Detachable cutter for milling machine

A cutting tool and milling machine technology, which is applied in the field of detachable cutting tools for milling machines, can solve the problems of reducing work efficiency and the inability of ordinary milling cutters to achieve the effects of improving work efficiency, convenient operation, and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

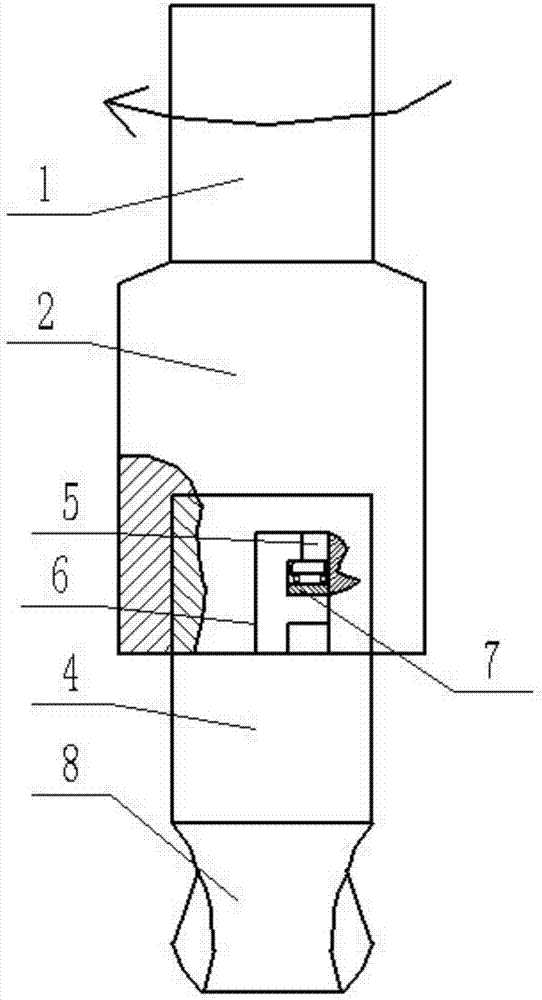

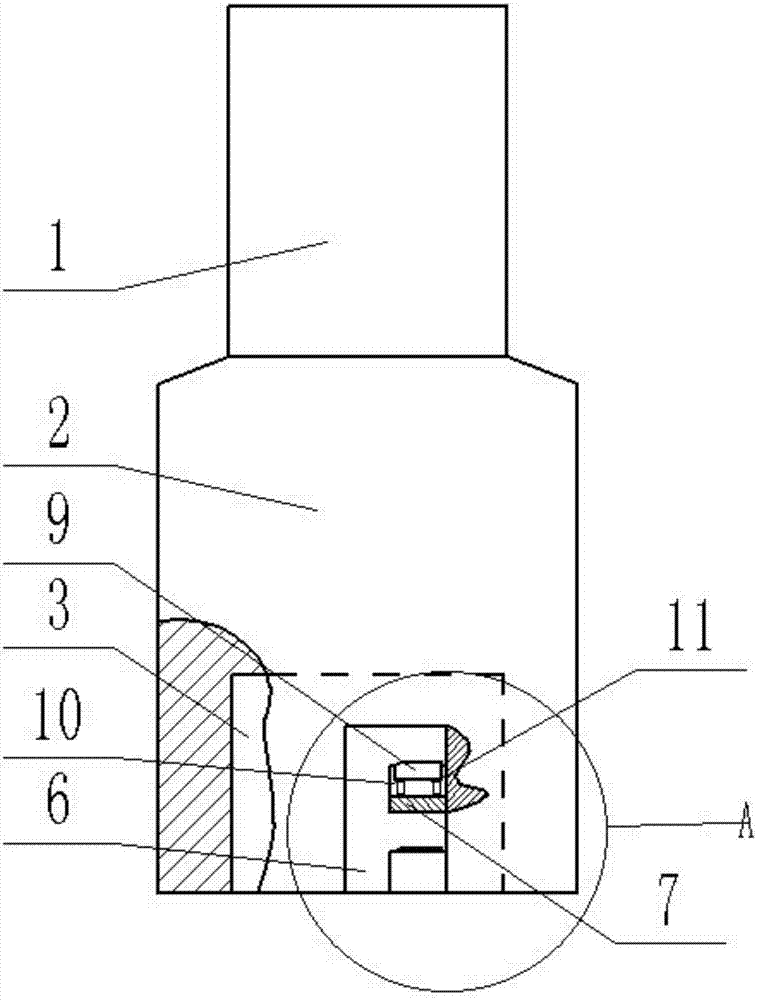

[0021] Such as figure 2 , 4 As shown in , 5, a detachable cutter for milling machine includes a first connecting portion and a second connecting portion, the first connecting portion includes a handle 1, the handle 1 is connected to the connecting sleeve 2, and the lower end surface of the connecting sleeve 2 is provided with Slot hole 3, the side wall of slot hole 3 is evenly provided with a plurality of vertical grooves 6 parallel to the axial centerline of connecting sleeve 2, according to the axial centerline symmetry of connecting sleeve 2, the two vertical grooves 6 are opposite A plurality of corresponding bumps 7 are arranged on the side surfaces, and grooves 10 are arranged on the surface of the bumps 7 facing the upper end surface of the connecting sleeve 2, and a jacking block 9 is arranged in the groove 10, and springs are passed on both sides of the lower end of the jacking block 9. 11 is connected with the bottom surface of groove 10.

[0022] Such as image 3 A

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap