Distorted grain boundary phase-A liquid crystal mixed material with wide temperature range and preparation method of grain boundary phase-A liquid crystal mixed material

A liquid crystal mixing and twisting crystal technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of weak temperature sensitivity and cumbersome operation, and achieve the effect of easy-to-obtain experimental materials and simple mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing a phase A liquid crystal mixed material with twisted grain boundaries in a wide temperature range, the method comprising:

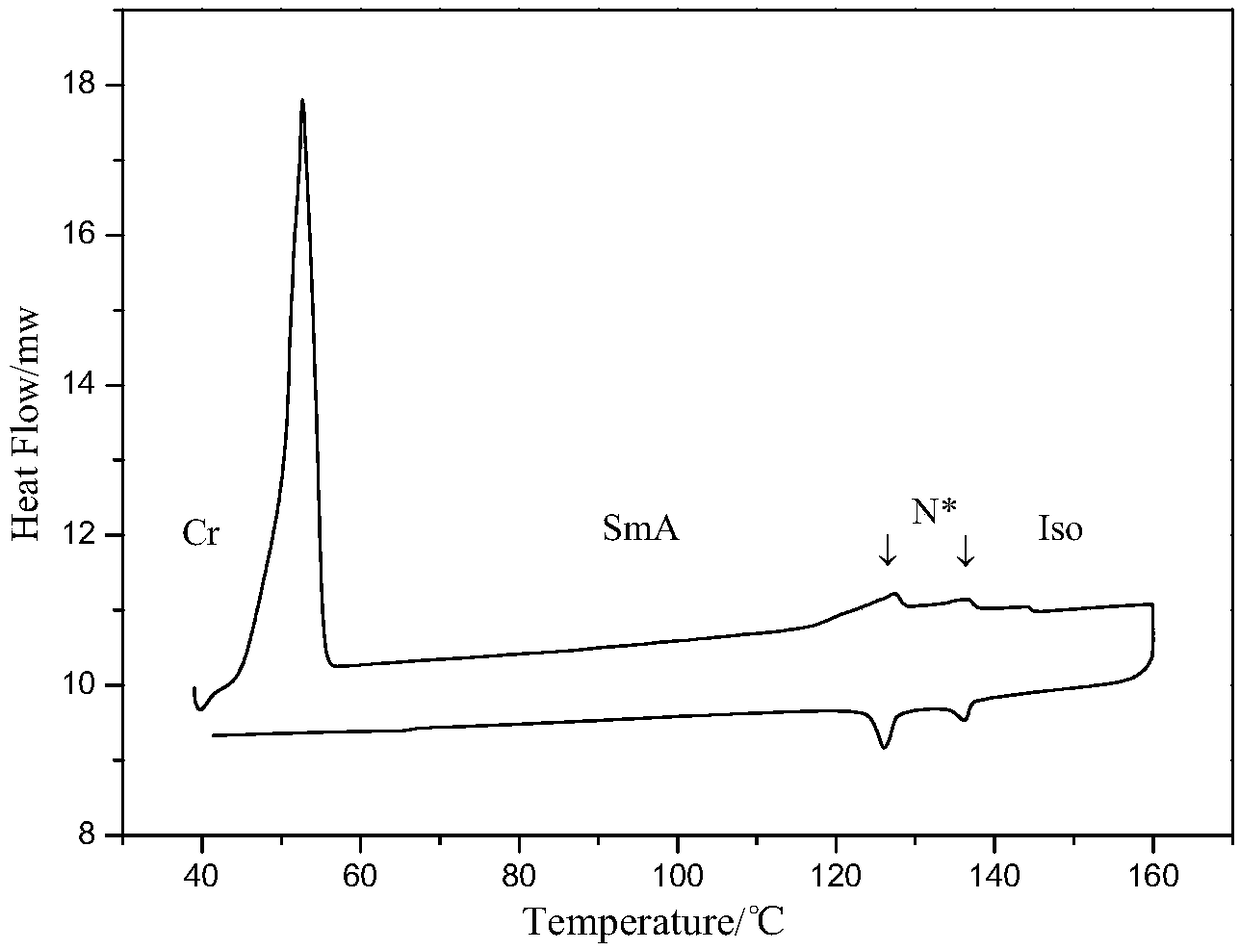

[0038] The twisted grain boundary A phase was obtained by mixing the smectic A (SmA) phase-cholesteric N* phase transition liquid crystal molecules (SCM), nematic small molecule liquid crystals and nematic-smectic liquid crystal molecules, and passed through the mixing process Control the mixing ratio of the three to obtain the wide temperature range twisted grain boundary A phase, that is, the wide temperature range TGBA phase;

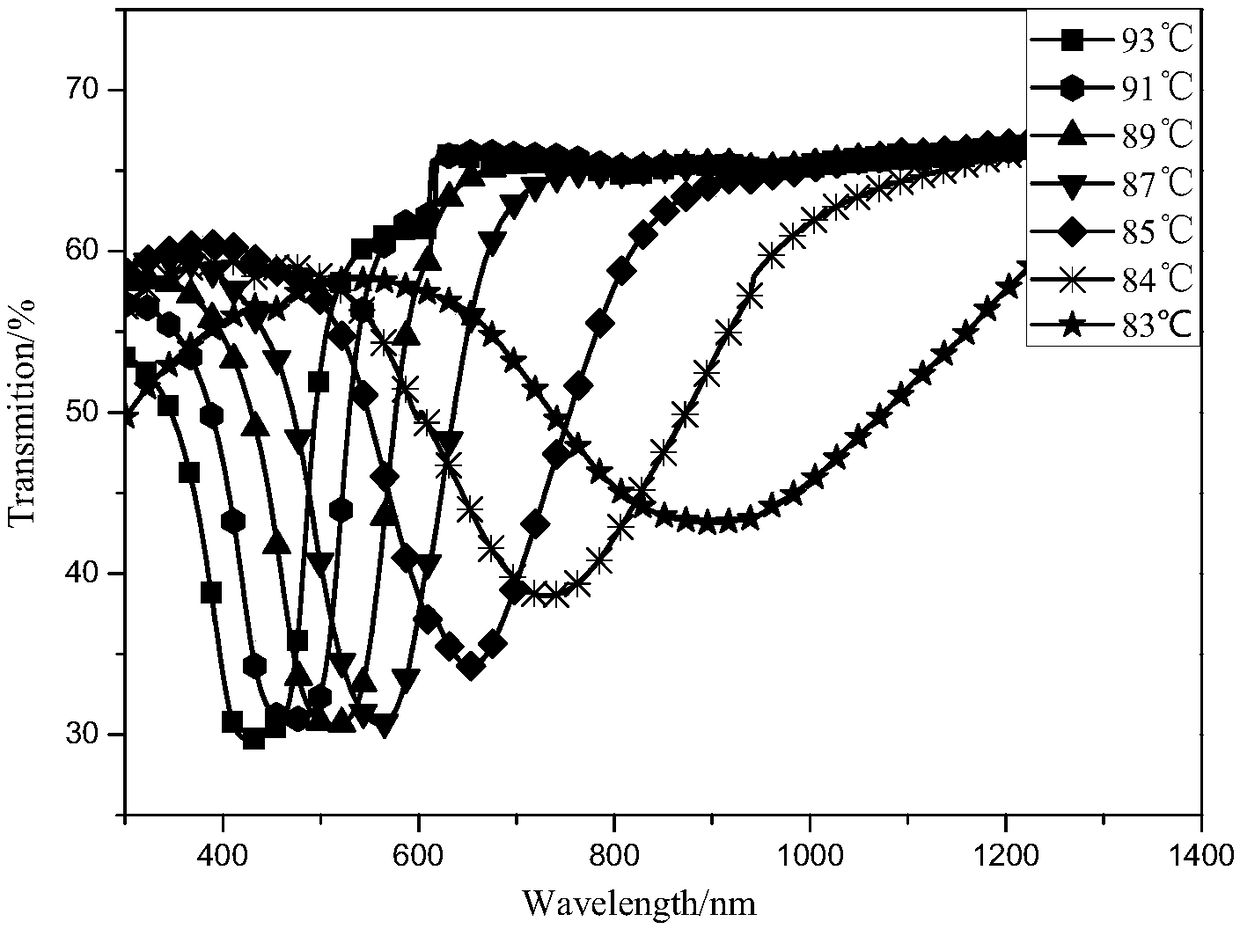

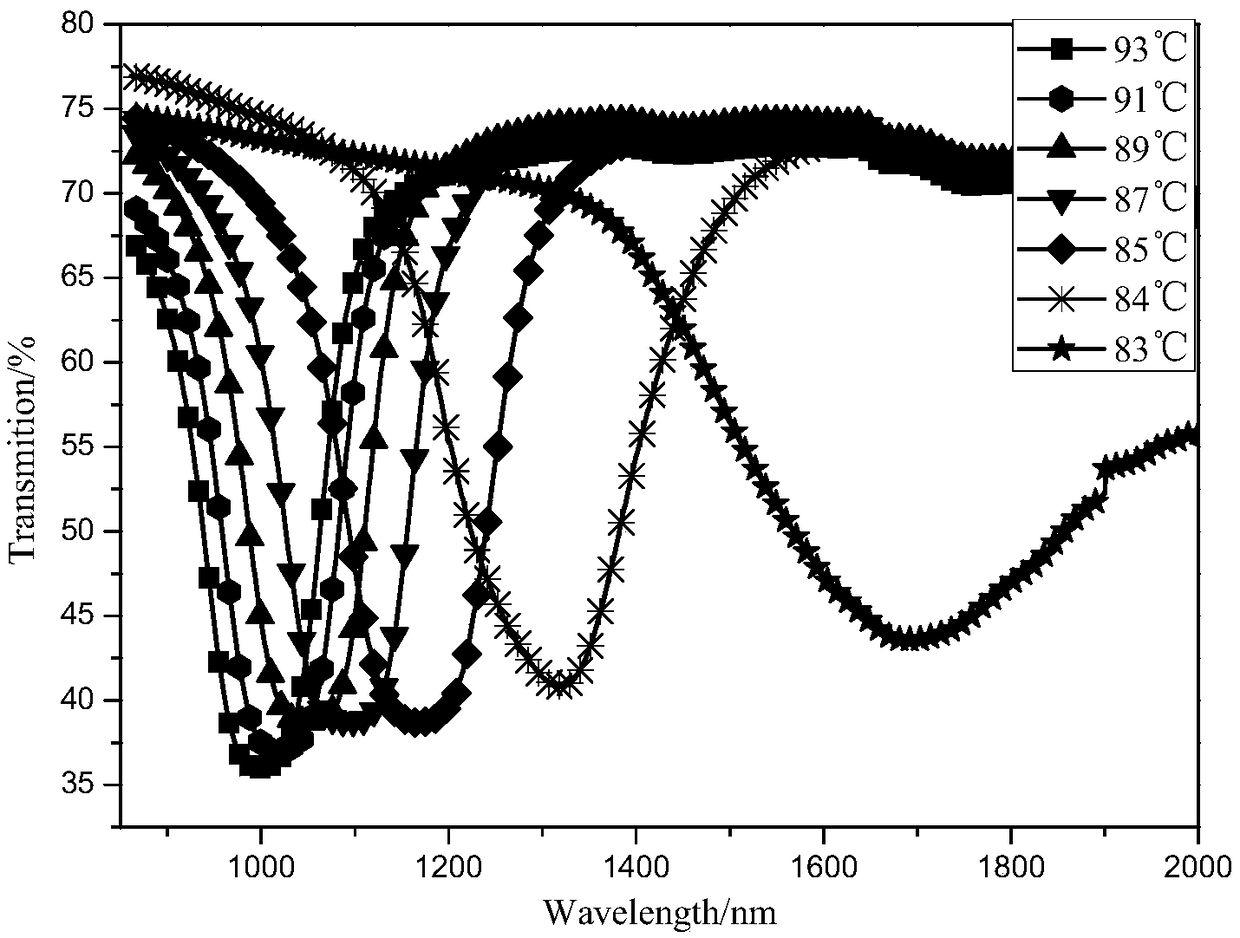

[0039] A chiral additive is added to the TGBA phase after the ratio of the three is determined to adjust the initial reflection wave position of the liquid crystal mixed material in the TGBA phase.

[0040] In the process of mixing the smectic A phase-cholesteric N* phase transition liquid crystal molecules, nematic small molecule liquid crystals and nematic-smectic phase liqui

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap