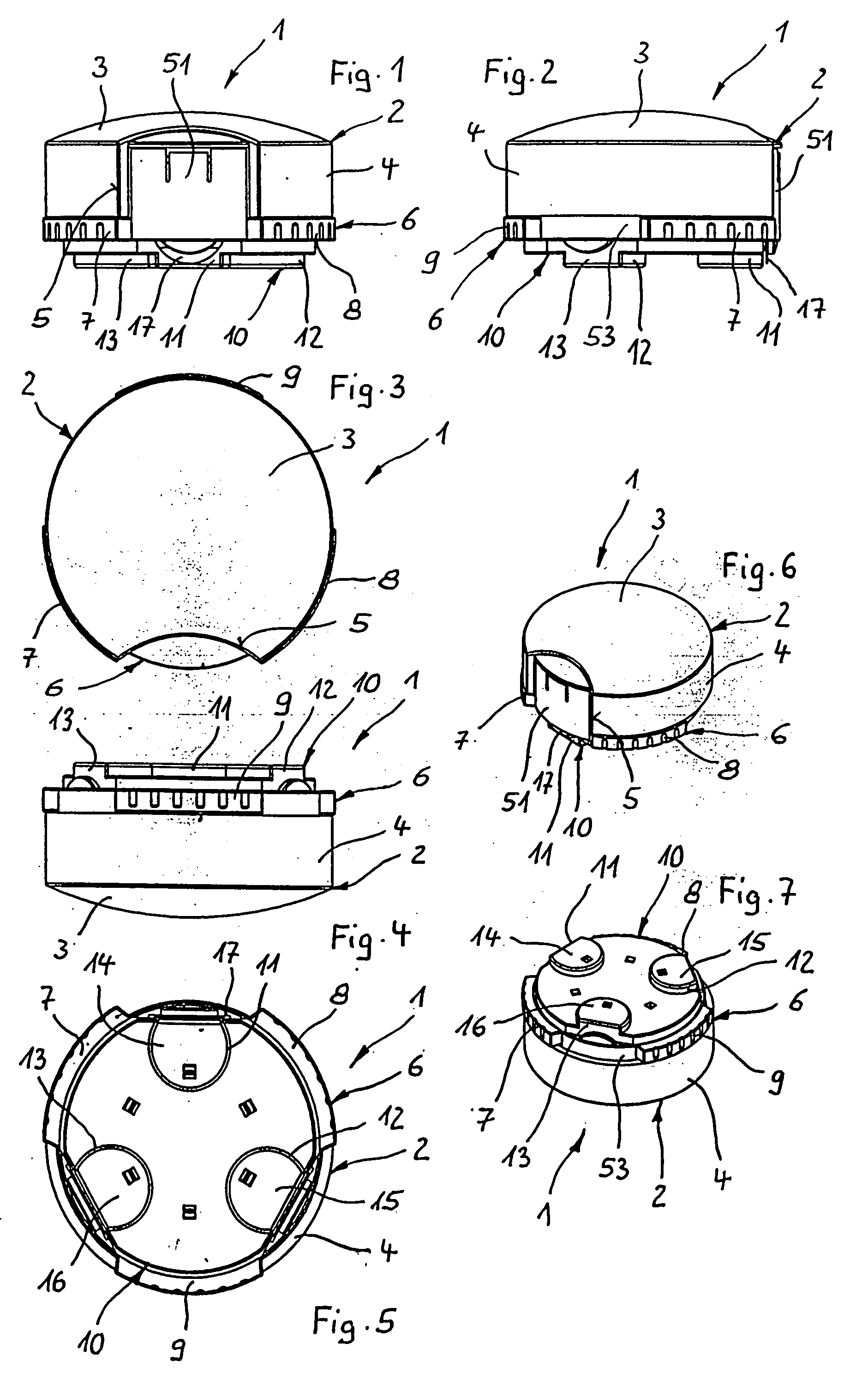

Mat

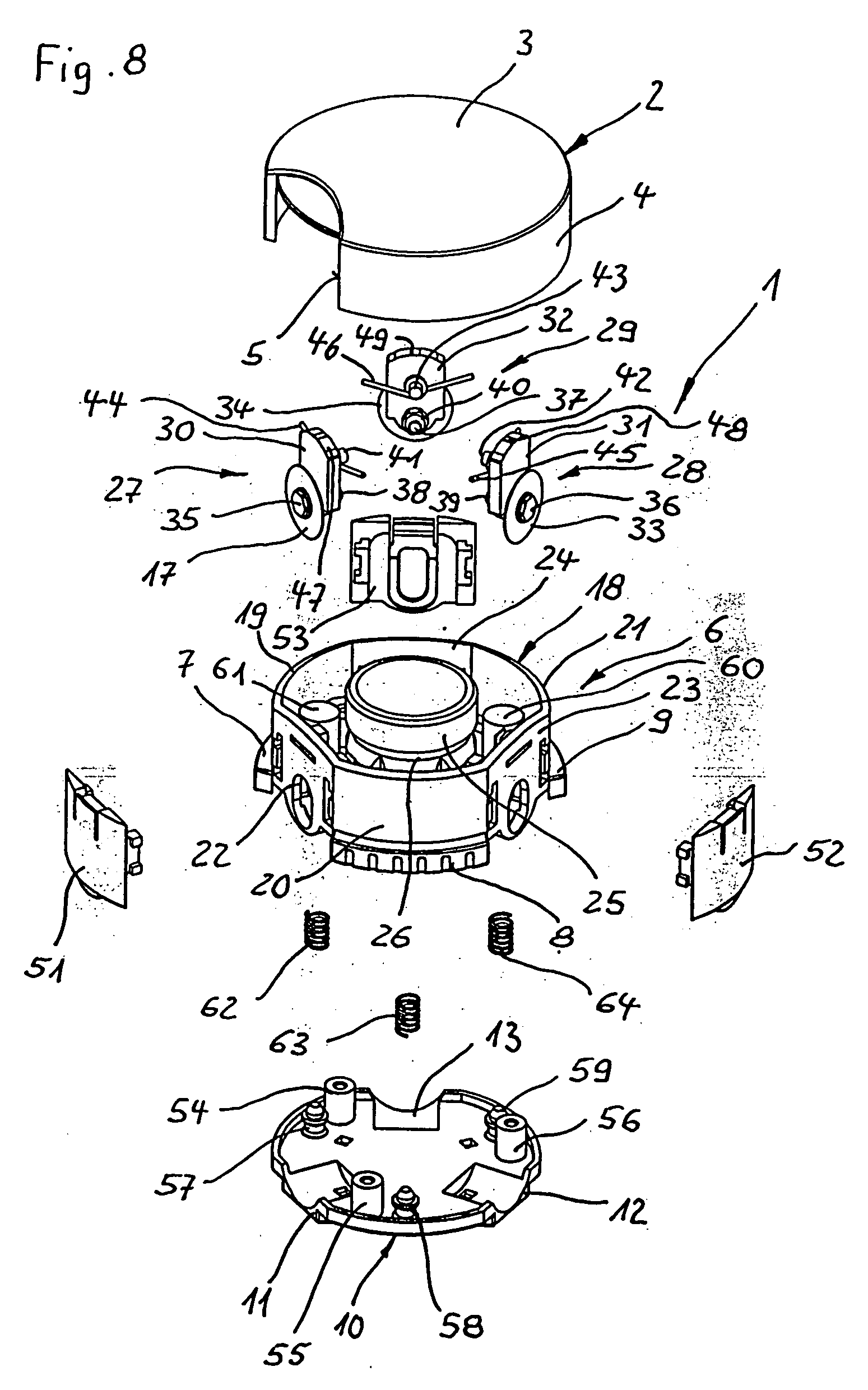

InactiveUS20030017915A1Easy to useConvenient to accommodateStiltsShock absorber matsAxis of symmetryEngineering

Owner:PRINZMETAL JAN

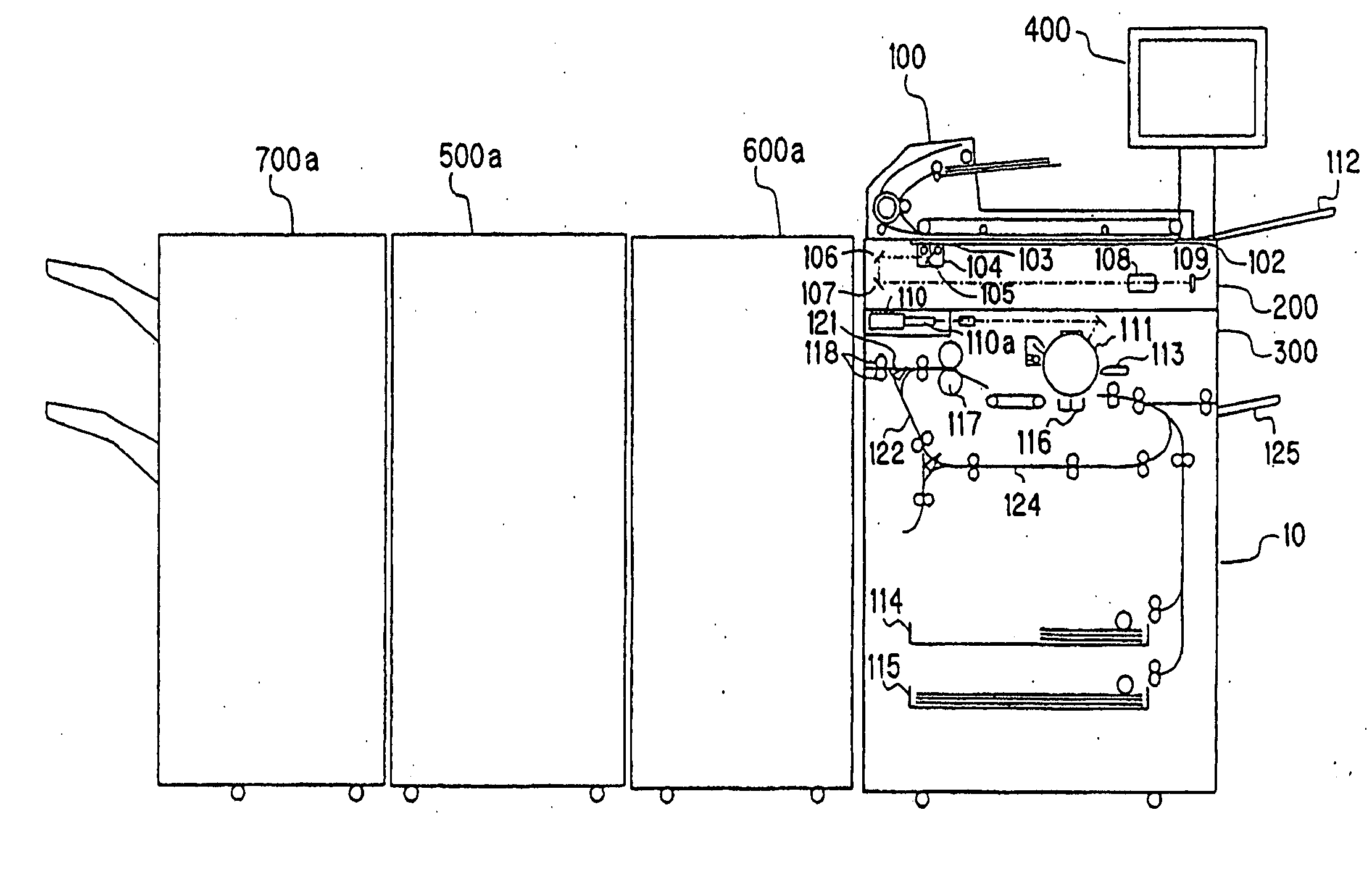

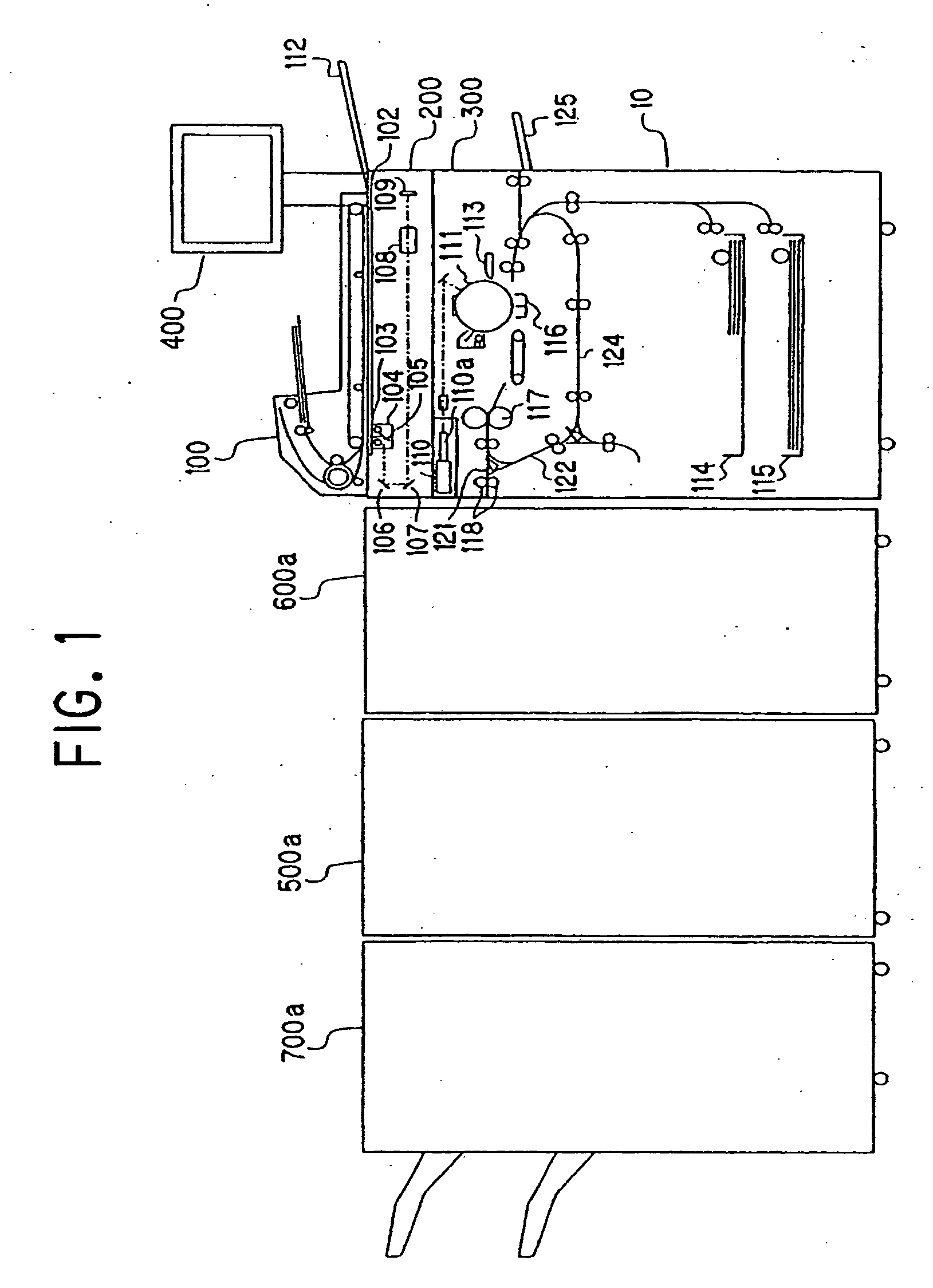

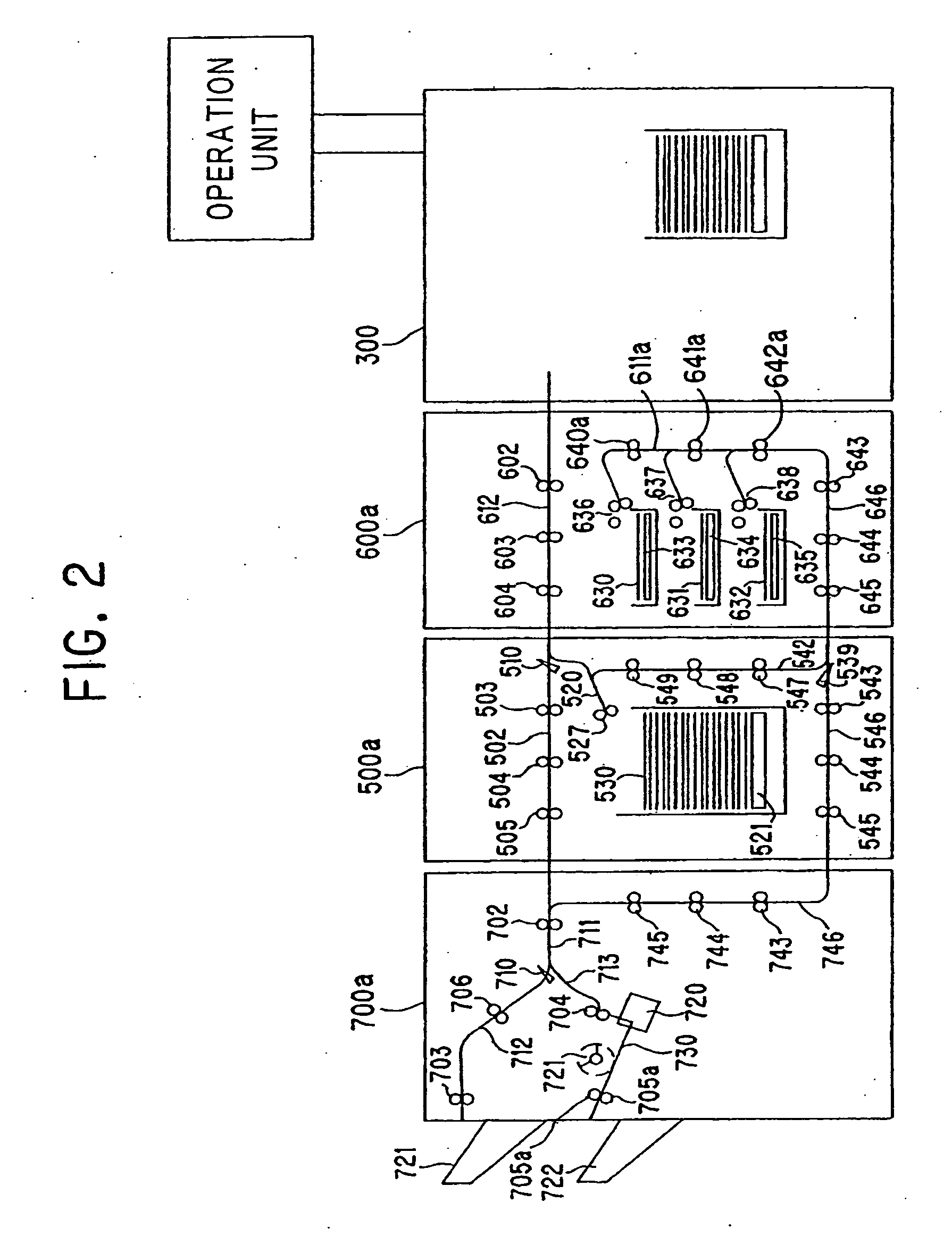

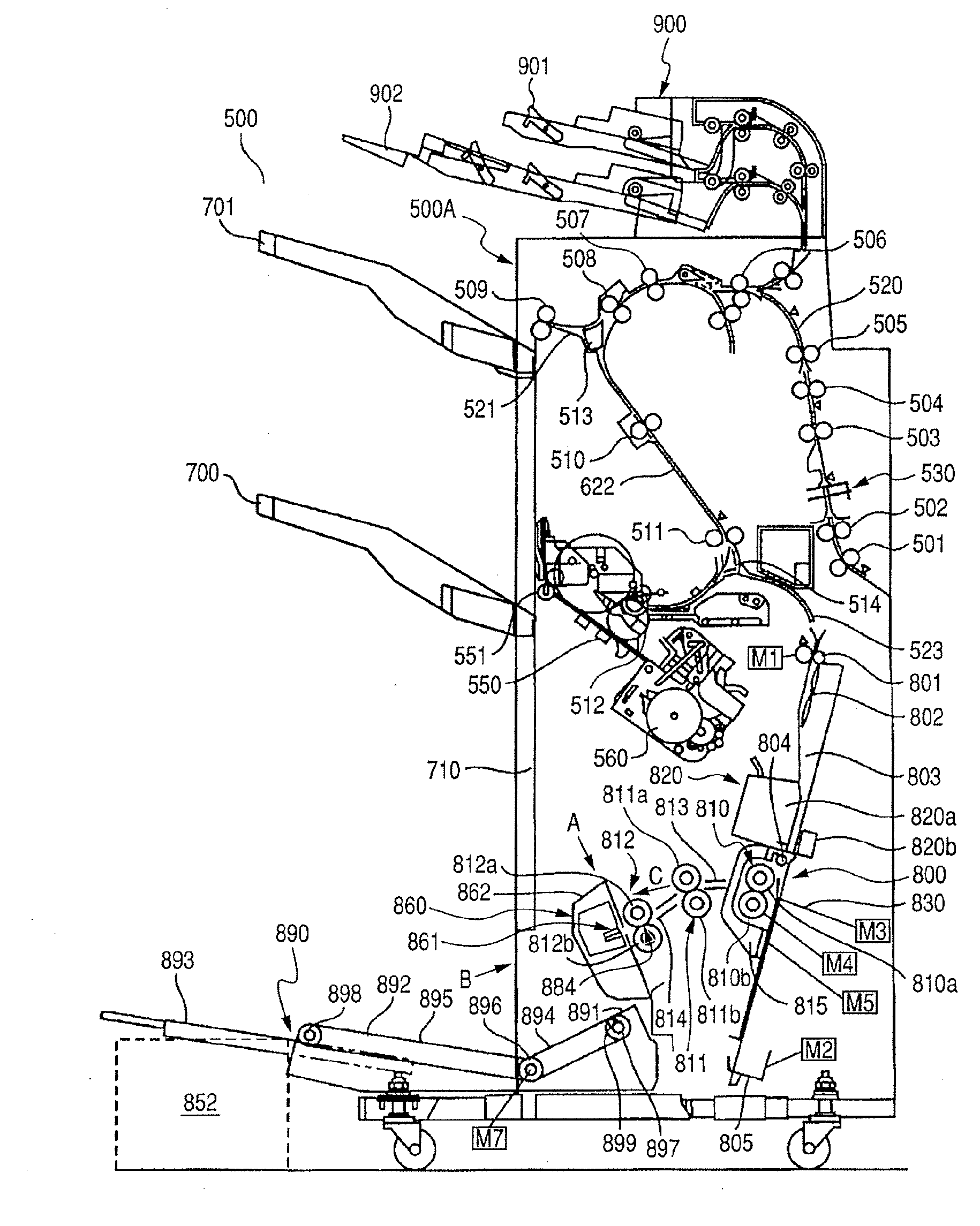

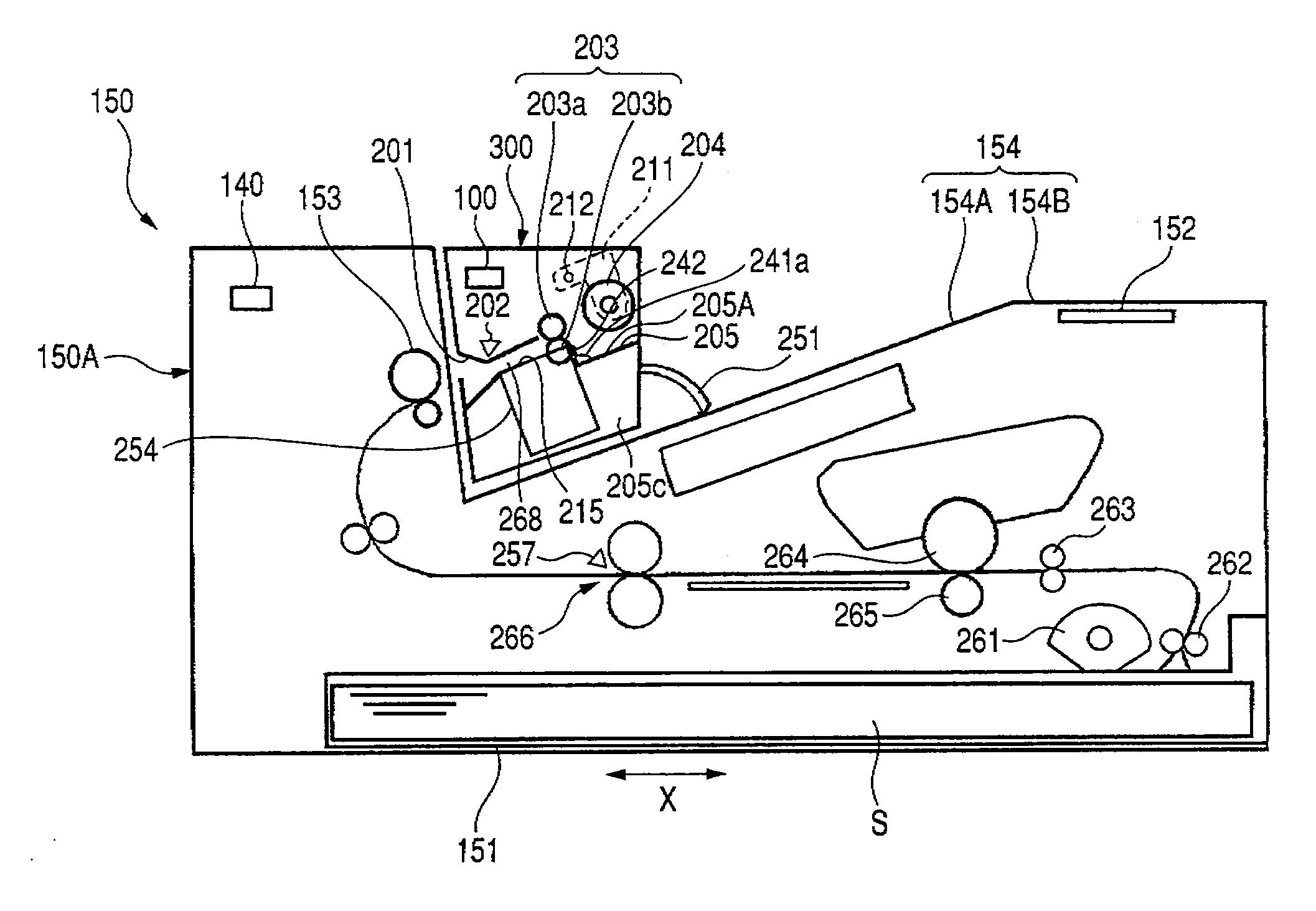

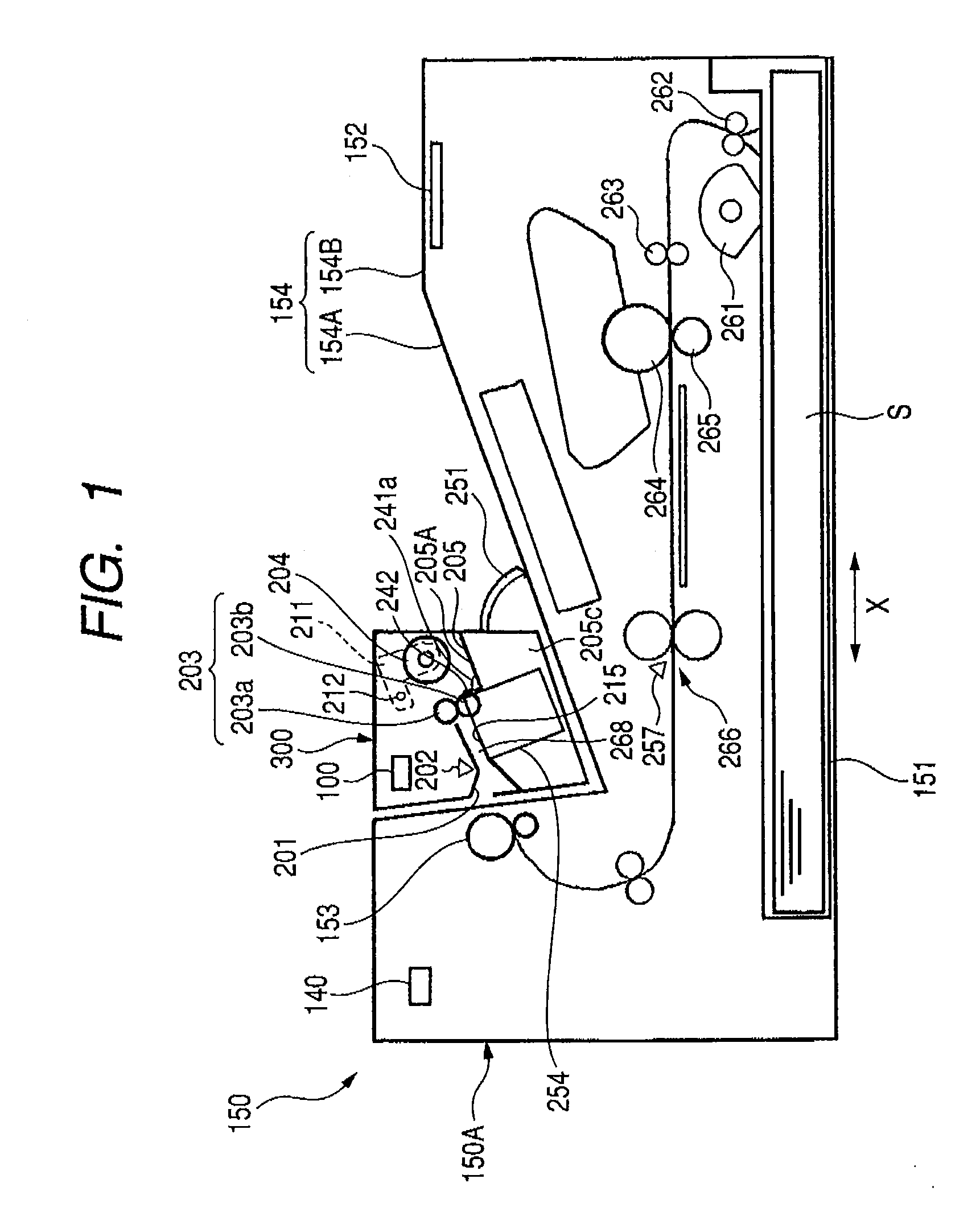

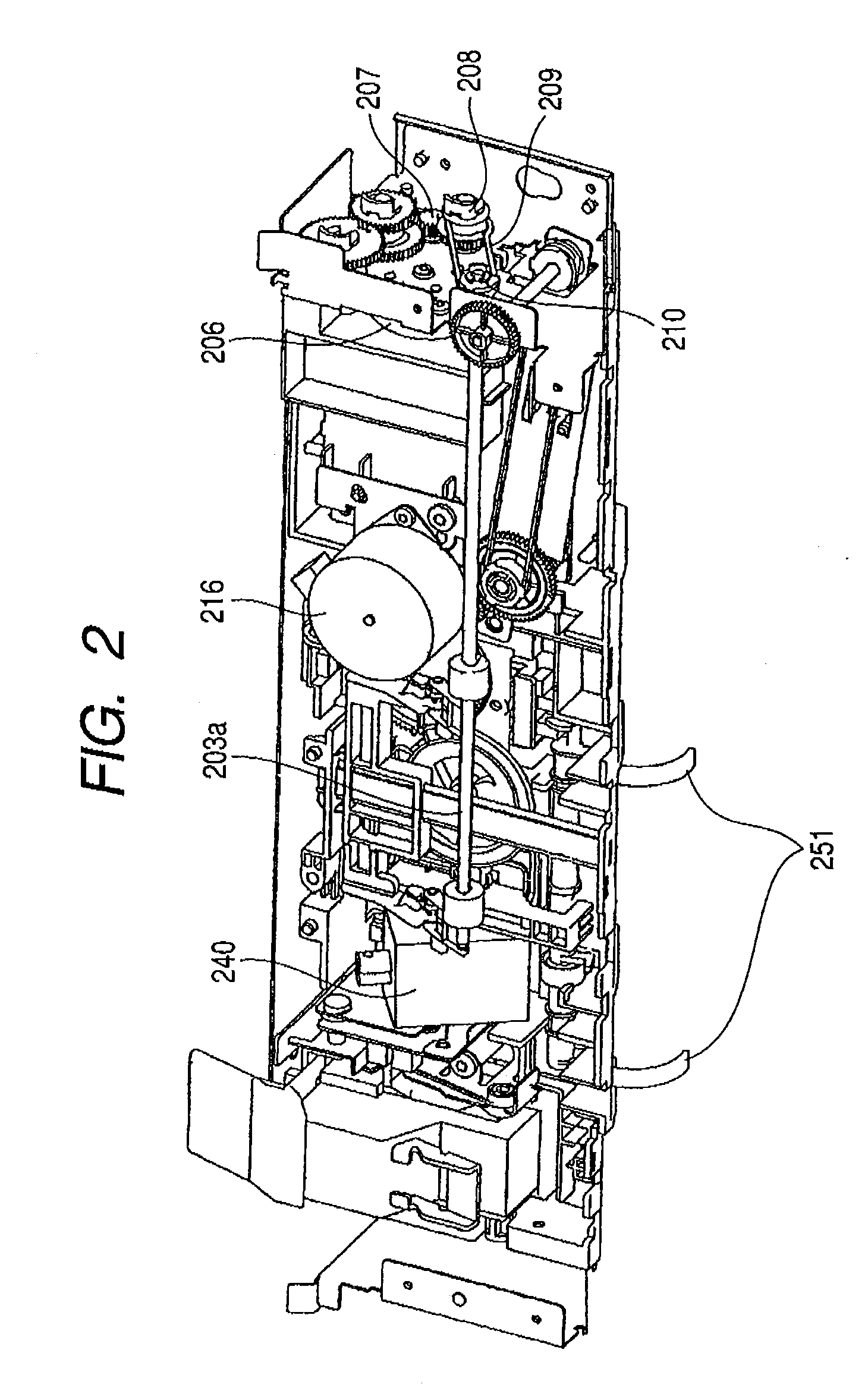

Sheet processing system

InactiveUS20050082735A1Improve productivityFunction indicatorsElectrographic process apparatusEngineeringPaper sheet

Owner:CANON KK

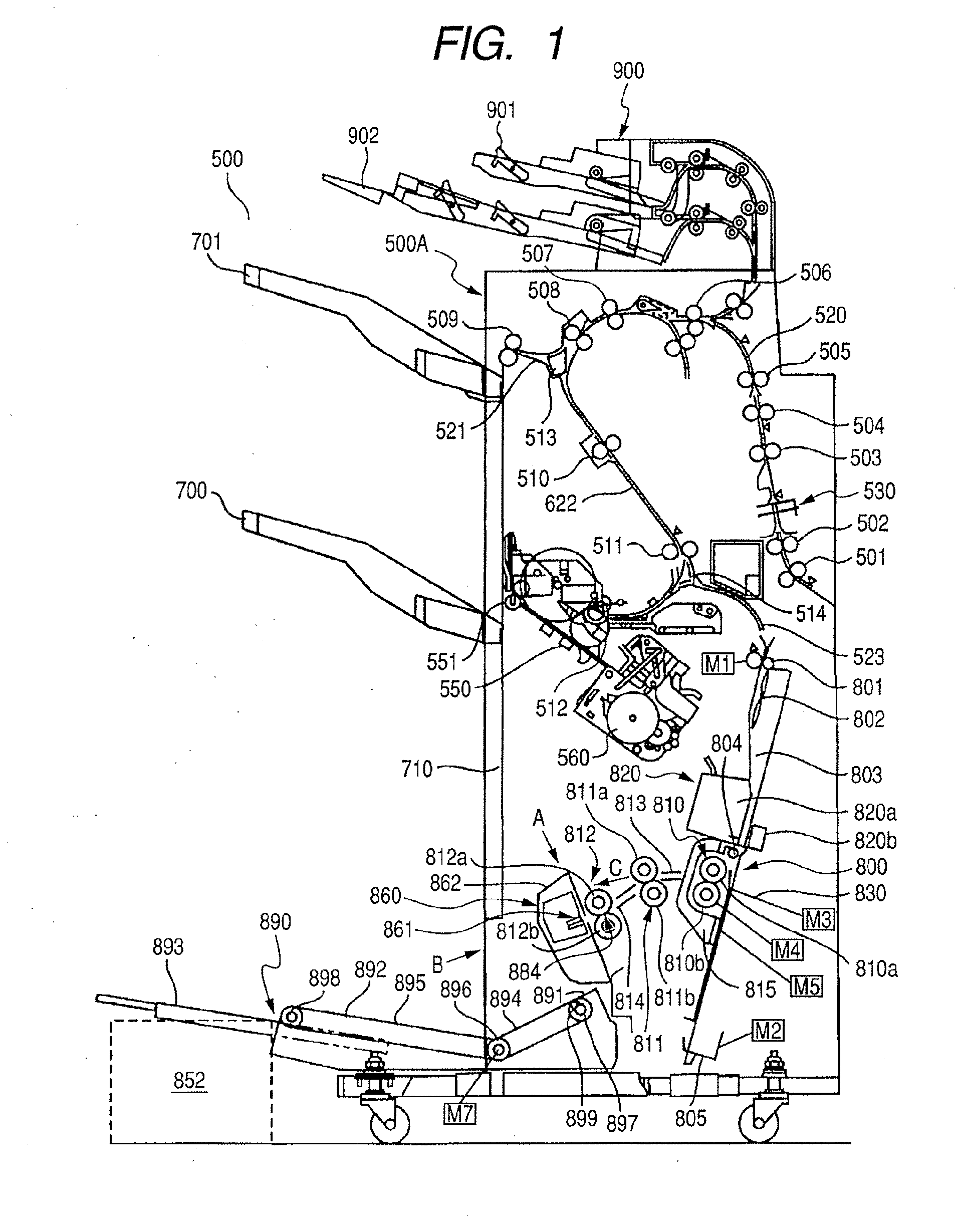

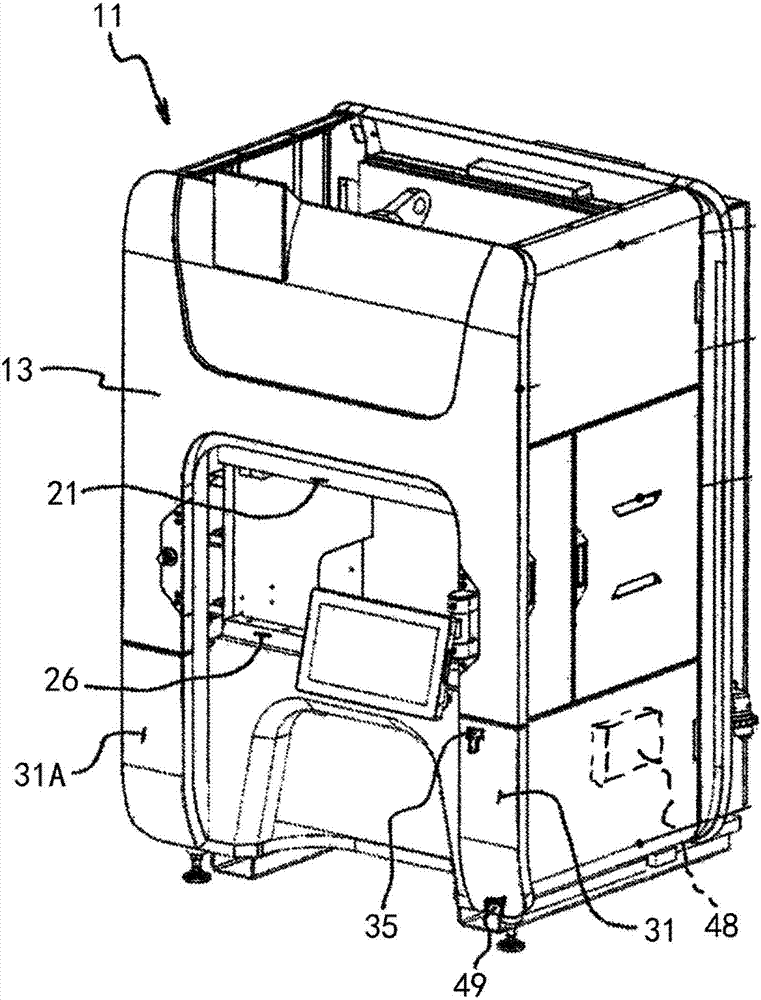

Sheet processing apparatus and image forming apparatus

ActiveUS20070045919A1Folding thin materialsElectrographic process apparatusLeading edgeImage formation

Owner:CANON KK

HDPE(high-density polyethylene) membrane composited by high foaming of LDPE(Low-Density Polyethylene) and preparation method of HDPE membrane

ActiveCN104401076AHigh mechanical strengthImprove performanceSynthetic resin layered productsLaminationLow-density polyethyleneFoaming agent

The invention discloses an HDPE(high-density polyethylene) membrane composited by high foaming of LDPE(Low-Density Polyethylene) and a preparation method of the membrane. The HDPE membrane composited by the high foaming of the LDPE comprises the HDPE membrane, wherein a sheet layer formed by the high foaming of the LDPE is arranged on the surface of the HDPE membrane, and a PE(Poly Ethylene) bonding layer is arranged between the HDPE membrane and the sheet layer; the sheet layer consists of the following components in percentage by weight: 95% of the LDPE, 3.5% of a nucleating agent, 1.39% of a foaming agent, 0.1% of an antisbrinking agent and 0.01% of an auxiliary addition agent. Compared with the prior art, the HDPE membrane composited by the high foaming of the LDPE is a novel environmental-friendly packaging material with high buffering capacity and shock resistant capacity, the membrane has the advantages that the flexibleness and the buffering capacity are good, the heat conductivity is low, the heat-shielding performance is excellent, the membrane does not pollute the environment, and the membrane belongs to the materials capable of being recycled.

Owner:SUZHOU JIUDING

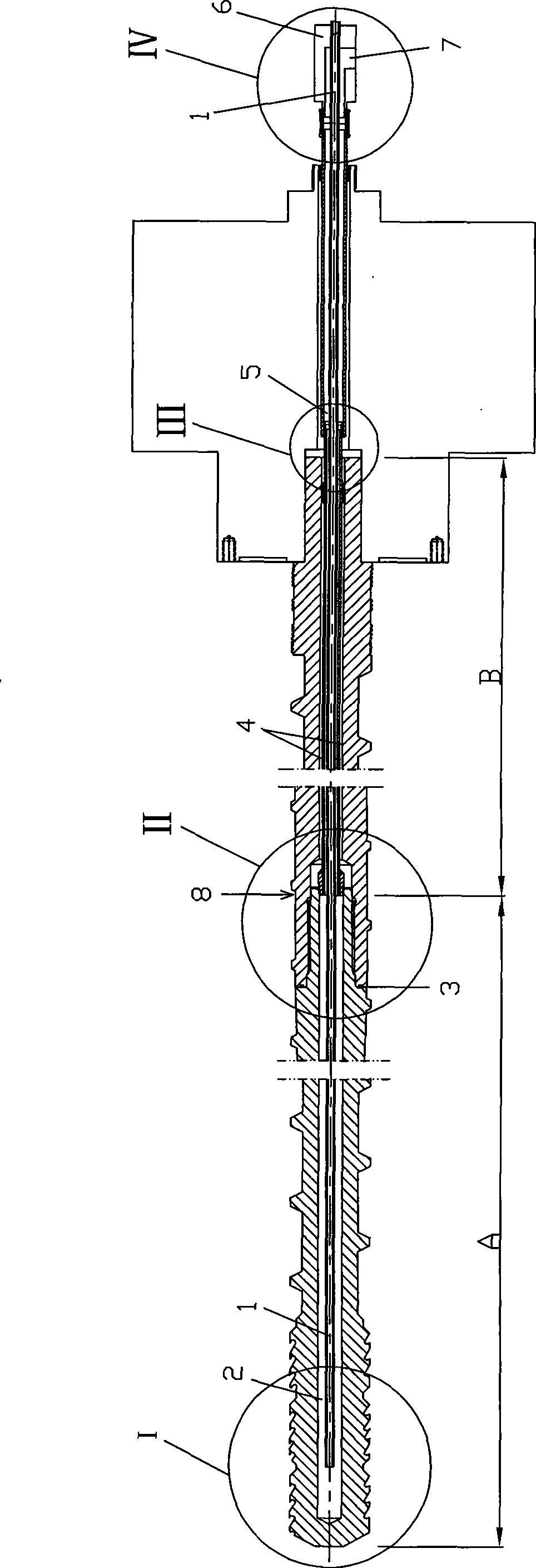

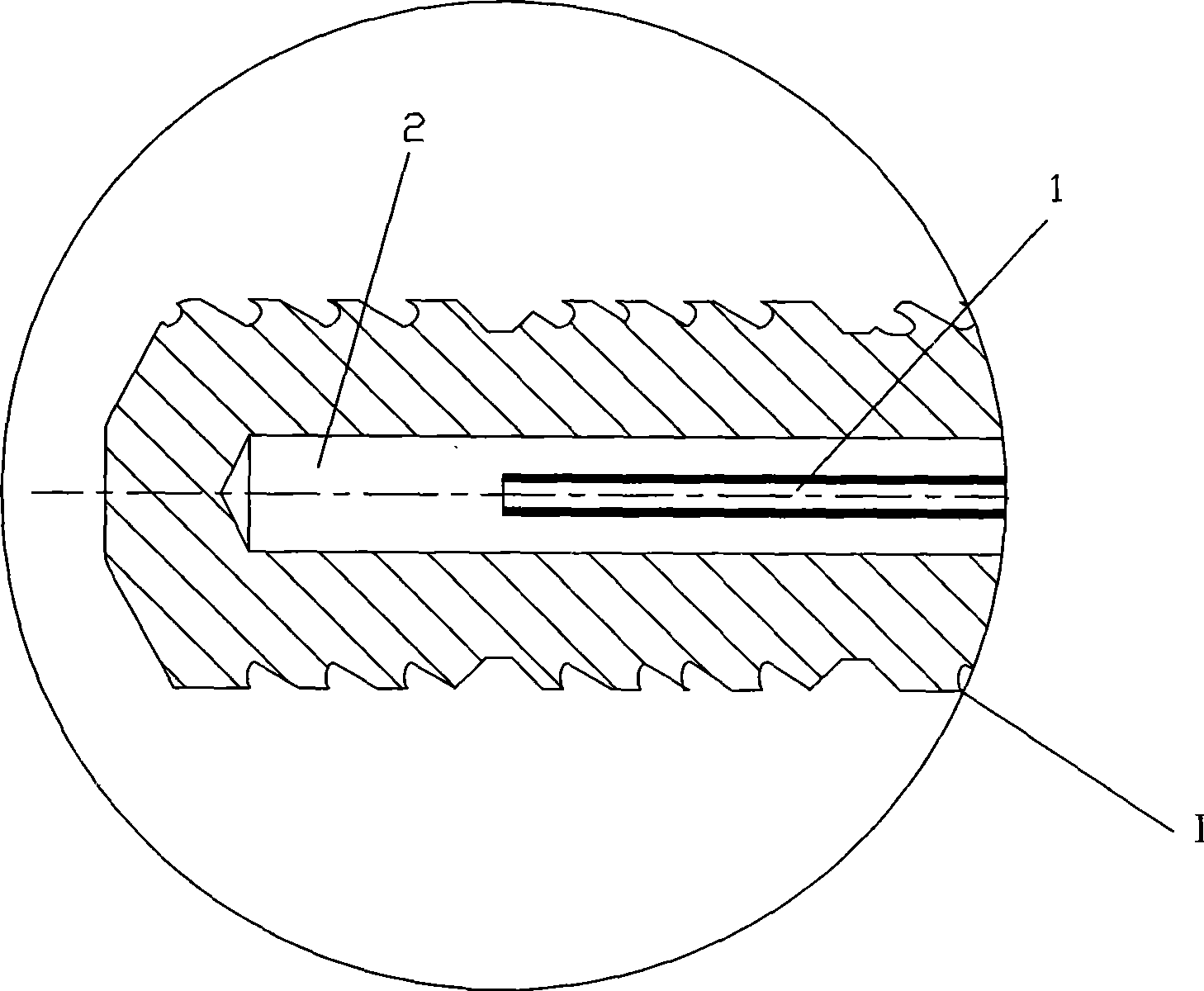

Screw rod of EPE/EPS single-screw rod foam extrusion machine with constant temperature oil for cooling forepart inner wall

InactiveCN101480841AIncrease elasticitySatisfy the processing technology requirements of subsection coolingFoaming agentReturn channel

Owner:罗承绪

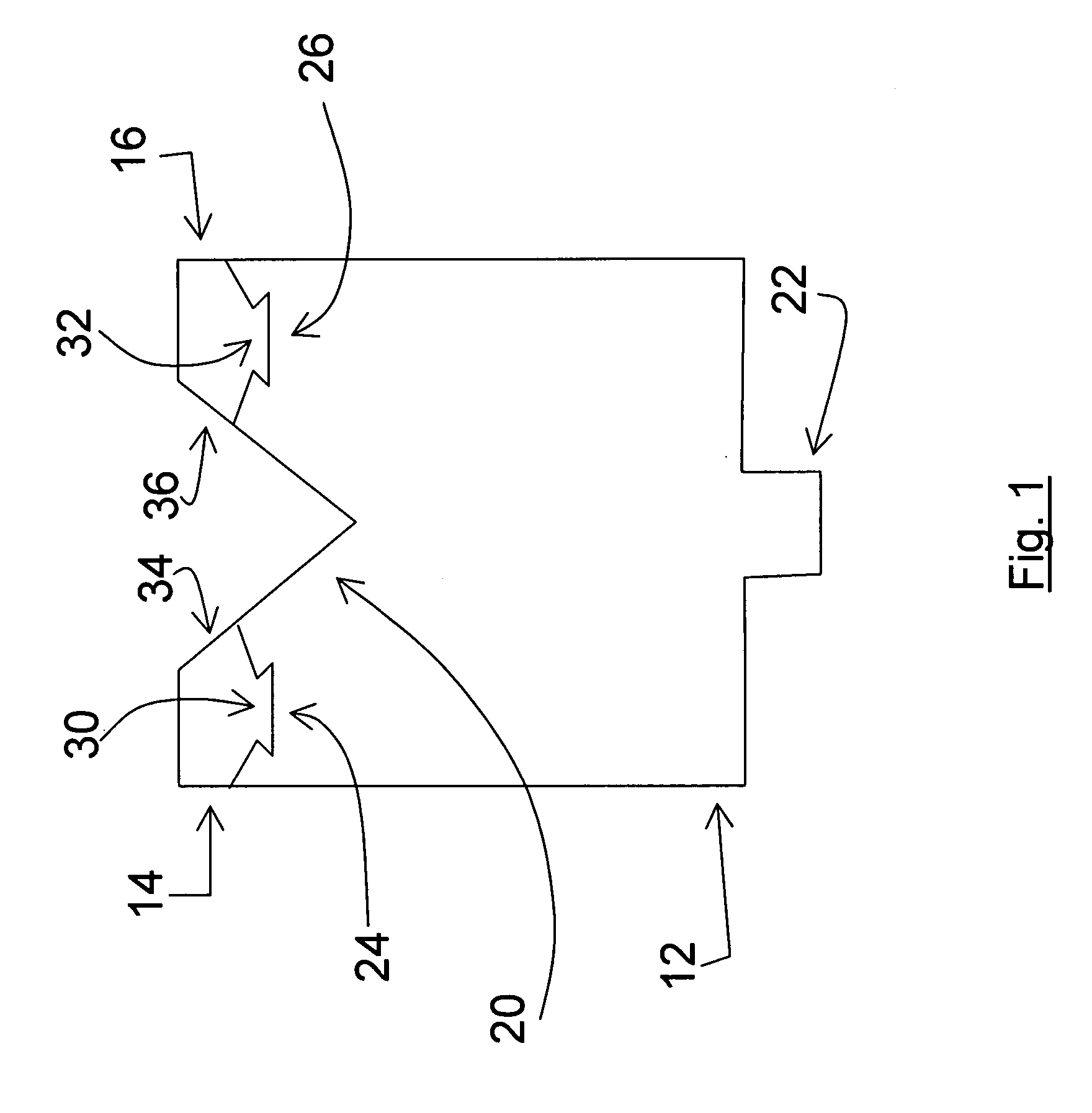

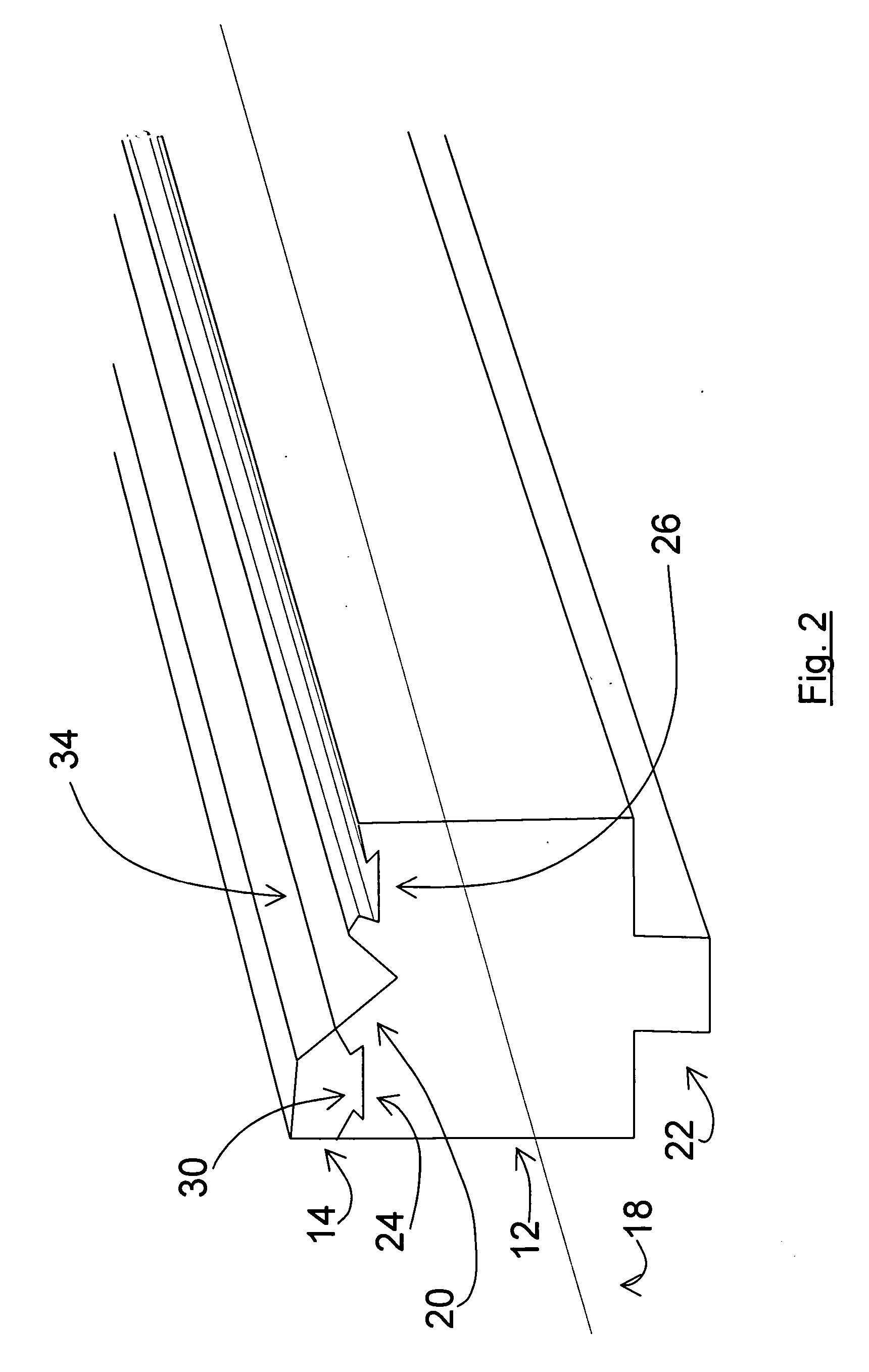

Cutting unit for cutting sheet material

InactiveUS20070186745A1Small space requirementReduce usageThrusting weaponsWeapon componentsEngineeringSheet material

Owner:MONOLITH

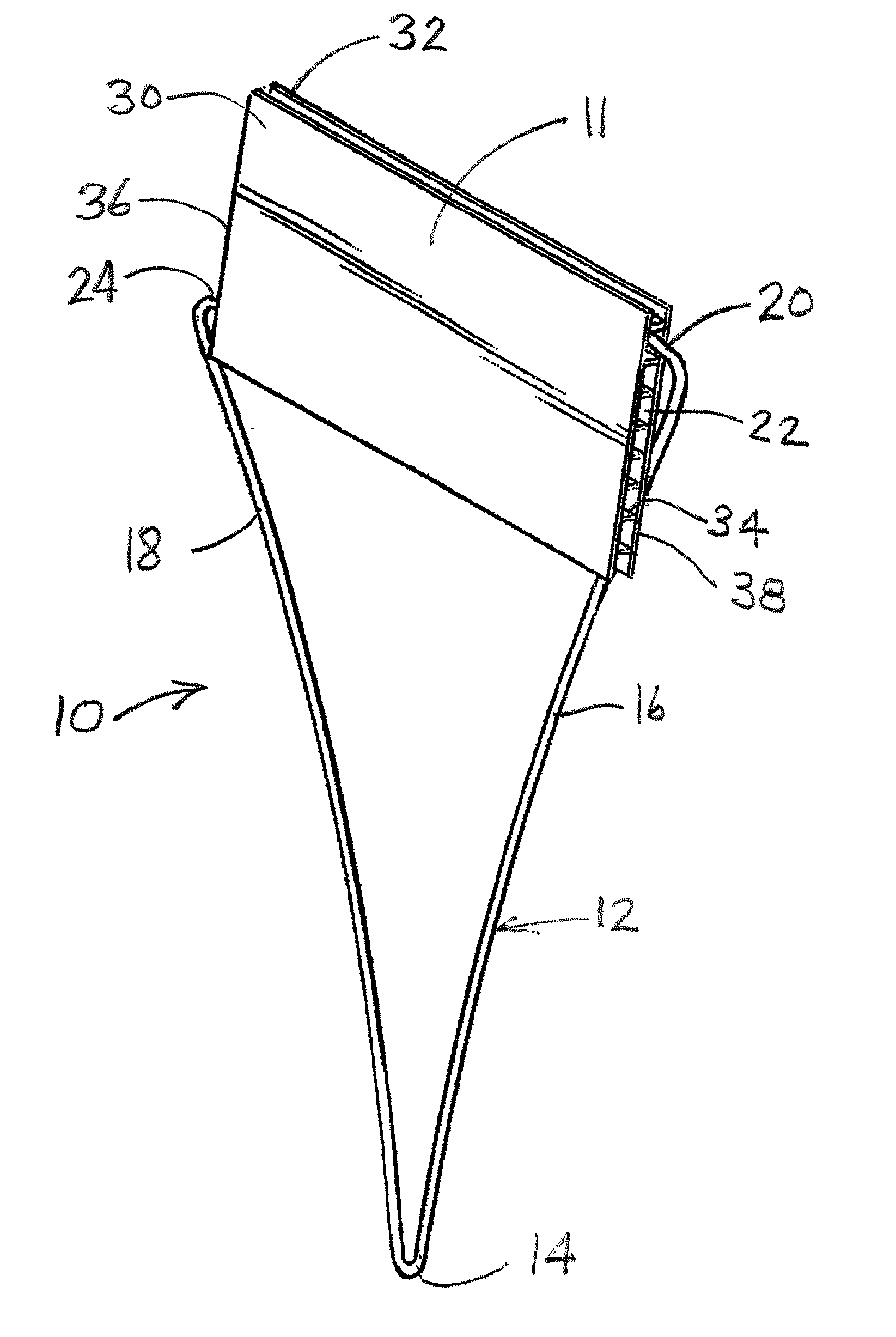

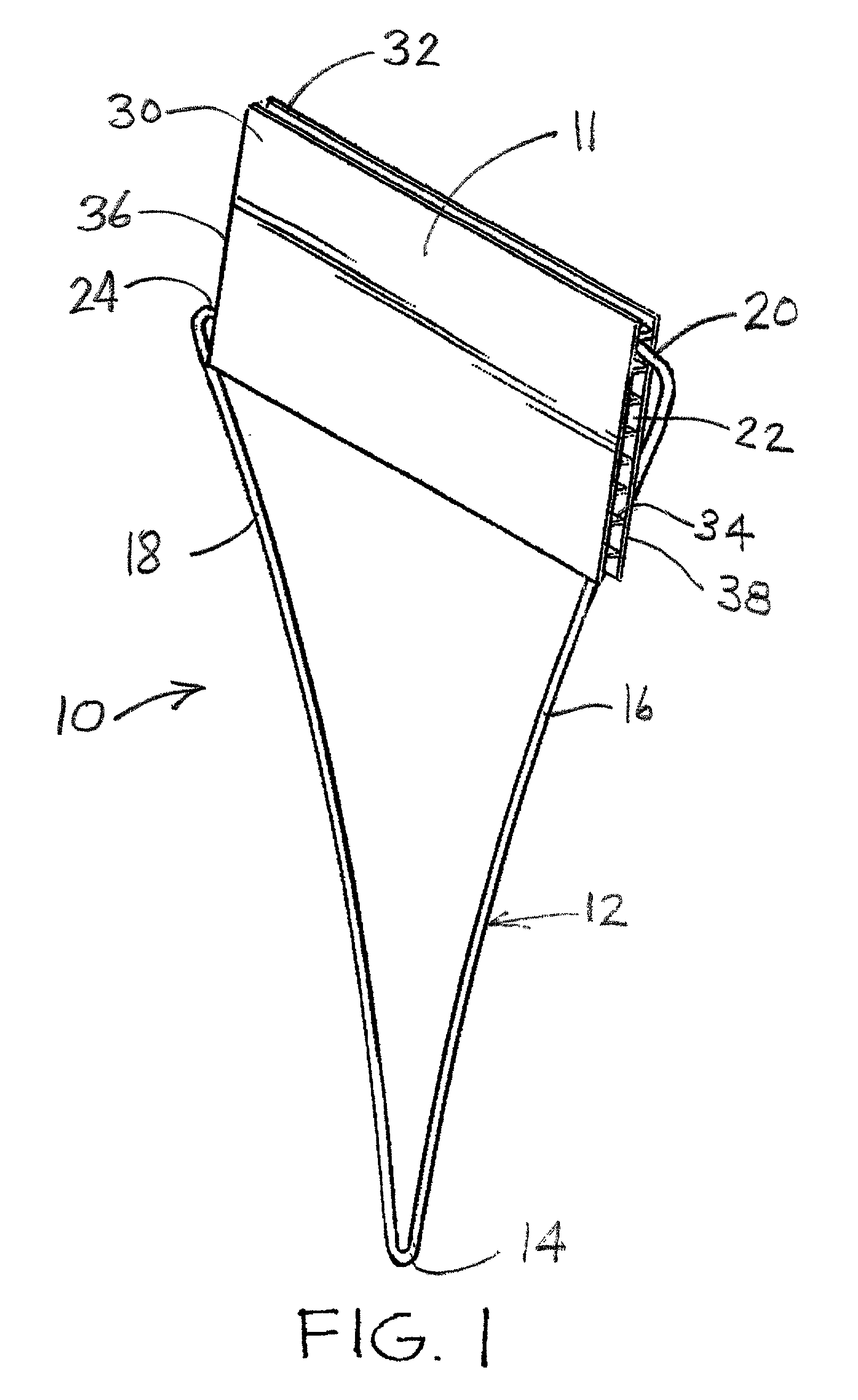

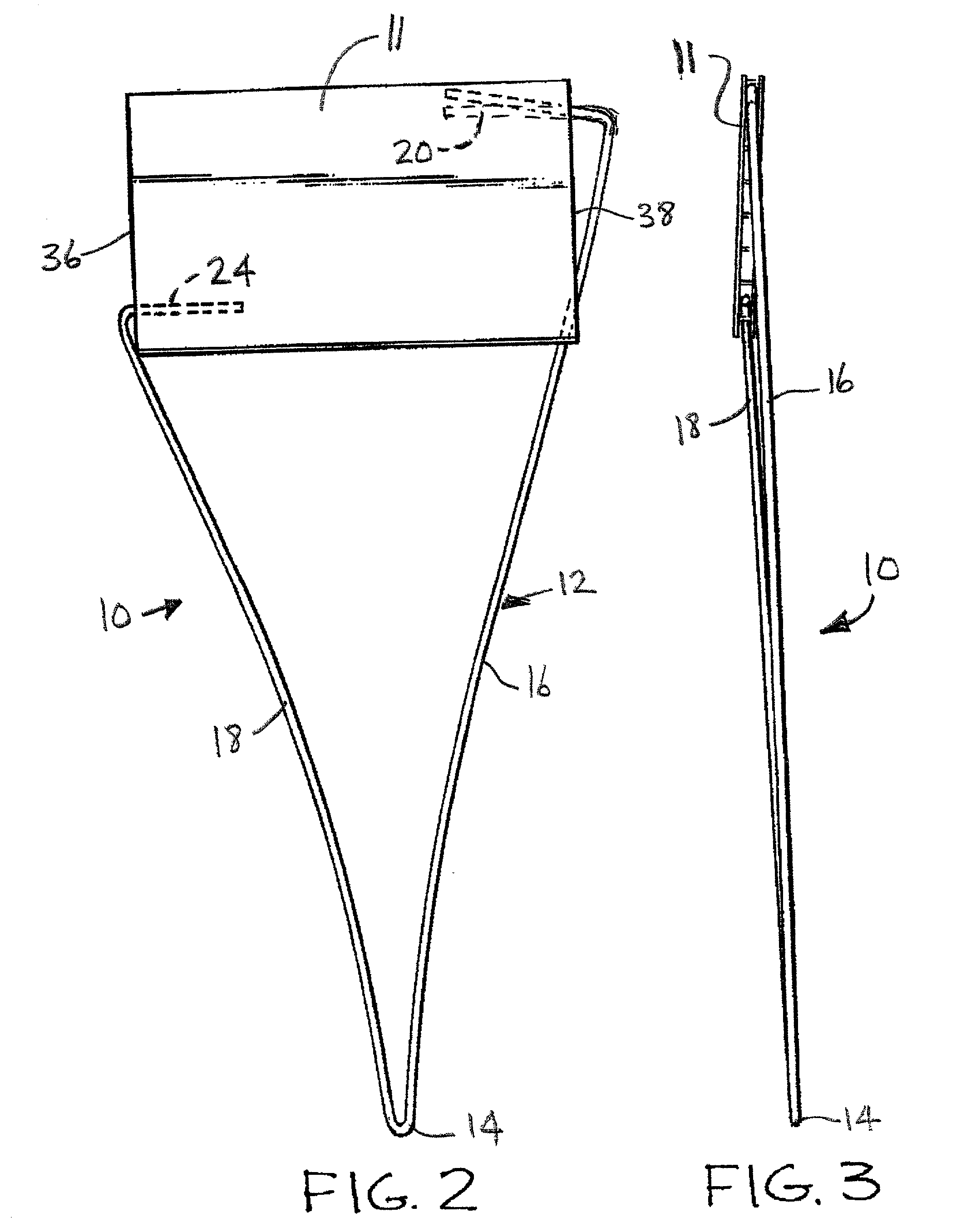

Sign holder

Owner:BARBER MARVIN M

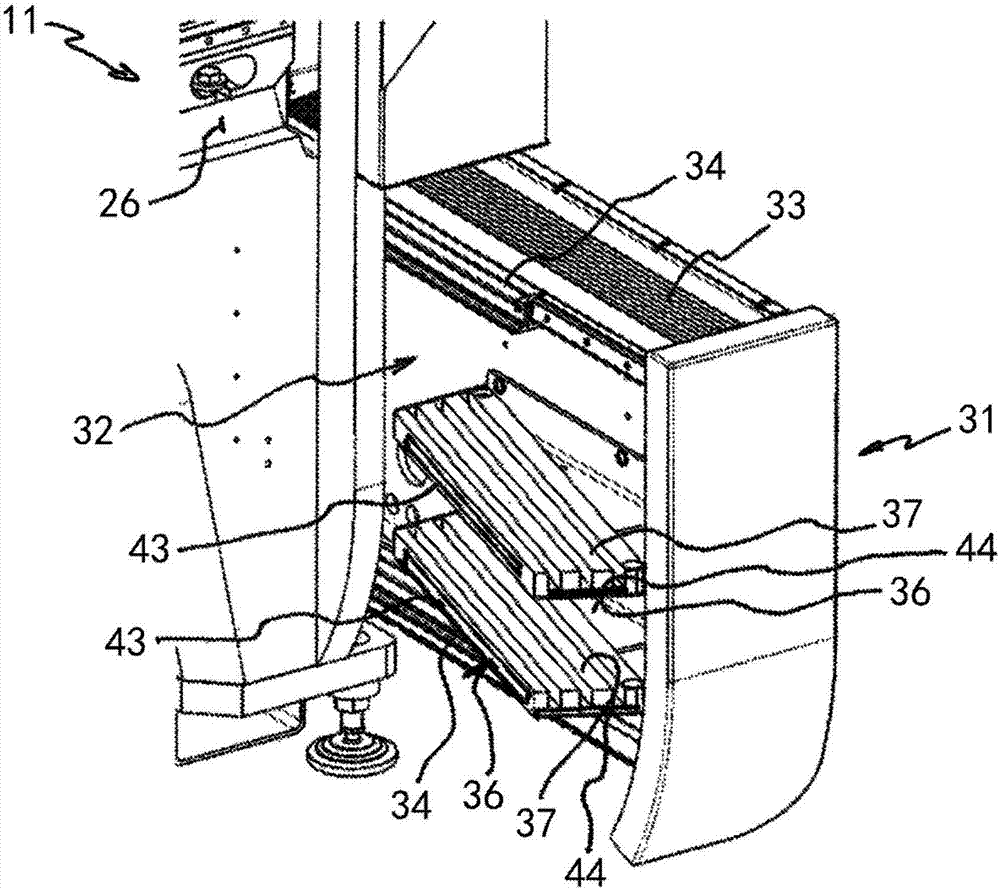

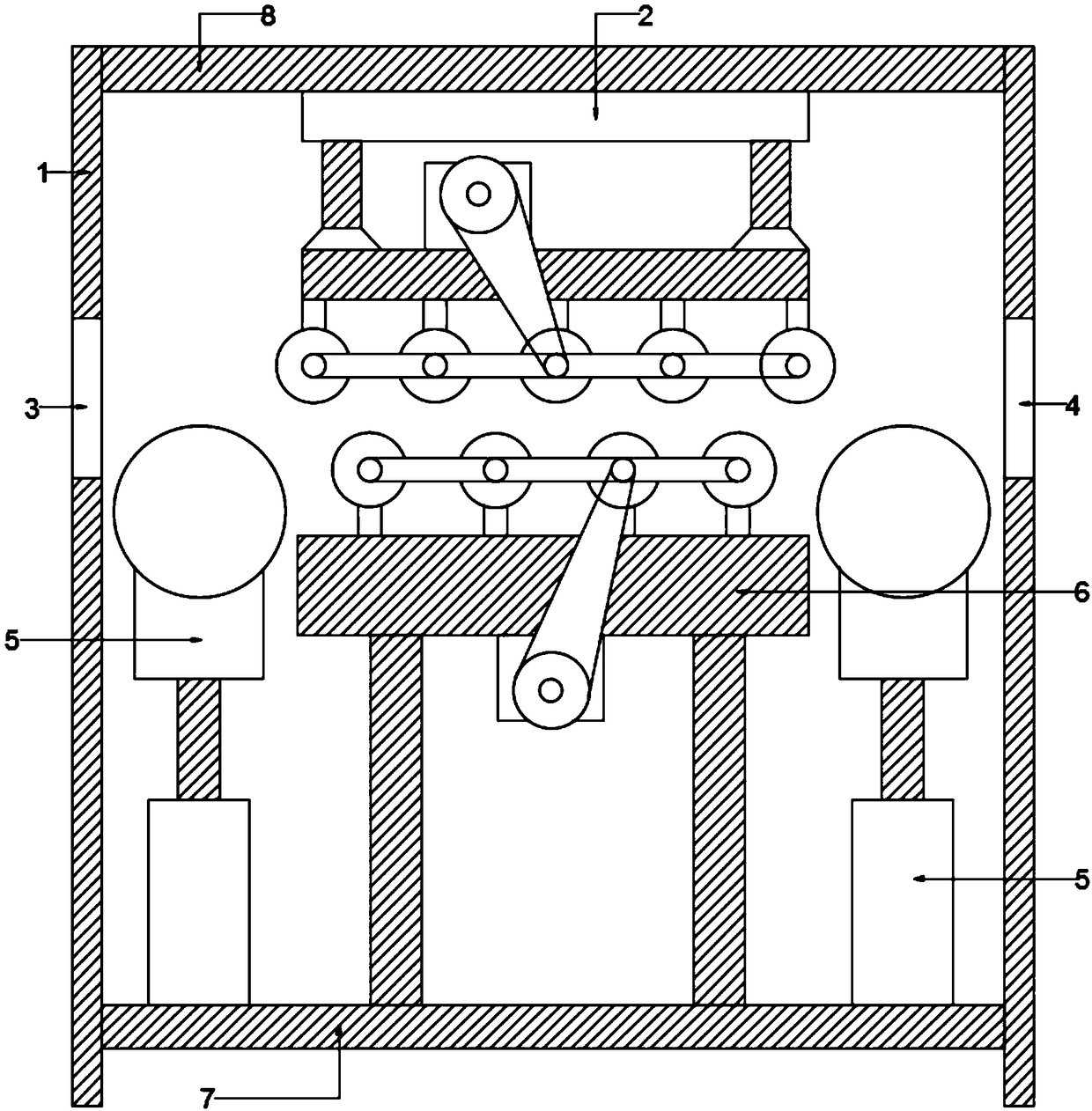

Composite sheet material production technology and production equipment

ActiveCN107160812ASimple structureIncrease productivityLamination ancillary operationsLaminationProduction lineCorona treatment

The invention discloses a composite sheet material production technology and a production equipment. The production equipment comprises a core material unreeling device, a core material conveying processing device, a gluing device, a combination device, a fine rolling combination device, and a subsequent production line which are connected successively; the core material conveying processing device comprises a first conveying device, a second conveying device, a corona processing device, a third conveying device, and a first machine frame; the first conveying device, the second conveying device, and the third conveying device are arranged on the first machine frame successively; and the corona processing device is arranged on the second conveying device. The composite sheet material production technology and the production equipment possess following advantages: structure is simple, process is novel, and the composite sheet material production technology is safe and reliable.

Owner:沈惠华

Fixing apparatus

ActiveUS20130266353A1Suppress of uneven glossinessElectrographic process apparatusEngineeringSheet material

Owner:CANON KK

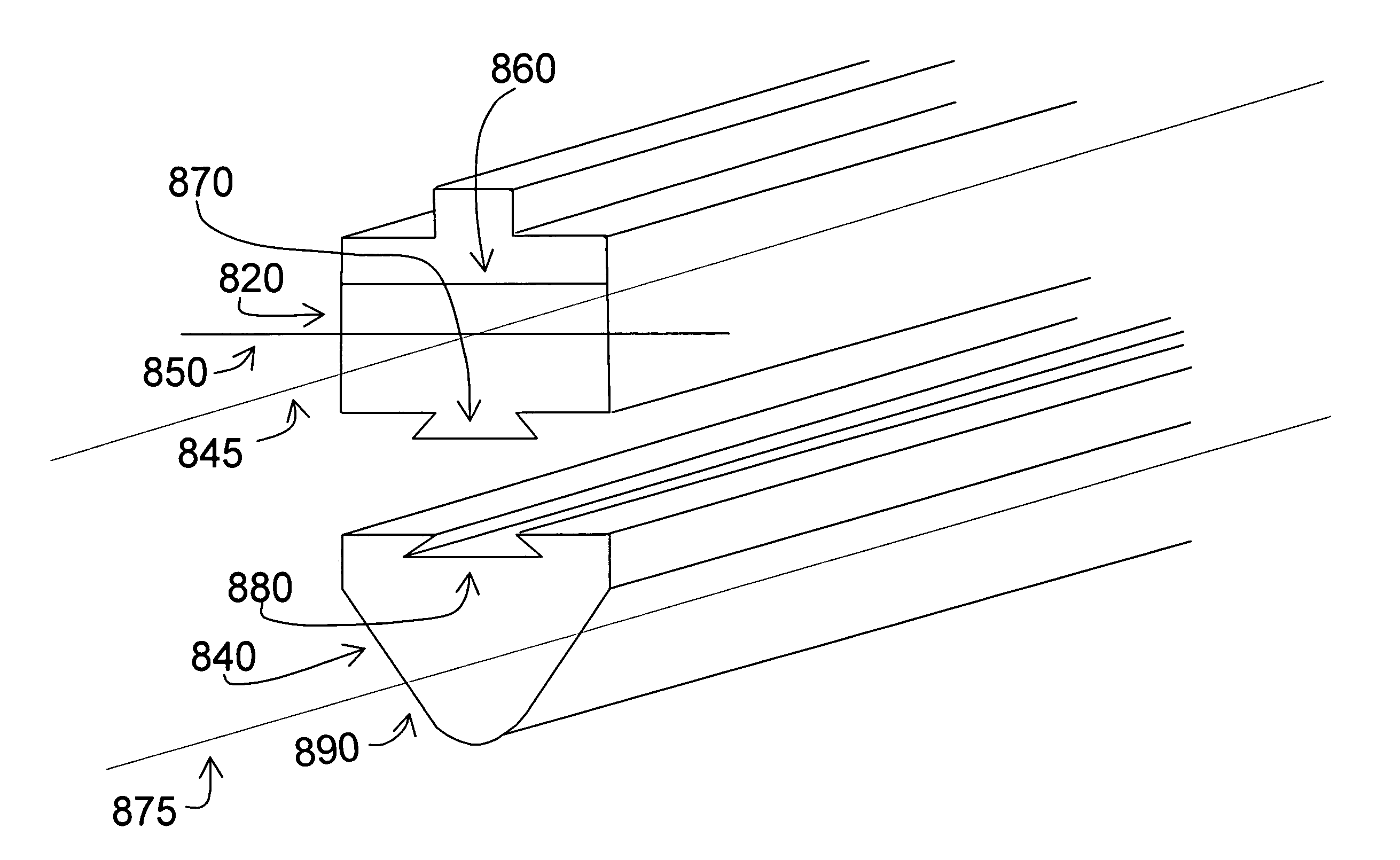

Brake punch inserts

Owner:LELAND DAVID

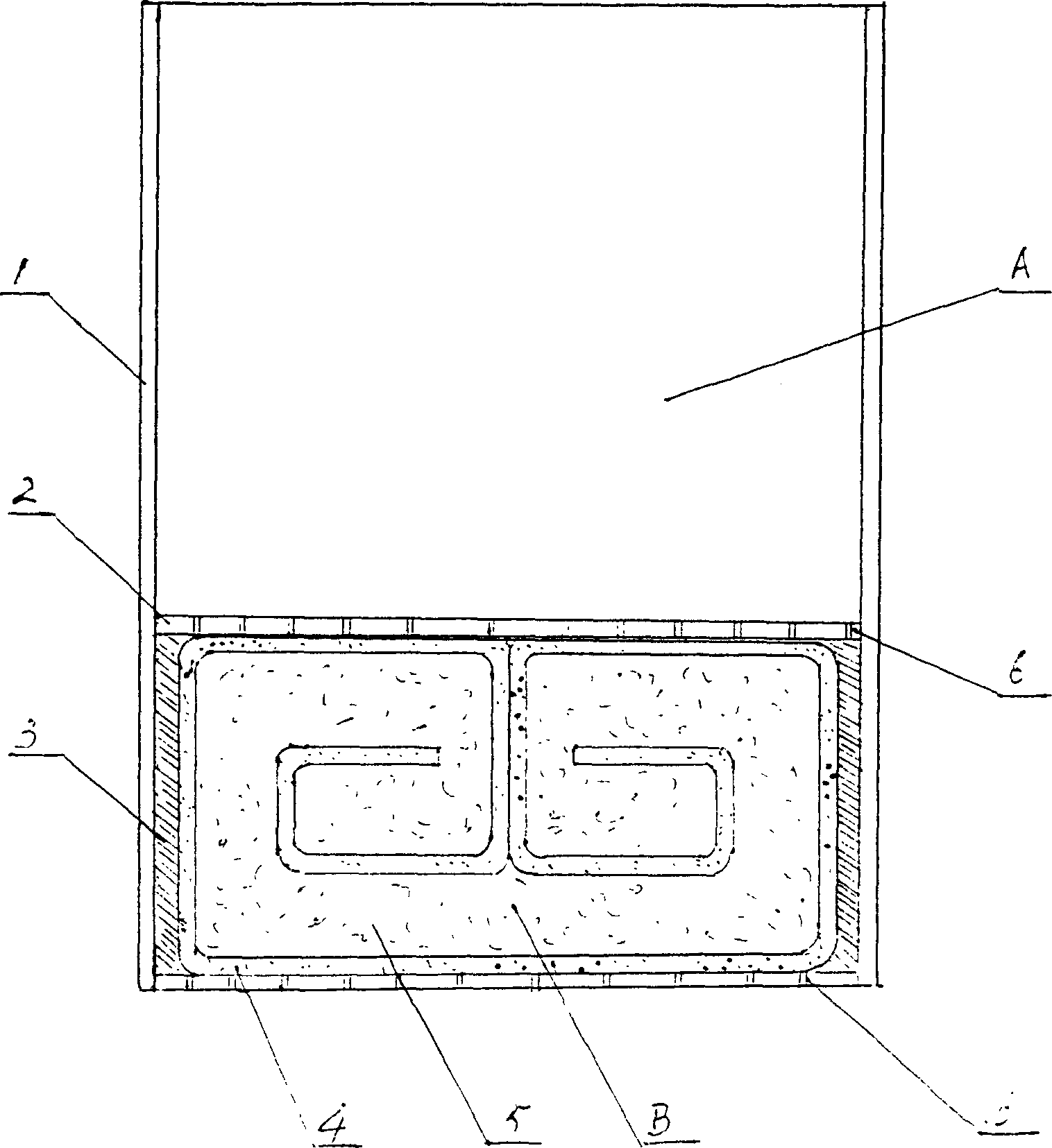

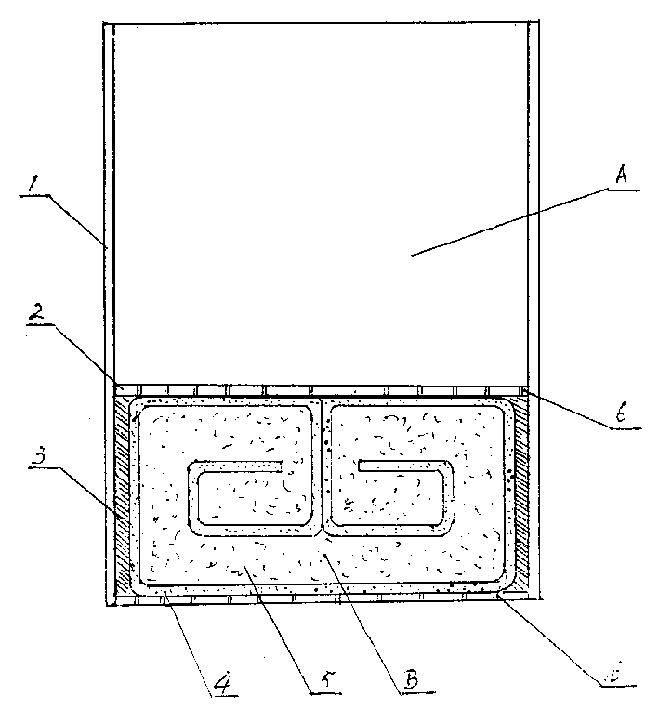

Plant protection and water saving device

A blank for a plant protection and water saving device includes four generally trapezoidal panels arranged in a row and connected to each other at a widest part of each panel, which panels in use form four side walls of the device. Two flaps each extend from one trapezoidal panel at a narrowest part of the panel, with a cut-out being defined at a free leading edge of each flap and several spaced apart lines of weakness being provided around the cut-out. The blank is manufactured from a fluted sheet material.

Owner:RUGHEIMER ROBERT DEREK

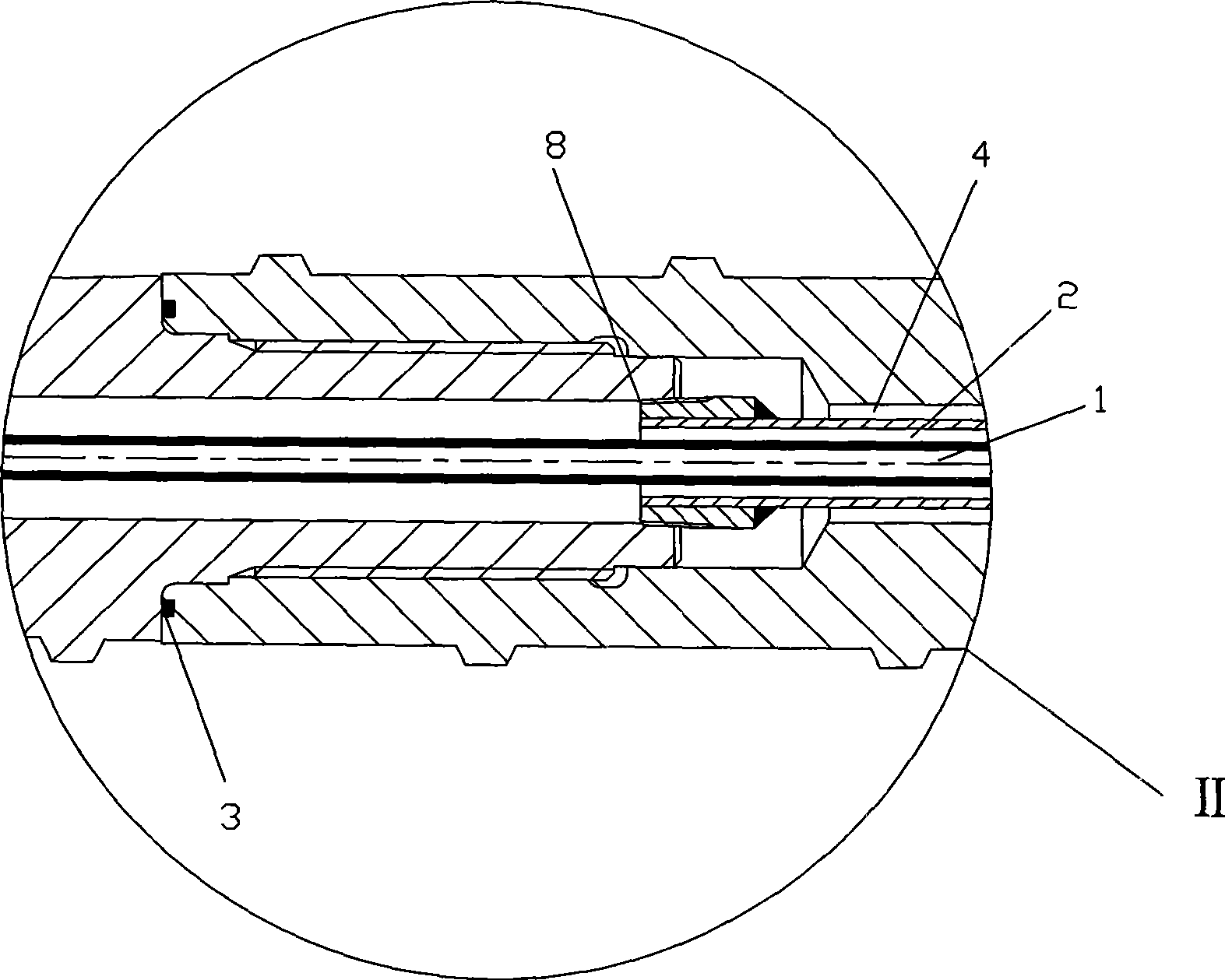

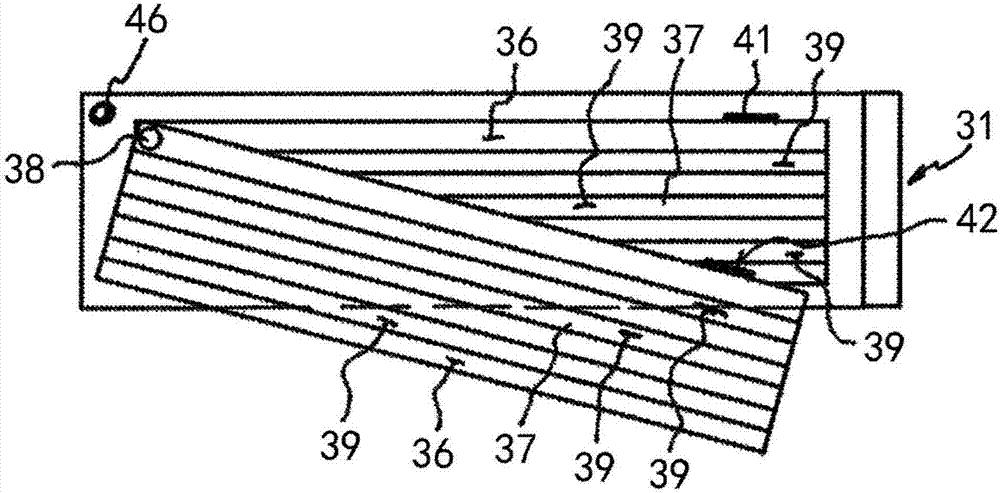

Sheet material supplying device

ActiveCN104955749ASmall footprintShock-sensitive articlesGlass severing apparatusSource materialBiomedical engineering

A sheet material supplying device comprises a pair of holding means (5, 6) that hold, in the width direction, both ends of a sheet material (4) made by cutting a strip sheet source material (1) into prescribed lengths, and a pair of guide members (12) that moveably support each of the pair of holding means (5, 6) between a cutting position and a supplying position of the sheet material (4). Each guide member (12) is supported by being suspended from a building beam (20).

Owner:NIPPON ELECTRIC GLASS CO LTD

Wear-resistant composite microcrystalline sheet material

Owner:HENAN JINGXIANG ABRASION PROOF MATERIAL

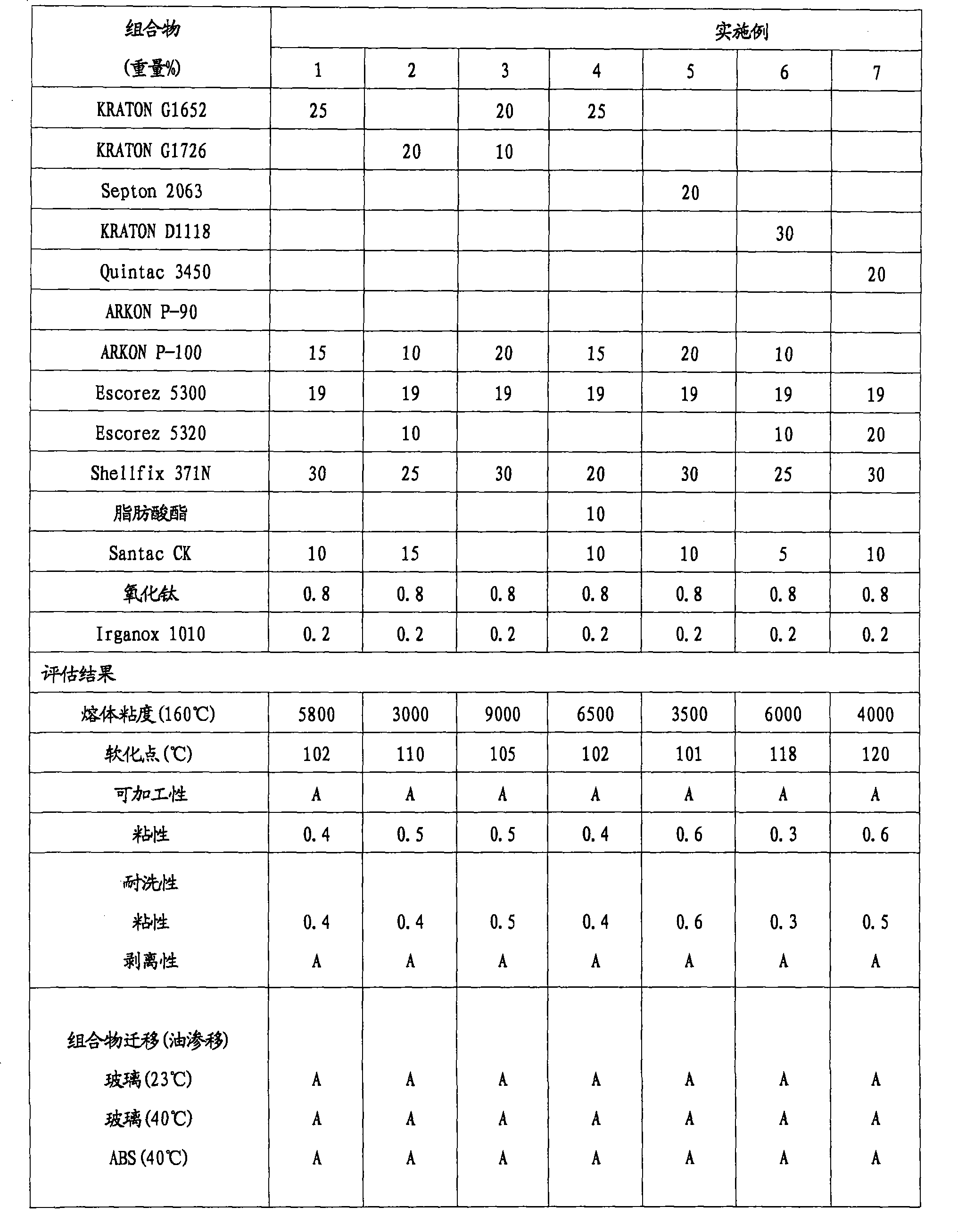

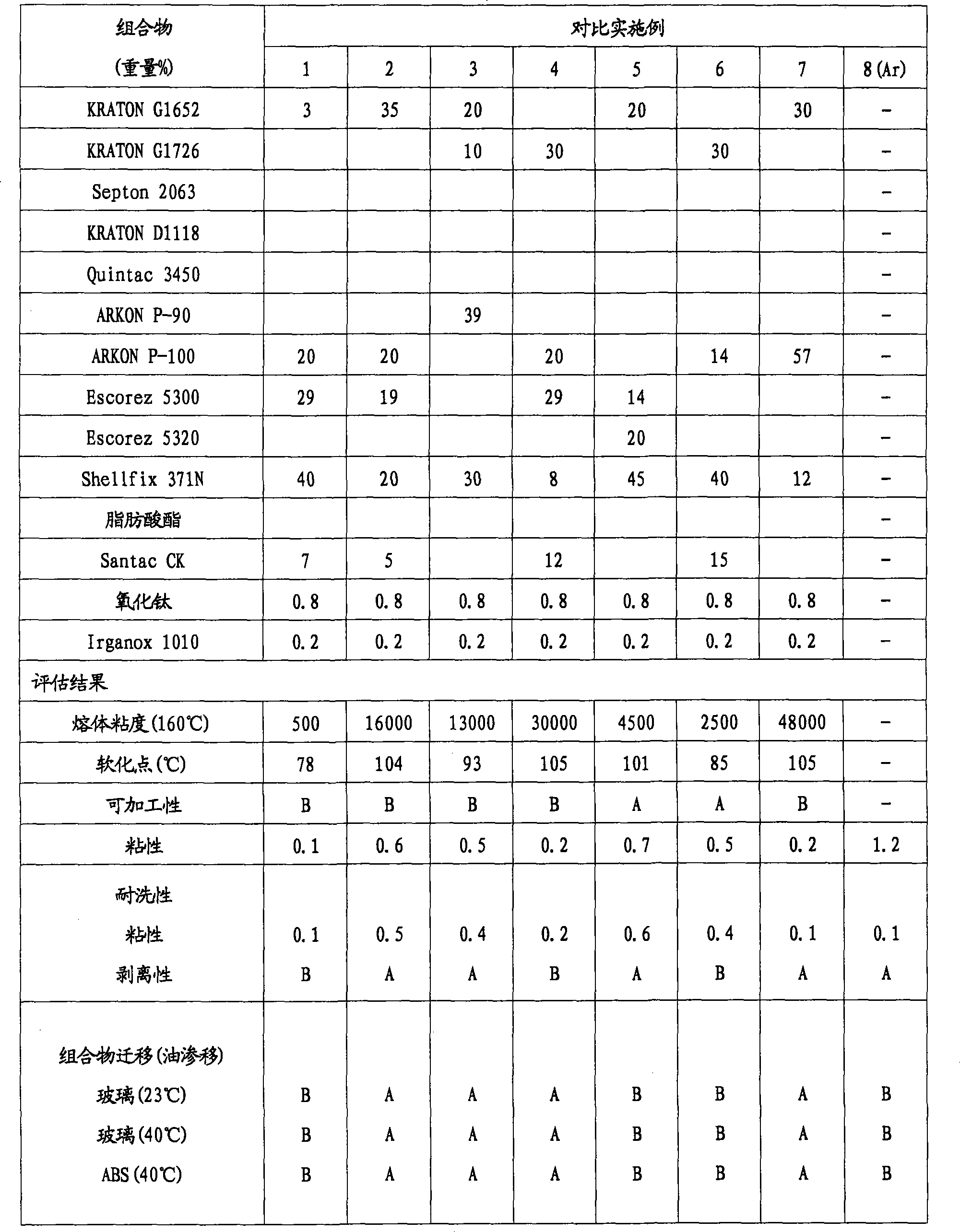

Hot melt composition for toilet seat sheet and toilet seat sheet

InactiveCN101381588AReduce manufacturing costIncrease productionBathroom coversAdhesivesPolyolefinEngineering

Owner:NISSHIN CHEM IND CO LTD

Special unsaturated polyester resin adhesive for quartz stone sheet material

InactiveCN106753148AImprove impact toughnessHigh bonding strengthNon-macromolecular adhesive additivesGas phasePhosphine oxide

The invention discloses a special unsaturated polyester resin adhesive for a quartz stone sheet material. The special unsaturated polyester resin adhesive is prepared from the following raw materials: unsaturated polyester resin, acrylic acid-2-hydroxyethyl ester, pentaerythritol triacrylate, 2-methyl-1-(4-methylthiophenyl)-2-morpholinyl-1-acetone, biphenyl-(2,4,6-trimethylbenzoyl)phosphine oxide, a flatting agent, a de-foaming agent, a silane coupling agent, gas-phase silicon dioxide, glass microsphere and modified aluminum hydroxide. The special unsaturated polyester resin adhesive for the quartz stone sheet material, provided by the invention, has high binding performance, good impacting toughness and excellent flame-retarding performance.

Owner:ANHUI AIDIBEI BIOLOGICAL CO LTD

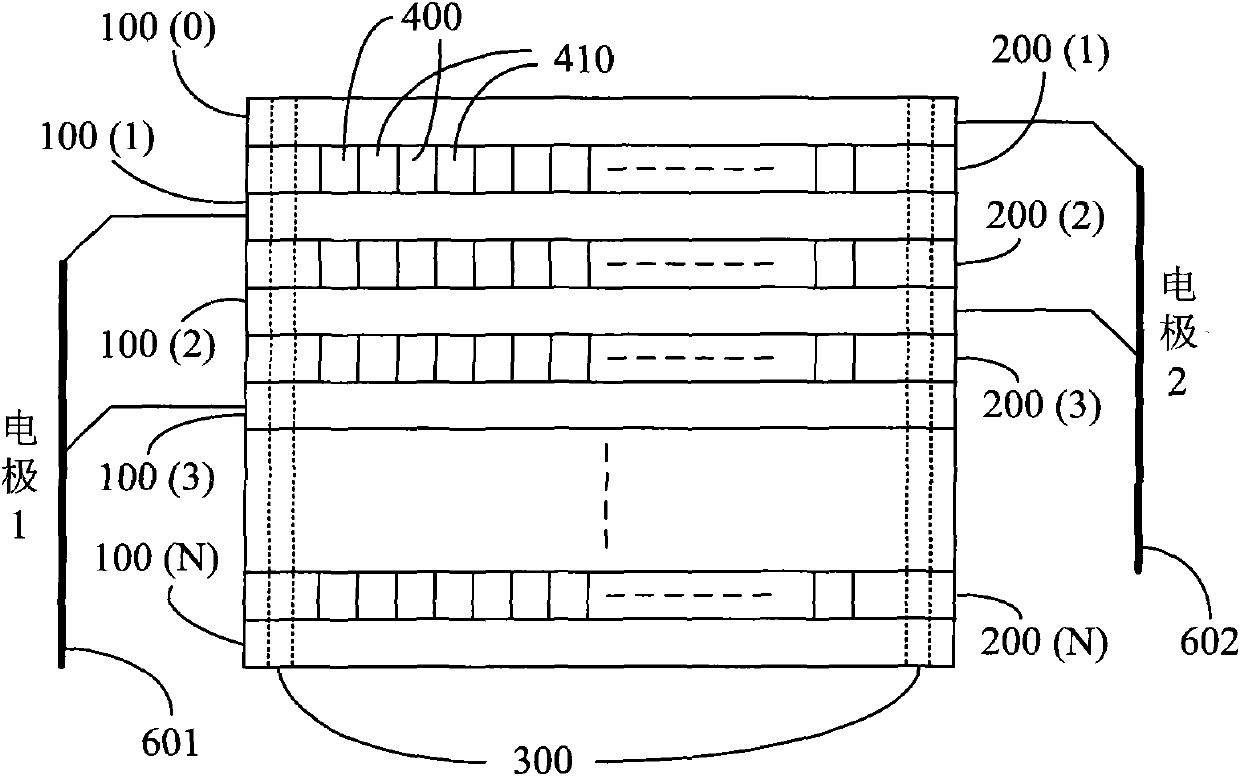

Configurable two-dimensional micro-plasma array device and preparation method thereof

InactiveCN101794699AIncreased size flexibilityIncrease array densityCold-cathode tubesCold cathode manufactureConductive materialsDielectric layer

Owner:SHANDONG UNIV

Fixing device and image forming apparatus

Owner:RICOH KK

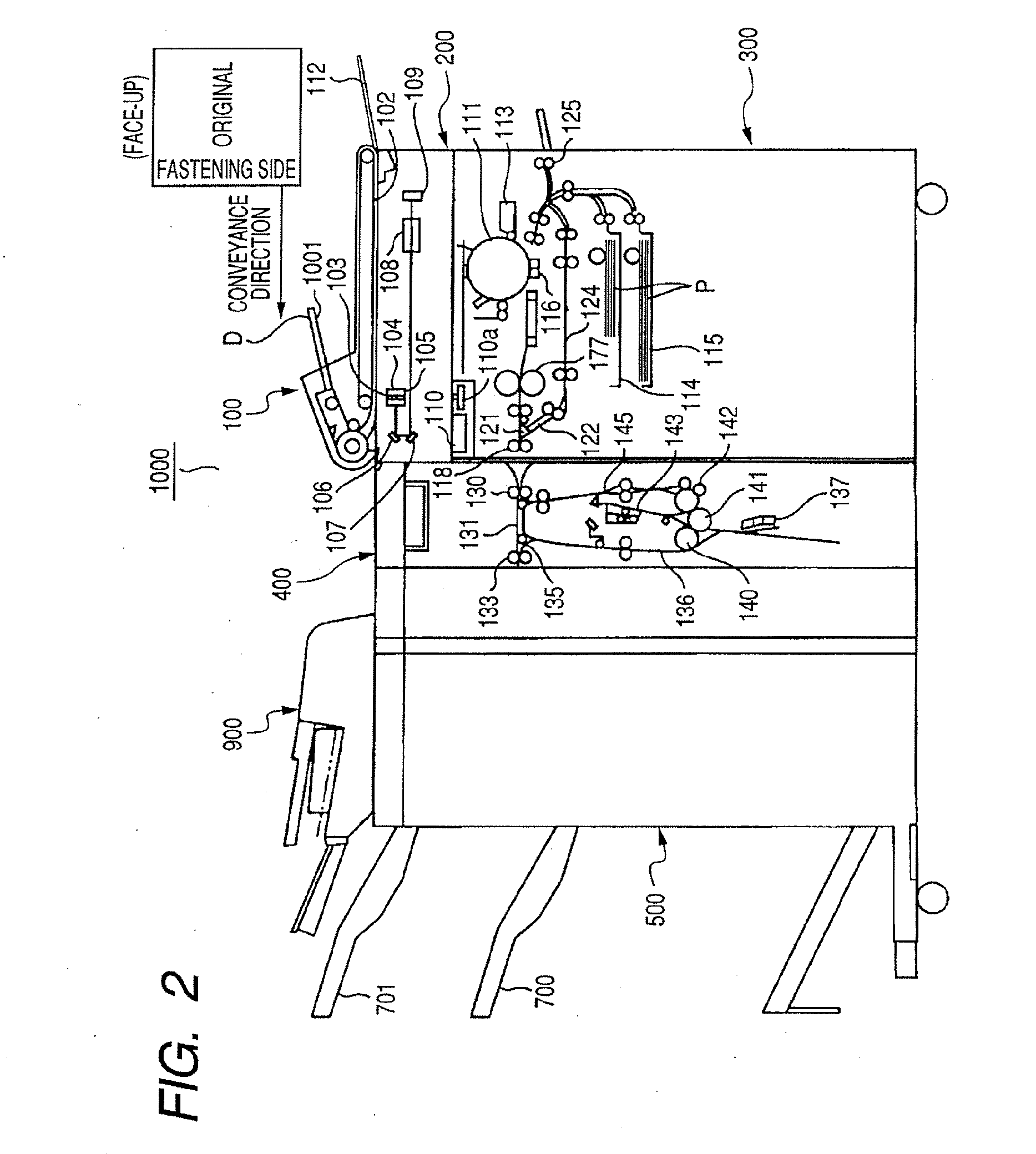

Sheet processing apparatus and image forming apparatus

ActiveUS20090074493A1Improve cooling effectIncrease in operation soundElectrographic process apparatusImage formationTime processing

Owner:COPYER

Bending press

Owner:BYSTRONIC LASER

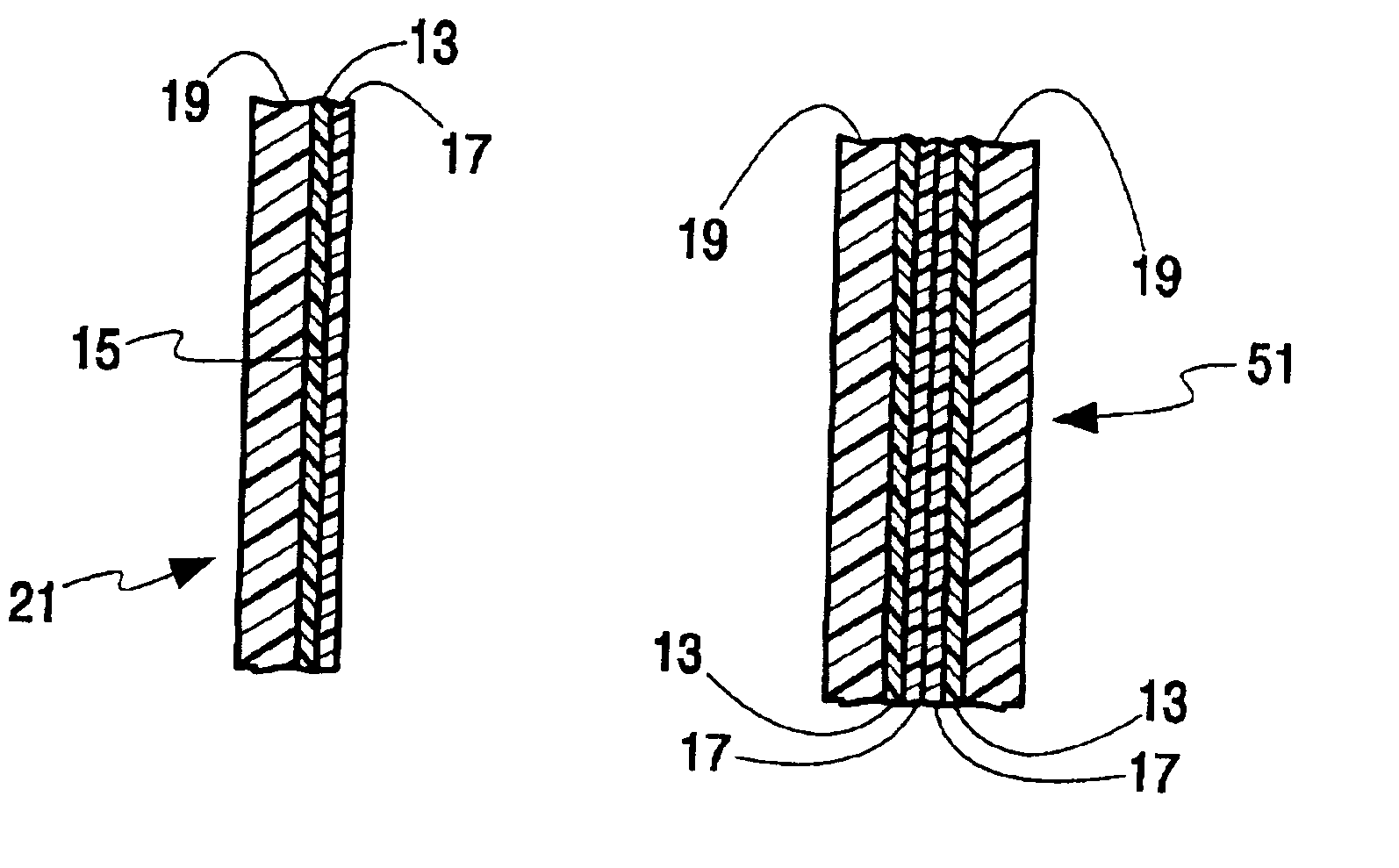

Thermal-dye-transfer receiver element with polylactic-acid-based sheet material

Disclosed is a thermal dye-transfer dye-image receiving element comprising a thermal dye-transfer receiver element comprising a dye-receiving layer 1; beneath layer 1, a substrate layer 2 containing a microvoided layer 2 comprising, in a continuous phase, a polylactic-acid-based material, wherein microvoids in said microvoided layer provide a void volume of at least 25% by volume, and wherein at least about half of the microvoids are formed from void initiating particles less than 1.5 micrometer in average diameter; and beneath layer 2, an optional support layer 3.

Owner:EASTMAN KODAK CO

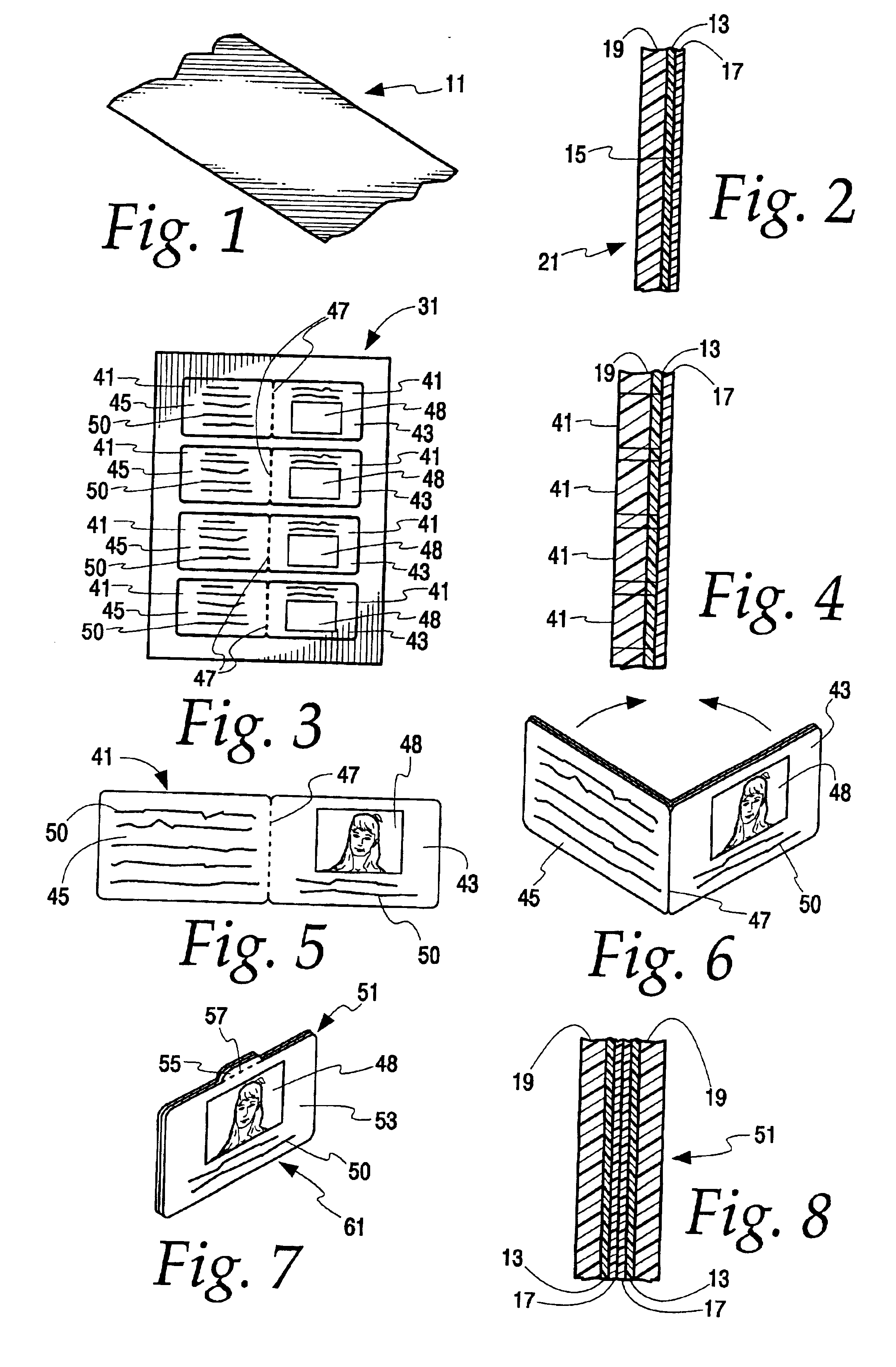

Identification card

InactiveUS6908527B2Increase awarenessPositive identificationOther printing matterLamination ancillary operationsPolyolefinEngineering

Owner:TRANSCENDIA INC

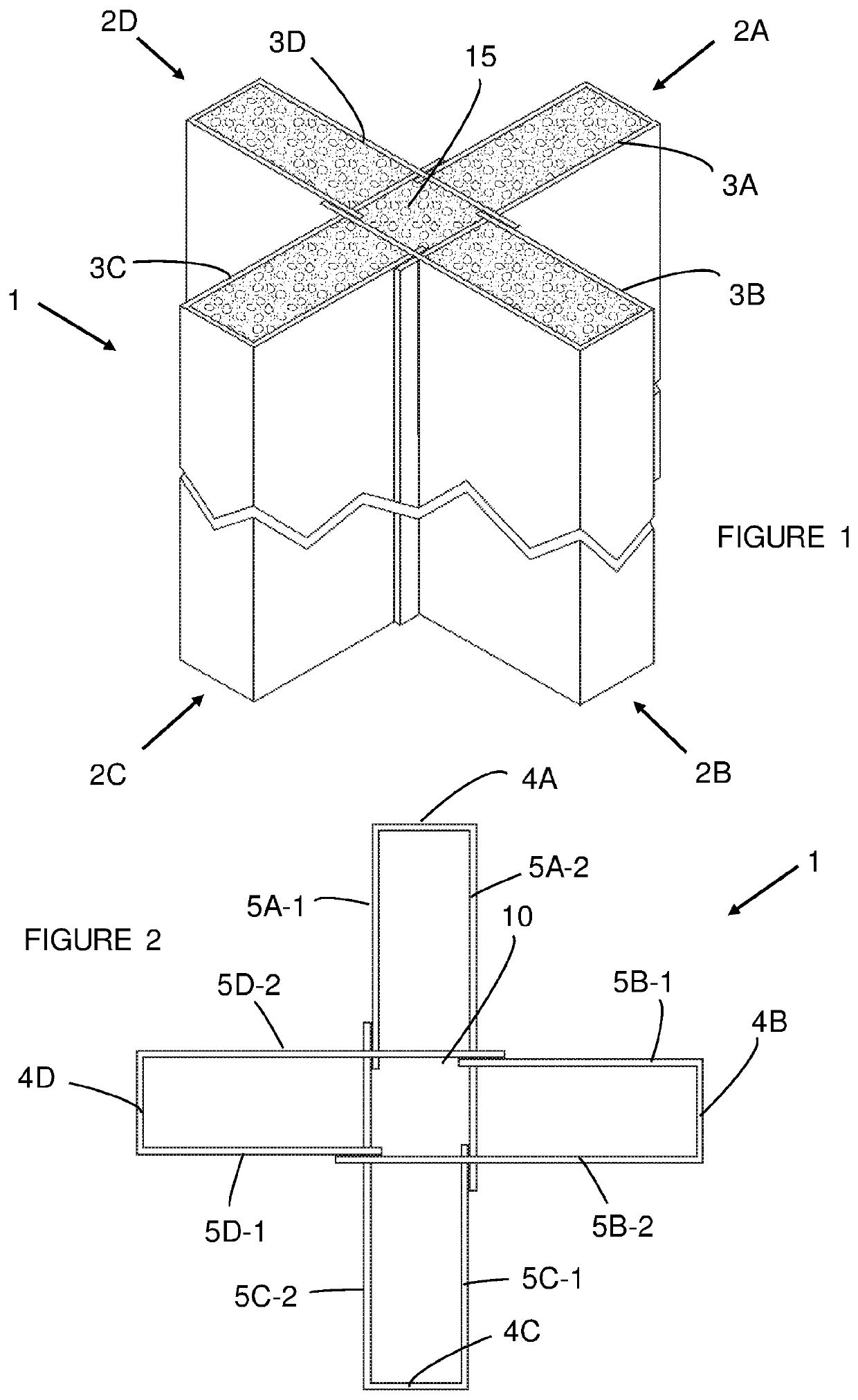

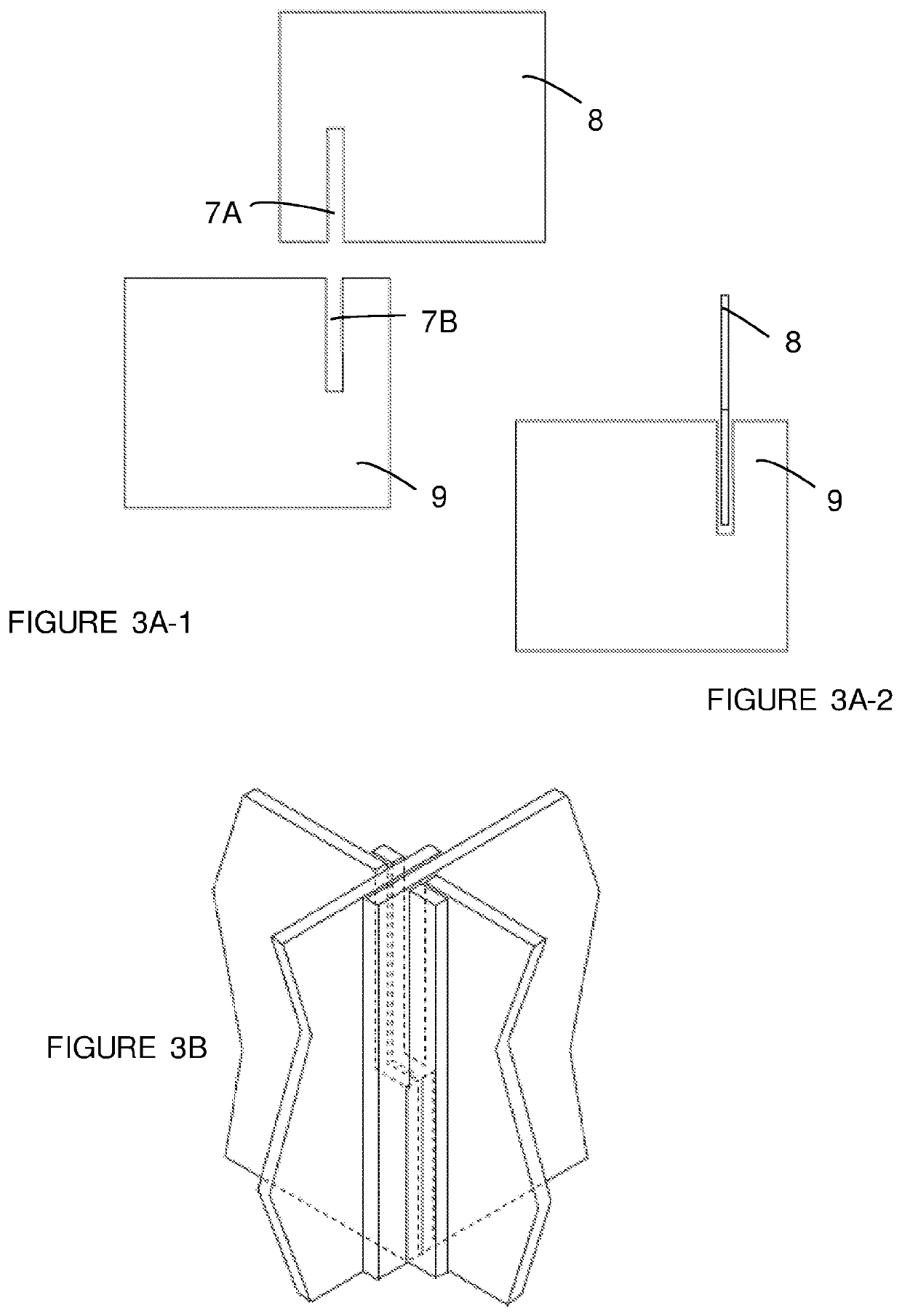

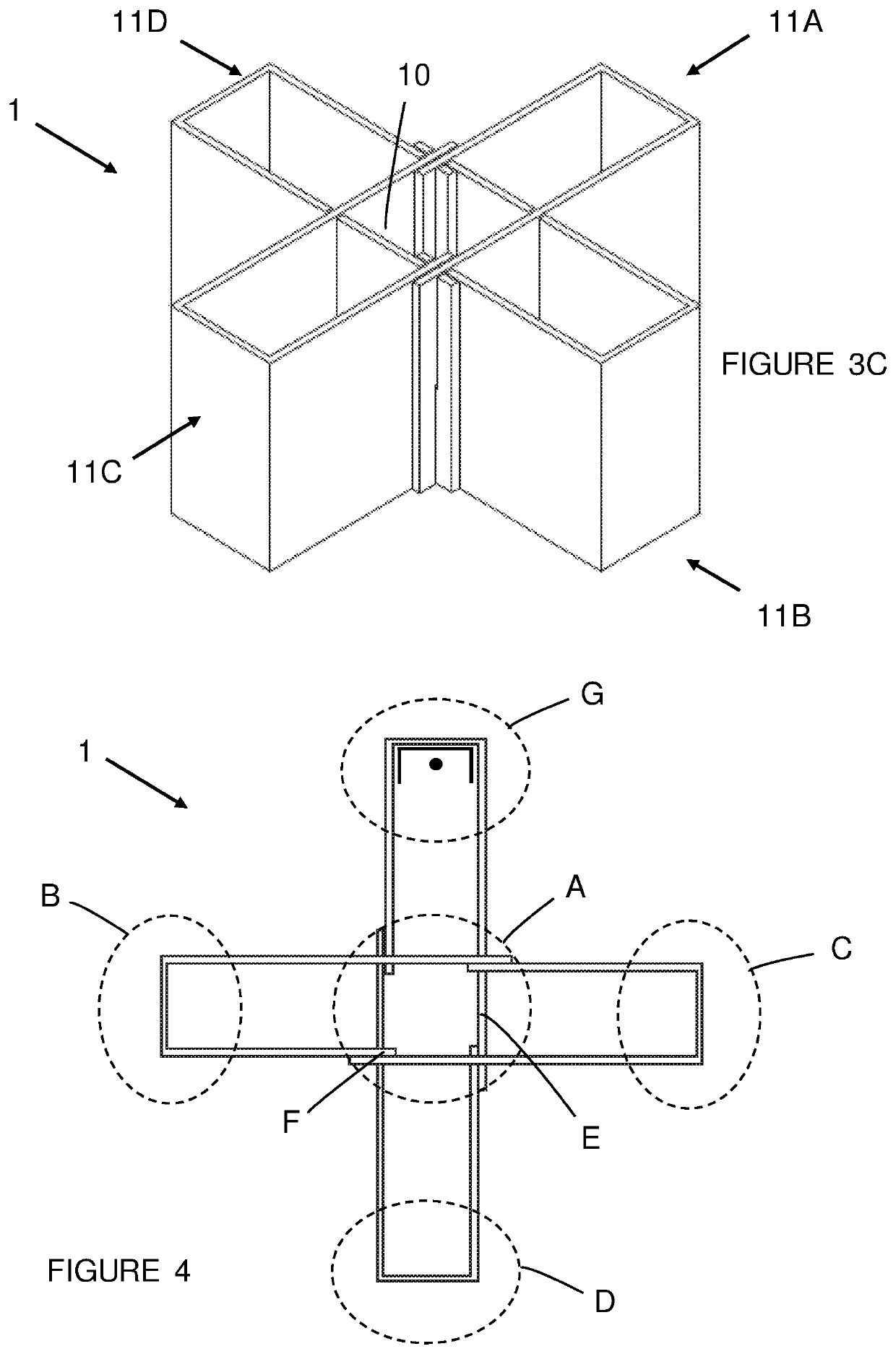

A structural element

Owner:LOUW ANDRIES AURET

Web processing system with multiple folding arrangements fed by a single web handling arrangement

A web processing system is provided. The web processing system supplies a processed continuous web of material to a cutting arrangement. The cutting arrangement forms sheets from the continuous web of material. The sheets are then supplied to multiple folding arrangements such that a single web of material is used to supply sheets to multiple folding arrangements.

Owner:C G BRETTING MFG

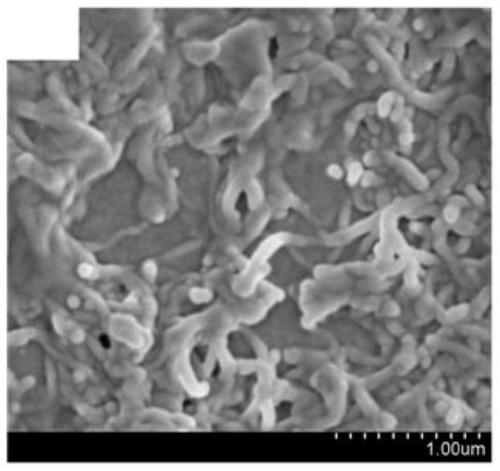

Preparation method of high-dielectric-performance polymer-based composite microporous material

Owner:SHAANXI UNIV OF SCI & TECH

Support device for securing sheet material to a backing surface and method of using same

InactiveUS20210046780A1Uniform widthChange widthMachine supportsSuspended filingsEngineeringStructural engineering

Owner:WHITE KOJO

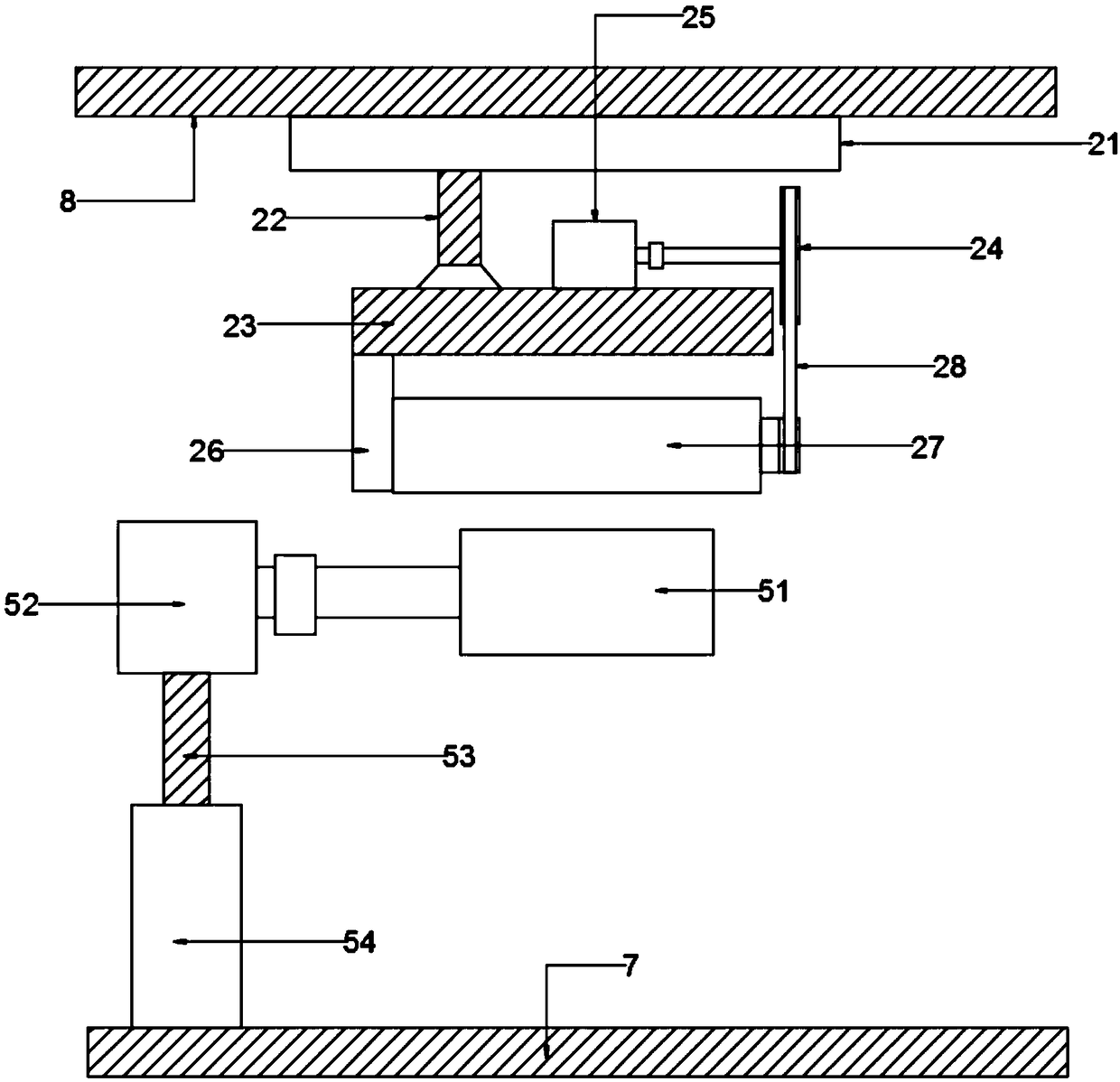

Sheet material polishing device for metal 3D printing

InactiveCN109202678AAdjustable positionAdjustable heightGrinding carriagesPolishing machinesMetal sheetMetal

Owner:广西慧思通科技有限公司

Novel vertical automatic bending device

The invention discloses a novel vertical automatic bending device comprising a whole machine positioning support, a male die, a clamping device, a three-dimensional movable stop device, a female die, a buffer unit, a five-shaft positioning power transmission device and an electric and operation control system. Four feet of the whole machine positioning support are provided with rotatable levelling nuts and sucking disc damping buffer seat cushions. The male die and clamping device are used for moulding and fixing a product to be processed. Different kinds of products can be processed by adopting the three-dimensional movable stop device. The female die is a mainly bending and forming part, and the buffer device is used for ensuring the balance stability of a whole machine. The five-shaft positioning power transmission device drives a die through a roller leading screw and a transmission guide rod. The electric and operation control system is composed of a high speed motor, a PLC controller, a safety operation switch, a safety protector and the like. The novel vertical automatic bending device is quick in processing speed, high in product precision, wide in the scope of application and long in service life. The novel vertical automatic bending device can be used for bending and forming a plurality of metal materials such as tubing and sheet materials.

Owner:HEFEI CITY KECHUANG RAPID TOOLING TECH DEV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap