Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Independent feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ball socket machining device for inner ring of socket curved groove ball bearing

InactiveCN111069671AShorten the timeHigh indexing accuracyPrecision positioning equipmentShaftsBall bearingMilling cutter

The utility model discloses a ball socket machining device for an inner ring of a socket curved groove ball bearing, and belongs to the field of mechanical engineering. In order to overcome the defects of low working efficiency, large workload, incapability of effectively ensuring the precision and the like of ball socket machining of the inner ring of the socket curved groove ball bearing. The machining device comprises a base, a rapid clamping device, a set of ball socket milling devices arranged in the circumferential direction, a set of indexing precision control blocks and a feeding precision control mechanism and the like; and an air cylinder is used for independent feeding, and a motor is used for driving a spherical milling cutter to conduct independent milling. The machining device for the inner ring of the socket curved groove ball bearing has the following advantages that (1) a plurality of ball sockets can be machined at the same time at a time, and time is saved; (2) the indexing precision of the ball sockets is improved by using a movable positioning block; and (3) the feeding power of the air cylinder is flexible force, so that the impact of the milling cutter can beavoided.

Owner:NORTHWEST A & F UNIV

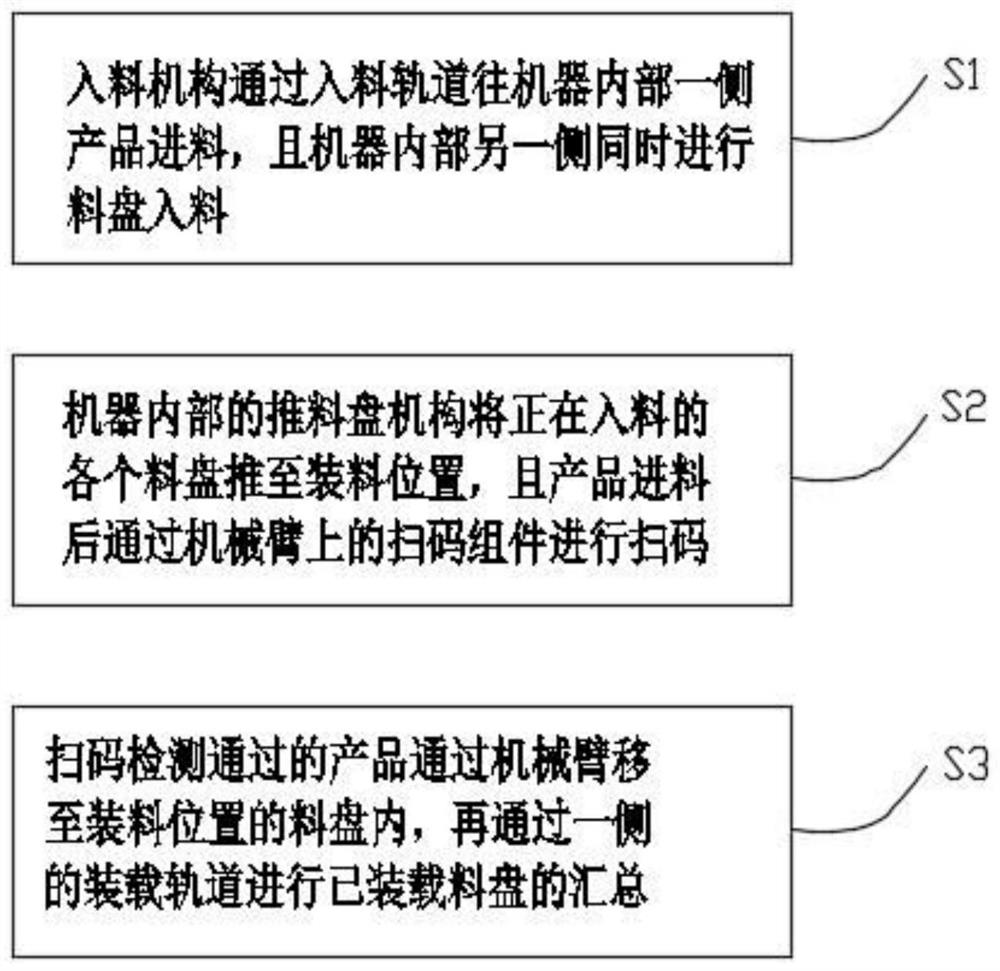

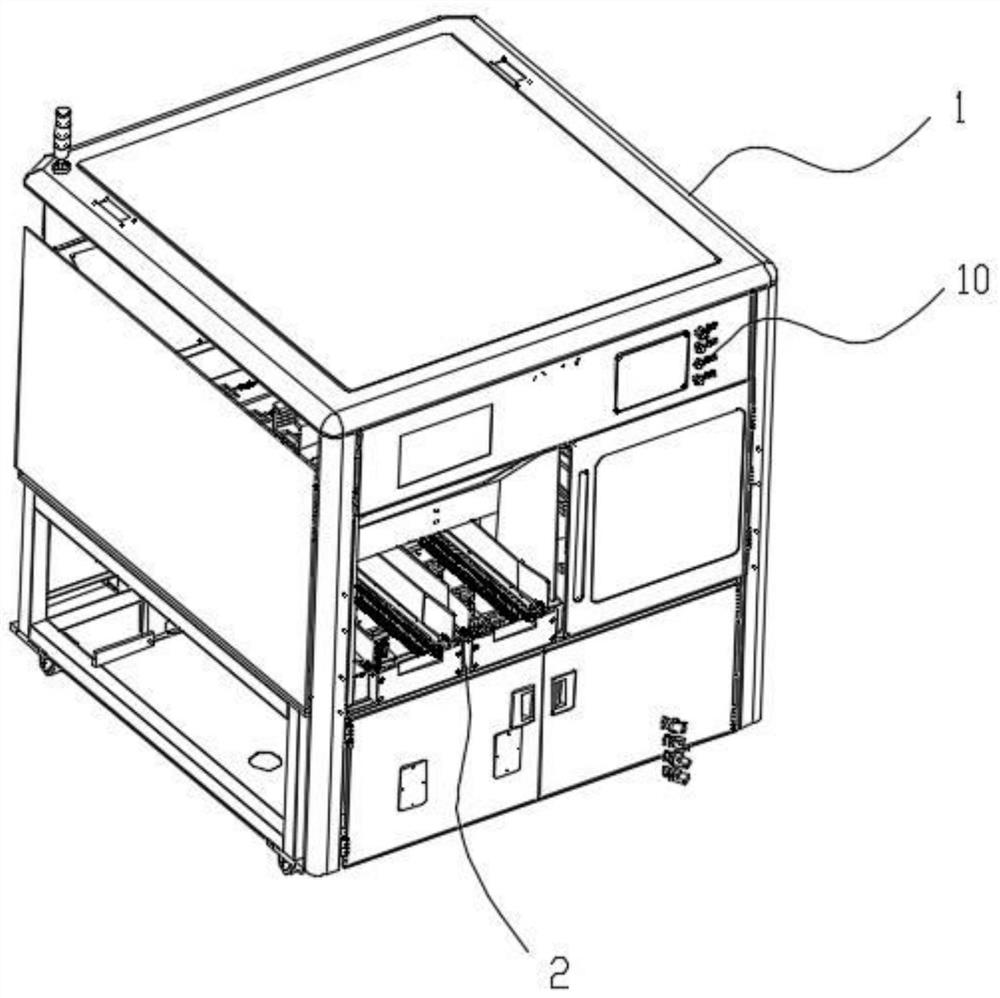

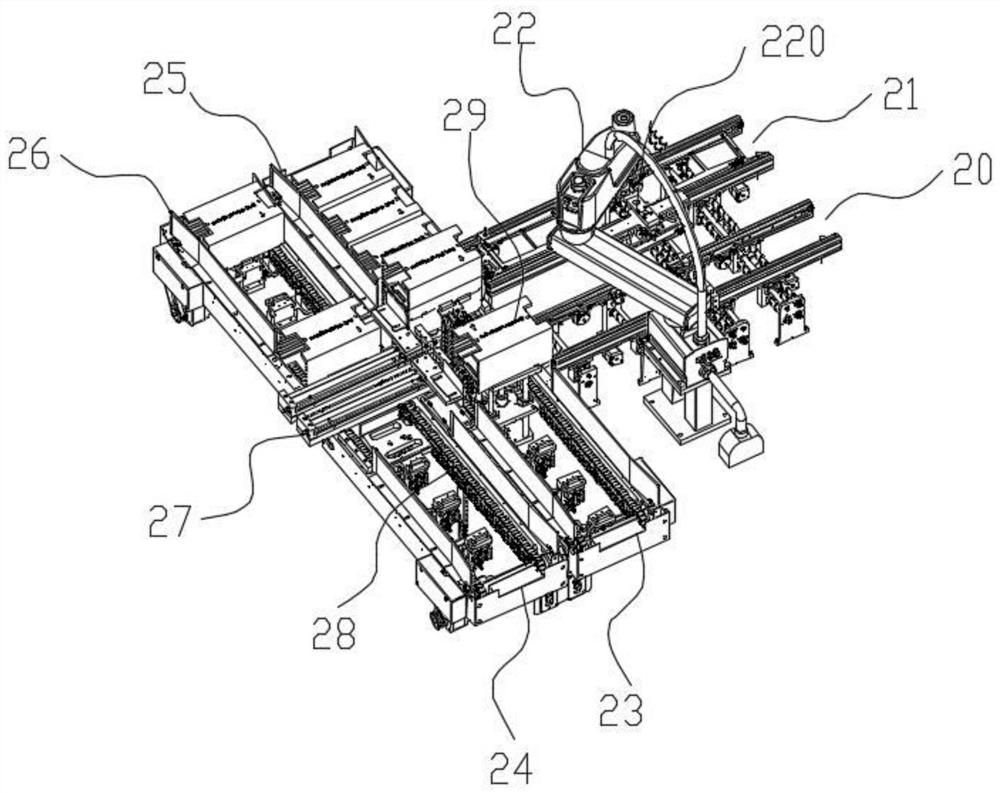

SIP feeding mechanism operation method and structure

Owner:深圳双十科技股份有限公司

Centralized sand supply system and 3D printing equipment

PendingCN114160754ARealize one machine with multiple functionsImprove work efficiencyAdditive manufacturing apparatusFoundry mouldsProcess engineeringIndustrial engineering

The invention relates to a centralized sand supply system which comprises a material mixing device, a feeding device and a supporting device, the material mixing device is arranged on the supporting device and comprises a raw material warehouse, a weighing measuring hopper and a material mixing mechanism, and every two of the raw material warehouse, the weighing measuring hopper and the material mixing mechanism are connected through a first valve; the feeding device is movably arranged on the supporting device, a second valve is arranged on the material mixing mechanism, a plurality of equipment stations are arranged in the extending direction of the supporting device at intervals, when the feeding device is in a first state, the feeding device is communicated with the material mixing mechanism through the second valve, and when the feeding device is in a second state, the feeding device is communicated with the material mixing mechanism through the second valve. And the feeding device is separated from the mixing device and moves to a plurality of equipment stations. The invention further relates to 3D printing equipment. According to the scheme, the problems that the switching process is complex, the operation difficulty is high and the like due to the fact that single equipment in the 3D printing equipment needs to be matched with an independent feeding system can be solved.

Owner:NINGXIA KOCEL MOLD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap