Formula and manufacturing method of antique tile with high-brightness surface

A production method and high-brightness technology, applied in the field of anti-ancient tiles, can solve the problems of low surface brightness, poor anti-aging performance of anti-ancient tiles, inconvenient decoration, etc., and achieve the effect of simple operation and high surface brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

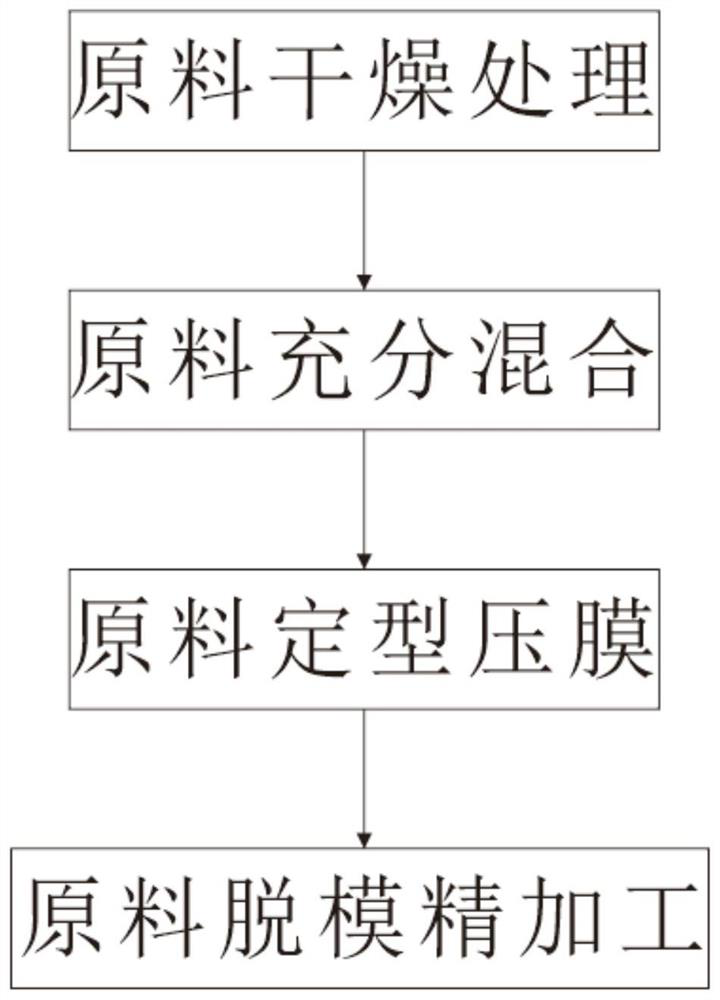

Method used

Image

Examples

specific Embodiment 1

[0104] Put 60 parts of resin, 35 parts of ceramic powder, 15 parts of neoprene, 15 parts of sodium acetate, 10 parts of triisopropanolamine, and 10 parts of ethylene glycol antimony in a drying oven, and dry them at a temperature of 15°C; Put the material into the mixer, add 2 parts of stabilizer, 1 part of curing agent, and 3 parts of defoamer in sequence, and then mix at high speed; put the mixture into the mold of the molding machine, pressurize at 24MPa at a temperature of 150°C , after shaping, exhausting and pressure keeping, after molding, use 1 part of the release agent to demould; heat the demoulding mold at a temperature of 200 ℃ to keep it warm, and finally use sandpaper to deburr and polish the paint to make a waterproof Guwa finished products.

specific Embodiment 2

[0106] Put 80 parts of resin, 50 parts of ceramic powder, 25 parts of neoprene, 25 parts of sodium acetate, 15 parts of triisopropanolamine, and 15 parts of ethylene glycol antimony in a drying oven, and dry them at a temperature of 30 °C; Put the material into the mixer, add 3 parts of stabilizer, 2 parts of curing agent, and 5 parts of defoamer in sequence, and then mix at high speed; put the mixture into the mold of the molding machine, pressurize at 32MPa at a temperature of 180°C , after shaping, exhausting and pressure keeping, after molding, use 2 parts of release agent to demould; heat treatment and heat preservation on the demoulding mold at 180 ℃, and finally use sandpaper to deburr, polish and paint, and make anti-corrosion Guwa finished products.

[0107] The invention is simple in operation, better adapted to the processing efficiency of anti-ancient tiles, and the prepared anti-ancient tiles have the advantages of light weight, high strength, aging resistance, high

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap