Production process of starch full-degradable disposable tableware

A technology for production process and tableware, which is applied in the direction of dishes, etc., can solve the problems of difficult handling, great harm to the ecological environment, and difficult to degrade, and achieves the effects of wide source of raw materials, simple manufacture and wide use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

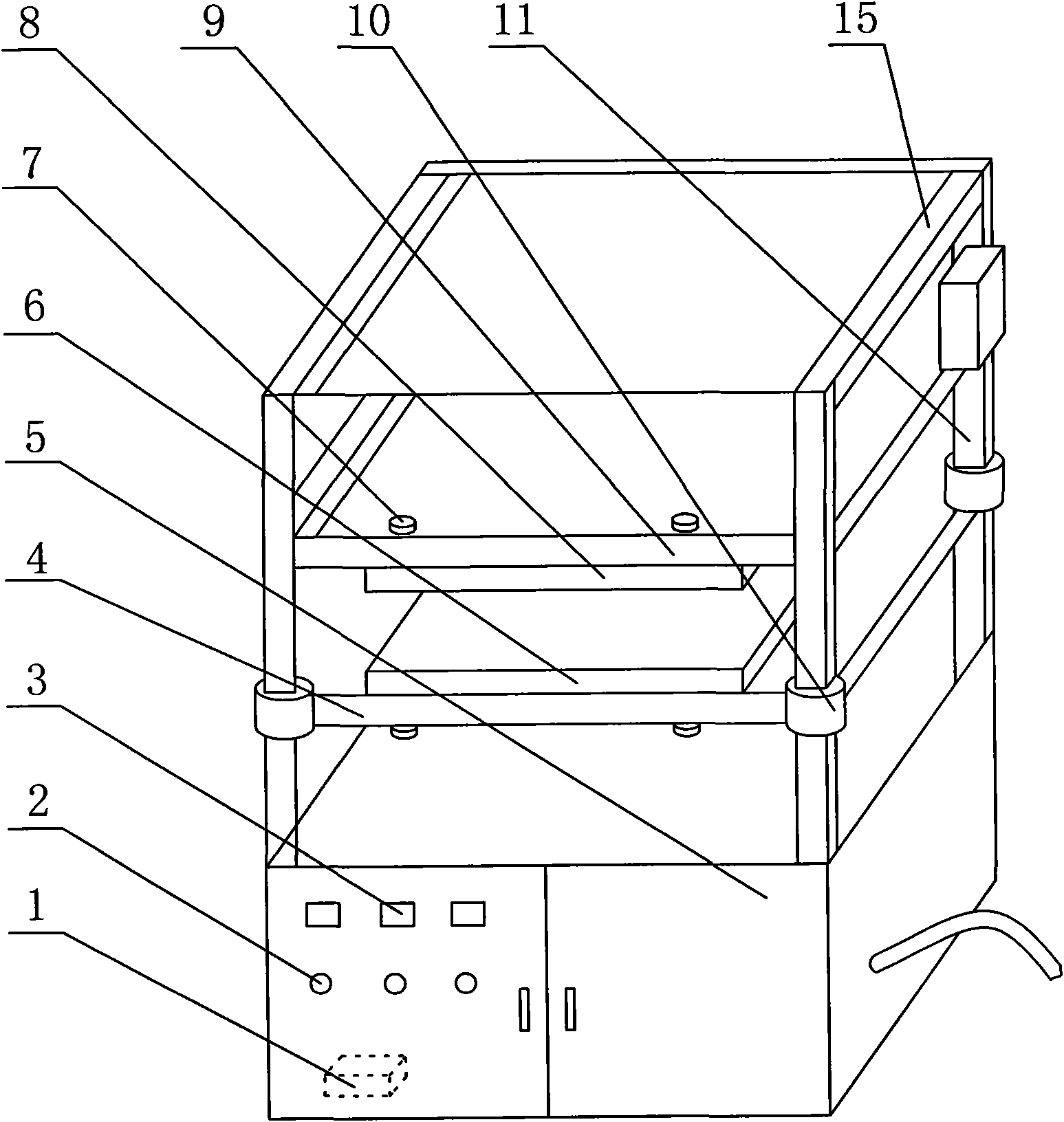

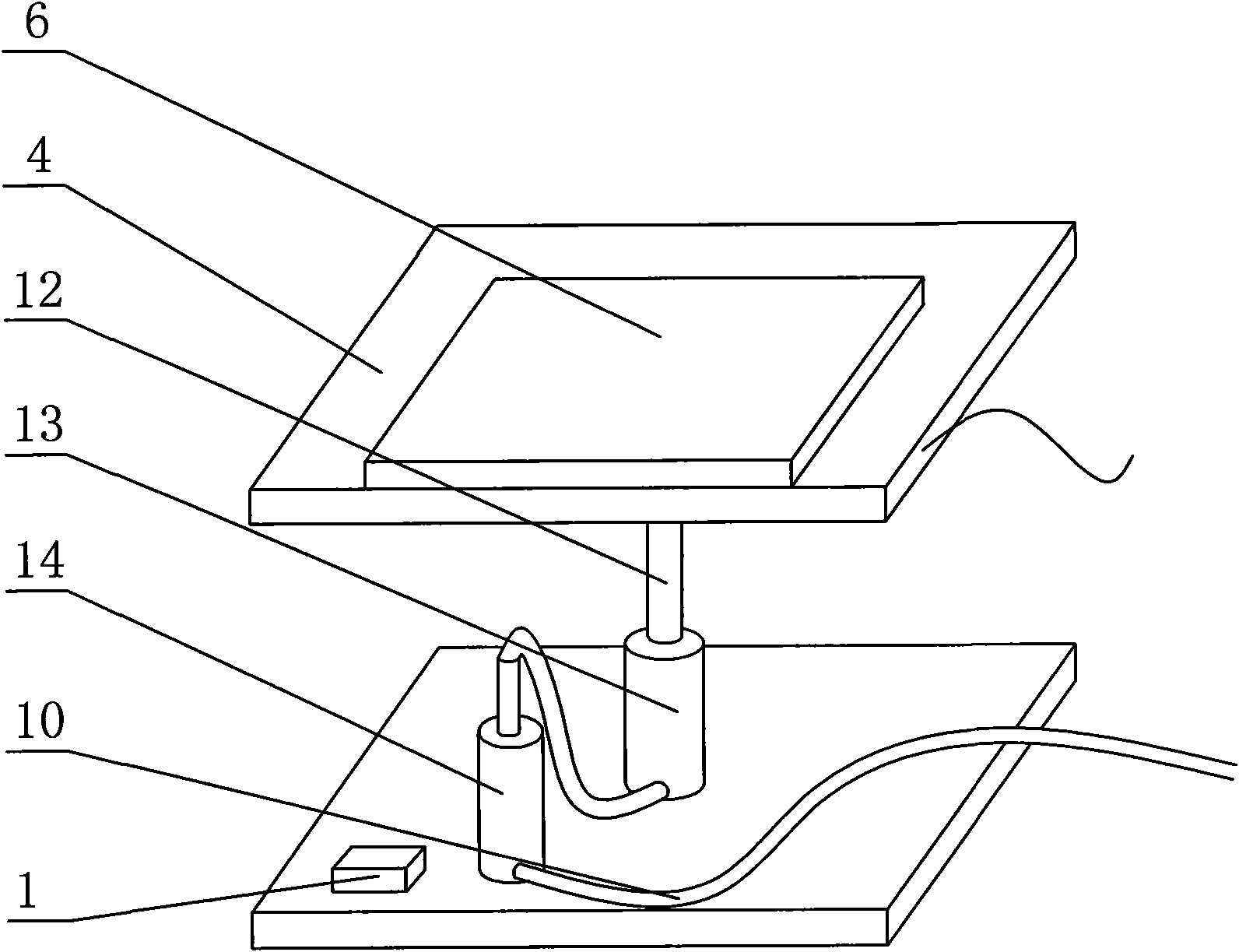

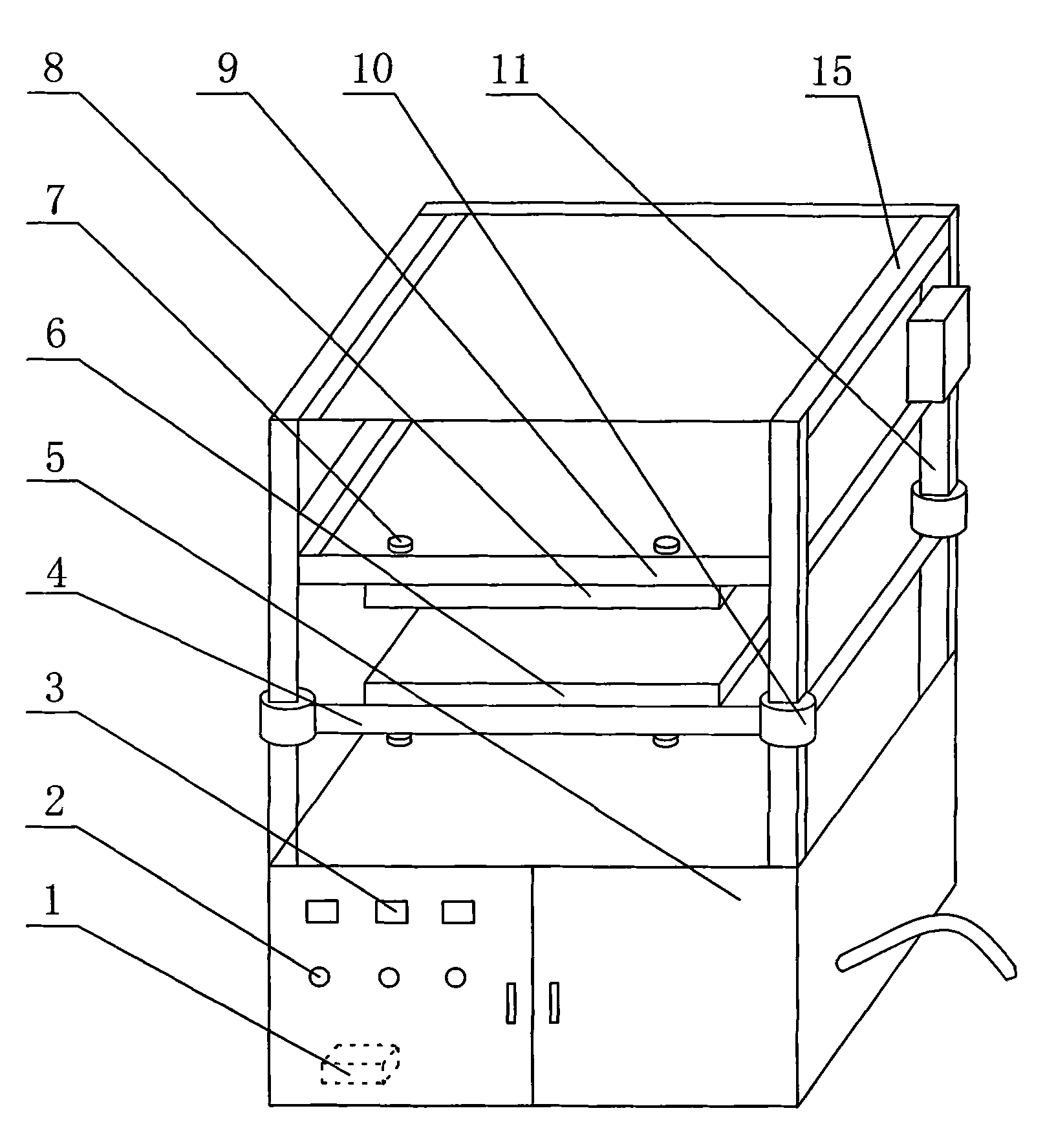

Image

Examples

Embodiment

[0013] Starch fully degradable disposable tableware production process, it comprises the following steps:

[0014] The first step is mixing, accurately weigh 70kg of starch, 8kg of wood fiber, 15kg of talcum powder, 0.5kg of paraffin, and 6.5kg of modified starch, and mix them thoroughly. In this embodiment, what starch adopts is tapioca starch or corn starch etc. Starch is stored in plants, so it has a wide range of sources, and starch can be completely degraded in nature without residue and will not cause environmental pollution. At the same time, it is non-toxic and will not endanger human health. It is a good substitute for plastic products Taste.

[0015] The second step is to put the mixed material into the blender, then add an appropriate amount of water, and stir evenly with the blender. The mixer uses a small mixer that is now commonly used, and there is no need to design a special mixer, and there is no need to add additional costs.

[0016] The third step is to take

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap