Copper electrolytic plating bath and copper electrolytic plating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0069]Hereinafter, the present invention will be specifically described with reference to examples, but the invention is not limited to the following examples and can be carried out by appropriate modifications within a range adaptable to the above-mentioned and the later-described purposes, and all the modifications are encompassed within the technical scope of the invention. In the following, unless specified otherwise, the term “%” means “mass %”.

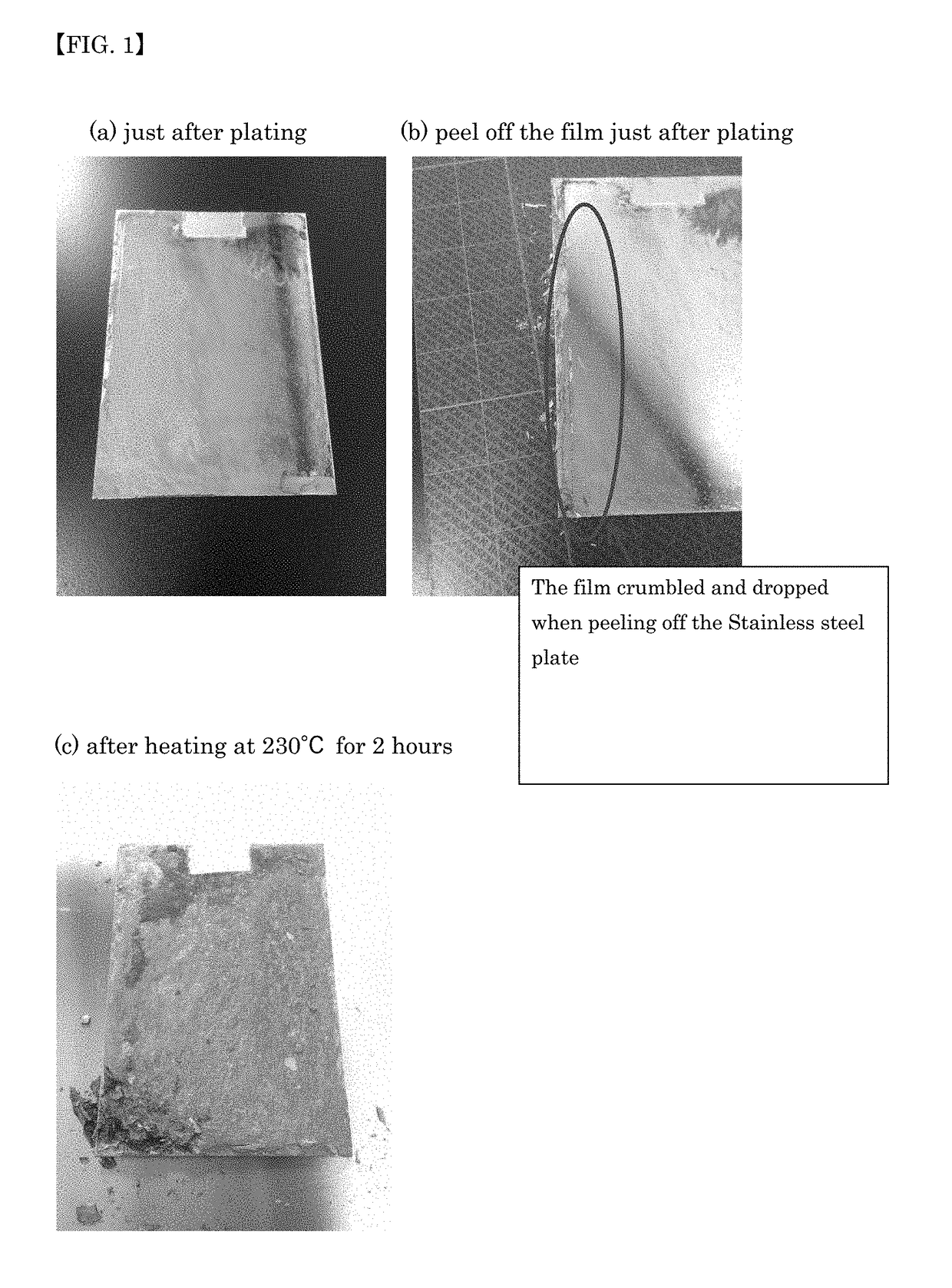

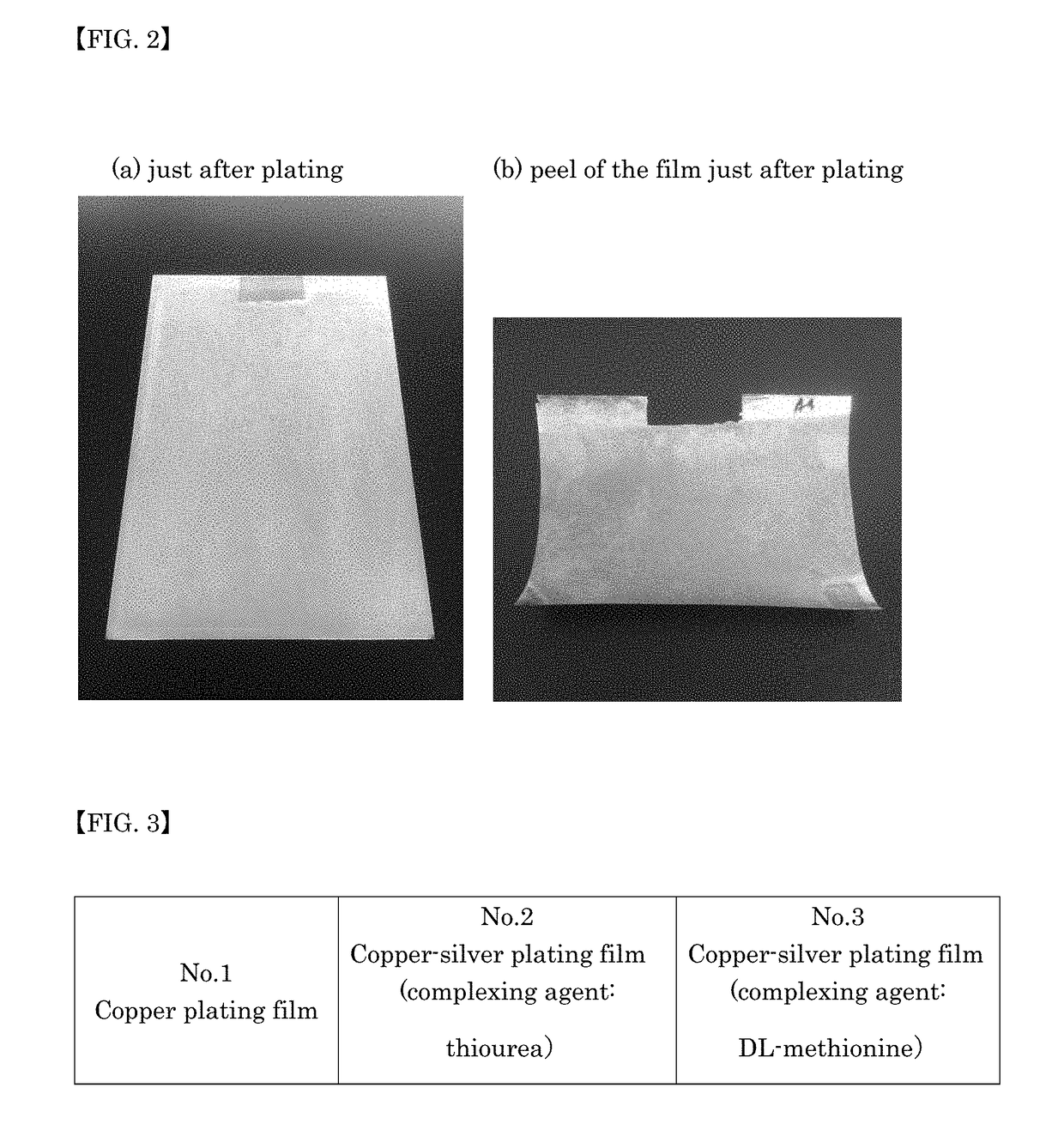

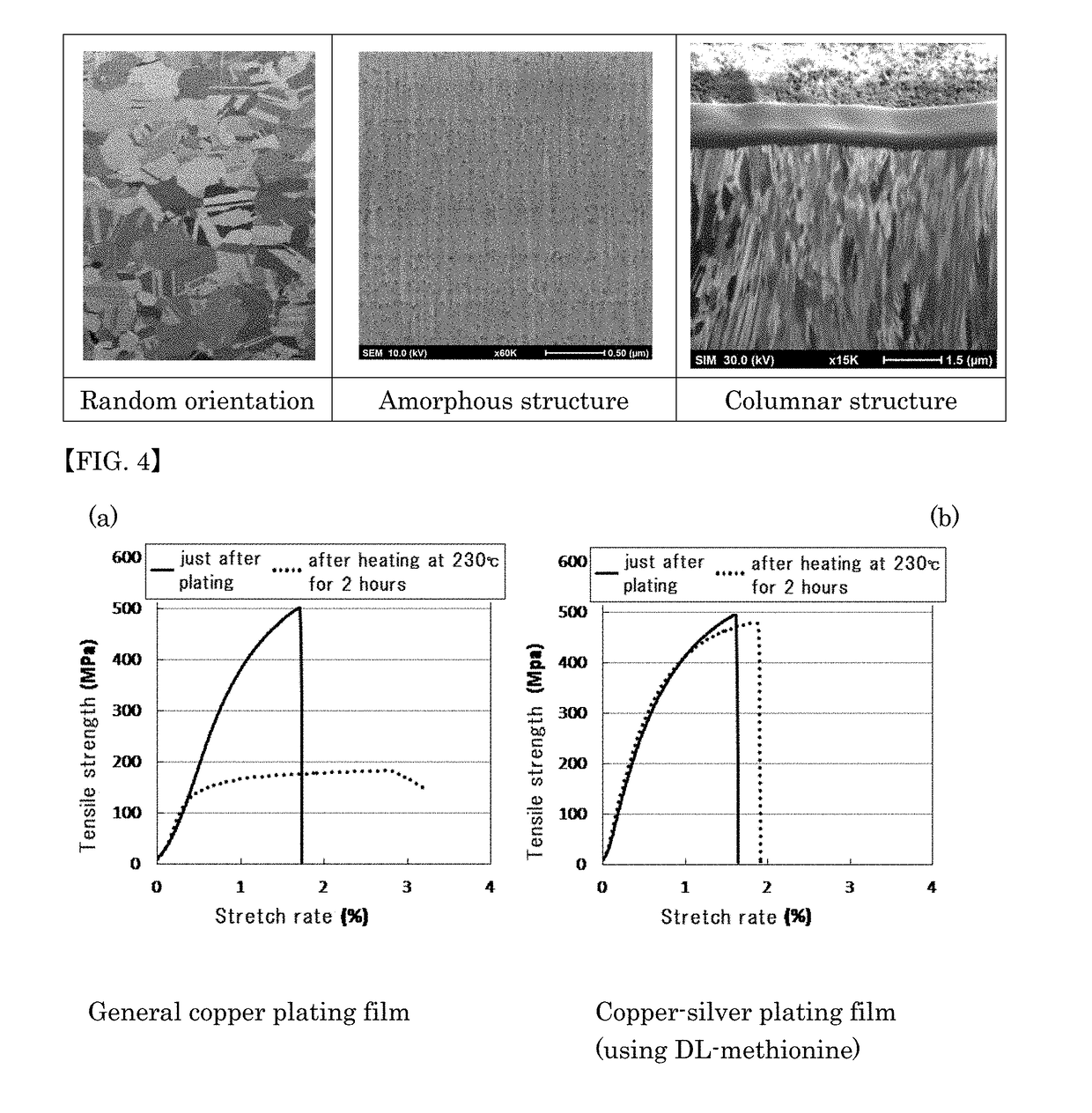

[0070]In this example, using a copper plating bath (without the addition of an alloy component and a complexing agent, the conventional example), and a copper-silver alloy plating bath [with the use of thiourea as a complexing agent (the comparative example); or with the use of DL-methionine, N-acetyl-DL-methionine, or DL-methionine sulfoxide (the examples of the present invention)], various properties were examined when electroplating was carried out as described below.

No. 1 (Conventional Example)

[0071]A copper plating solution having the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap