Inserting pin component of optical cable connector and tensile connecting structure of inserting pin component and optical cable

An optical fiber connector and pin technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of difficult installation, lack of fixed and tensile structure, lack of sealing protection, etc., and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

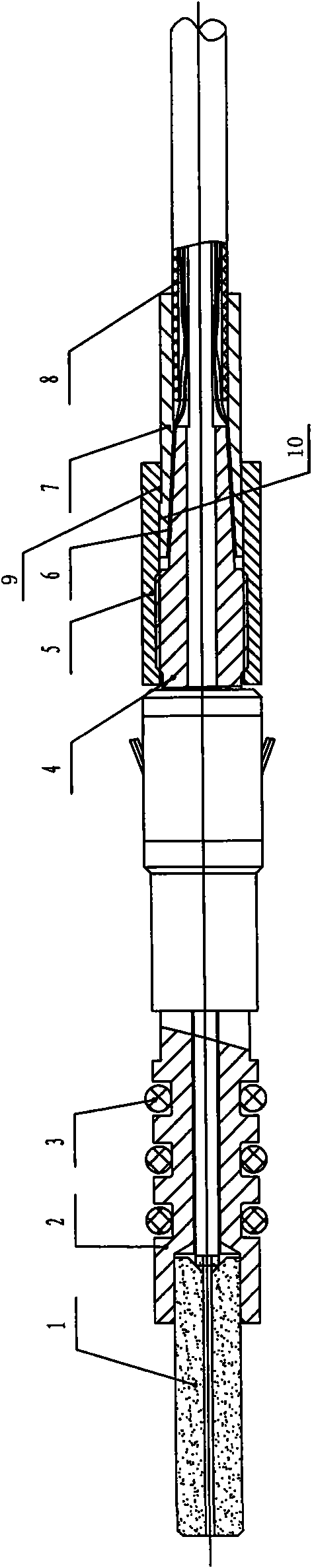

[0013] Such as figure 1 As shown, the pin part includes a pin 1, and the pin 1 is inserted in the front port of the flange 2, the rear end of the flange 2 is connected with the rear sleeve 4, and the outer ring of the flange 2 is along the shaft A plurality of annular grooves are arranged side by side, and O-ring seal rings 3 are fastened in each annular groove. The outer surface of the tail of the rear sleeve 4 has a tapered surface with a gradually smaller outer diameter. The taper sleeve 7 of closing structure, the nut 5 is movably assembled on the outer ring of the taper sleeve 7, the front end inner wall of the nut 5 is provided with an internal thread, and the front of the cone face of the back sleeve 4 is provided with an external thread column matching the internal thread of the nut 5 noodle. The joint surface between the inner ring of the nut 5 and the outer ring of the taper sleeve 7 is provided with an axial engagement structure. Along 10 poses. When in use, the ara

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap