Separation apparatus for iron-filing waste slag

A separation device and waste slag technology, applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of hidden safety hazards, low work efficiency, large labor force, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

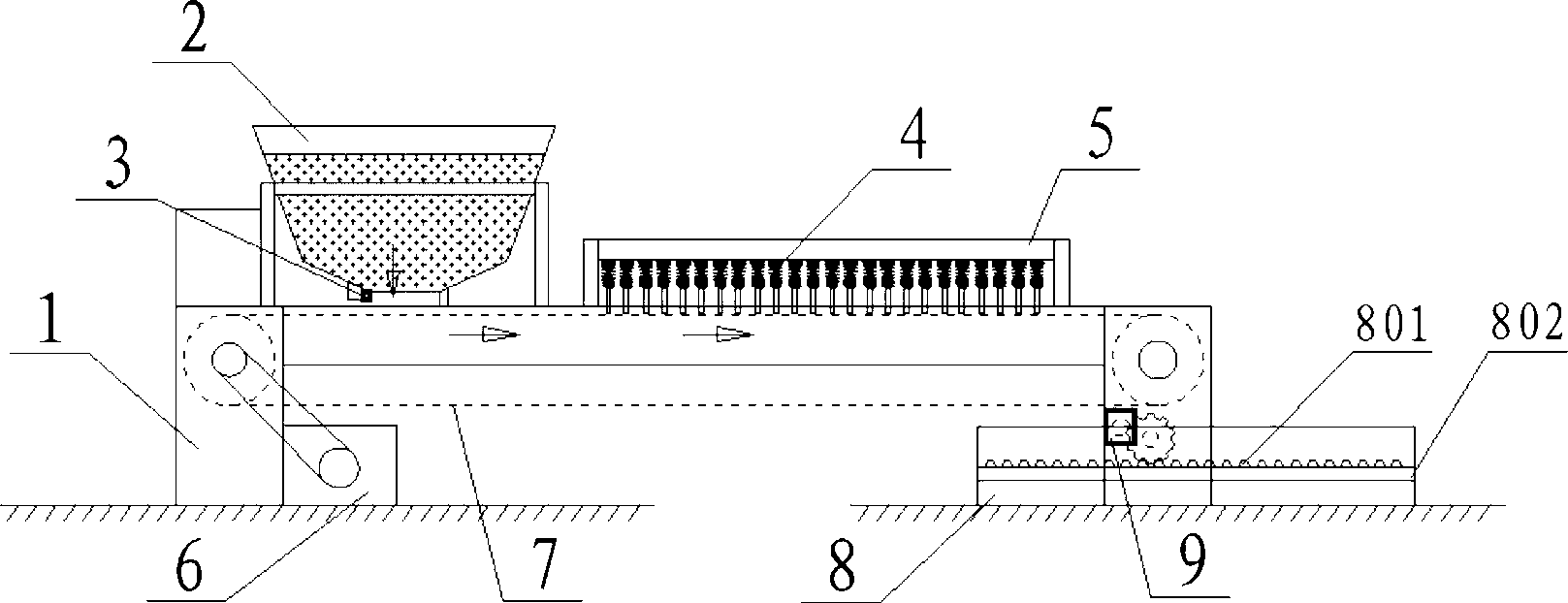

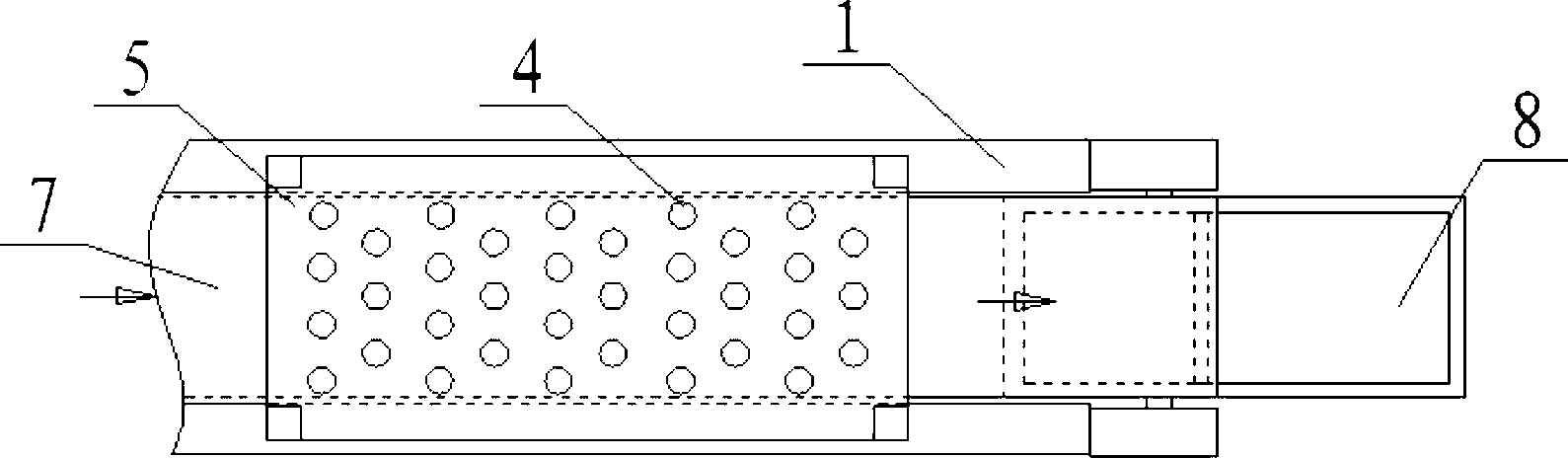

[0013] Referring to the accompanying drawings, a separation device for iron filings and waste slag includes a machine base 1, a conveyor belt 7 and a motor 6 that drives the conveyor belt to run. The feeding port at the bottom of the feed bin 2 is provided with an inductor 3, and the back of the feed bin 2 is provided with a plurality of electromagnet rods 4, and the electromagnet rods 4 are installed on the machine base 1 through a bracket 5 , the end of the conveyor belt 7 is located under the machine base 1 with a distribution bin 8, the distribution bin 8 is installed on the support leg of the machine base 1 through a track 802, and the distribution bin 8 is connected to the servo motor through a gear bar 801 9; the electromagnet rods 4 are evenly and densely arranged on the support 5, and the lower end of the electromagnet rods 4 is 5cm-15cm higher than the plane of the conveyor belt 7; The partitions are separated; the servo motor 9 is connected with the inductor 3 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap