Method for predicting surface washout topography of petroleum drilling tool

A drilling tool and oil drilling technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the operating range has not been raised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

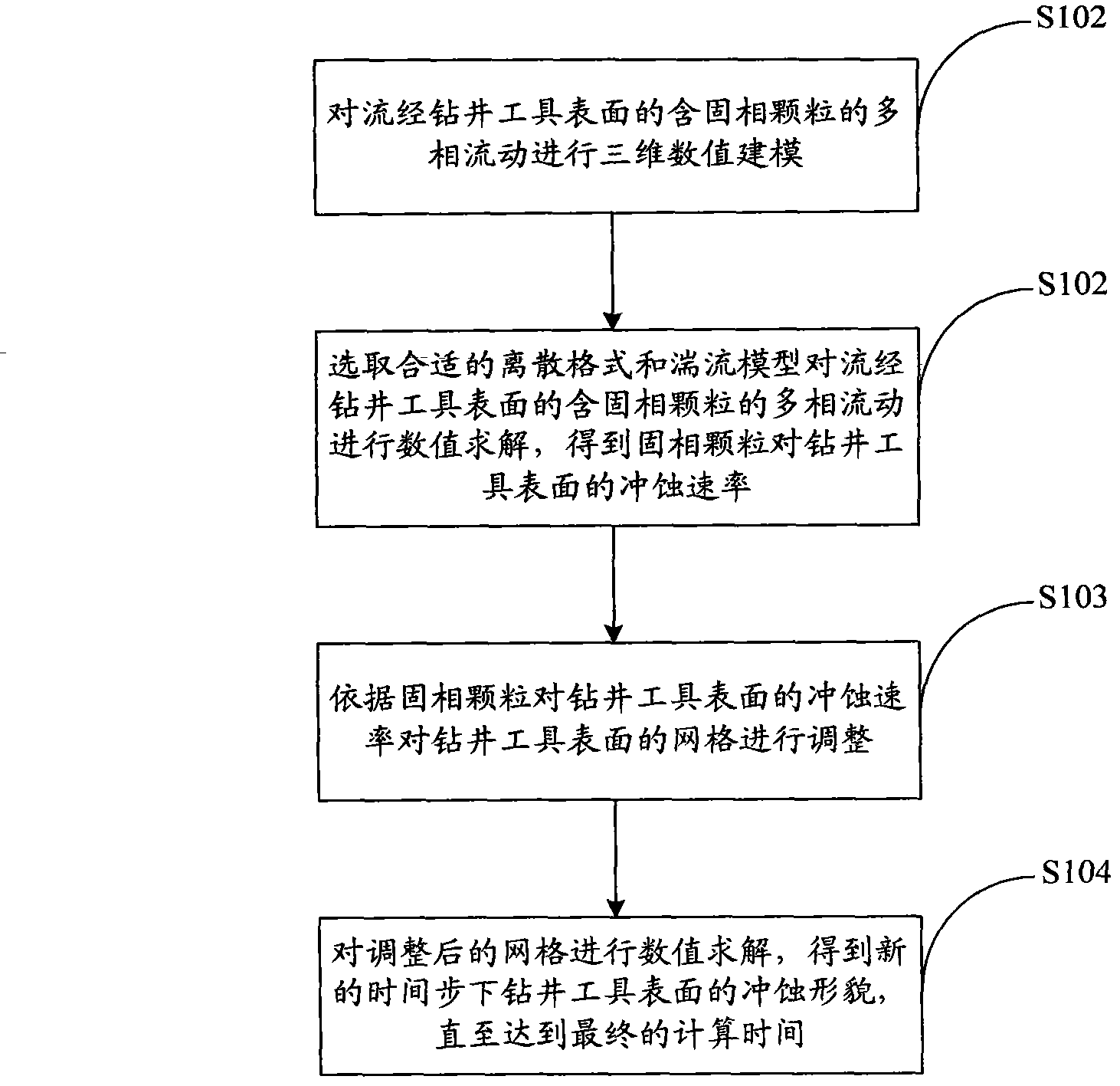

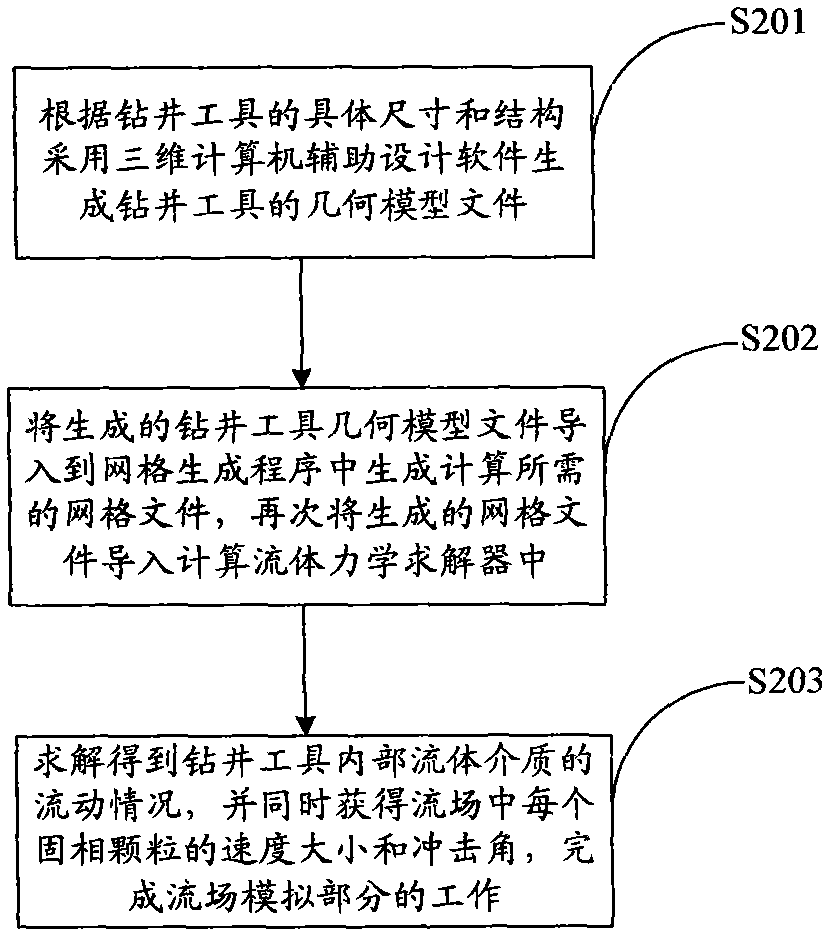

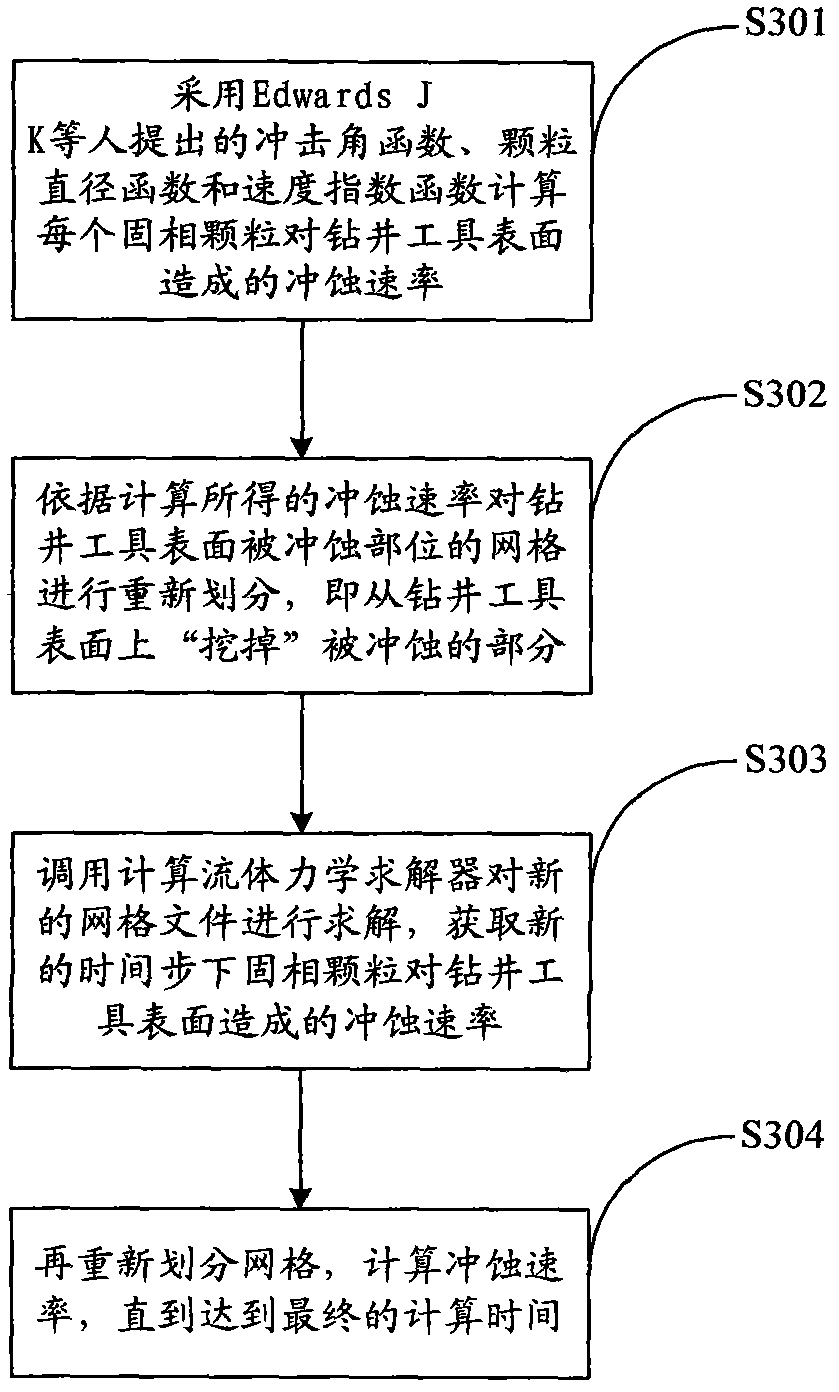

Method used

Image

Examples

Embodiment 1

[0050] Example 1: When the fluid medium is drilling fluid, its state is: temperature 30°C, pressure: 10.5MPa, density: 1150kg / m 3 , Viscosity: 0.02Pa·s. The particle size of the solid phase particles in the fluid medium is 0.4mm, and the velocity of the fluid medium flowing through the surface of the drilling tool is 10m / s. When the fluid medium that satisfies the above conditions carries solid phase particles through Image 6 When the inside of the drilling tool is shown, there will be obvious erosion at the connection between the horizontal pipe and the bypass pipe. Image 6 The magnification of the erosion site after the flow has been carried out for 300 hours is shown in the figure, and it can be seen that material erosion has occurred near the connection between the bypass pipe and the horizontal pipe.

[0051] The present invention analyzes and studies the process of the erosion of the surface of the drilling tool by the fluid medium containing solid phase particles,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap