Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Particle flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

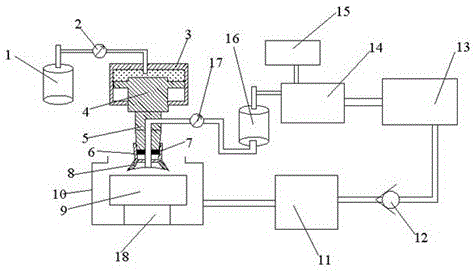

Abrasive particle flow ultra-precision machining device

InactiveCN105058245AImprove machining accuracyGuaranteed accuracyEdge grinding machinesPolishing machinesPneumatic cylinderParticle flow

The invention provides an abrasive particle flow ultra-precision machining device. Injection pressure and speed of abrasive particle flows are adjusted by adjusting threads between a pressure head and an abrasive particle flow injection polishing nozzle, and pressure is provided for a sealed box through a pneumatic cylinder, so that pressure is applied to the pressure head through a pressure plug. According to the abrasive particle flow ultra-precision machining device, the pneumatic cylinder for replacing a spring applies pressure to the pressure head so that accuracy of pressure of the abrasive particle flow injection polishing nozzle to a work-piece can be effectively improved, the abrasive particle flow machining accuracy is improved, and ultra-precision machining is achieved; meanwhile, concentration of abrasive particles in the abrasive particle flows is monitored and controlled in real time, so that machining accuracy and efficiency are guaranteed; Injection pressure and speed of the abrasive particle flows are adjusted by adjusting the threads between the pressure head and the abrasive particle flow injection polishing nozzle, and a pressure-maintaining flow stopping part is arranged at the tail end of the abrasive particle flow injection polishing nozzle so that the machining efficiency can be effectively improved. By means of the abrasive particle flow ultra-precision machining device, both machining efficiency and ultra-precision machining accuracy can be guaranteed.

Owner:CHANGCHUN UNIV OF SCI & TECH

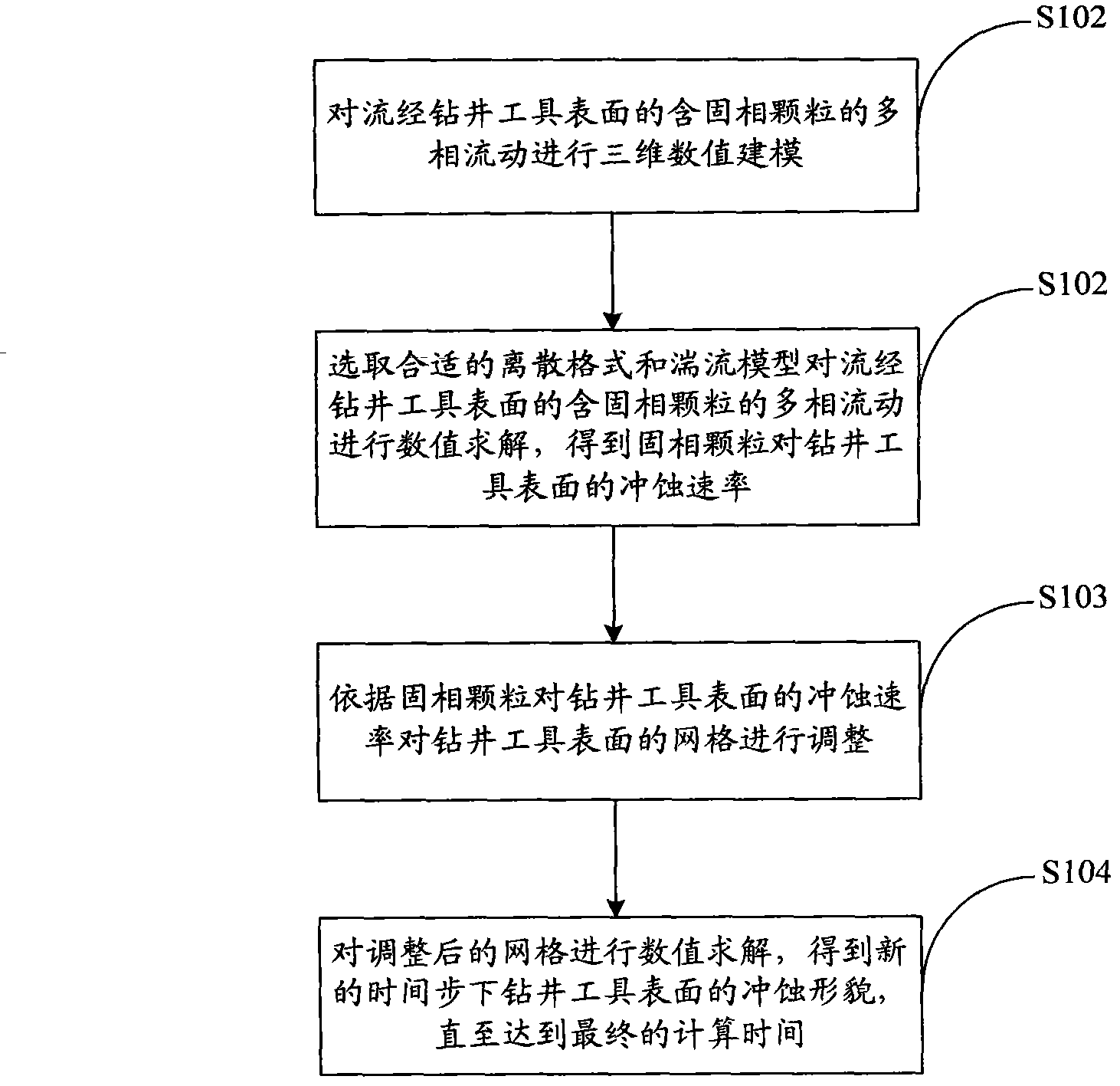

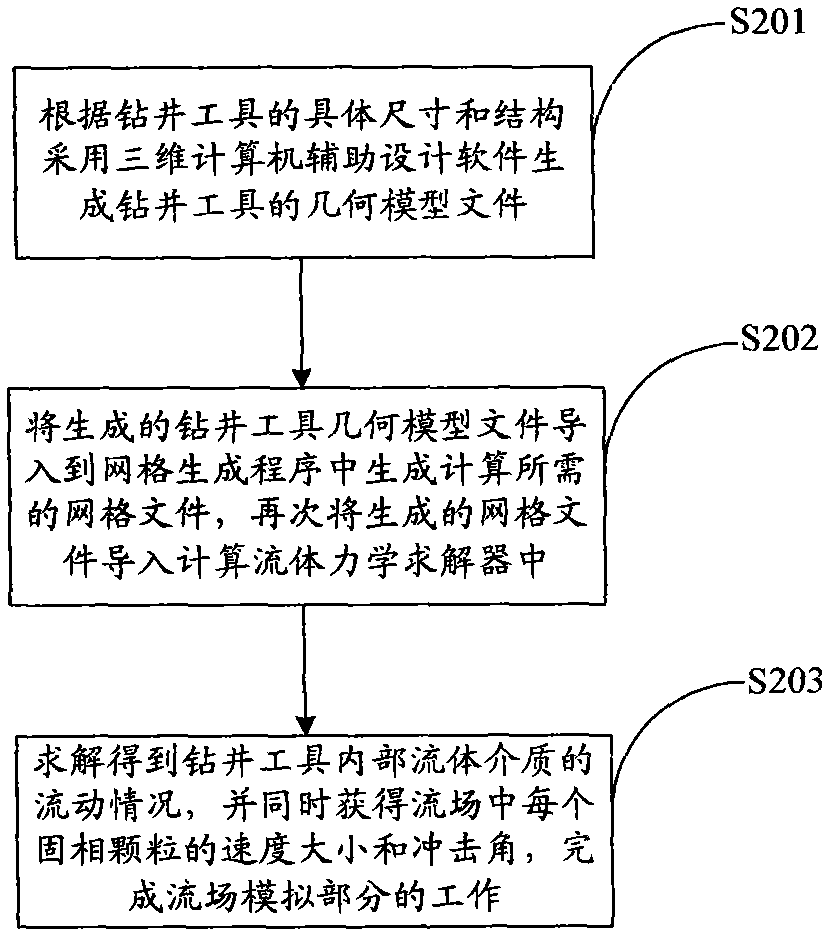

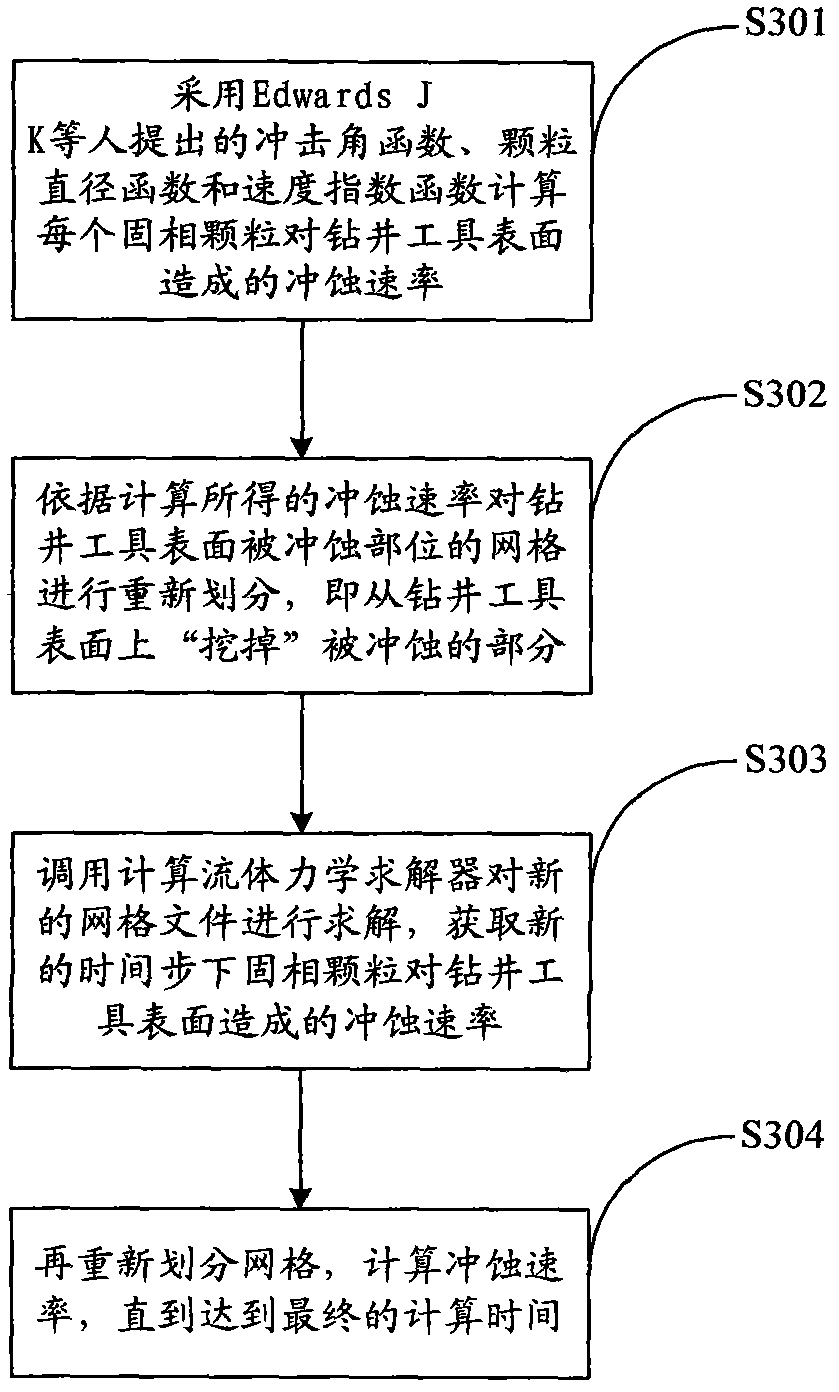

Method for predicting surface washout topography of petroleum drilling tool

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-precision automatic roundness screening device and method for micro-particles

The invention discloses a high-precision automatic roundness screening device and method for micro-particles. The device and method are characterized in that to-be-screened micro-particles are placedinto a funnel, the flow of the micro-particles flowing into a nozzle is controlled by controlling the opening degree of an electromagnetic valve, the frequency of pulse airflow in the nozzle is controlled through the flow, the flow of the pulse airflow is controlled through a speed sensor, and thus the whole process is controlled. The micro-particles sprayed out of the nozzle enter a first screening plate through a flow guiding groove, waste falls into a waste trough, and the micro-particles with good roundness enter a second screening plate, flow into an oblique funnel and then fall into a finished product trough through a guide pipe in the funnel. The device and method have the beneficial effects that the efficiency and the finished product rate of original devices are improved to a great extent, and the device is controllable and high in precision.

Owner:ZHANGJIAGANG CHUANGBO METAL TECH CO LTD

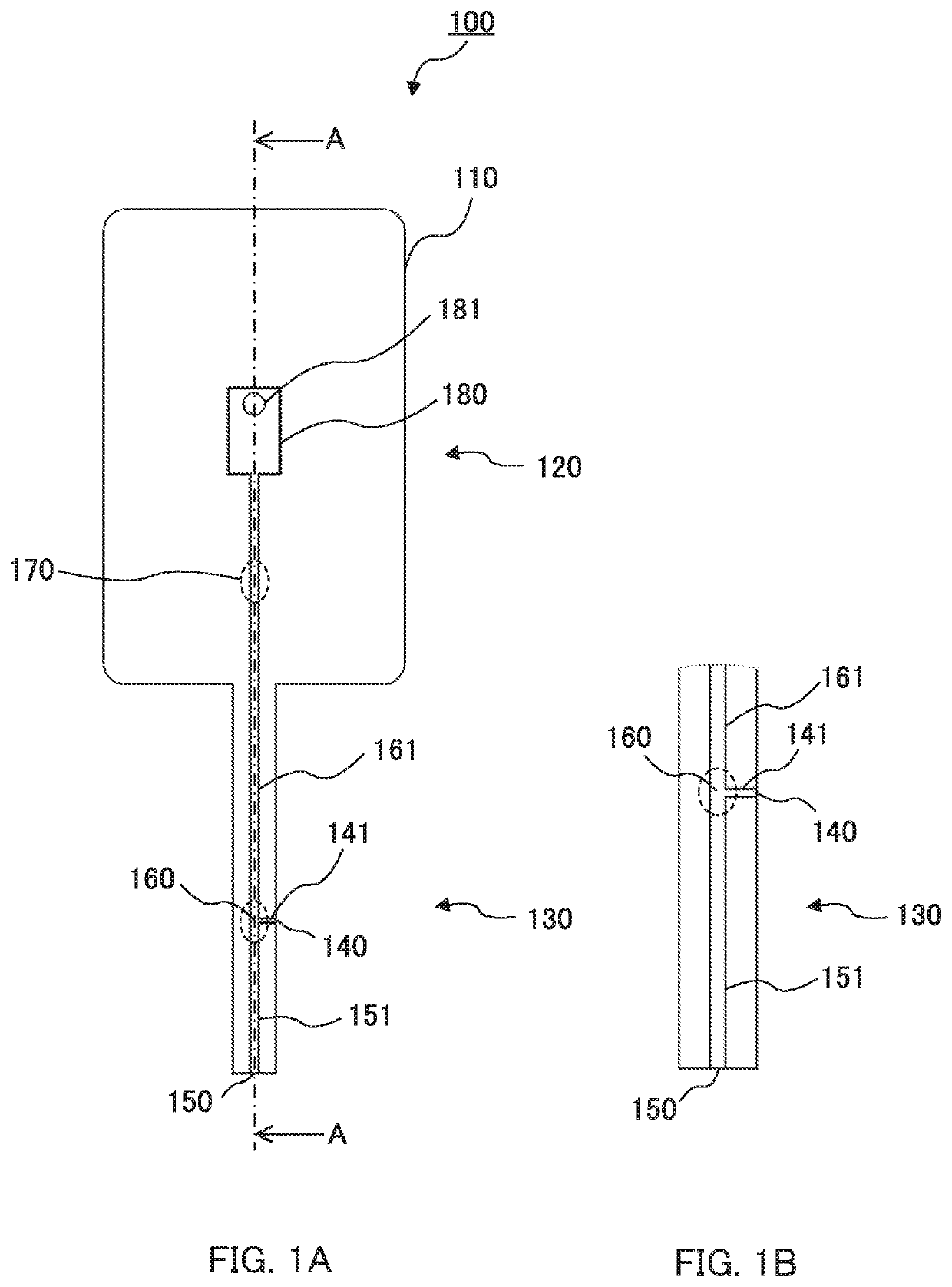

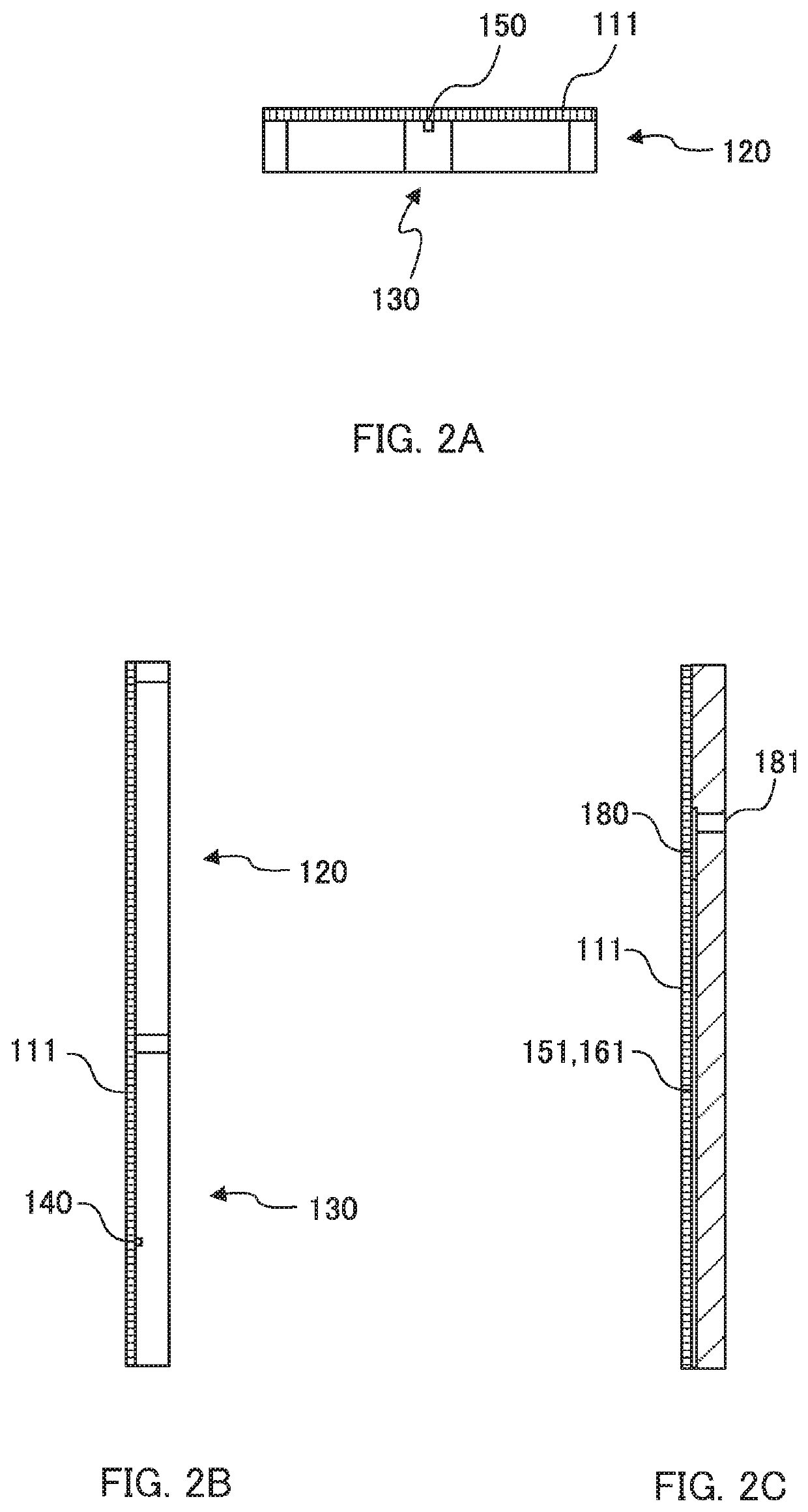

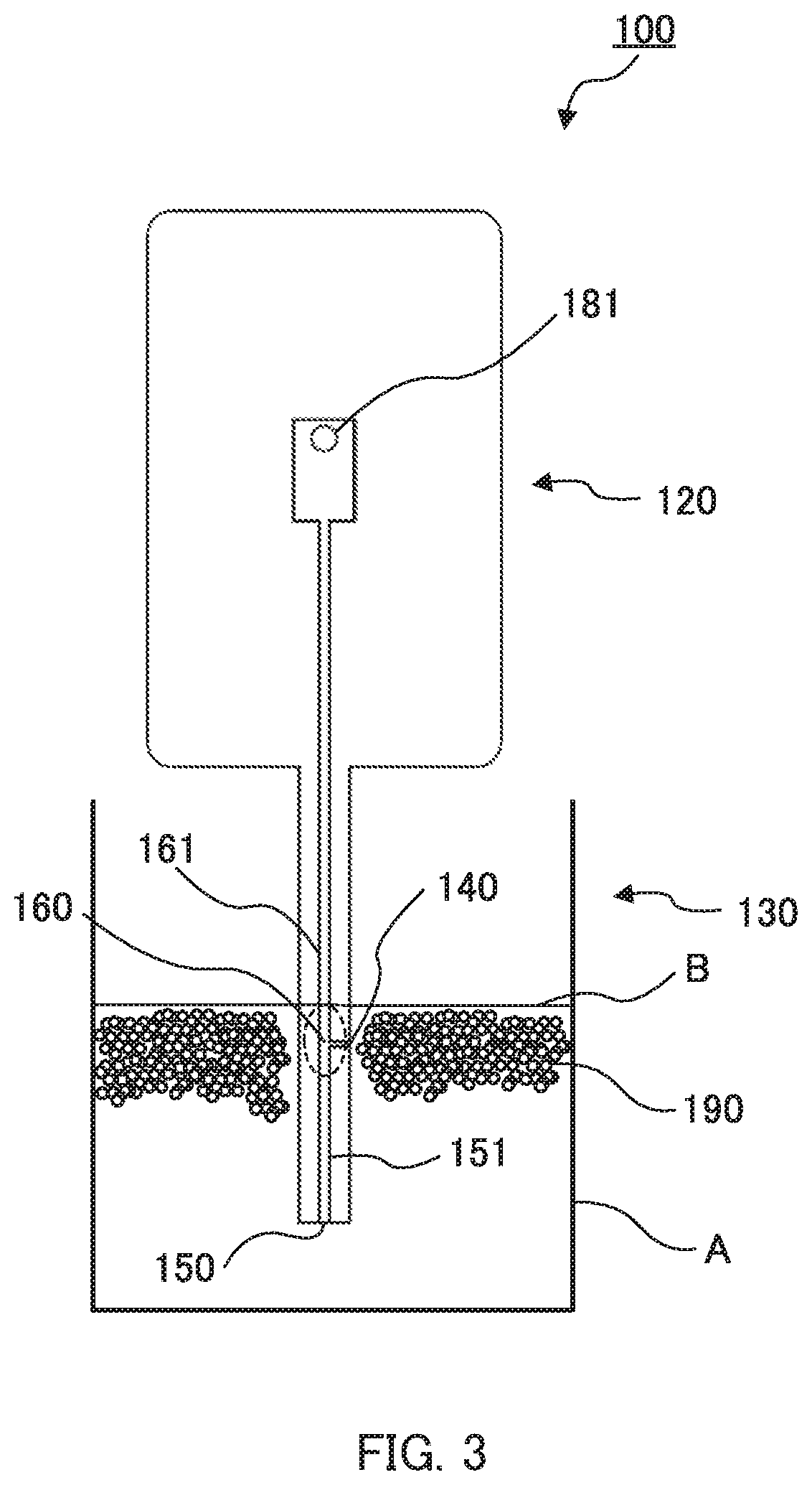

Fluid handling device

PendingUS20210023551A1Reduce fluid volumeLaboratory glasswaresMaterial analysisParticle flowEngineering

Owner:ENPLAS CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap