Combined process for treatment and qualified discharge of garbage leachate

A technology of landfill leachate and combined process, which is applied in the field of landfill leachate treatment and discharge combined process, can solve the problems of high difficulty in "aging" liquid treatment, inability to ensure stable operation, high investment and operating costs, and achieve internal digestion of metabolites. The effect of strong ability, strong load resistance and convenient equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

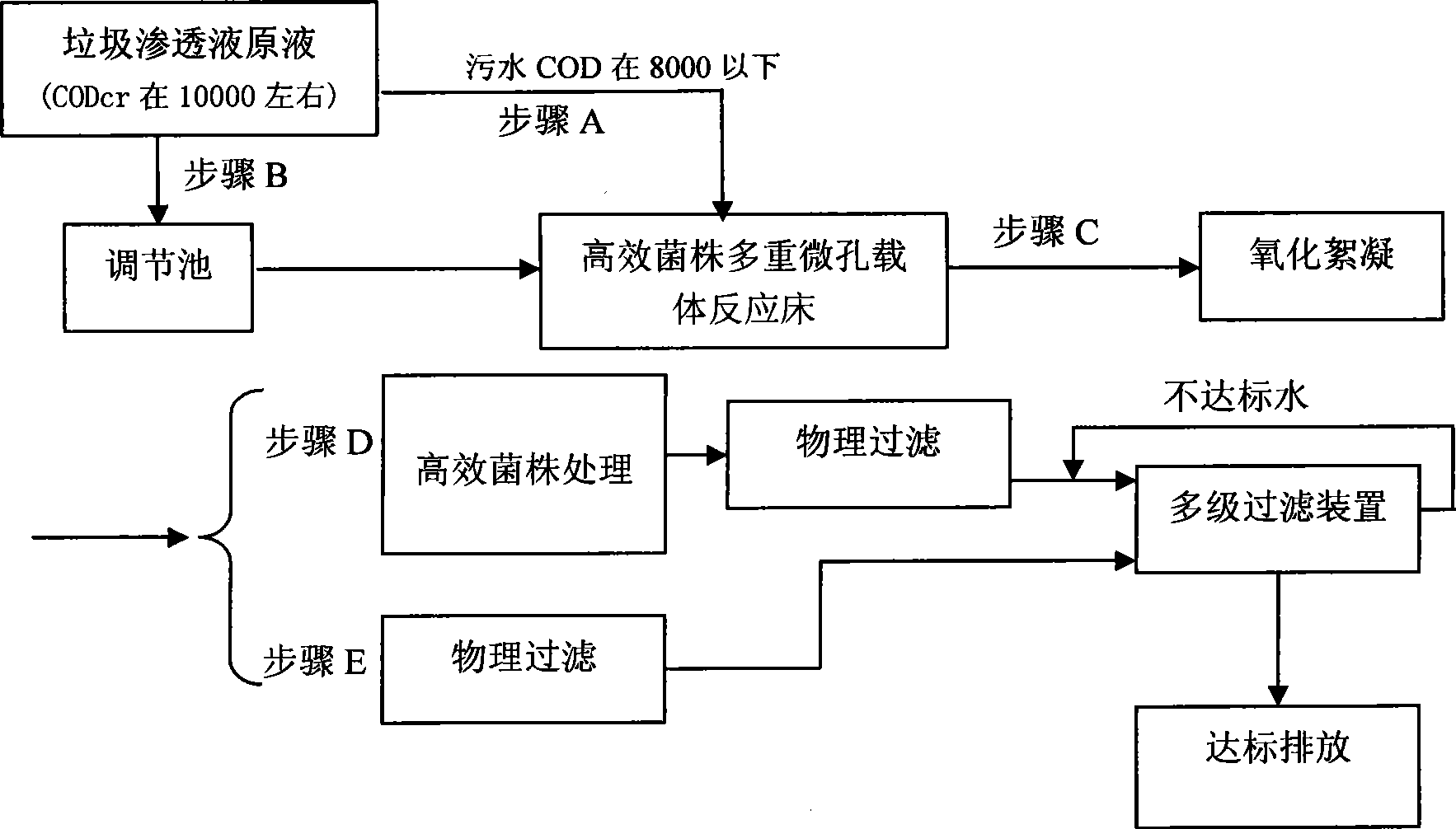

[0048] see figure 1 As shown in the process flow chart of the present invention, a combined process for treating landfill leachate up to standard discharge, taking the stock solution of landfill leachate containing refractory organic matter as the treatment object, and the CODcr is below 8000, the treatment process is followed by steps A-step C- Step D, specifically includes:

[0049] The first step: the landfill leachate to be treated is treated by a multi-microporous carrier reaction bed with microorganisms on the membrane. The microporous carrier is a microporous ceramic, which decomposes the organic matter in the landfill leachate, and the reaction bed is a method of hanging membrane microorganisms for:

[0050] (1) Dilute the leachate to be treated to 10 to 20 times the sewage repeatedly sprayed on the old garbage to form leachate, sprinkle the leachate on the multi-microporous carrier for domestication, and spray the landfill leachate on the multi-microporous carrier At t

Embodiment 2

[0060] see figure 1 As shown in the process flow chart of the present invention, a landfill leachate treatment process takes the landfill leachate pretreated by the anaerobic regulating tank as the treatment object, and the CODcr of the landfill leachate stock solution is about 10000, and the treatment process is followed by steps B- Step C-step E, specifically include:

[0061] The first step: the landfill leachate to be treated is treated by a multi-microporous carrier reaction bed with microorganisms on the membrane. The microporous carrier is a microporous ceramic, which decomposes the organic matter in the landfill leachate, and the reaction bed is a method of hanging membrane microorganisms for:

[0062] (1) Repeatedly spray the sewage diluted to 10 to 20 times on the old garbage to form leachate, and sprinkle the leachate on multiple microporous carriers for domestication. The domestication time is 20±3°C for one month or 30±3°C Domesticated for half a month;

[0063] (

Embodiment 3

[0071] see figure 1 As shown in the process flow chart of the present invention, a combined process for treating landfill leachate up to standard discharge, using landfill leachate pretreated in an anaerobic regulating tank containing refractory organic matter as the treatment object, and the CODcr of the landfill leachate stock solution is about 10,000 , the treatment process goes through step B-step C-step D successively, specifically including:

[0072] The first step: the landfill leachate to be treated is treated by a multi-microporous carrier reaction bed with microorganisms on the membrane. The microporous carrier is a microporous ceramic, which decomposes the organic matter in the landfill leachate, and the reaction bed is a method of hanging membrane microorganisms for:

[0073] (1) Dilute the leachate to be treated to 10 to 20 times the sewage repeatedly sprayed on the old garbage to form leachate, sprinkle the leachate on the multi-microporous carrier for domesticatio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap