SIP feeding mechanism operation method and structure

An operation method and a material tray technology, which are applied in the field of mechanical processing, can solve problems such as low efficiency, lack of front-end scanning code detection, assembly and combination functions, etc., and achieve the effect of saving space and saving process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

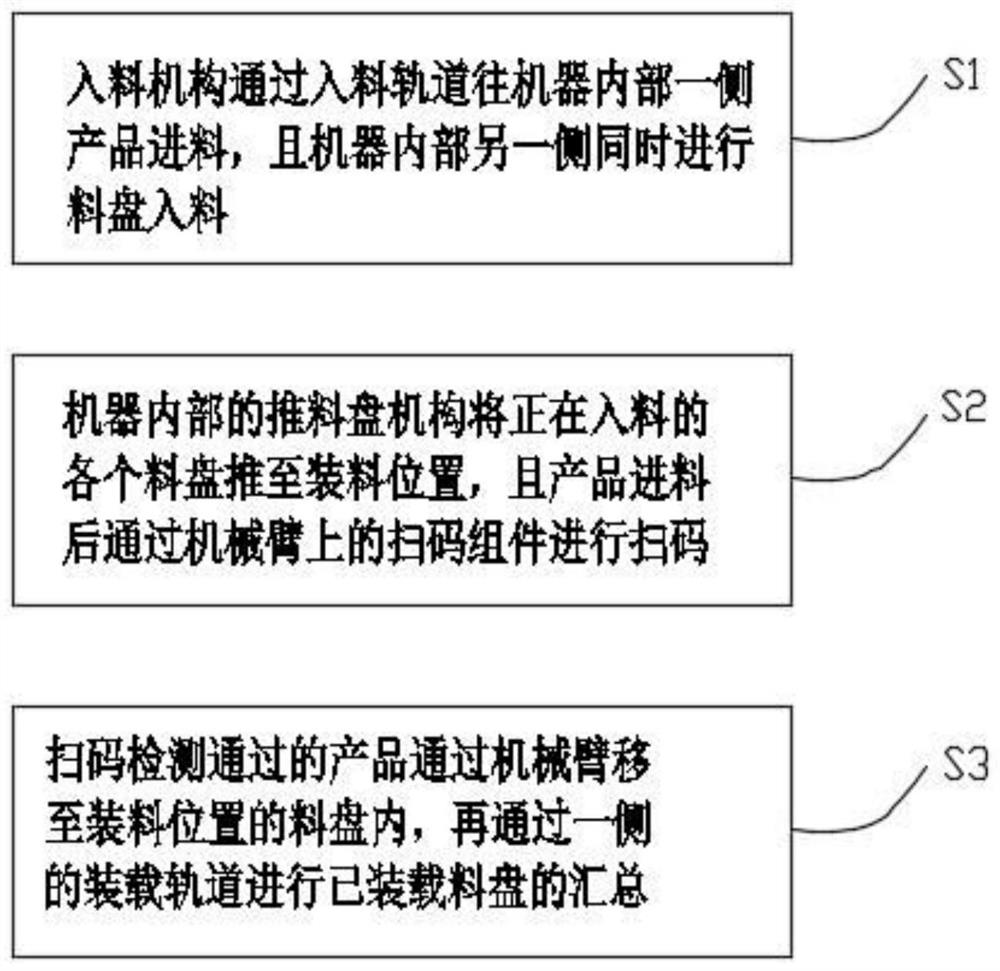

[0037] refer to Figure 1 to Figure 5 , a method for operating a SIP feeding mechanism, comprising the following operating steps:

[0038] The feeding mechanism feeds the product on one side of the machine through the feeding track, and the other side of the machine simultaneously feeds the material into the tray;

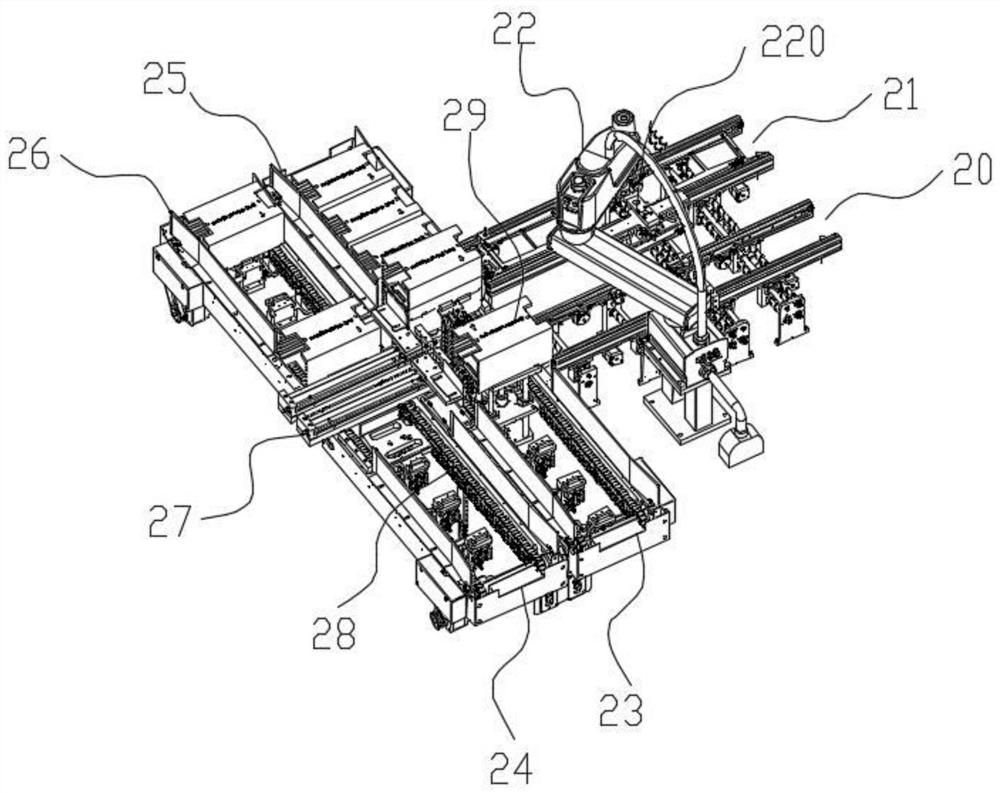

[0039] The pushing tray mechanism inside the machine pushes each feeding tray to the loading position, and after the product is fed, it scans the code through the code scanning component 221 on the mechanical arm;

[0040] The products that pass the scanning code inspection are moved to the tray at the loading position by the robotic arm, and then the loaded trays are collected through the loading track on one side.

[0041] When the detection fails, the NG product is loaded into the NG tray by the mechanical arm and moved to the NG loading track.

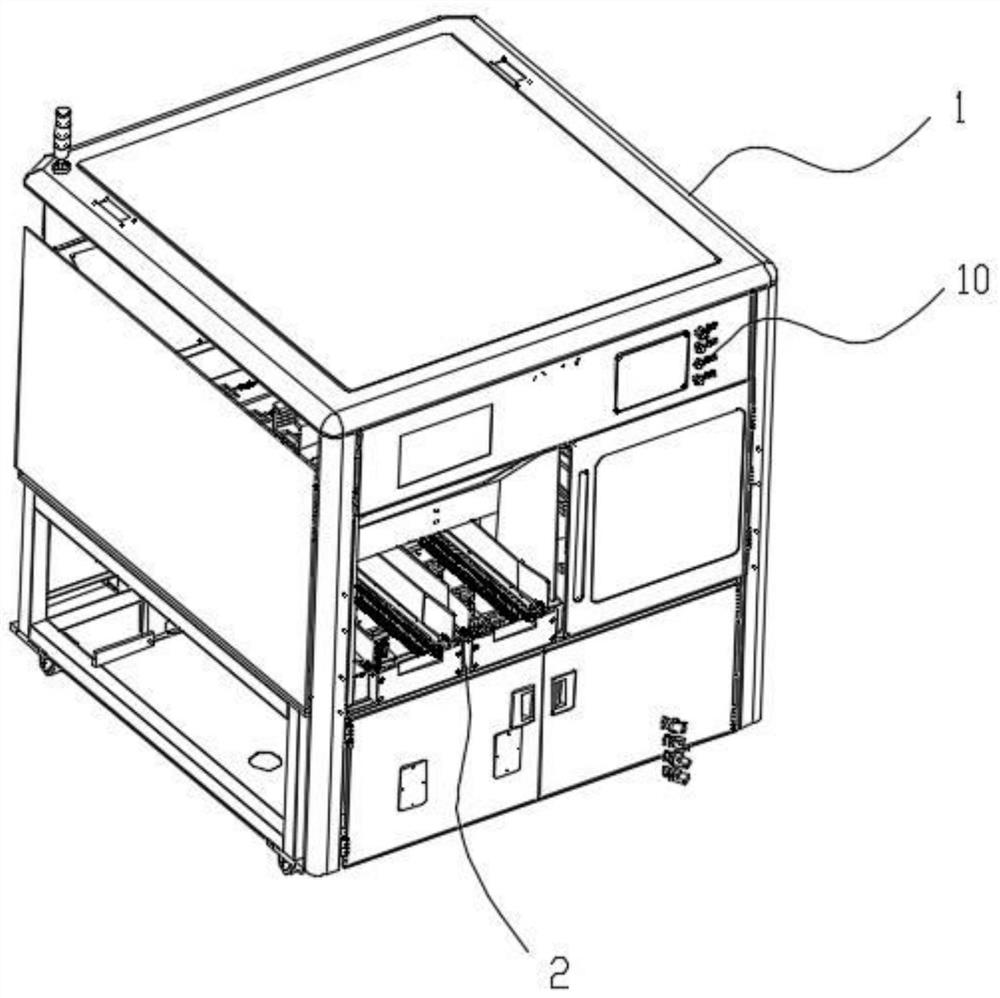

[0042] refer to Figure 1 to Figure 5 , the SIP feeding mechanism structure includes an external casing 1 and a mater

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap