Composite electronic component and board having the same

a technology of electronic components and composites, applied in the direction of printed circuit non-printed electric components association, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of user discomfort, specific research into the degree of removal of acoustic noise, and the thickness of a ceramic chip disposed on a lower portion of a multi-layer ceramic capacitor. achieve the effect of decreasing acoustic nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example

[0131]Composite electronic components according to Inventive Examples and Comparative Examples were manufactured as follows.

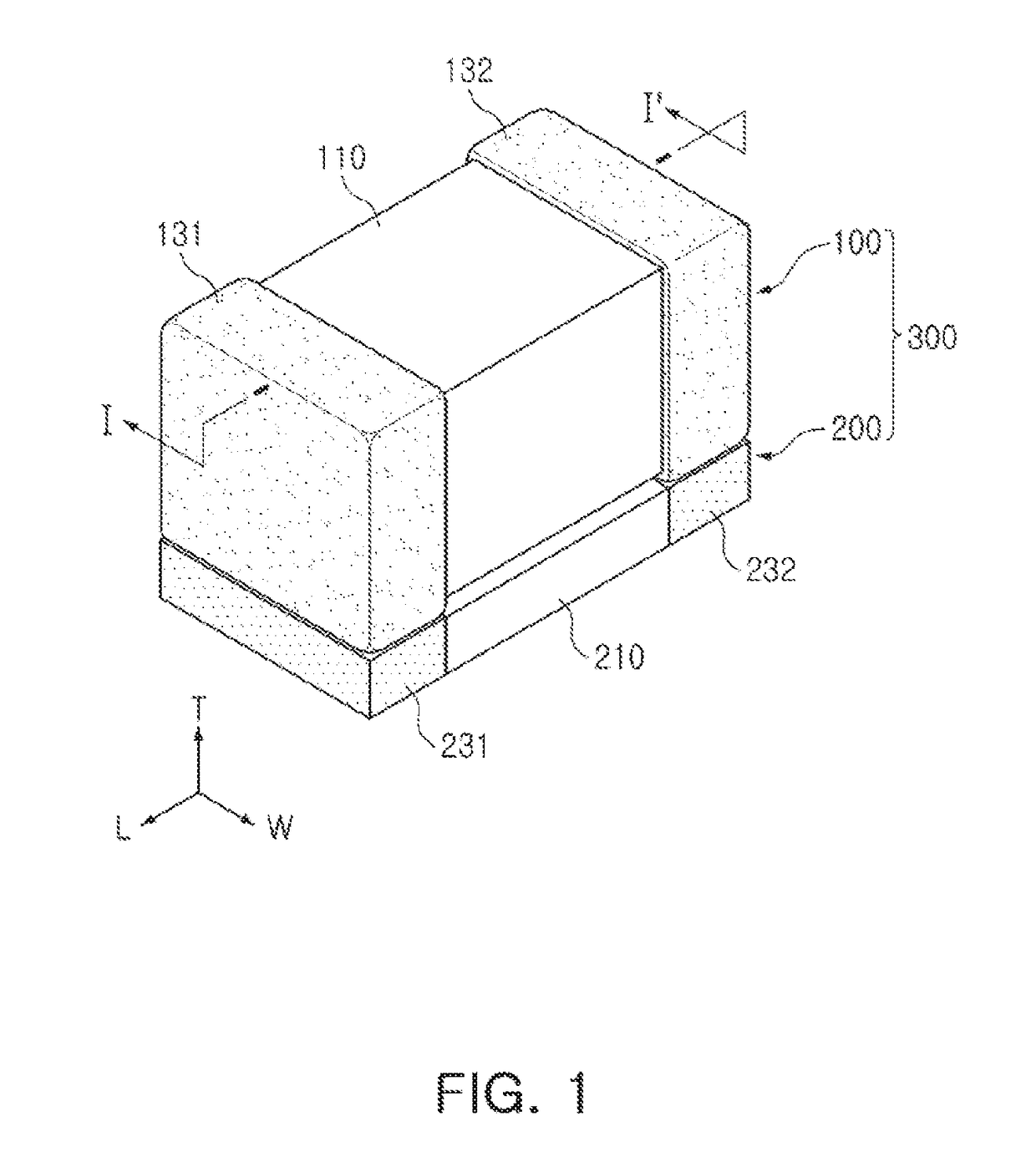

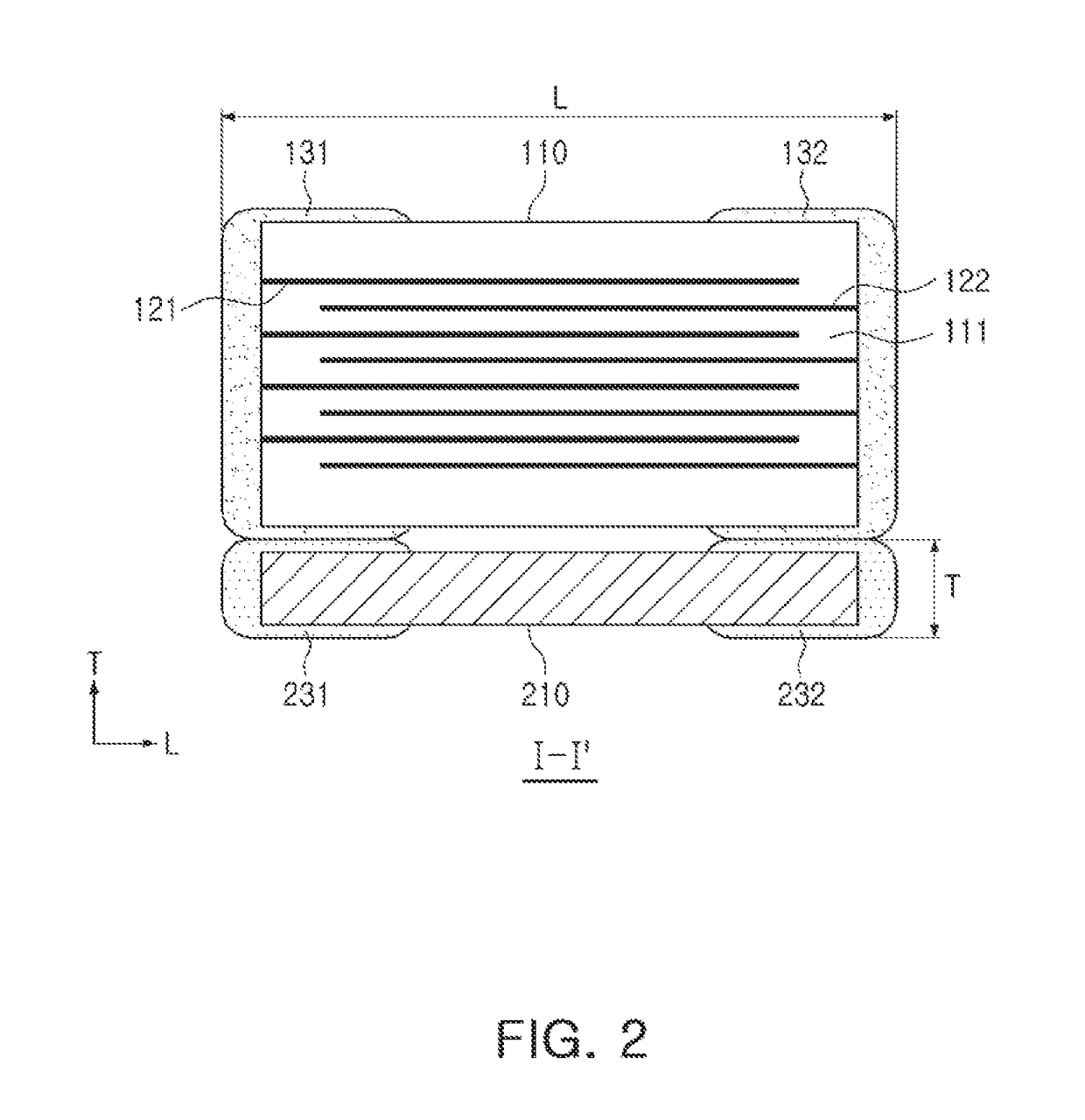

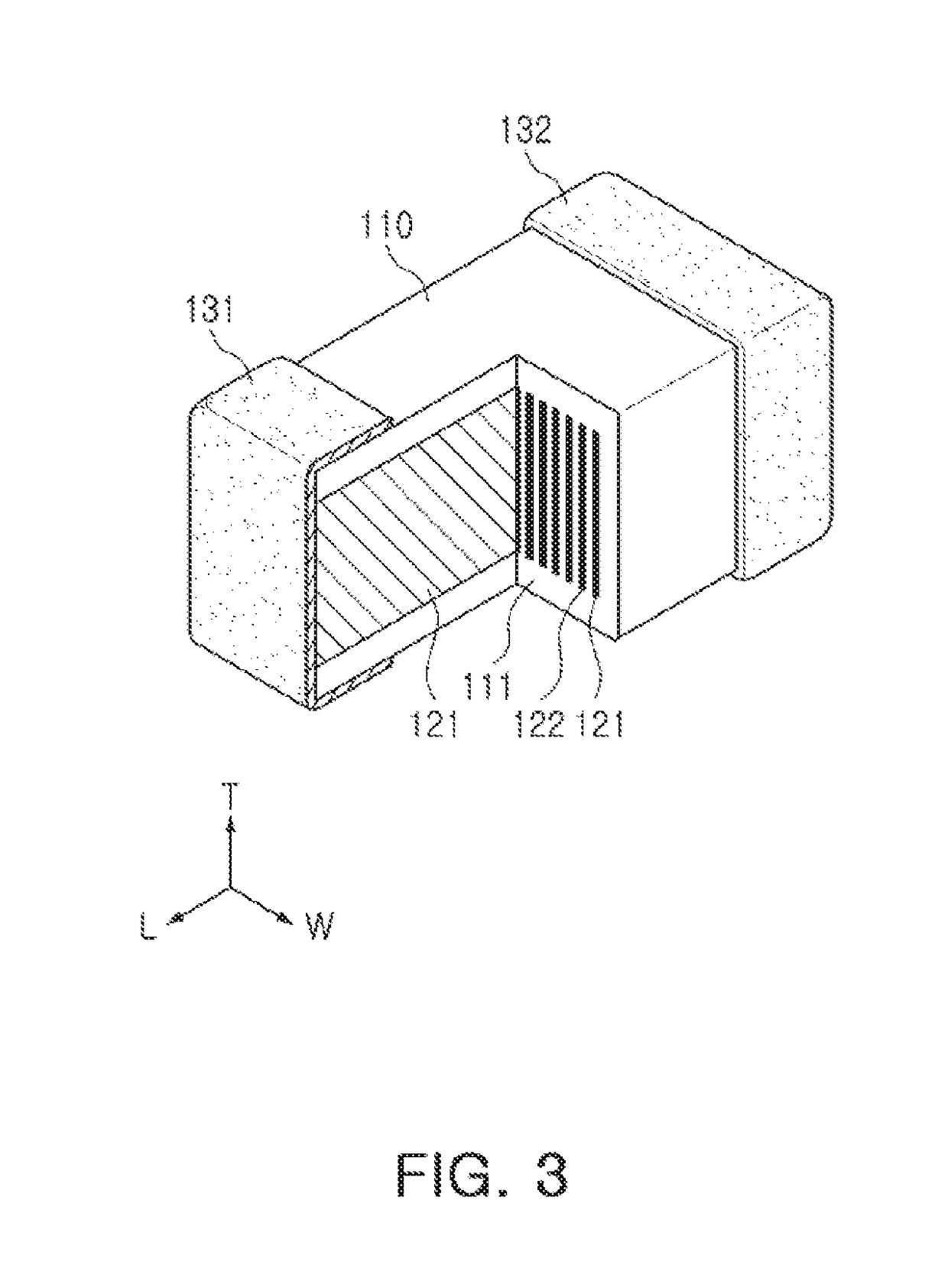

[0132]In Inventive Examples and Comparative Examples according to the present disclosure, a ceramic chip was disposed on a lower portion of a multilayer ceramic capacitor, and a composite electronic component was manufactured depending on a length of the multilayer ceramic capacitor and a mounting form of internal electrodes. Acoustic noise levels depending on a ratio (T / L) of a thickness T of a second ceramic chip 200 to a length L of the multilayer ceramic capacitor 100 was compared.

[0133]More specifically, the following [Table 1] illustrates results obtained by comparing acoustic noise levels when the length of the multilayer ceramic capacitor was 2.078 mm and the internal electrodes were stacked to be horizontal to a mounting surface of a printed circuit board.

[0134]In Comparative Examples 1 to 4 and Inventive Examples 1 to 3, each 5 samples were manufacture

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap